Method of producing polysilicon with mixed source of trichloro-hydrosilicon and silicon tetrachloride

A technology of silicon tetrachloride and trichlorosilane, applied in the direction of silicon, etc., can solve the problems of low production rate, low conversion rate, high energy consumption, etc., and achieve the goal of ensuring growth uniformity, quality and yield, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

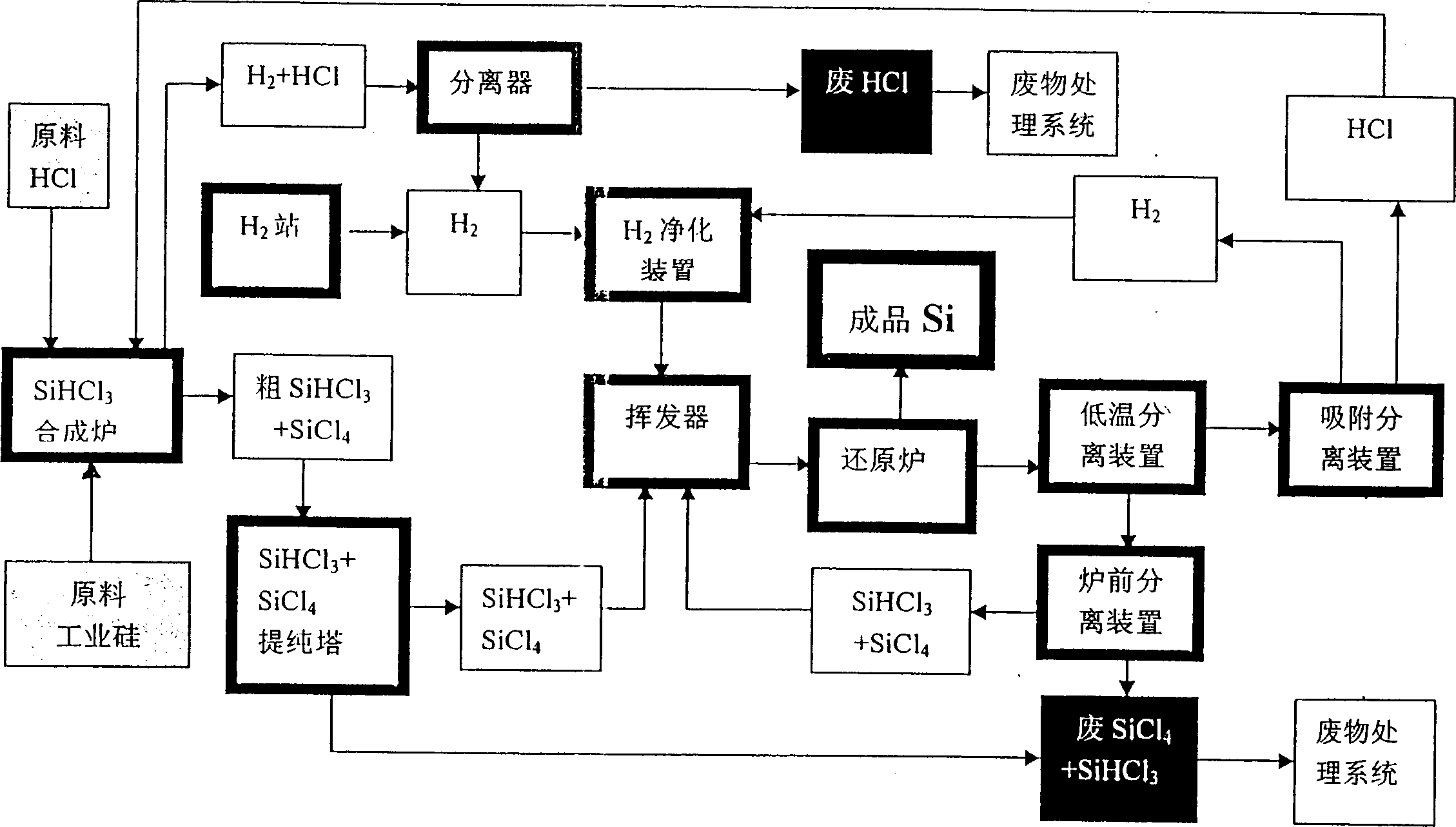

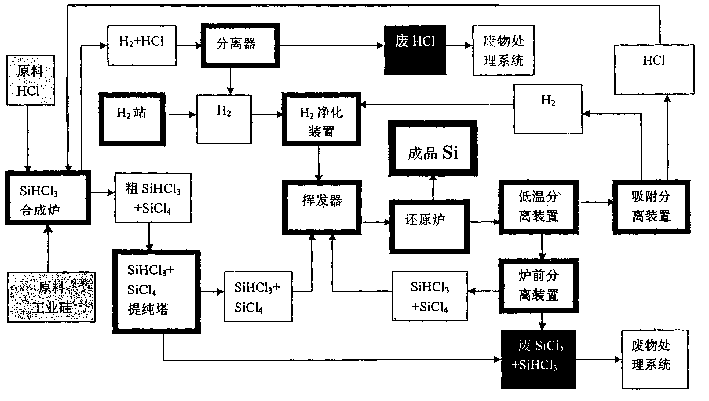

[0015] Please refer to the attached figure 1 , firstly, pass the raw material HCl into SiHCl filled with industrial silicon powder 3 In the synthesis furnace (bubbling bed), crude SiHCl is obtained 3 and SiCl 4 . Then, on the one hand, crude SiHCl 3 and SiCl 4 into SiHCl 3 and SiCl 4 Refining and purification in the purification tower to remove unqualified waste SiCl 4 and SiHCl 3 , SiHCl with a purity of 9 or more 3 and SiCl 4 into the vaporizer. SiHCl on the other hand 3 H produced in the synthesis furnace 2 and residual HCl enter the separator to separate the waste HCl, and the remaining H 2 Join H 2 Standing H 2 Enter H together 2 Purification device, purified to 6 9 H 2 also enters the volatile. Next, put the SiHCl that meets the purity in the evaporator 3 and SiCl 4 and H 2 The gas is injected into the reduction furnace according to the conventional flow rate to carry out the hydrogen reduction reaction. The reduction temperature is controlled at 115...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com