Chocolate composition for coating freezing beverage

A technology of frozen drinks and compositions, applied in applications, frozen desserts, food science, etc., can solve problems such as unseen products on the market, and achieve the effect of enhancing shape retention, melting resistance, and good moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

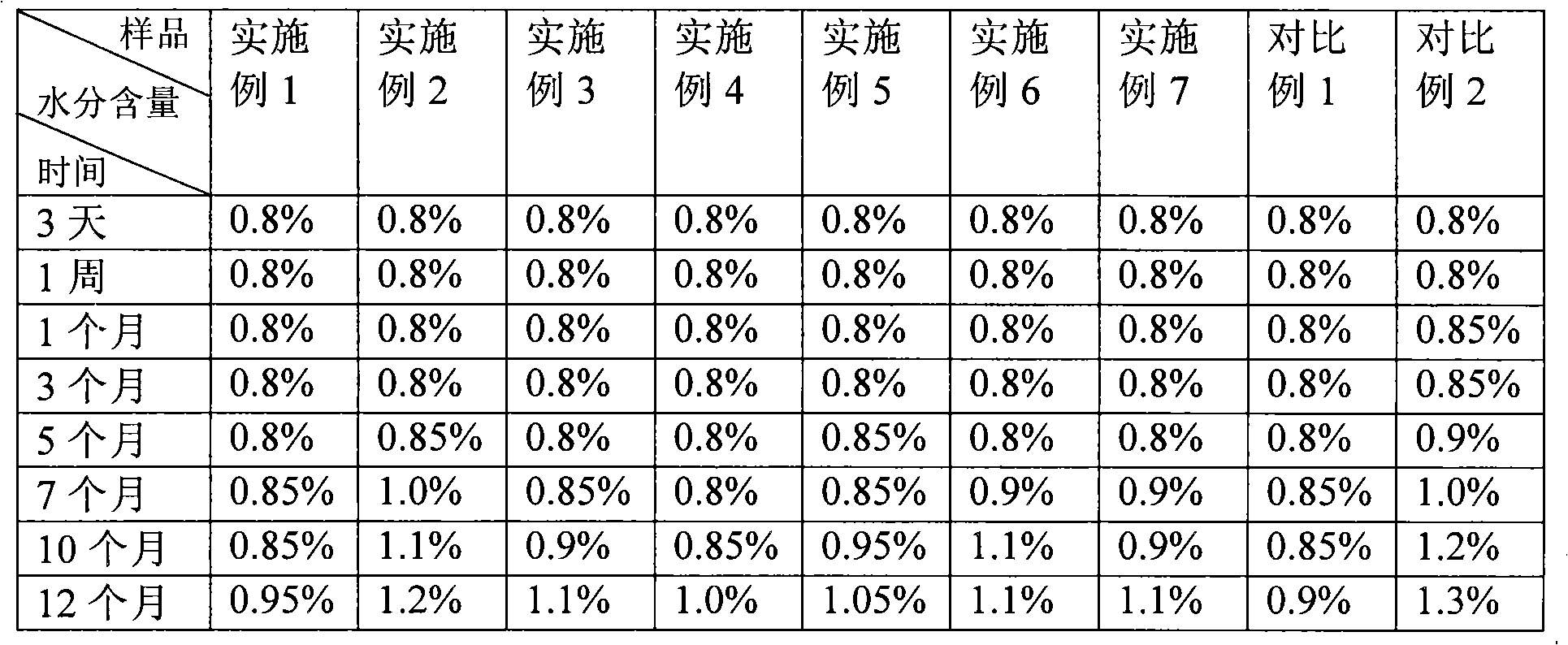

Examples

Embodiment 1

[0044] The xylitol chocolate composition formula in the present embodiment is:

[0045] 42 parts by weight of xylitol; 5 parts by weight of cocoa mass; 10 parts by weight of butter; 33 parts by weight of cocoa butter; 9 parts by weight of milk powder; 0.3 parts by weight of lecithin; ; Vanillin 0.2 parts by weight.

[0046] When utilizing the composition of the present embodiment to coat and hang frozen drinks, it mainly operates according to the following methods:

[0047] Preparation of chocolate paste for coating: heating and melting cocoa liquid mass and cocoa butter for later use; In the mill, add the powdered raw material xylitol and milk powder in the formula; then raise the temperature to 65-68°C and keep it for 30 minutes to sterilize; then cool down to 45-48°C and keep the temperature for fine grinding for 10 hours; then add emulsifier (lecithin and polyglycerol ricinoleate) and vanillin, refined grinding 12 hours again, to slurry fineness less than 35 μ m, namely ...

Embodiment 2

[0050] The formula of the xylitol chocolate composition in the present embodiment is: 42 parts by weight of xylitol; 5 parts by weight of cocoa mass; 10 parts by weight of cream; 33 parts by weight of cocoa butter; 9 parts by weight of milk powder; 0.5 parts by weight of lecithin; 0.2 parts by weight of vanillin.

[0051] In the process of applying the composition of this embodiment to frozen drinks, the method of preparing the chocolate slurry for coating is basically the same as that in Example 1. When the chocolate slurry is coated in frozen drinks, the chocolate The temperature of the slurry is 30°C. The formed frozen drink core material is immersed in the slurry for 0.8 seconds by mechanical means, taken out, and a 1mm thick chocolate coating is formed on the frozen drink to obtain a xylitol chocolate coating. Frozen drinks.

Embodiment 3

[0053] The formula of the xylitol chocolate composition in the present embodiment is: 42 parts by weight of xylitol; 5 parts by weight of cocoa mass; 10 parts by weight of cream; 33 parts by weight of cocoa butter; 9 parts by weight of milk powder; (PGPR90) 0.5 parts by weight; vanillin 0.2 parts by weight.

[0054] The process of coating the frozen drink with the composition of this embodiment is the same as in Example 1, and a frozen drink with a 1 mm thick xylitol chocolate coating is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com