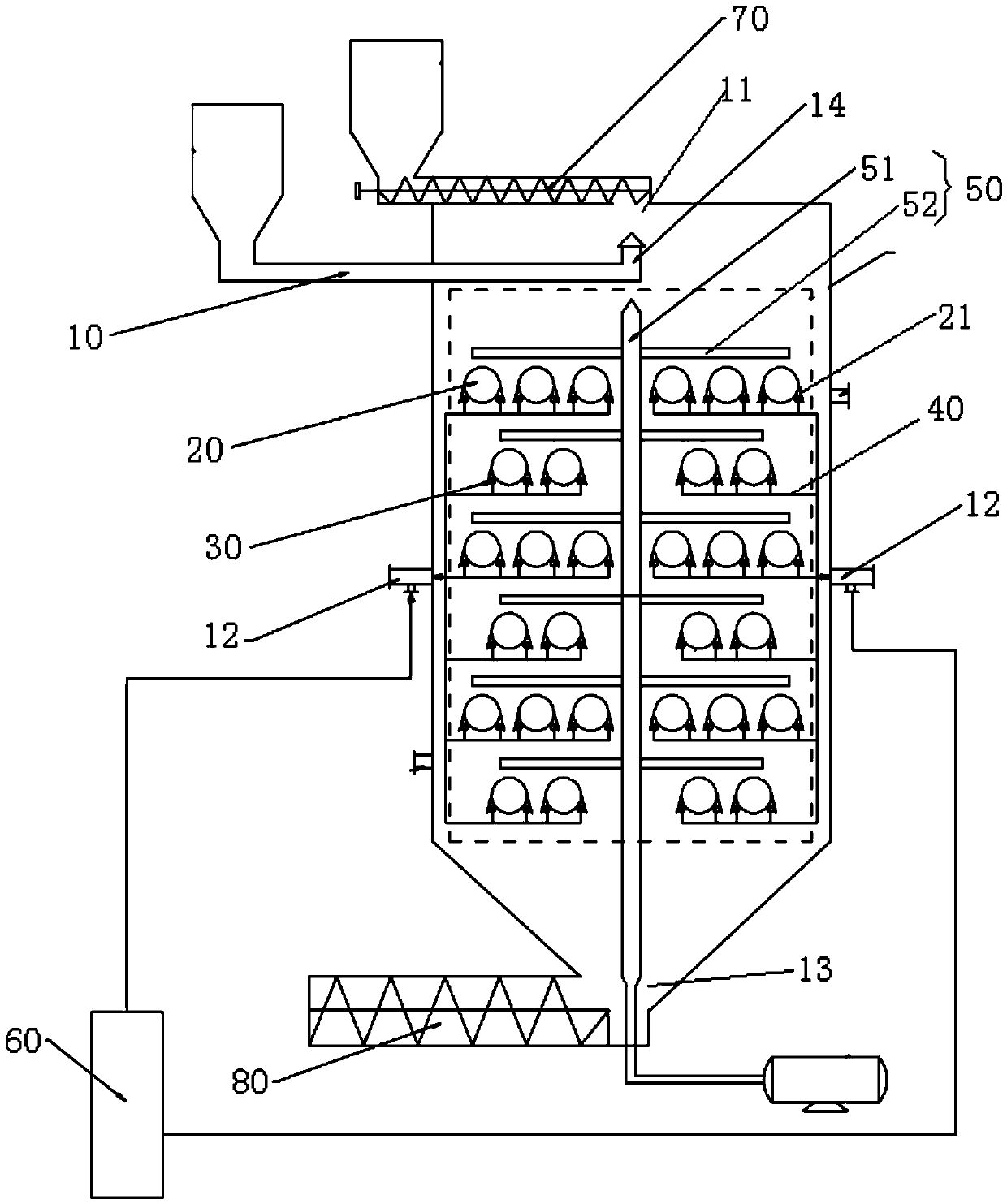

Downer rapid catalytic pyrolysis reactor

A catalytic pyrolysis and reactor technology, applied in the field of coal chemical industry, can solve the problems of high pressure in purification process, large gas consumption of gas heat carrier, complicated process of solid heat carrier method, etc., and achieve the effect of avoiding heat transfer efficiency and avoiding coking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] The down-bed fast catalytic pyrolysis reactor is used to process Indonesian lignite. The basic data and pyrolysis products of raw materials are shown in Table 1 and Table 2.

