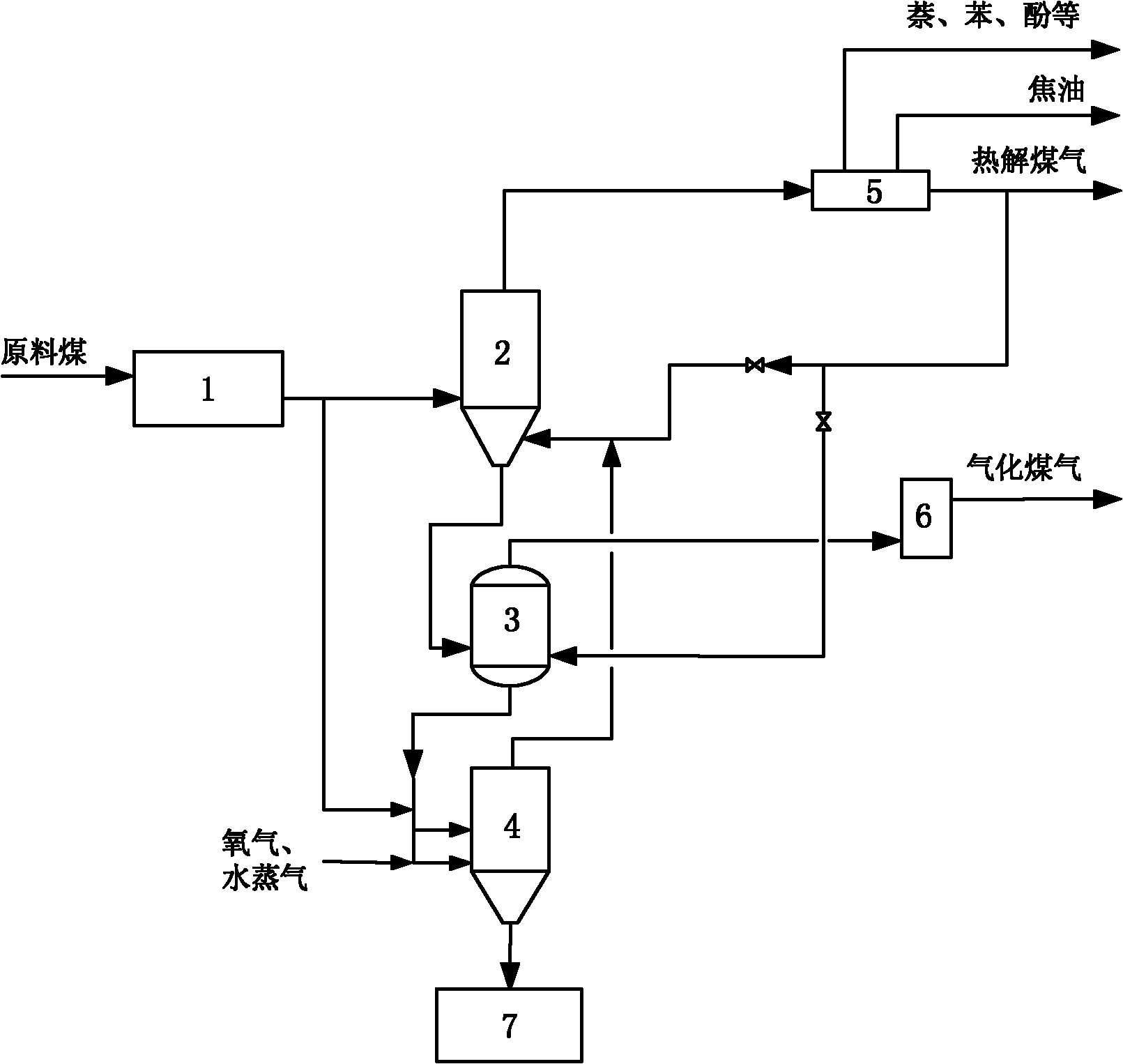

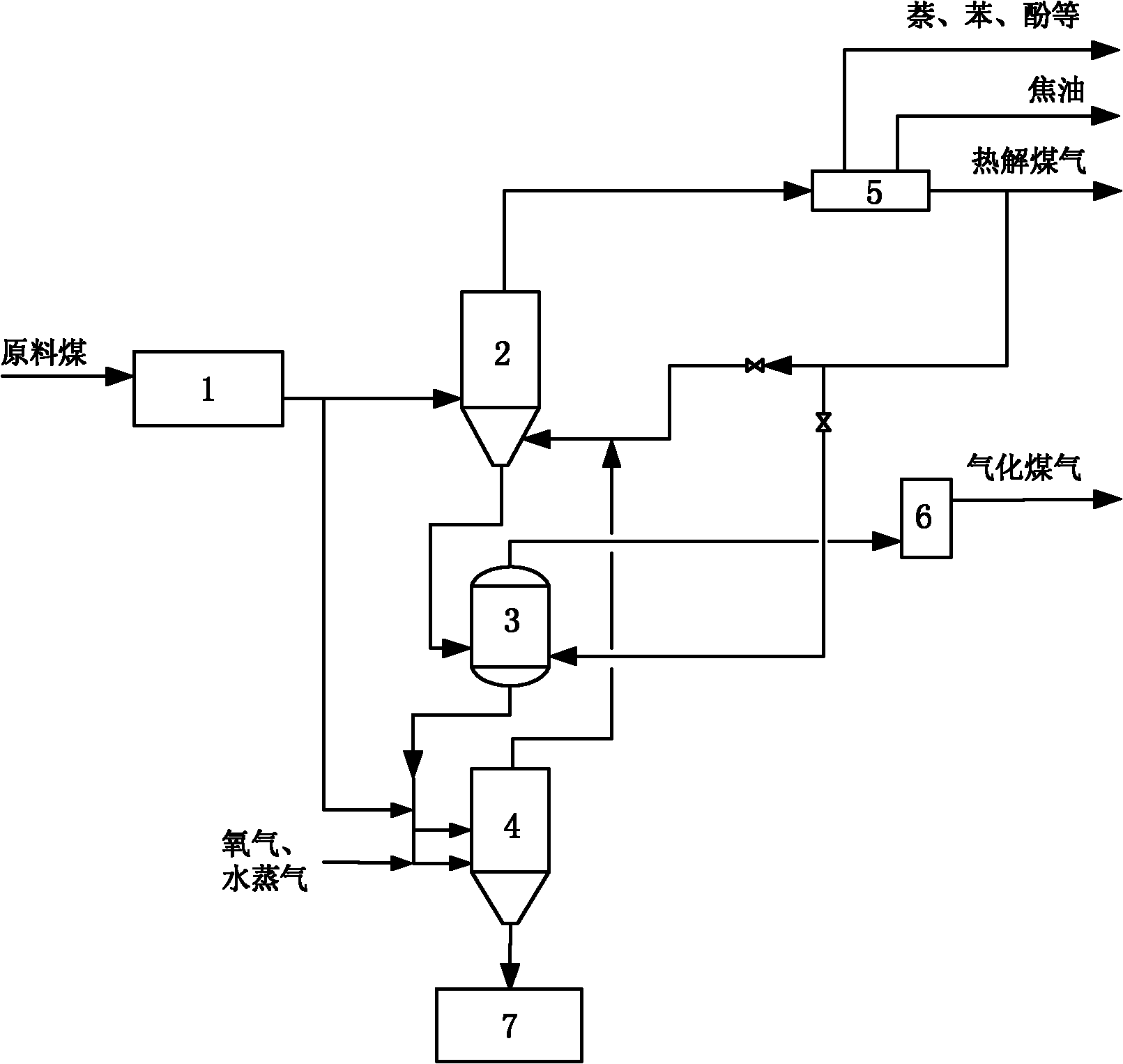

Method for coal hydrogenation pyrolysis and gasification coupling

A technology for coal hydrogenation and pyrolysis of coal gas, which is applied in gasification process, combustible gas purification, direct heating and dry distillation, etc., can solve the problems of low tar yield, inability to extract naphthalene coal chemical products, low utilization rate of total carbon of raw materials, etc. , to achieve the effect of improving tar yield and light component content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0025] Taking the production scale of coal processing capacity of 2t / h as an example, the industrial analysis before and after the upgrading of raw coal is shown in Table 1. After the raw coal with an average particle size of 0.6mm is dried and preheated in the coal drying preheating system (1), the preheating temperature is 270°C, and 60% of the raw coal first enters the coal hydro-pyrolysis furnace (2), and then Under the conditions of pressure 1.0MPa and temperature 600°C, hydropyrolysis is carried out, and the pyrolysis gas phase product enters the pyrolysis gas purification and separation system (5) for purification and separation, wherein the yield of pyrolysis gas is 19.68% (52% containing methane gas), tar The yield is 14.63%, and the yield of naphthalene, benzene, phenol, etc. is 4%. The solid product semi-coke all enters the coke hydrogenation gasification furnace (3), and is hydrogenated and gasified under the conditions of pressure 1.0 and temperature 327 ° C, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com