Triangle roll-over type moving grate

A movable grate and reversible technology, which is applied in the direction of rotary grate, oscillating grate, grate, etc., can solve the problems of easy failure of movable grate, inability to fully burn fuel, large amount of maintenance, etc., and achieve structural Simple, not easy to break down, and easy to maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

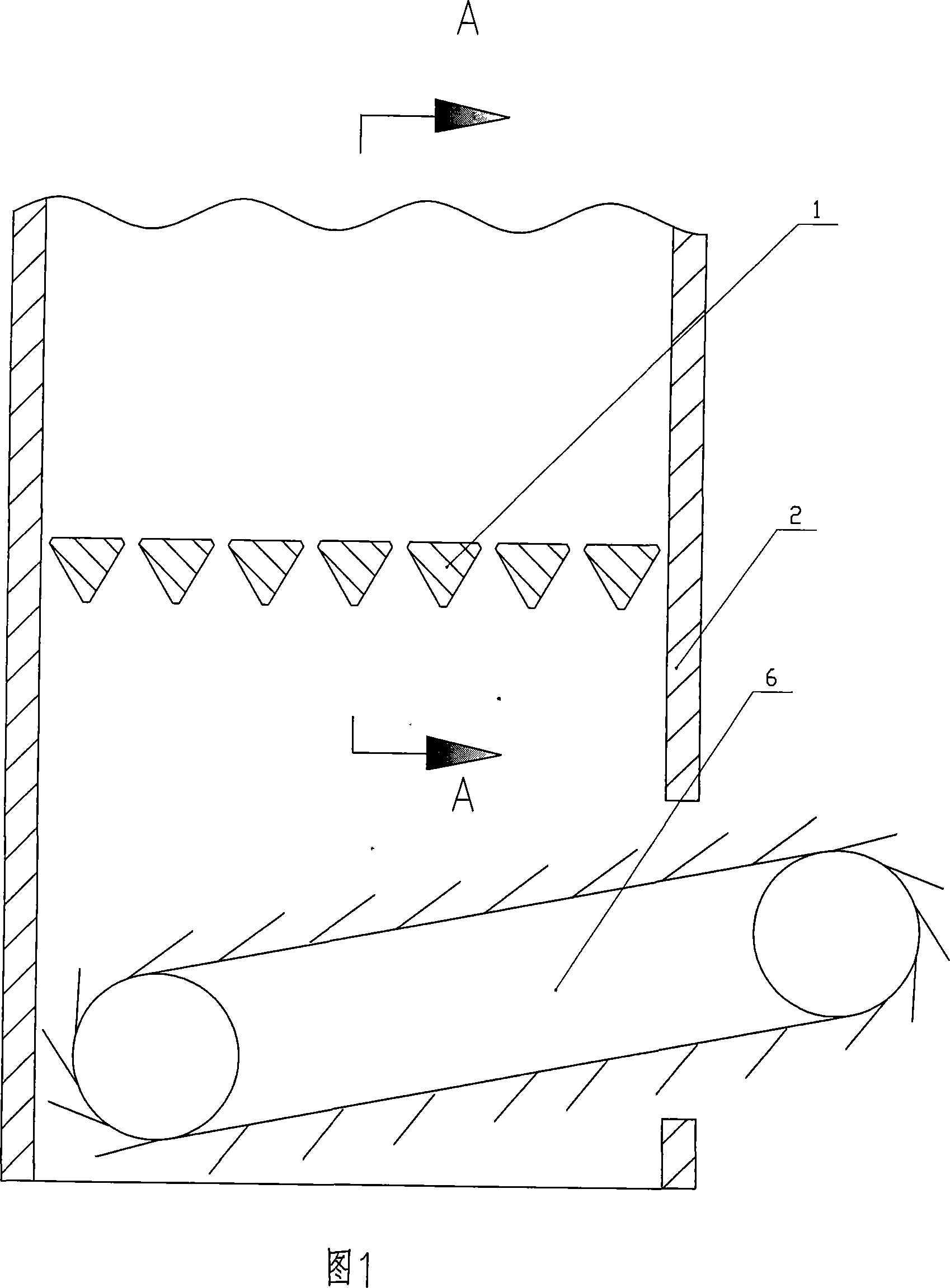

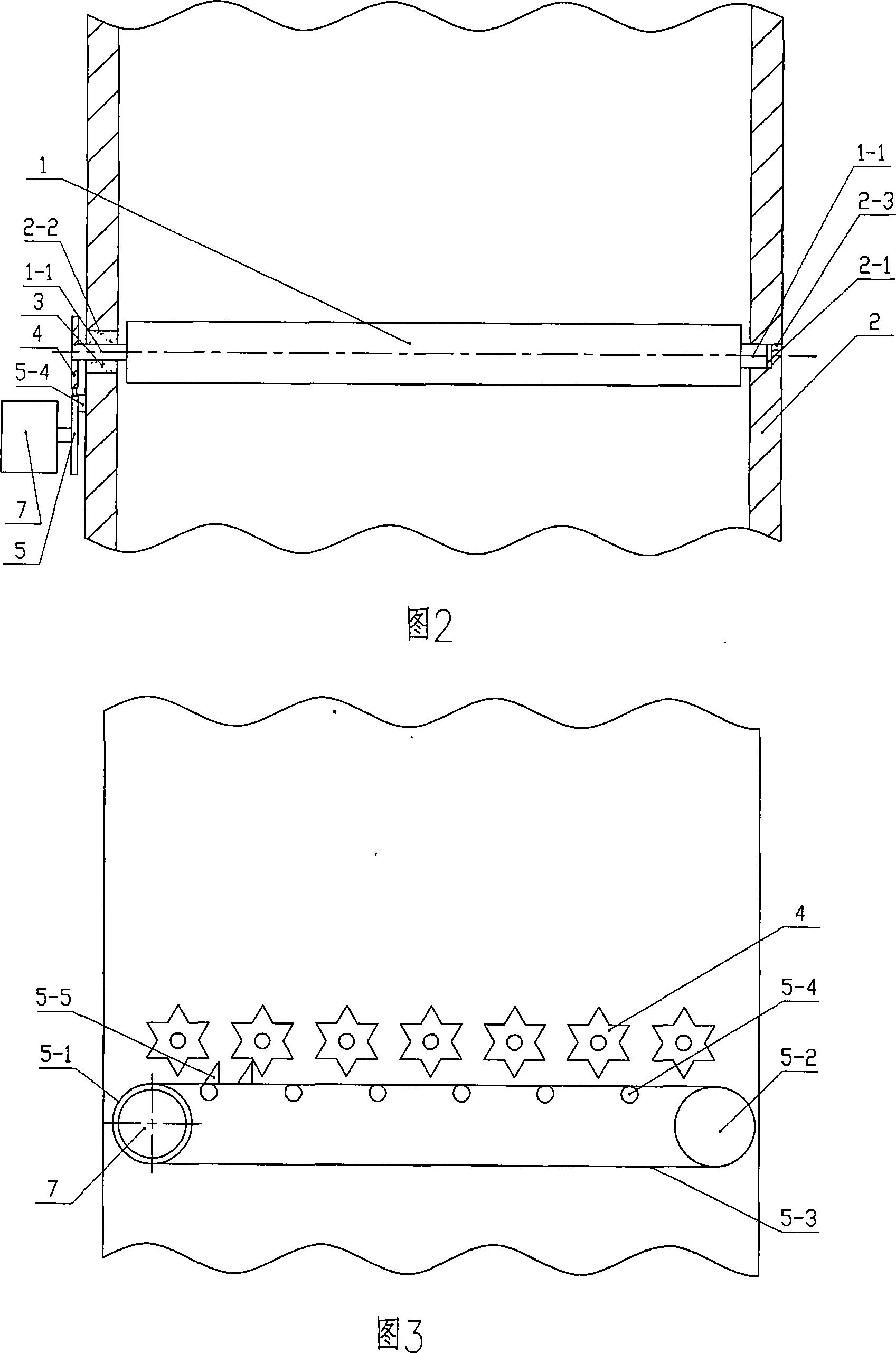

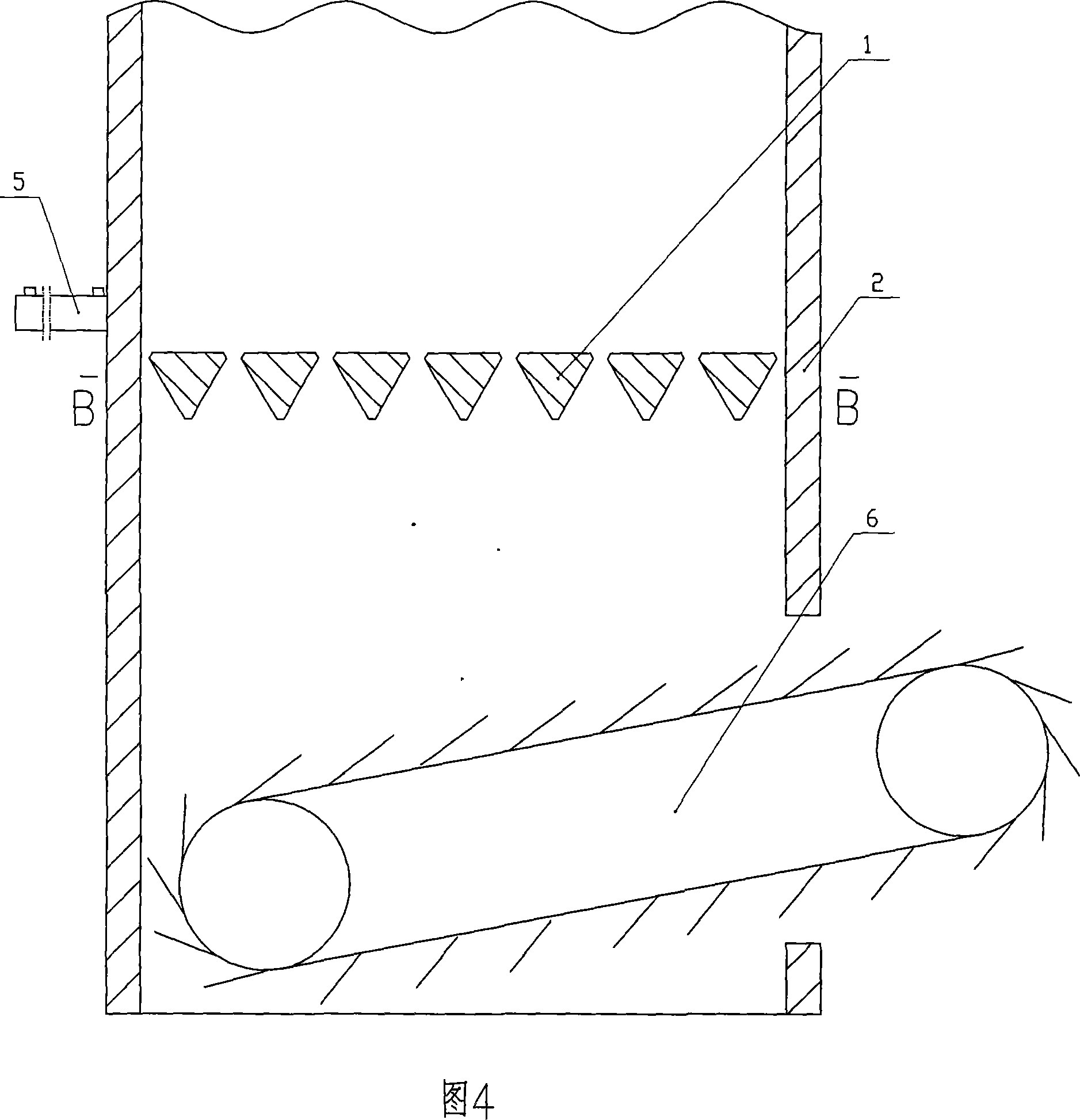

[0020] As shown in Figures 1 to 3, the first embodiment of the triangular overturnable movable grate of the present invention has a plurality of bars 1 arranged in parallel, the main body of the bar 1 is a triangular prism, and the corners of the main body of the bar 1 are inverted There is a shaft head 1-1 concentric with the furnace bar at both ends of the furnace bar, a row of blind holes 2-1 is provided on the inner wall of the furnace body 2, and a row of through holes 2-2 is provided on the inner side wall of the furnace body on the opposite side; The shaft head 1-1 at one end of each furnace bar 1 is set in the blind hole 2-1, and the furnace body 2 is provided with a lubricating powder adding hole 2-3 communicating with the blind hole 2-1, through which the lubricating powder adding hole 2-1 3 Add graphite or carbon between the blind hole 2-1 and the shaft head 1-1 to make the furnace bar 1 rotate flexibly; the shaft head 1-1 at the other end of each furnace bar 1 passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com