Method and device for preparing semi-coke

A semi-coke and hot semi-coke technology, applied in the field of semi-coke preparation, can solve the problems affecting the long-term stable operation of the pyrolysis system, low tar yield, large amount of powder coke, etc., and achieves improved quality and reduced powder coke amount. , the effect of high proportion of combustible components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

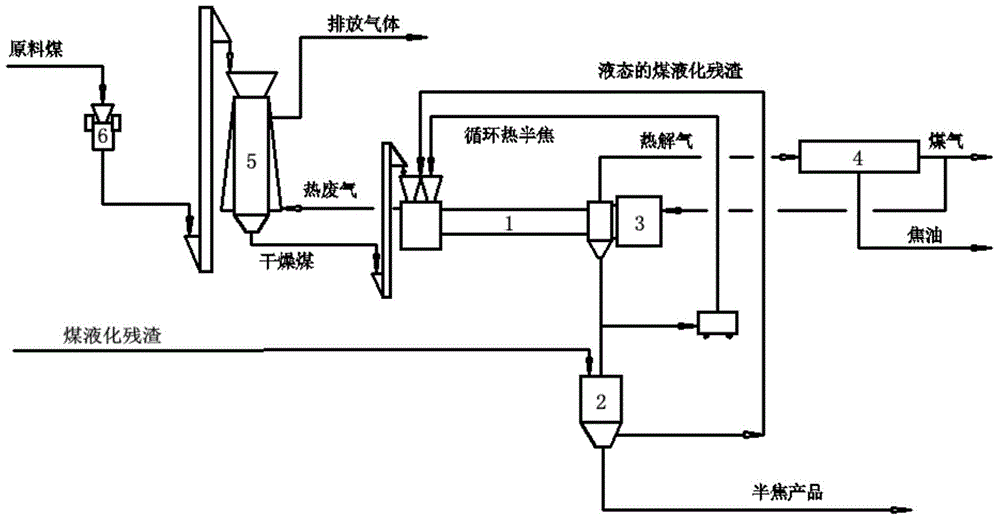

Image

Examples

Embodiment 1

[0059] This example is used to illustrate the method for preparing semi-coke of the present invention.

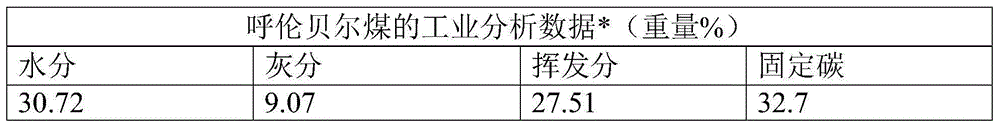

[0060] (1) dry. Put the Hulunbuir coal with a particle size of <30mm into the vertical drying furnace for drying. The final drying temperature is 180°C, and the drying time is 2.5 hours to obtain dry coal;

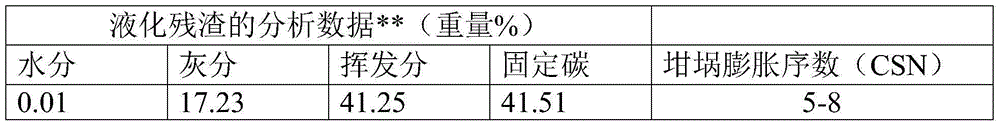

[0061](2) Co-pyrolysis. The obtained dry coal, liquid coal liquefaction residue (the coal liquefaction residue comes from the direct coal liquefaction production plant, see Table 2 and 3 for the analysis data) and circulating hot semi-coke, according to the weight ratio of the liquid coal liquefaction residue to the dry coal is 15:100, the weight ratio of circulating hot semi-coke to dry coal is 2.5:1, put into the pyrolysis furnace for co-pyrolysis. The temperature of the liquid coal liquefaction residue is 220°C, and the temperature of the circulating hot semi-coke is 450°C. The temperature of the feed section of the pyrolysis furnace was 330°C. A thermal annular...

Embodiment 2

[0079] This example is used to illustrate the method for preparing semi-coke of the present invention.

[0080] (1) dry. After the Shendong coal is crushed by a crusher to a particle size below 30mm, it is added to a vertical drying furnace for drying. The final drying temperature is 200°C, and the drying time is 1.0h to obtain dry coal;

[0081] (2) Co-pyrolysis. The obtained dry coal, liquid coal liquefaction residue and recycled hot semi-coke are calculated according to the weight ratio of liquid coal liquefaction residue to dry coal is 15:100, and the weight ratio of recycled hot semi-coke to dry coal is 2:1 , into the pyrolysis furnace for co-pyrolysis. The temperature of the liquid coal liquefaction residue is 240°C, and the temperature of the circulating semi-coke is 480°C. The temperature of the feed section of the pyrolysis furnace was 340°C. A thermal annular coil is arranged at the discharge section of the pyrolysis furnace, and the combustion exhaust gas disch...

Embodiment 3

[0089] This example is used to illustrate the method for preparing semi-coke of the present invention.

[0090] (1) dry. After the Hulunbuir coal is crushed by a crusher to a particle size of less than 30mm, it is added to a vertical drying furnace for drying. The final drying temperature is 160°C, and the drying time is 3 hours to obtain dry coal;

[0091] (2) Co-pyrolysis. The obtained dry coal, liquid coal liquefaction residue and circulating hot semi-coke are calculated according to the weight ratio of circulating hot semi-coke to dry coal is 3:1, and the weight ratio of liquid coal liquefaction residue to dry coal is 25:100 , into the pyrolysis furnace for co-pyrolysis. The temperature of the liquid coal liquefaction residue is 210°C, and the temperature of the circulating hot semi-coke is 430°C. The temperature of the feed section of the pyrolysis furnace was 320 °C. A thermal annular coil is arranged at the discharge section of the pyrolysis furnace, and the combus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com