Method for increasing tar yield in hydropyrolysis of coal by using ferric ammonium salt

A technology of tar yield and iron ammonium salt, which is applied in the field of coal hydropyrolysis, can solve the problems of complex process, harsh reaction conditions, expensive catalyst and the like, and achieves the effect of simple and easy process and improved tar yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

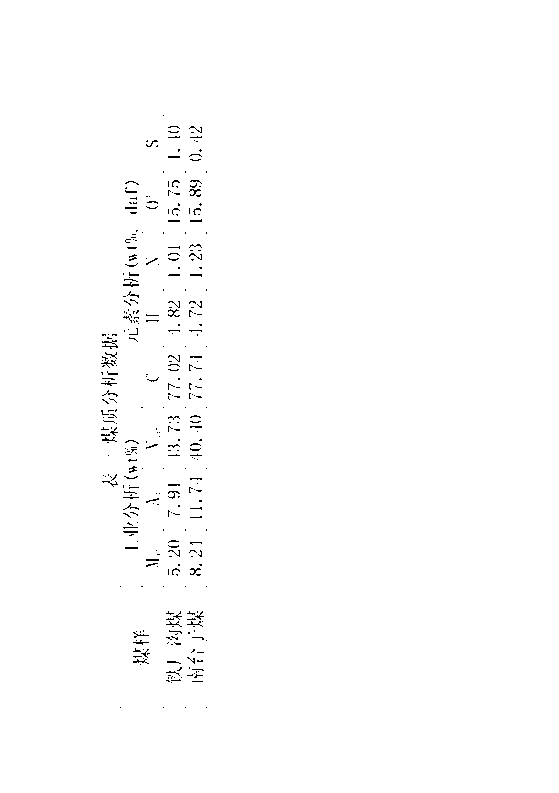

Image

Examples

Embodiment 1

[0025] Embodiment 1, this iron ammonium salt improves the method for tar yield in coal hydropyrolysis, carries out according to the following steps:

[0026] The first step is to add catalyst by impregnation method:

[0027] (1) Tiechanggou coal, iron ammonium salt (calculated as iron) and distilled water are mixed uniformly in a mass ratio of 100:1:150 to 100:7:300, and the temperature is kept at a constant temperature of 30°C to 80°C. From 8h to 16h, mechanical stirring was added at the same time at a constant temperature, and the stirring rate was 100 r / min to 300 r / min; 4 ) 2 Fe(SO 4 ) 2 ·6H 2 O;

[0028] (2) Vacuum drying is carried out after immersion, and coal samples are obtained after vacuum drying. The temperature of vacuum drying is 60℃ to 120℃, the vacuum degree is 0.02MPa to 0.08MPa, and the drying time is 12h to 36h;

[0029] (3) Transfer the coal sample obtained after drying to a desiccator for storage;

[0030] The second step, coal hydropyrolysis reacti...

Embodiment 2

[0035] Embodiment 2, the difference with embodiment 1 is that the iron ammonium salt catalyst adopts NH 4 Fe(SO 4 ) 2 ·12H 2O, the resulting tar yields ranged from 14.8 wt % daf to 17.4 wt % daf, with an average of 16.2 wt % daf.

Embodiment 3

[0036] Example 3 is different from Example 1 in that Nantaizi coal is used as the coal, and the obtained tar yield is 15.6 wt% daf to 21.2 wt% daf, and the average tar yield is 18.2 wt% daf.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com