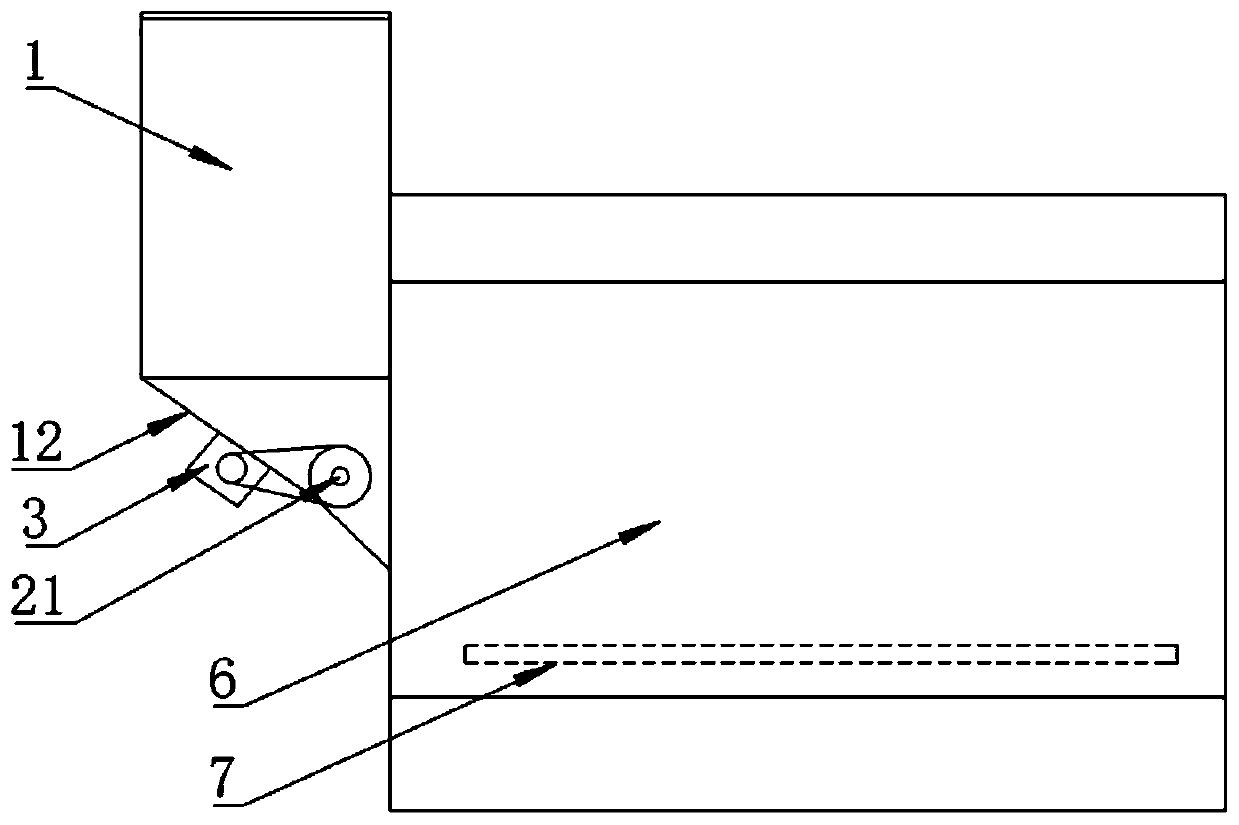

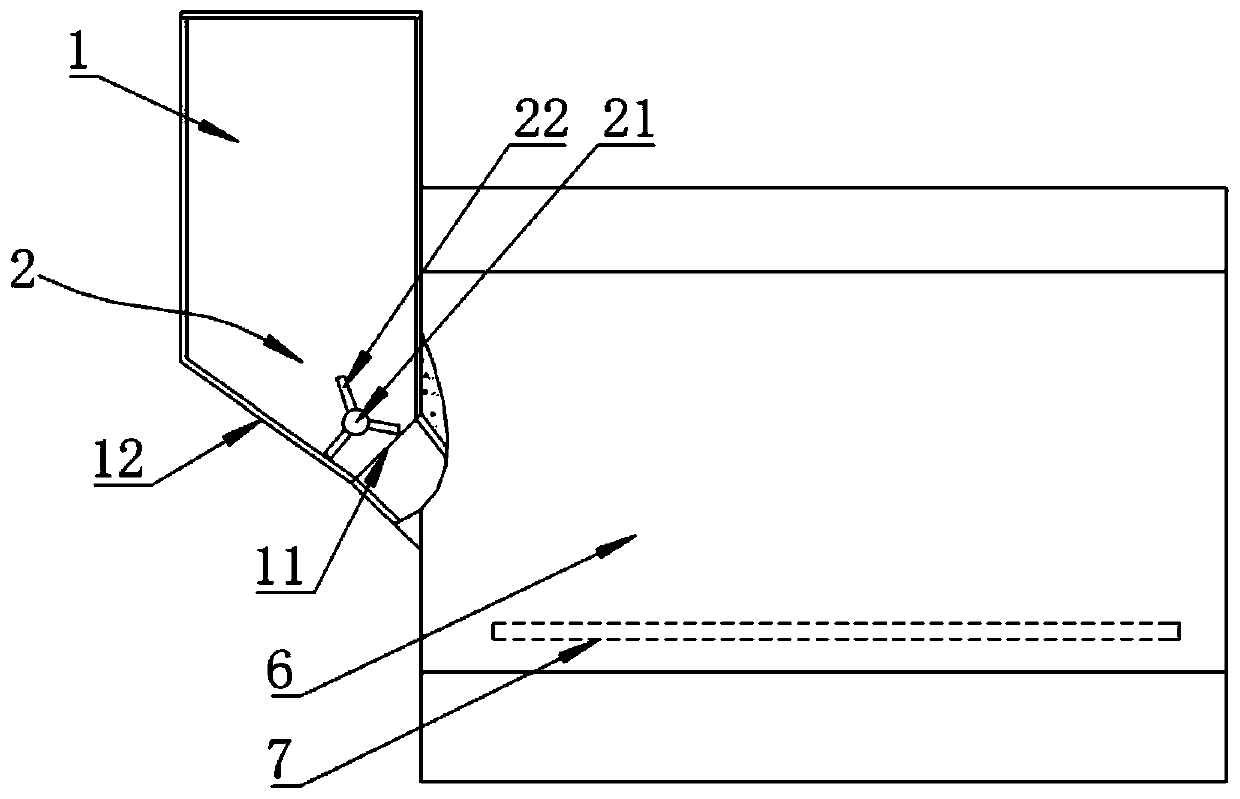

Biomass fuel feeding device and biomass fuel furnace

A technology of biomass fuel and feeding device, which is applied in the direction of fuel supply, grate, combustion method, etc., can solve problems such as unfavorable combustion, interruption of feeding, stuck biomass fuel, etc., and achieve the effect of avoiding crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

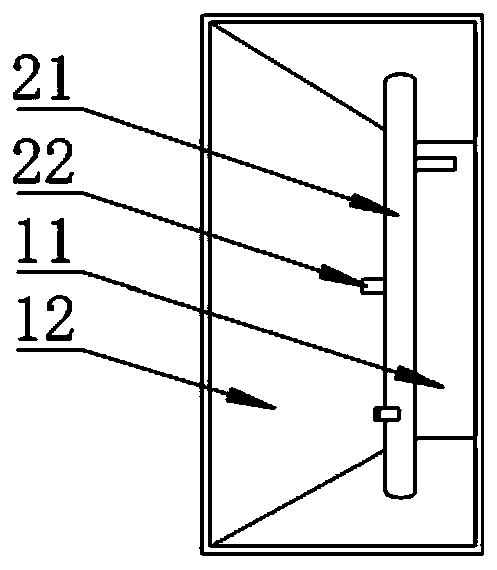

[0059] Please also refer to Figure 6 to Figure 11 , as a specific embodiment of the biomass fuel stove provided by the present invention, the rotating part includes a rotating cross bar 721 . The rotating bar 721 is arranged on the bottom of the furnace 61 for rotating, and the rotating bar 722 is arranged on the rotating bar 721 along the radial direction of the rotating bar 721 .

[0060] Specifically, the rotating cross bar 721 is a long straight bar, and its two ends are respectively rotatably connected to the furnace wall of the furnace body 6 . The rotating furnace bar 722 is a long straight rod, and is vertically welded on the side of the rotating cross bar 721 . One end of the rotating bar 721 can extend out of the furnace body 6 for controlling the rotation of the rotating bar 722 . The end of the rotating cross bar 721 passing through the furnace body 6 is driven by a motor, so that the motor can be controlled by the electric control system to control the rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com