Oscillating type pushing mechanical grate

A mechanical grate and forward push technology, which is applied in the direction of shaking grate, rotary grate, grate, etc., can solve the problems of polluting the environment, reducing the efficiency of waste heat recovery, affecting sanitary landfill, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

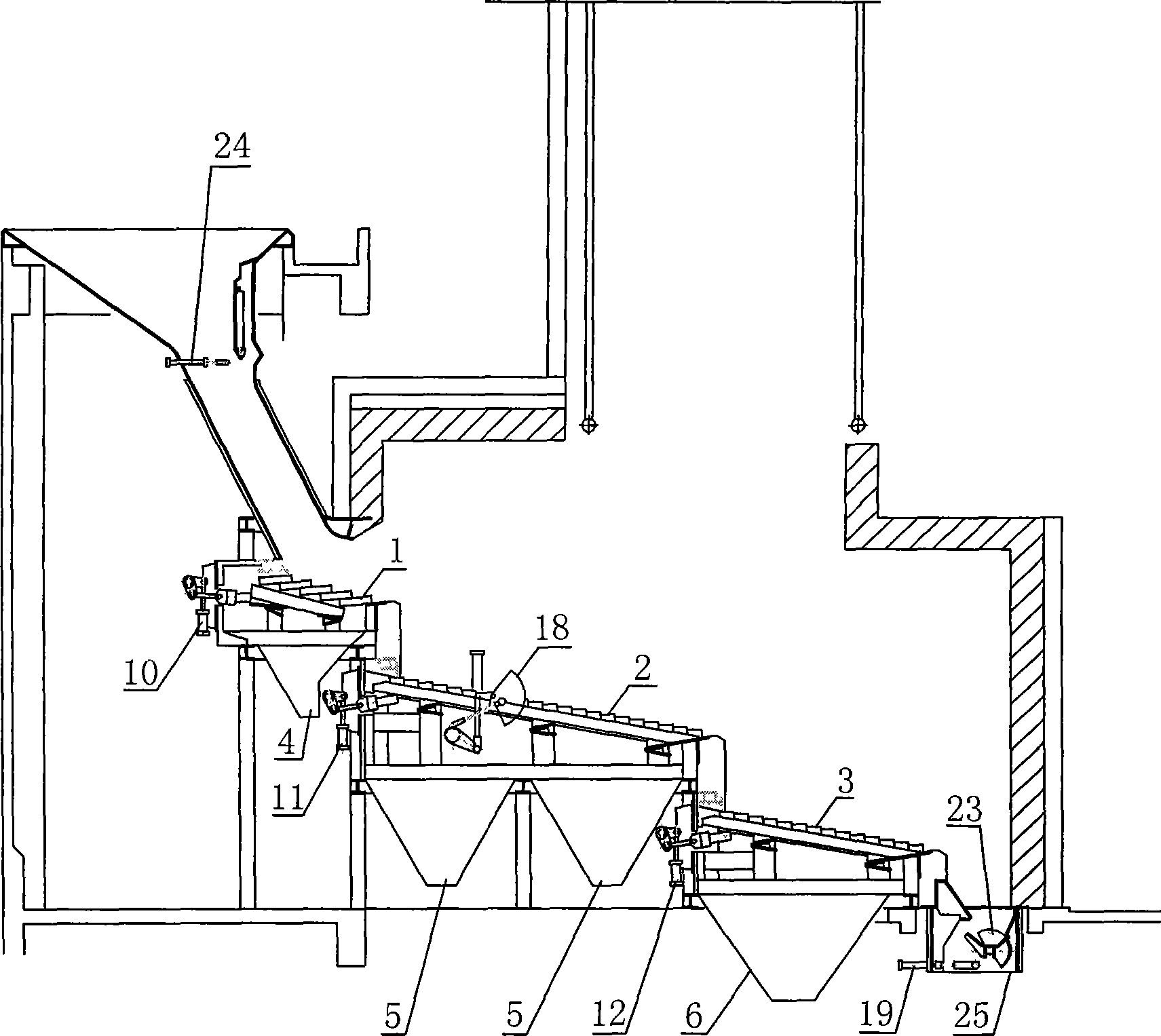

[0012] Depend on figure 1 It can be seen that the oscillating forward-moving mechanical grate of the present invention is composed of a drying grate 1, a combustion grate 2 and a post-combustion grate 3, with a drop between each grate. There is a large drop at the ends of the drying grate 1, the combustion grate 2 and the post-combustion grate 3. The purpose is that when the burning garbage falls from the upper grate to the lower grate, due to the impact of the falling The pieces of rubbish are crushed so that the air is easy to contact with the rubbish, so that the flame can quickly spread throughout the rubbish. The ash hopper 4 is arranged under the drying grate 1, the ash hopper 5 is arranged under the combustion grate 2, and the ash hopper 6 is arranged under the post-combustion grate 3.

