Dry distillation device for coal with wide particle size distribution and method

A dry distillation and wide-grain technology, which is applied in the field of coal chemical industry, can solve the problems of high resistance to pyrolysis gas escape, long residence time, and slow heat transfer rate, and achieve improved heat and mass transfer effects, reduced secondary reactions, and uniform heating Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

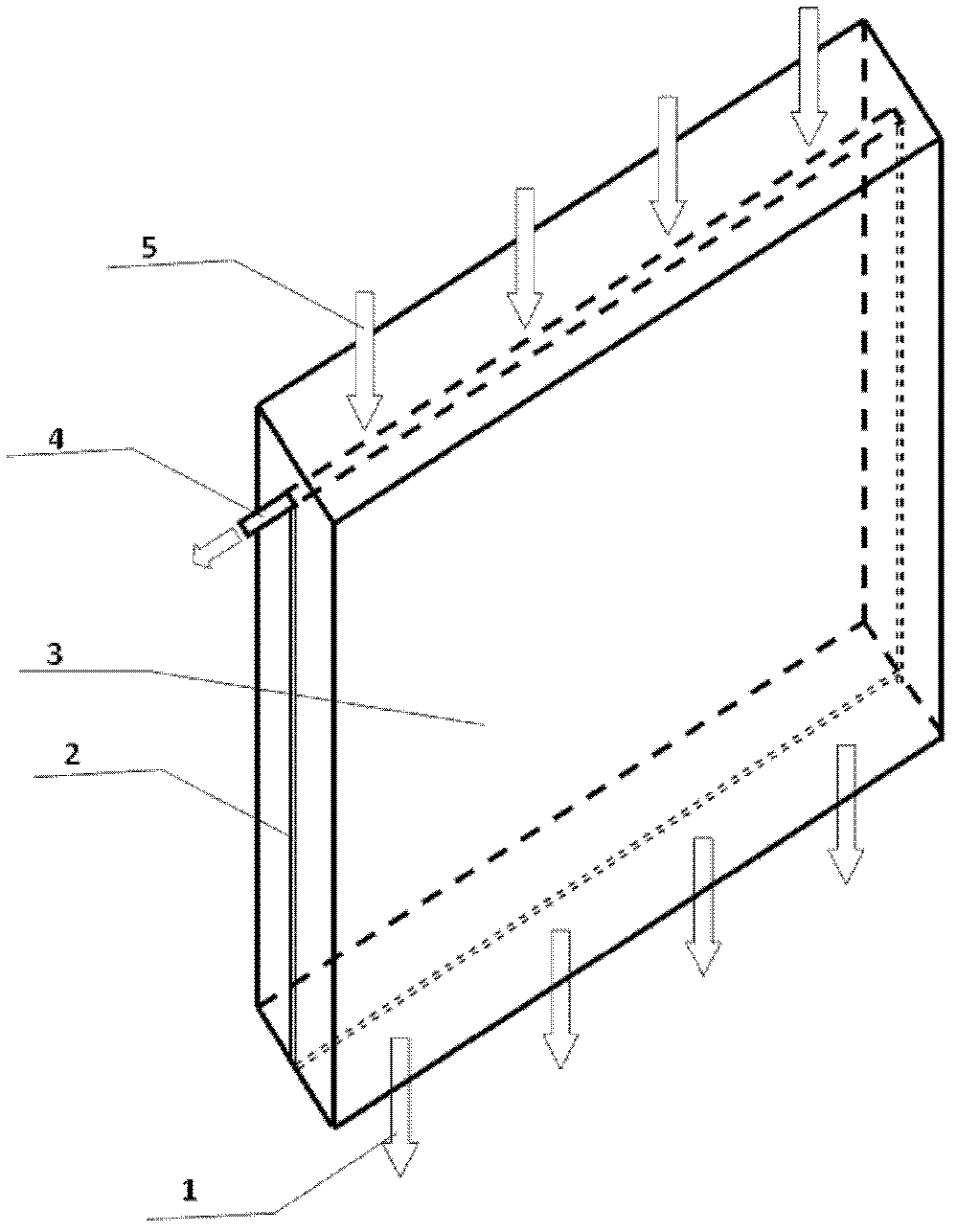

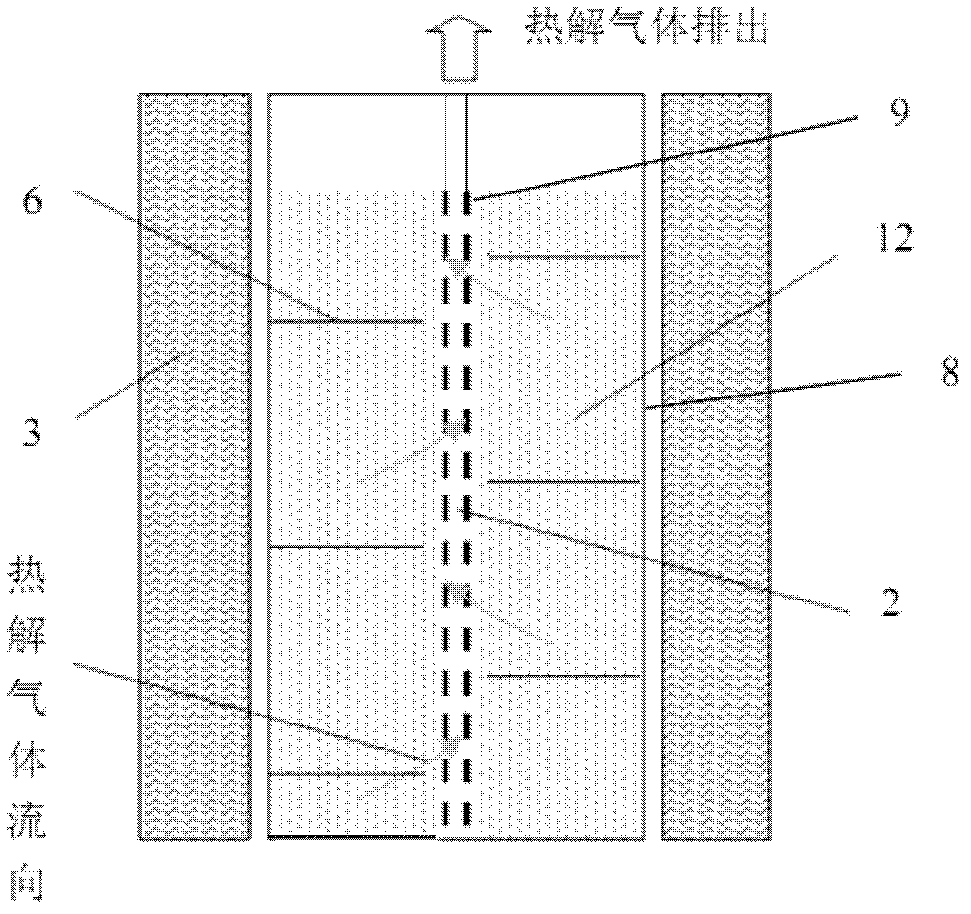

[0046] This embodiment is the pyrolysis of Fugu coal whose particle size is less than 5mm in fixed bed and indirect heating mode, such as figure 1 As shown, there is a pyrolysis gas channel 2 inside the carbonization device, including a coal filling port 5, a combustion heating chamber 3, a pyrolysis gas discharge pipe 4, and a semi-coke discharge port 1. The two walls of the pyrolysis gas channel 2 are connected with the combustion heating chamber 3 parallel. Gas combustion in the combustion chambers on both sides of the dry distillation device provides heat, which is transferred into the pyrolysis coal seam from the combustion heating chamber 3 . The raw coal is loaded into the carbonization device through the coal inlet 5, and the temperature is raised and pyrolysis reaction occurs. The pyrolysis gas phase products enter the pyrolysis gas channel 2 and are finally collected in the pyrolysis gas discharge pipe 4 to be drawn out. After reaching the predetermined reaction tem...

