Wind-powered pneumatic engine and a motor vehicle equipped with the engine

a pneumatic engine and motor vehicle technology, applied in the field of machines, can solve the problems of only passively receiving limited wind force of engines, polluting the environment, etc., and achieve the effects of reducing the amount of hpca used, and enhancing the utilization of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]The present invention is further described in detail with accompanying drawings and embodiments.

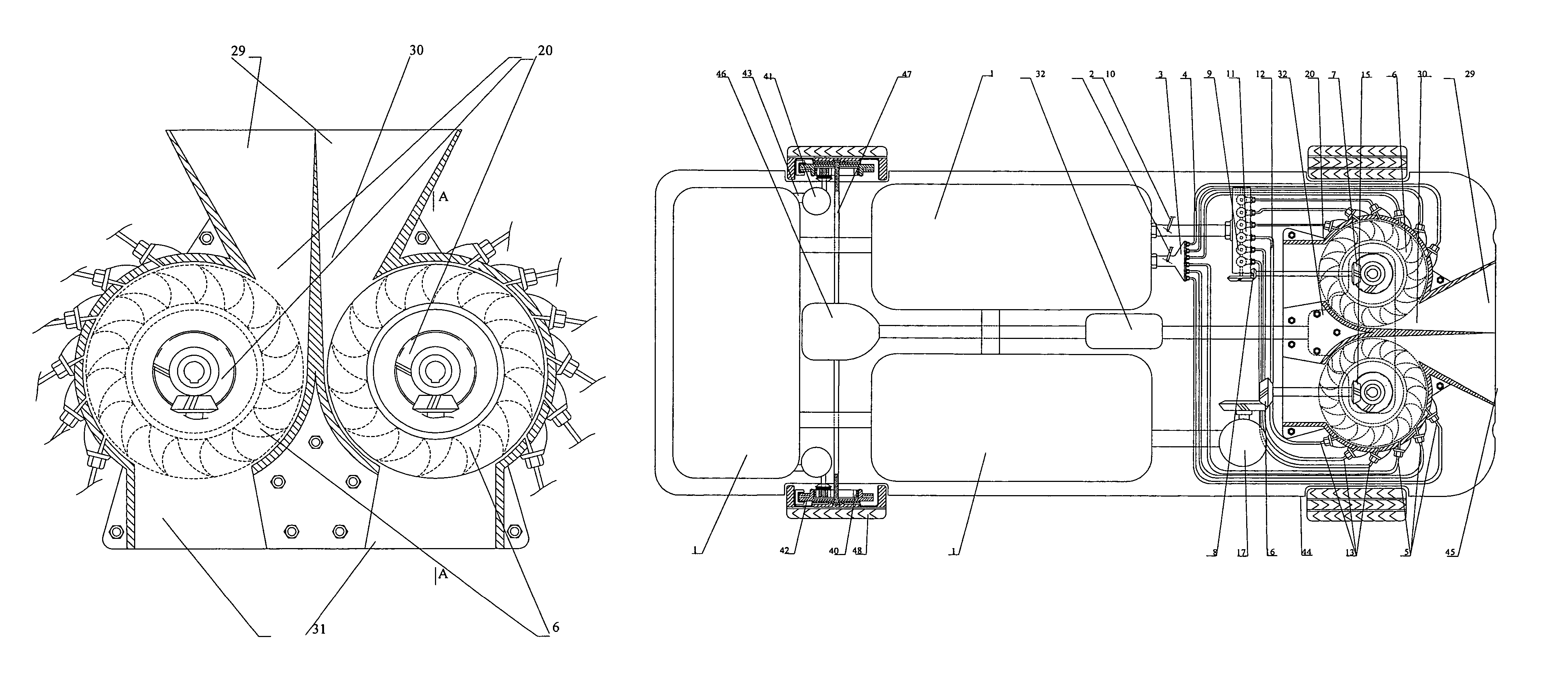

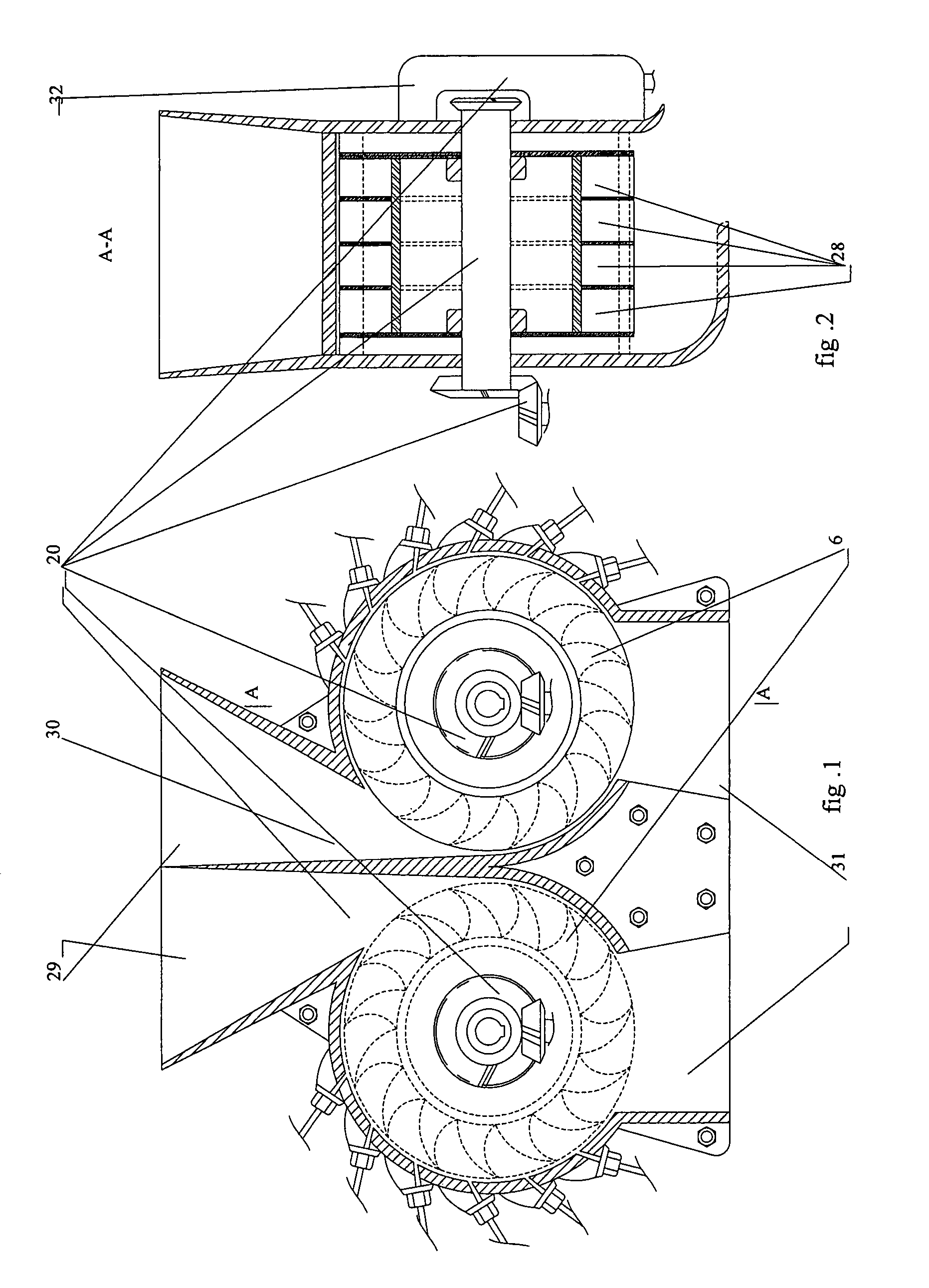

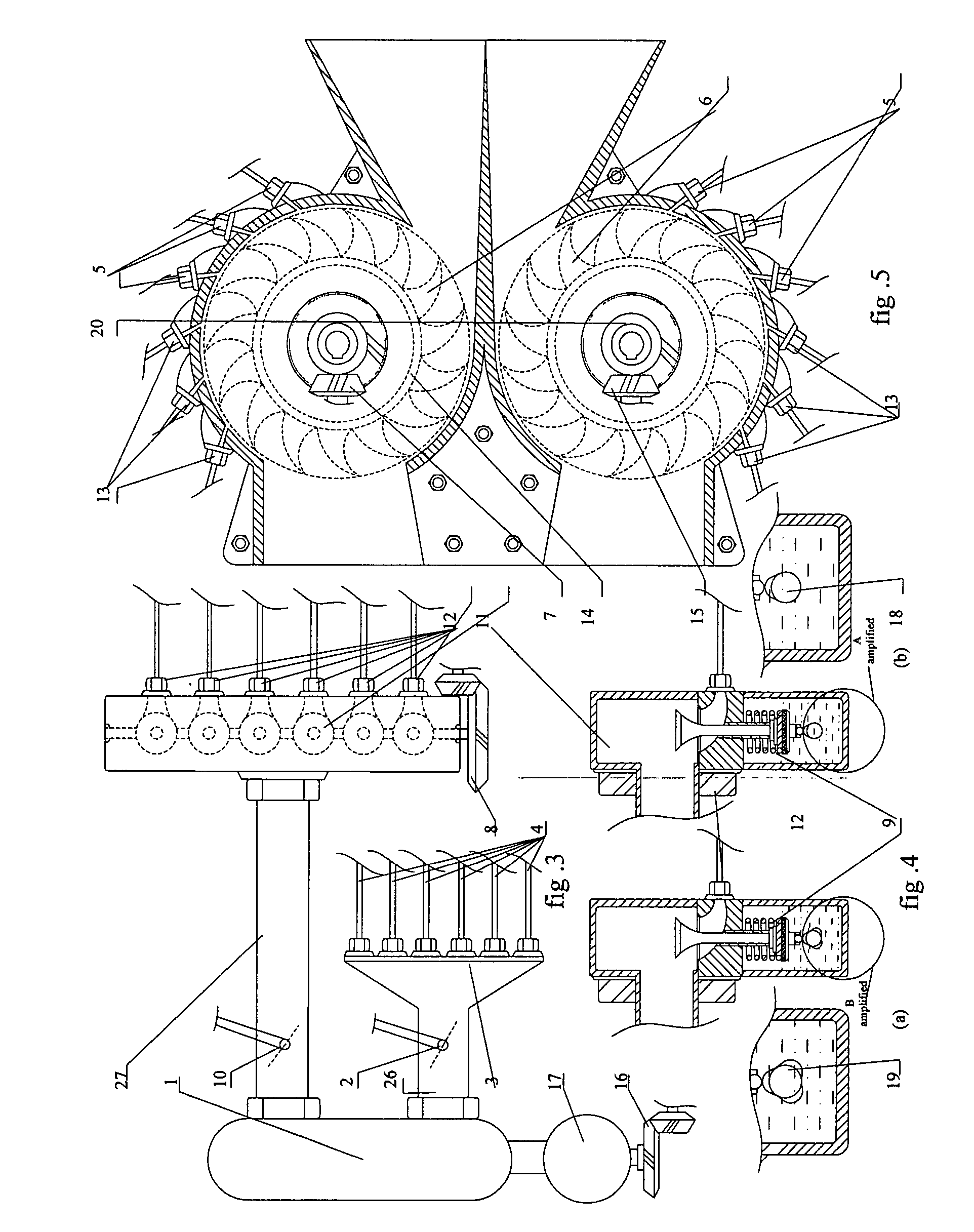

[0046]As shown in FIGS. 1-8, a wind-powered pneumatic engine 20 includes trunk shape inlets, each having an outer edge 29 and an inner edge 30, impeller chambers 28, impellers 6, impeller flywheels 14, a left impeller main shaft auxiliary power conical gear 7, a right impeller main shaft auxiliary power conical gear 15, a primary power output gear box 32, and air outlets 31; a HPCA regeneration, storage and supply system, including an air tank 1, a first HPCA compressor 17, and a conical gear 16 for transmitting the first HPCA compressor 17; an air-jet system for start and acceleration, including a first controller 2 for opening the HPCA to perform start and acceleration, a distributor 3, a first air-jet pipe set 4 connected with the distributor 3, a first air-jet nozzle set 5, a second controller 10 for opening the HPCA to perform automatic intermittent burst air-jet acceleration, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com