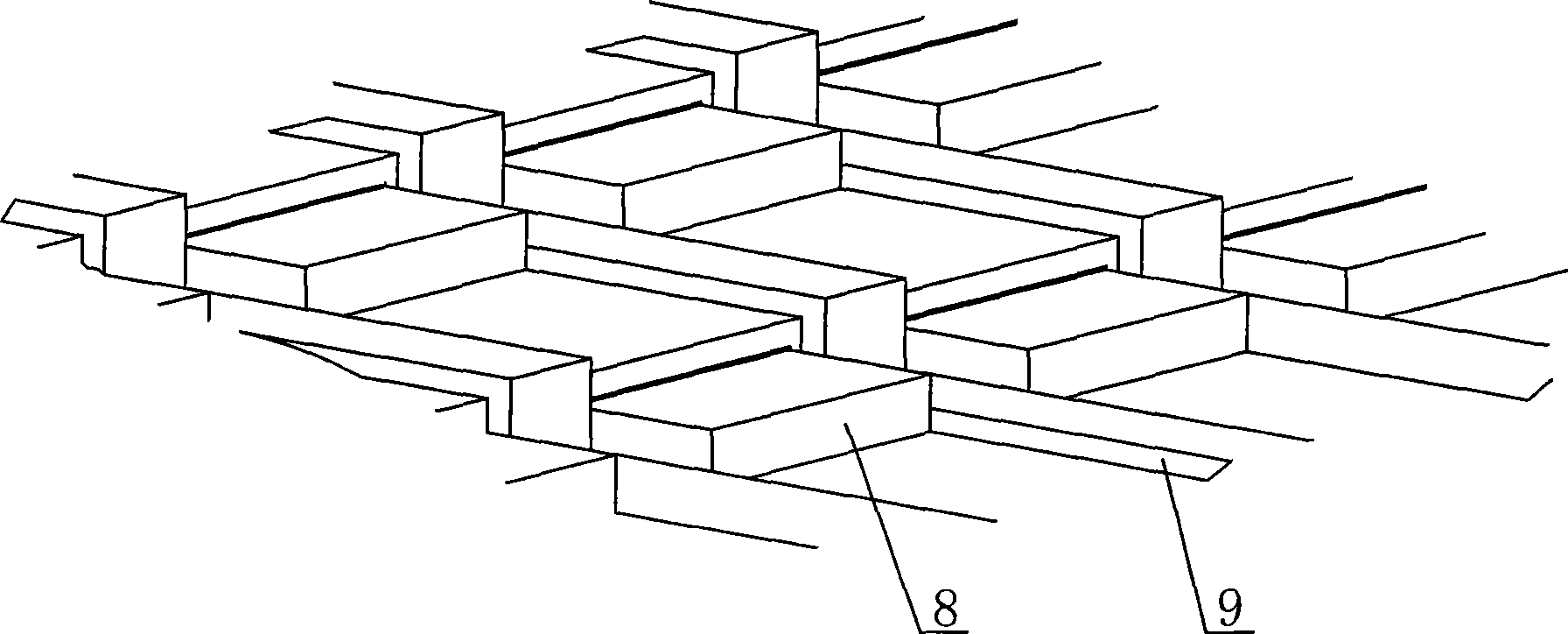

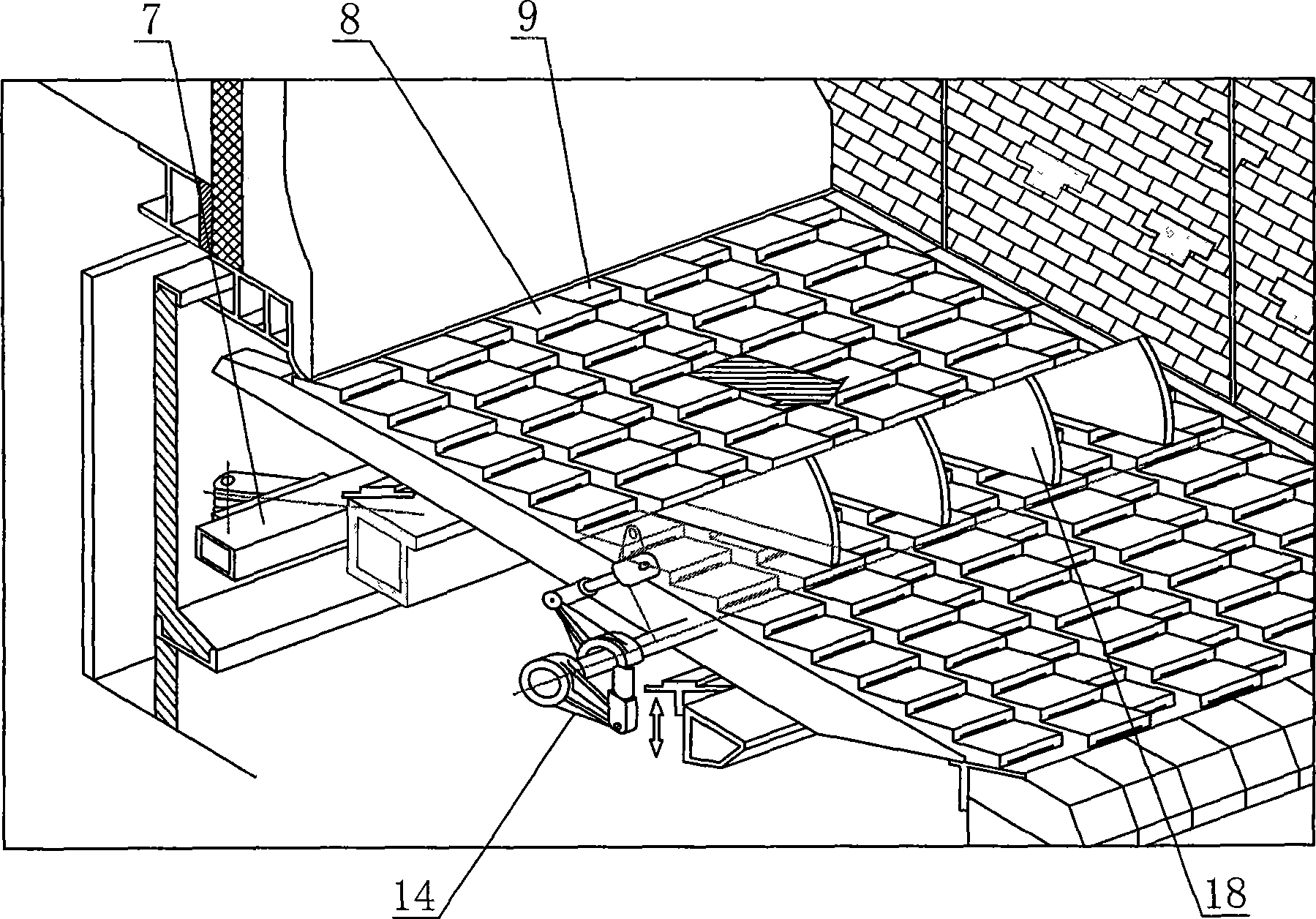

[0013] see figure 2 and image 3 , each section of grate is composed of grate pieces interlaced with each other to form a downward-sloping stepped movable furnace arrangement and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com