Gasification of carbonaceous material

A carbonaceous material, gasifier technology, applied in fixed bed gasification, mechanical details of gasification devices, combustion methods, etc., can solve problems such as poor alignment, functional failure of grid components, unsuitable biomass gasification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

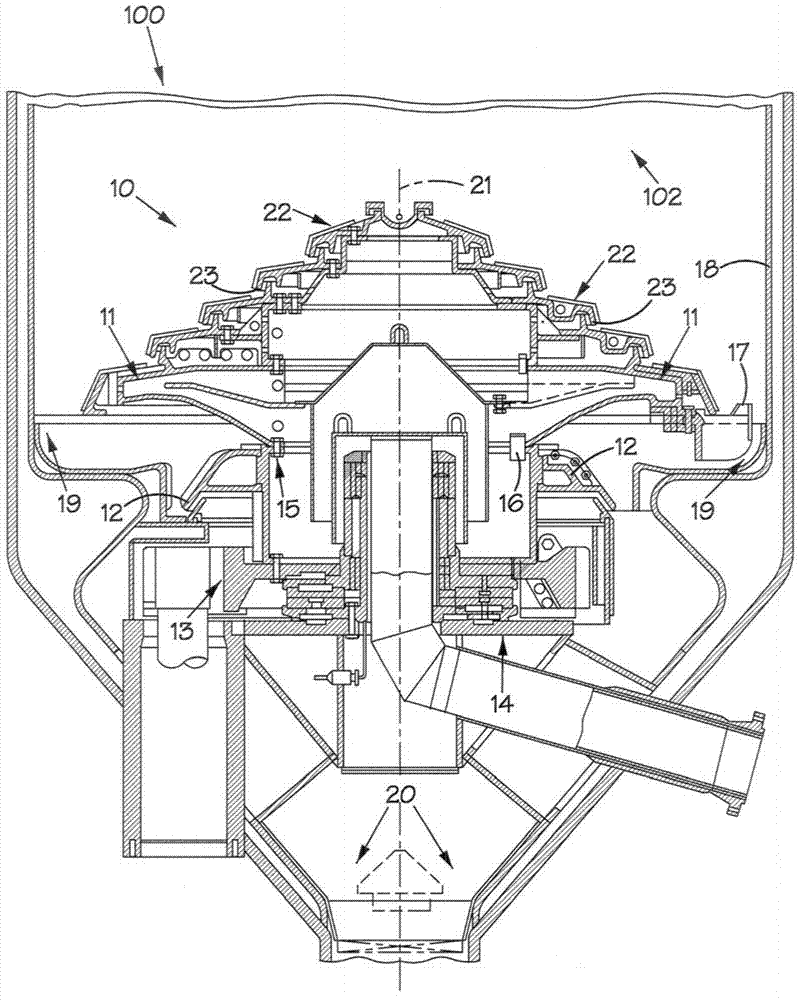

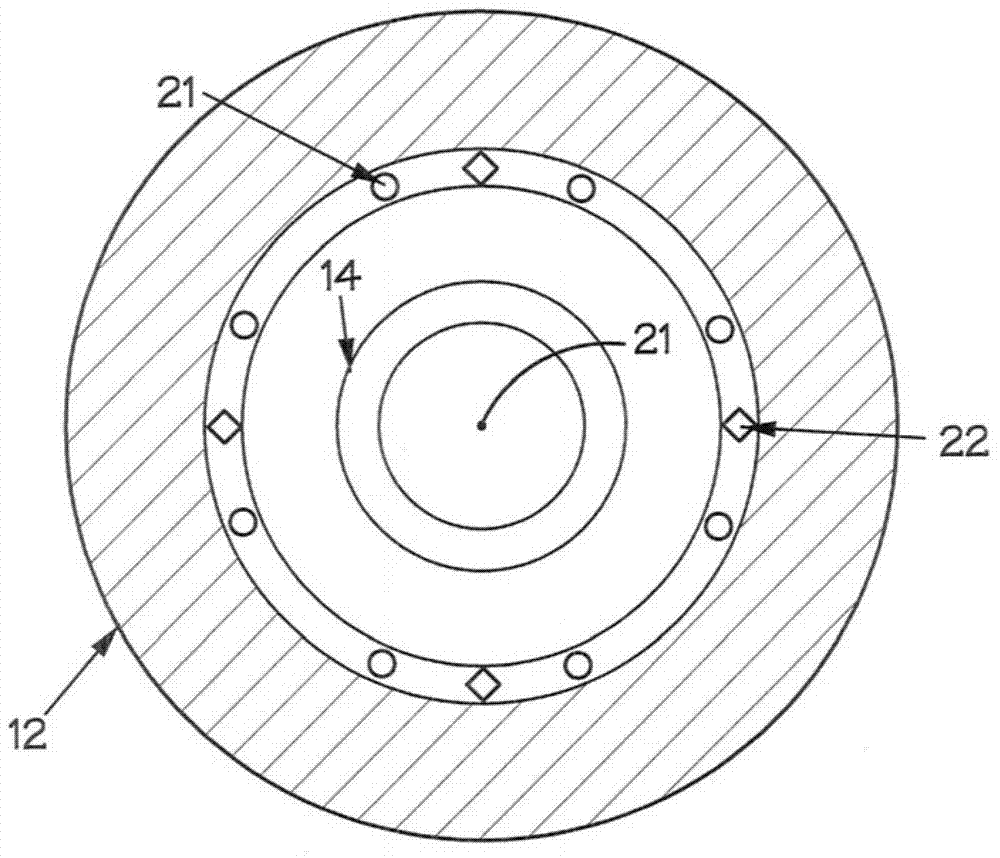

[0039] refer to the attached figure 1 , the reference numeral 10 generally refers to a grid assembly according to the present invention, which is installed in a gasification vessel 100 of a fixed bed dry bottom coal gasifier according to the present invention. The gasification vessel 100 defines a gasification chamber 102 within which the grid assembly 10 is located. The gasification chamber 102 has walls 18 .

[0040] The grill assembly 10 includes an upper rotatable grill member 11 that is fixedly connected to the lower rotatable support structure 12 using a plurality of connecting bolts 15 and at least two keyed torque transmitting devices 16 . The lower rotatable support structure 12 is drivingly connected to a ring gear 13 which is connected via a gearbox to an electric motor (not shown). In use, the electric motor and gearbox are used to rotate the rotatable members 11 , 12 , 13 of the grille assembly 10 .

[0041] The rotatable members 11 , 12 , 13 are supported by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com