Shaft-rotating coal stirring boiler

A coal furnace and rotary shaft technology, which is applied in the directions of rotary grate, grate, and swing grate, can solve the problems of high labor intensity, large amount of fly ash, and high heat loss, and achieves reduction of labor and manufacturing. Simple, easy-to-assemble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

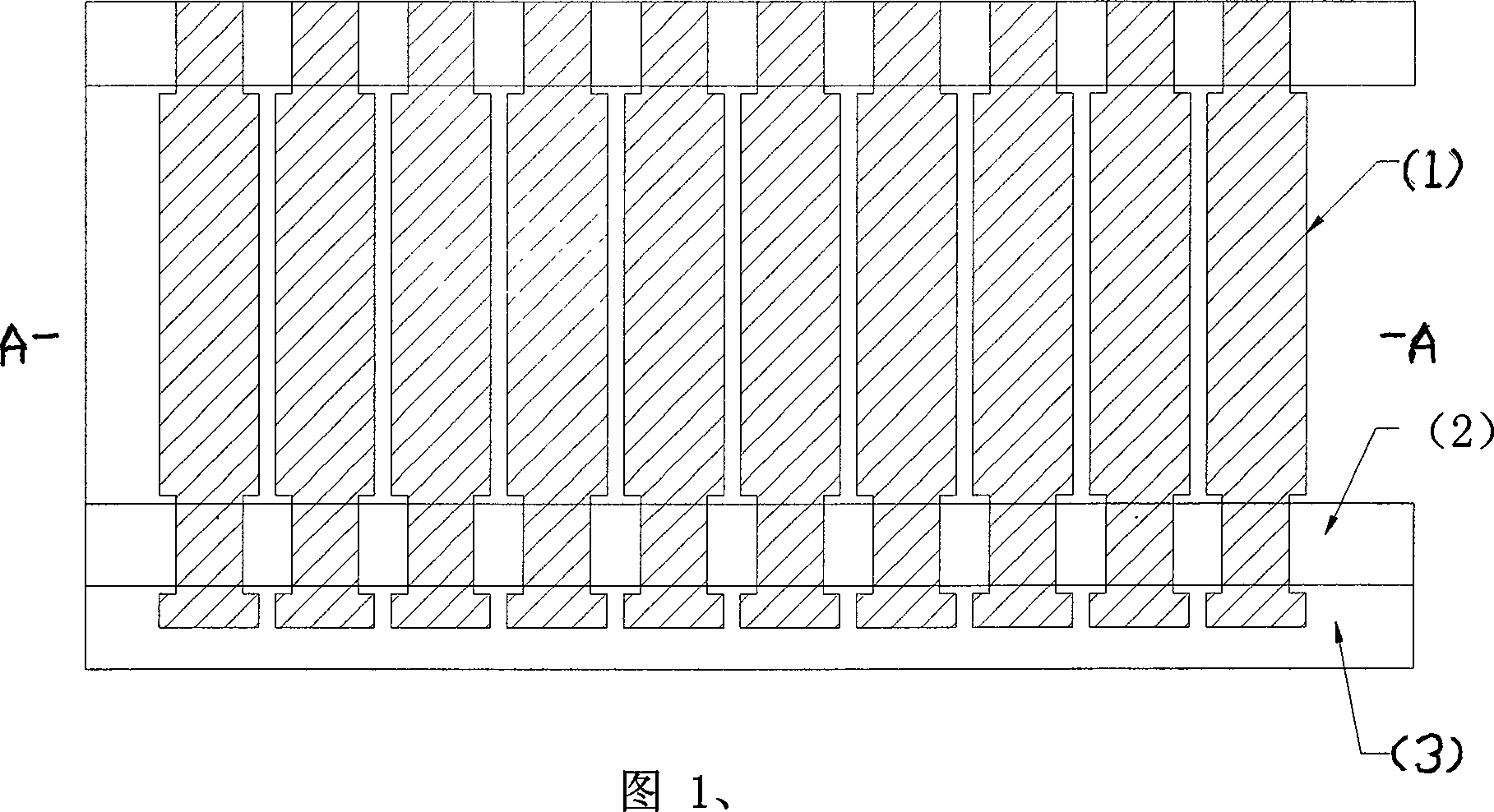

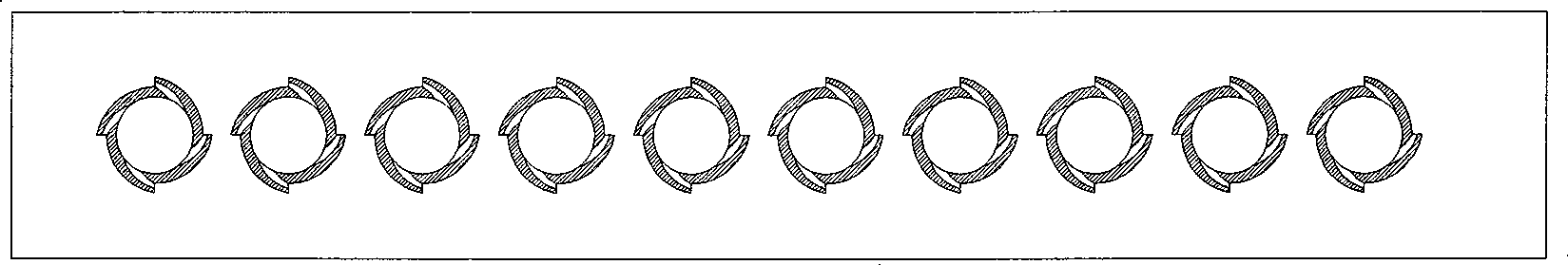

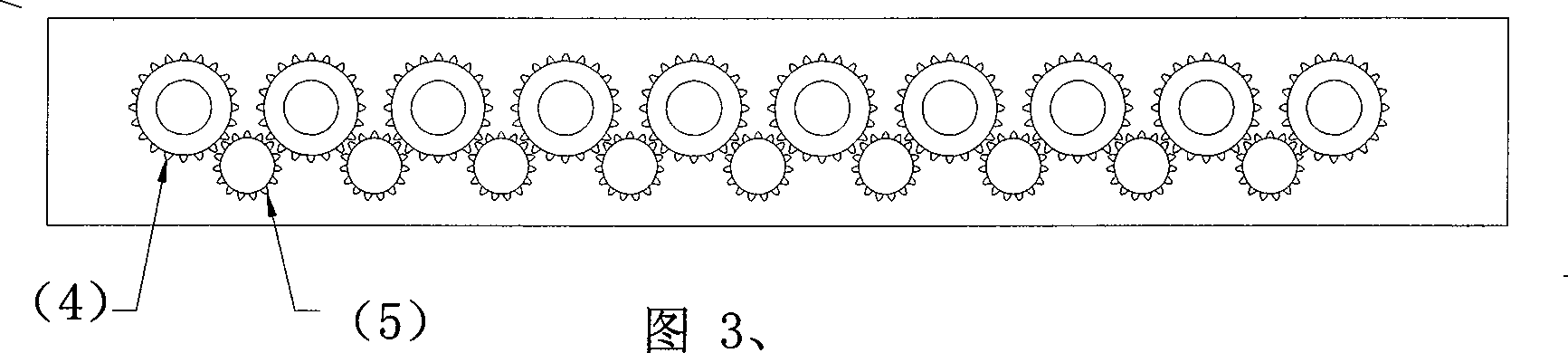

[0159] Manufacture the rotary shaft according to the instructions, and assemble it with the shaft frame to form a rotary shaft coal sowing fire grate. The rotary shaft coal sowing grate is matched with the horizontal boiler. It is located in the middle of the boiler furnace, and the lower part is equipped with a general grate, and it is manufactured into a rotary shaft coal sowing horizontal boiler. It is also possible to transform the existing horizontal boiler and install a rotary shaft coal sowing fire grate to form a rotary shaft coal sowing horizontal boiler. The rotary shaft coal sowing grate is combined with the fluidized bed, and the rotary shaft coal sowing grate is used to feed coal above the boiling section, which is a rotary shaft coal sowing fluidized furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com