Flexible and extendable electronic device based on biocompatible films and manufacturing method

A biocompatible film and electronic device technology, applied in electrical components, printed circuit components, elastic polymer dielectrics, etc., can solve the problems of low bending stiffness and tensile stiffness, avoid skin impregnation, improve flexibility and extensibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

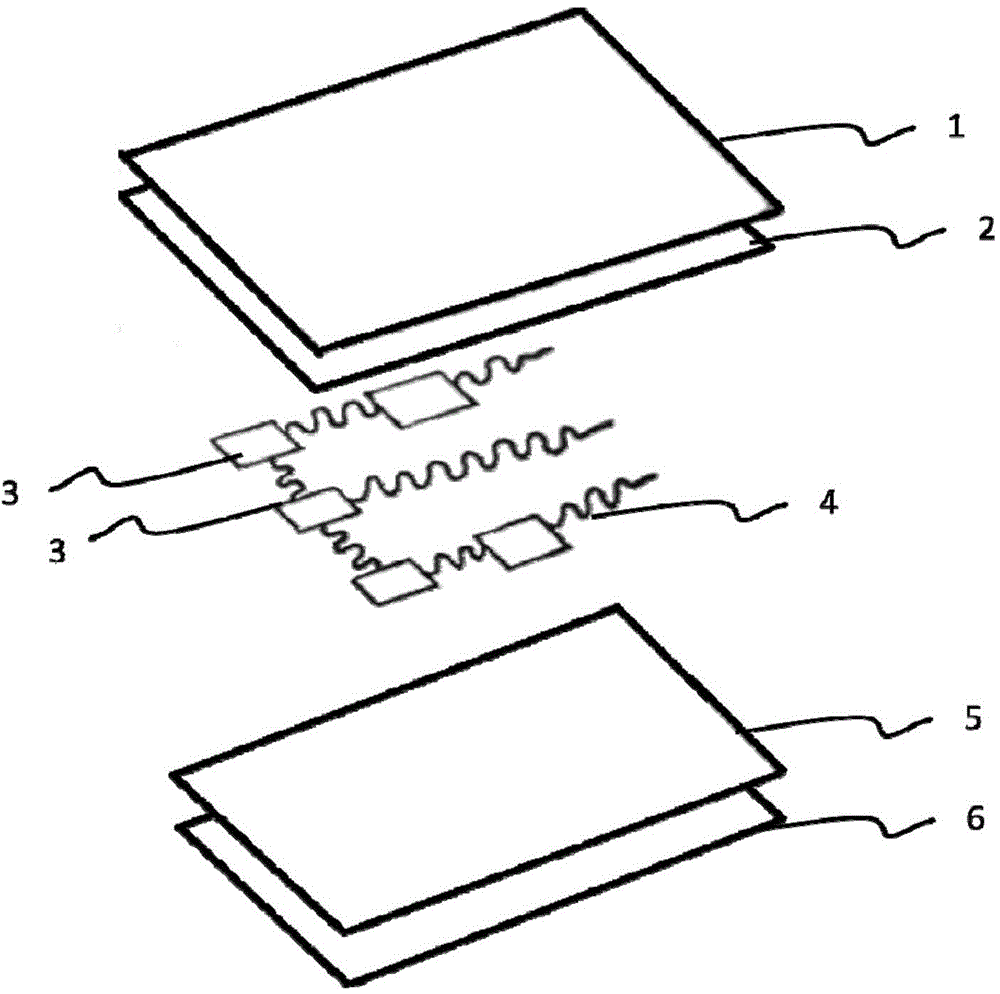

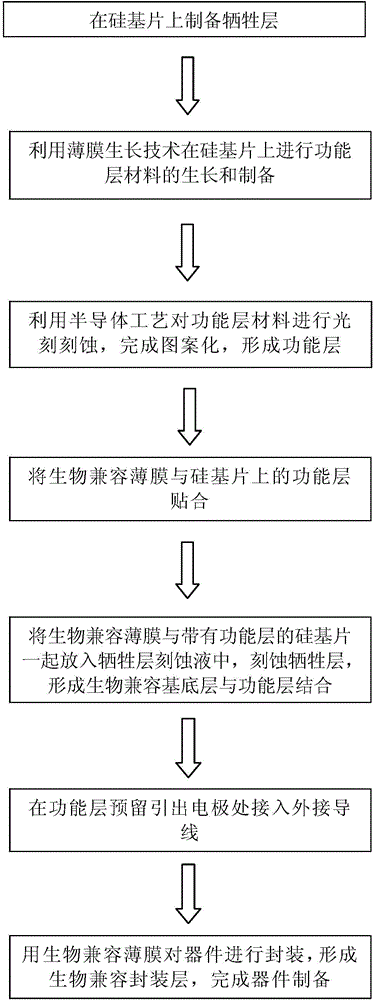

[0032] image 3 It is a process flow diagram of a method for preparing a flexible and extensible electronic device based on a biocompatible film provided by the present invention. The preparation method includes the following steps:

[0033] 1) preparing a sacrificial layer on a silicon substrate;

[0034] 2) Using thin film growth technology to grow and prepare functional layer materials on silicon substrates;

[0035] 3) Photolithography is used to etch the functional layer material by semiconductor technology to complete the patterning and form the functional layer;

[0036] 4) bonding the biocompatible film to the functional layer on the silicon substrate;

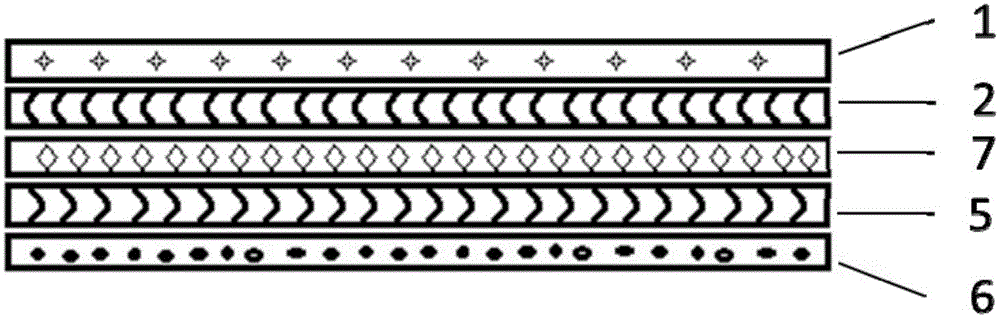

[0037] 5) Putting the biocompatible film and the silicon substrate with the functional layer into the sacrificial layer etchant, etching the sacrificial layer to form a combination of the biocompatible base layer 5 and the functional layer;

[0038] 6) Access the external wires at the reserved lead-out electrodes of...

Embodiment 1

[0044] Example 1: A flexible and extensible temperature sensor based on a biocompatible film

[0045] This embodiment is a stretchable electronic device based on a biocompatible thin film utilizing the temperature resistance effect of gold. The device is manufactured using the design method and preparation process proposed in the technical solution of the present invention, wherein the biocompatible encapsulation layer 1 and the biocompatible base layer 5 are both made of a 50 μm thick porous polyurethane film, and the bonding layer 2 and the adhesion layer 6 are made of low-density Sensitive, highly viscous acrylic, functional elements 3 and interconnection wires 4 in the functional layer adopt patterned gold nano film, which can be used to measure human body temperature. The preparation method is as follows:

[0046] 1) First prepare a flat sacrificial layer on the silicon substrate, that is, prepare a layer of PI thin film on the silicon substrate by spin coating, place it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com