Plugging device of pen head and pen holder

A plug-in device and pen head technology, which is applied in the field of pen making, can solve problems such as waste, low production efficiency, and high manual assembly costs, and achieve stable working conditions, high production efficiency, and stable and reliable equipment operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

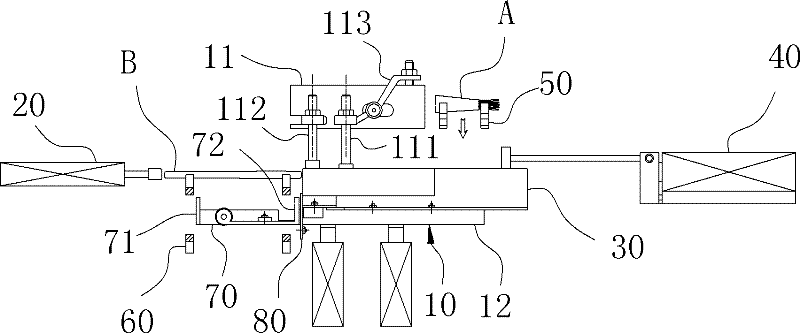

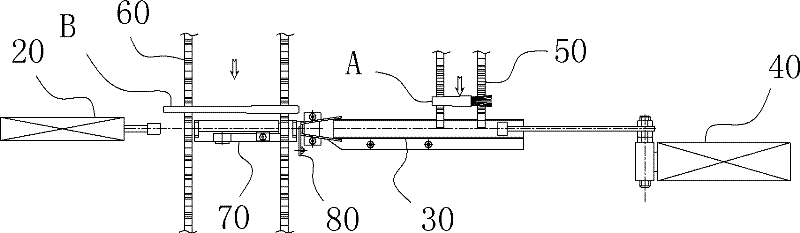

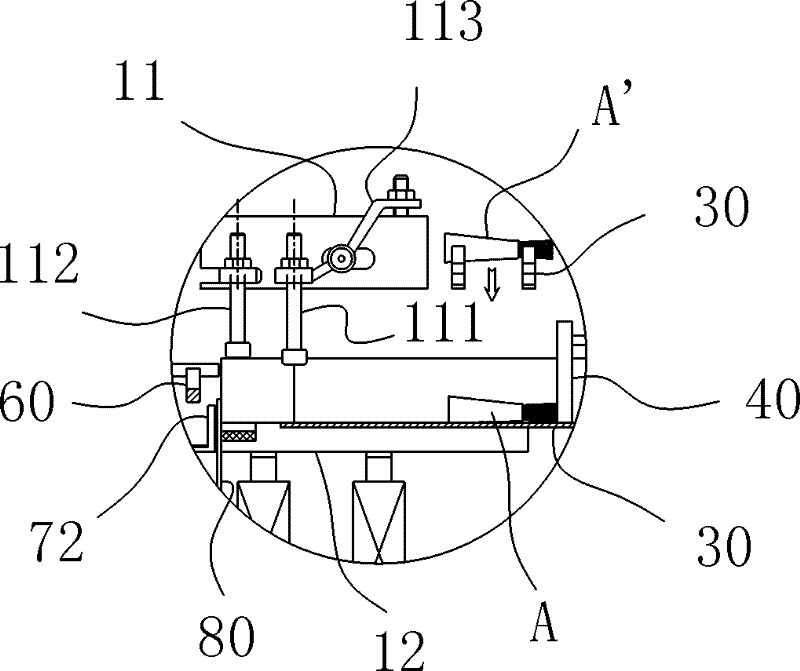

[0020] A plug-in device for a nib and a penholder, including a clamping mechanism 10 for fixing a nib A and a penholder pushing mechanism 20 for pushing a penholder B. When assembled, the nib A and the penholder B are in a " Arranged in a "" shape, such as figure 1 shown.

[0021] Further, in order to realize the clamping function of the clamping mechanism 10, the clamping mechanism 10 includes an upper jaw body 11 and a lower jaw body 12, the lower jaw body 12 has two position states of high position and low position, and the two positions of the lower jaw body 12 The two positions constitute the opening and closing states of the clamping mechanism 10 .

[0022] Further, the plug-in device also includes a guide rail 30 for orienting the nib A. The opening of the guide rail 30 faces upwards and its bottom is attached to the upper side of the lower jaw body 12. In actual operation, the staff can directly place the nib A Placed in the guide rail 30 to implement clamping, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com