Puffed pleurotus eryngii chip production process and puffed pleurotus eryngii chip products

A production process, technology of Pleurotus eryngii, applied in food preparation, application, food science, etc., to achieve the effect of maintaining good nutrition and color, uniform color, and reducing nutritional loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Preparation of puffed Pleurotus eryngii chips

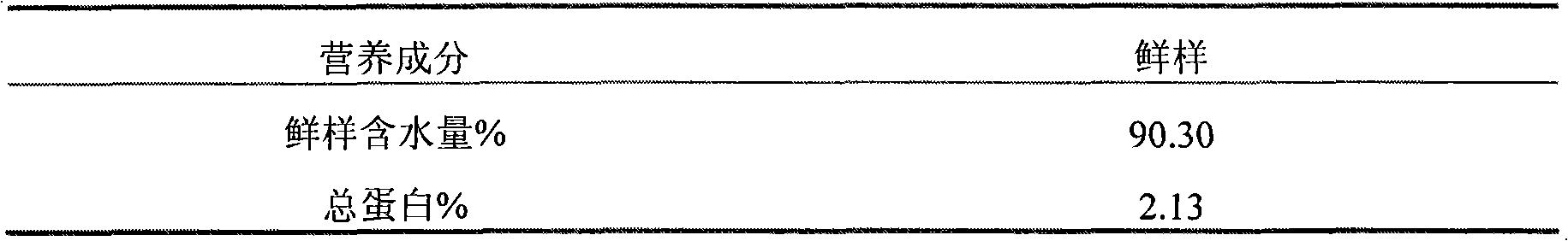

[0024] Get fresh Pleurotus eryngii (kind is Shan Xingbao No. 1) as raw material, measure each index according to the following methods:

[0025] Moisture content measurement method: Turn on the blower in the oven, put the chopped Pleurotus eryngii grains into a large petri dish, put the petri dish into the oven, dry it for 48 hours at 55°C-60°C, and turn it over every two hours. Weigh after 48 hours. After the moisture drops below 10%, change to 105°C and dry continuously for 1 hour, then open the oven door slightly, wait for the temperature to drop slowly, cool for 10-15 minutes, and then enter the dryer to stabilize for 30 Minutes, weighed, and repeated drying at 105°C until the weight of the two weighings was constant. Moisture (%)=sample mass / total sample mass after drying;

[0026] Determination method of total protein: according to GB / T 5009.5-2003, it is determined by Kjeldahl method;

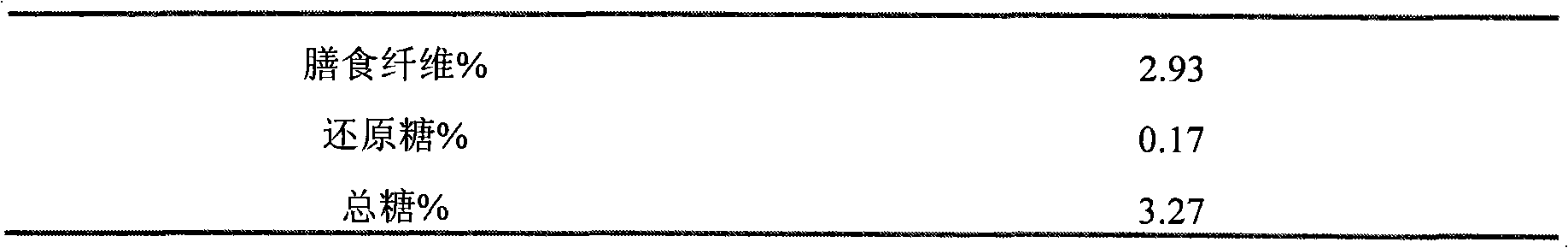

[0027] Dietary fiber: a...

Embodiment 2

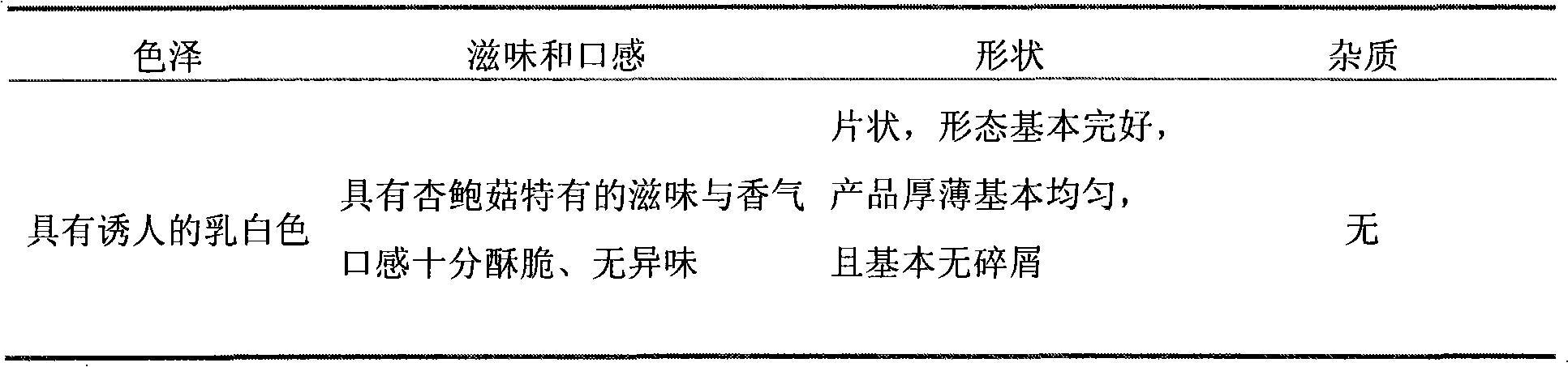

[0057] 1. The production steps of puffed Pleurotus eryngii chips: raw material cleaning, slicing, blanching, negative pressure far-infrared drying, uniform humidity, vacuum microwave puffing drying, packaging; the specific methods are as follows:

[0058] 1. Raw material selection: choose Jiaoke No. 2 Pleurotus eryngii as raw material;

[0059] 2. Cleaning: Rinse with clean water to remove the dirt on the surface of Pleurotus eryngii;

[0060] 3. Slicing: Slice the washed Pleurotus eryngii with a SA-300 semi-automatic slicer, and the slice thickness is 7mm;

[0061] 4. Blanching: Blanch the Pleurotus eryngii slices in a water bath at a temperature of 85°C for 6 minutes;

[0062] 5. Negative pressure far-infrared drying: Place Pleurotus eryngii slices in a ZGF-100 negative pressure far-infrared drying box for pre-expansion drying, set the expansion drying temperature to 54°C, dehumidification time to 43 minutes, and expansion drying time to 129 minutes. -0.085MPa, lower press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com