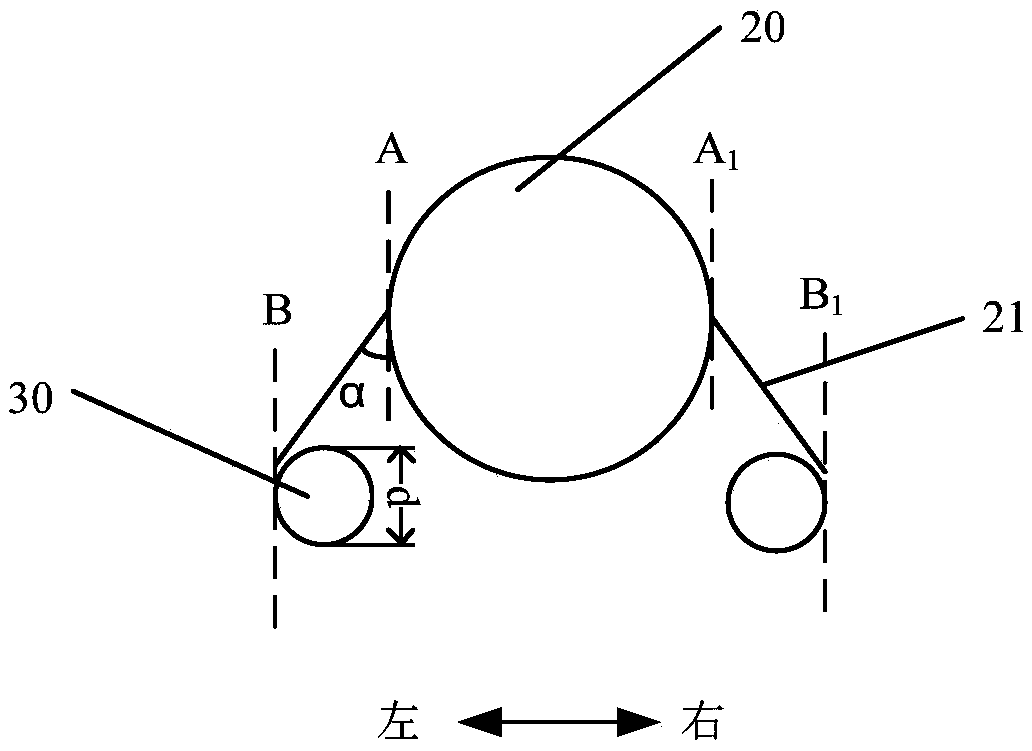

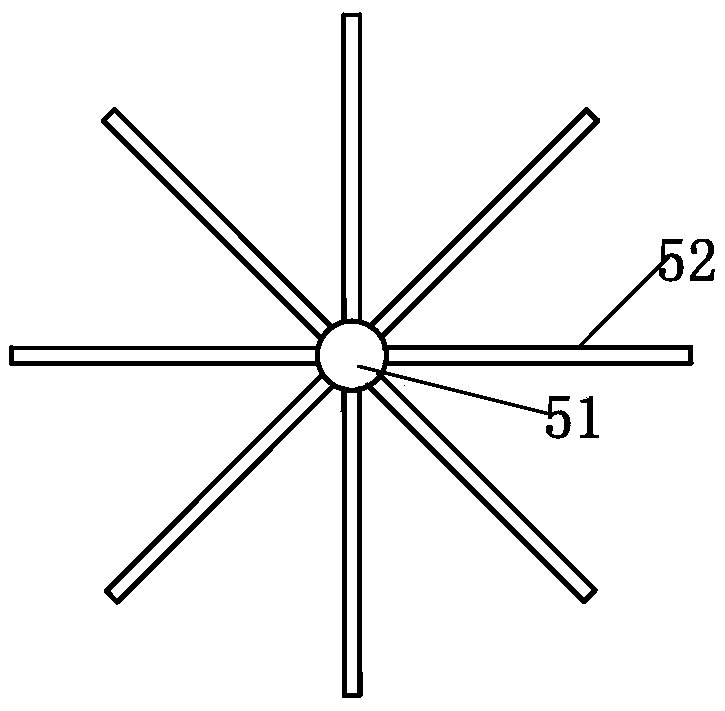

[0065] Start feeding Indonesian lignite with a particle size of ≤1mm through a screw feeder. At the same time, an iron oxide catalyst with a mass fraction of 3% relative to the Indonesian lignite and a particle size of less than 0.5mm is injected from the wind cap to make it uniformly mixed and distributed. The mixture passes through each layer in turn The radiant tube heats up quickly for catalytic pyrolysis, and the stirring device rotates at a frequency of 15Hz. The temperature of the upper two layers of radiant tubes is 650℃, and the temperature of each lower layer is 550℃; the steam generator produces steam at 300℃, and two oil and gas The outlets are switched alternately, switching once every 120s; the pyrolyzed oil and gas produced in the reaction are exported to the gas collector through the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com