Device and process for improving productivity of oil and gas and efficiently recovering oil and gas

An oil and gas recovery system, oil and gas technology, applied in the petroleum industry, gas dust removal, combustible gas purification, etc., can solve problems such as difficult to guarantee the quality of pyrolysis gas and tar, difficult to maintain the stability of the operation process, and the impact of effective recovery of pyrolysis products, etc. , to achieve high tar yield, ensure performance and service life, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

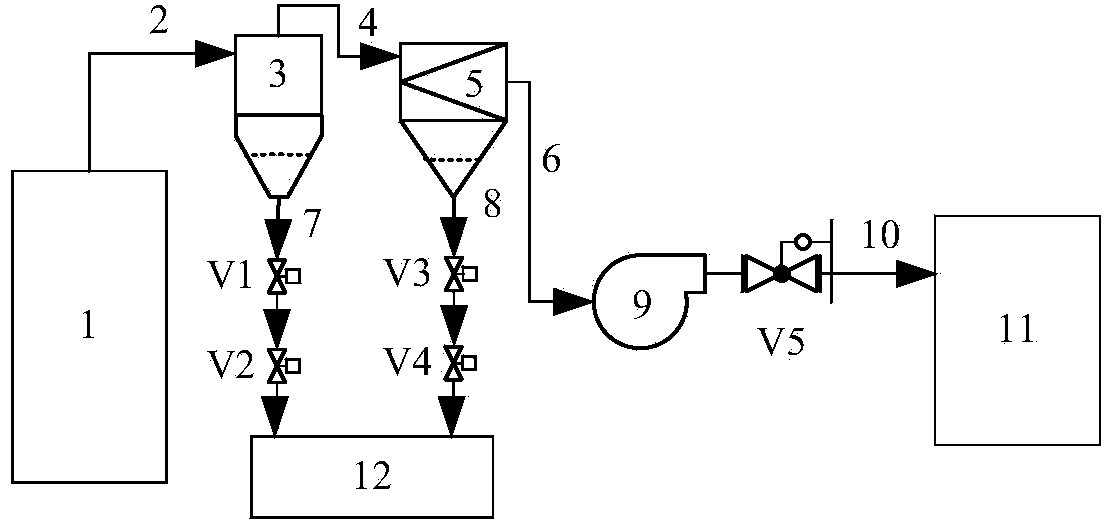

[0039] 5-210μm pulverized coal is placed in the pyrolysis furnace at 650°C, -1000pa (gauge pressure), and the residence time is 1s. The temperature of the dust-removed gas after the metal filter is controlled above 500°C. After the dust-removed gas is decompressed by the high-temperature fan and the pressure-reducing valve, the outlet pressure of the purified gas obtained is 0.03MPa (gauge pressure), and the temperature is 450°C. Oil vapor recovery system.

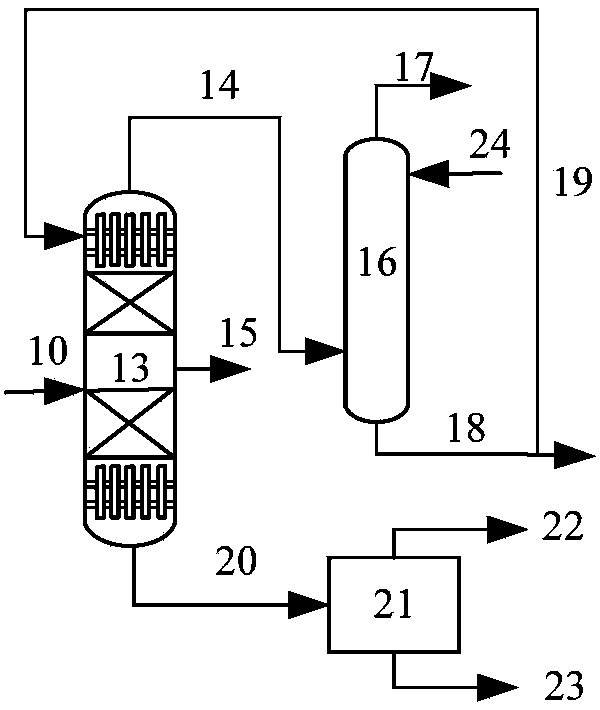

[0040] Such as figure 2 As shown, firstly, the purified gas enters the oil washing tower with 46 theoretical plates from the 19th theoretical plate. Oil, non-condensable gas and light oil, medium oil is drawn from the 10th theoretical plate of the oil scrubber, and the medium oil accounts for 26% of the tar yield. The non-condensable gas enters the gas-liquid separator for separation of light oil and gas. After gas-liquid separation, the temperature of the process water is 21°C, the temperature of the gas outlet is 29°C...

Embodiment 2

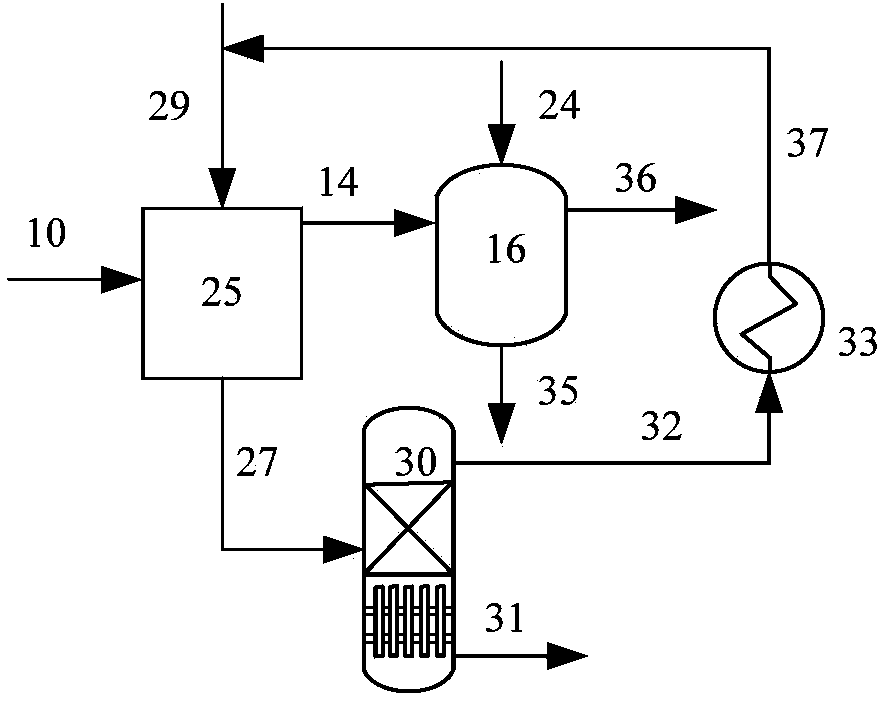

[0042] In the oil and gas recovery method provided by the present invention, according to the same process as in Example 1, the coal of the same raw material is pyrolyzed and the raw coal gas is dedusted. Such as image 3 As shown, the difference is that the oil vapor recovery system is different. Among them, the temperature of low-temperature methanol is -31°C, the temperature of non-condensable gas at the outlet of the condenser is 55°C, the temperature of circulating solvent is 45°C, and the temperature of pyrolysis gas is 36°C. The yields of pyrolysis products are shown in Table 2.

[0043] Table 2

[0044]

[0045] As can be seen from Table 2, the present invention can significantly improve the yield of tar, the tar is as high as 11%, while the traditional internal heating type vertical furnace, the tar yield is only 4-6%. And the gas yield of the invention is also improved, the content of solid impurities in the gas is low, and the quality is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com