Embodiment 2

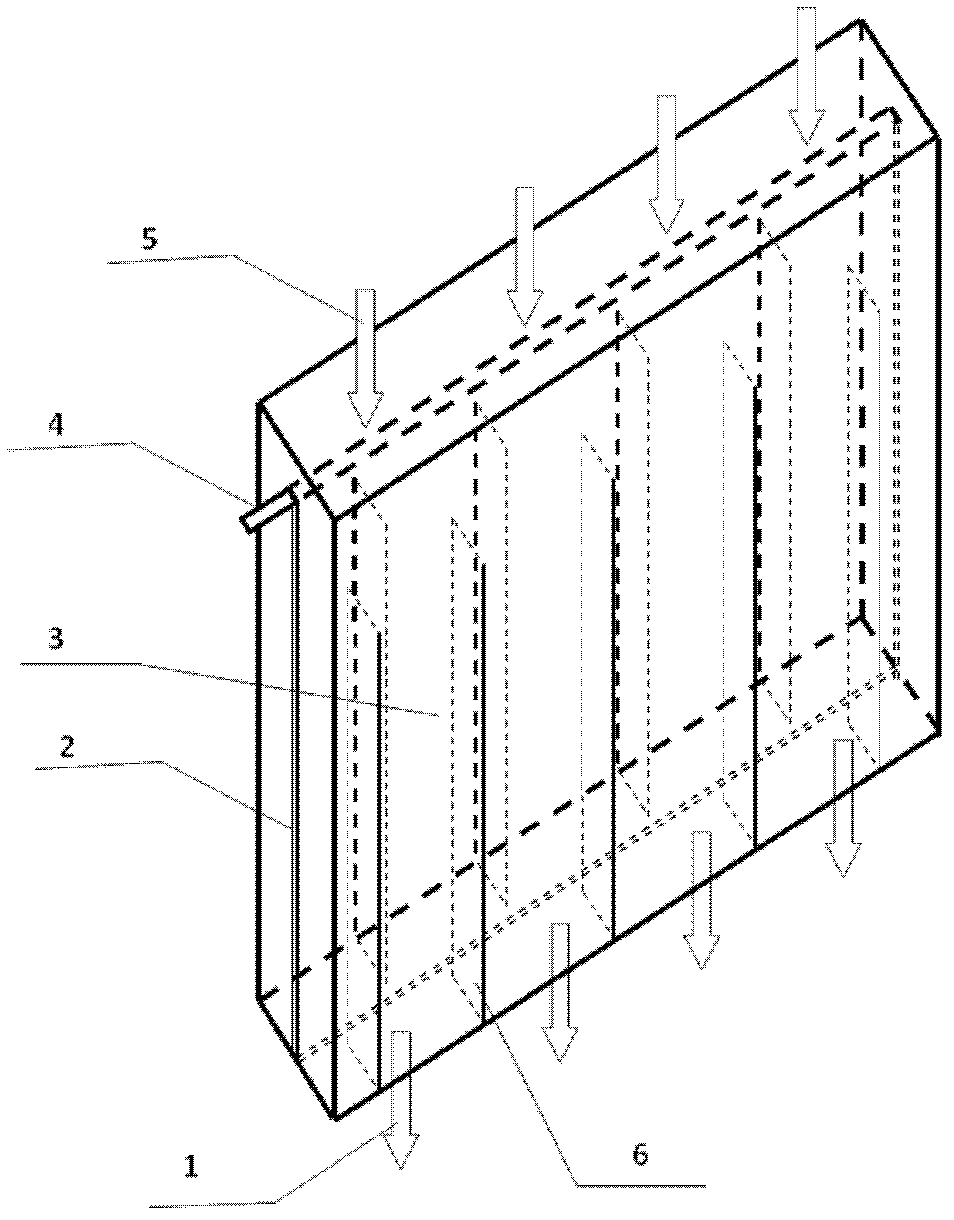

[0049] This embodiment is the pyrolysis of Fugu coal with a particle size of less than 5mm intensified by the plate internals of the fixed bed and indirect heating mode, such as figure 2 As shown, the carbonization device is equipped with a plate-type internal member 6 and a pyrolysis gas channel 2, including a coal inlet 5, a combustion heating chamber 3, a pyrolysis gas discharge pipe 4, and a semi-coke discharge port 1. The plate-type internal member 6 is vertical to the thermal The way of heating the walls and furnace bottom on both sides of the decomposition reactor is placed in the carbonization device, and the pyrolysis gas channel 2 is parallel to the combustion heating chamber 3 and is located between the plate-type inner members 6 at both ends. Gas combustion in the combustion chambers on both sides of the retort device provides heat, which is introduced into the pyrolysis coal seam by the combustion heating chamber 3 and the plate-type internal member 6 . The raw c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com