Coal carbonization and coal catalytic cracking combined technological method

A catalytic cracking and combined process technology, used in special forms of dry distillation, direct heating dry distillation, petroleum industry and other directions, can solve the problems that are difficult to meet industrial and civil requirements, have not been properly solved, and the moisture content of semi-coke products is high, and achieve long-term performance. The effect of periodic operation, convenient control and high operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

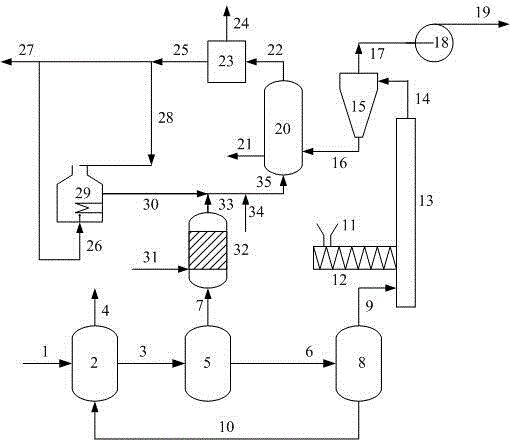

Image

Examples

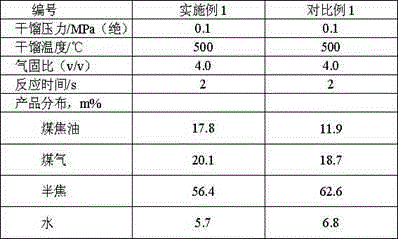

Embodiment 1

[0032] The catalytic cracking reaction is carried out on a small riser type catalytic cracking unit. The catalytic cracking catalyst used in the examples is an industrial equilibrium catalyst (see Table 1 for properties of the fresh catalyst). Hydrogenated residual oil (>350°C) is used as catalytic cracking raw material, the test conditions are: reaction temperature 520°C, solvent-oil ratio 6:1, space velocity 10h -1 . The operating data and flue gas composition of the regenerator are shown in Table 2. Lignite A from a certain area in northern Shaanxi was selected, and its industrial analysis is shown in Table 3. After the raw coal is crushed and screened, the coal powder <6mm is added to the riser dryer, and the raw coal is dried and lifted by the catalytic cracking and reheating flue gas at 753°C. The drying temperature is 150°C, and the dry coal powder enters the fluidization Bed dry distillation reactor, the circulating gas is heated to 620°C by the heating furnace, the...

Embodiment 2

[0045] The catalytic cracking reaction is carried out on a small riser type catalytic cracking unit. The catalytic cracking catalyst used in the examples is an industrial equilibrium catalyst (see Table 1 for properties of the fresh catalyst). Hydrogenated residual oil (>350°C) is used as catalytic cracking raw material, the test conditions are: reaction temperature 520°C, solvent-oil ratio 6:1, space velocity 10h -1 . The operating data and flue gas composition of the regenerator are shown in Table 5. Lignite A from a certain area in northern Shaanxi was selected, and its industrial analysis is shown in Table 3. After the raw coal is crushed and screened, the coal powder <6mm is added to the riser dryer, and the raw coal powder is dried and lifted by the catalytic cracking and reheating flue gas at 700°C. The drying temperature is 300°C, and the dry coal powder enters the flow stream. In the chemical bed dry distillation reactor, the circulating gas is heated to 680°C by t...

Embodiment 3

[0055] Feed trifluoroacetic acid vapor into the heat carrier fed with water vapor, the volume content of trifluoroacetic acid vapor in the heat carrier is 2%, the rest are the same as in Example 1, and the product distribution is shown in Table 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com