Odor discharging and energy-saving system of toilet and mounting method of odor discharging and energy-saving system

An energy-saving system and toilet technology, applied in water supply devices, flushing equipment with water tanks, sanitary equipment for toilets, etc., can solve problems such as difficulty in flushing toilets, low potential energy of flushing water, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

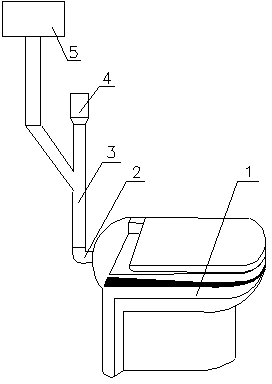

[0010] Embodiment 1: with reference to attached figure 1 . A toilet deodorization and energy-saving system, comprising a toilet 1 and a water tank 5, the body of the toilet 1 is not provided with a water tank, and the toilet flushing inlet 2 at the tail of the toilet 1 not only has the function of flushing the toilet, but also has the function of draining the toilet The suction port of toilet cavity odor, the one-way interface in the three-way 3 is communicated with the flushing water inlet 2 at the end of the toilet 1, and the other two-way interface of the three-way 3 is communicated with the water outlet of the water tank 5 through the water delivery pipe, and connected with the water outlet of the water tank 5 through the water pipeline. The negative pressure air extraction port of the negative pressure air extractor 4 is communicated, and the exhaust port of the negative pressure air extractor (4) is communicated with the pipeline through the exhaust pipe or directly lead...

Embodiment 2

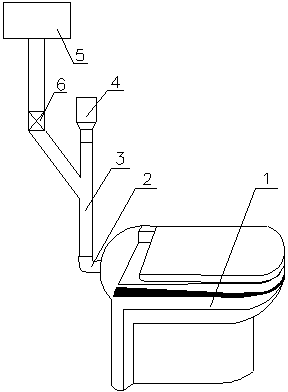

[0011] Embodiment 2: with reference to attached figure 2 . On the basis of Embodiment 1, when the three-way port 3 and the other two-way port are in communication with the water outlet of the water tank 5 through the water valve 6 and the water pipeline, the water tank 5 does not have a water valve.

Embodiment 3

[0012] Embodiment 3: On the basis of Embodiment 1, the tee 3 is a Y-shaped tee structure to reduce fluid resistance. The pipe is made into a Y shape, and the lower end is connected to the body. One end of the upper end is connected to the water tank, and the other end is connected to the air extractor. The specific connection method depends on the location of the ventilation pipe of the building.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com