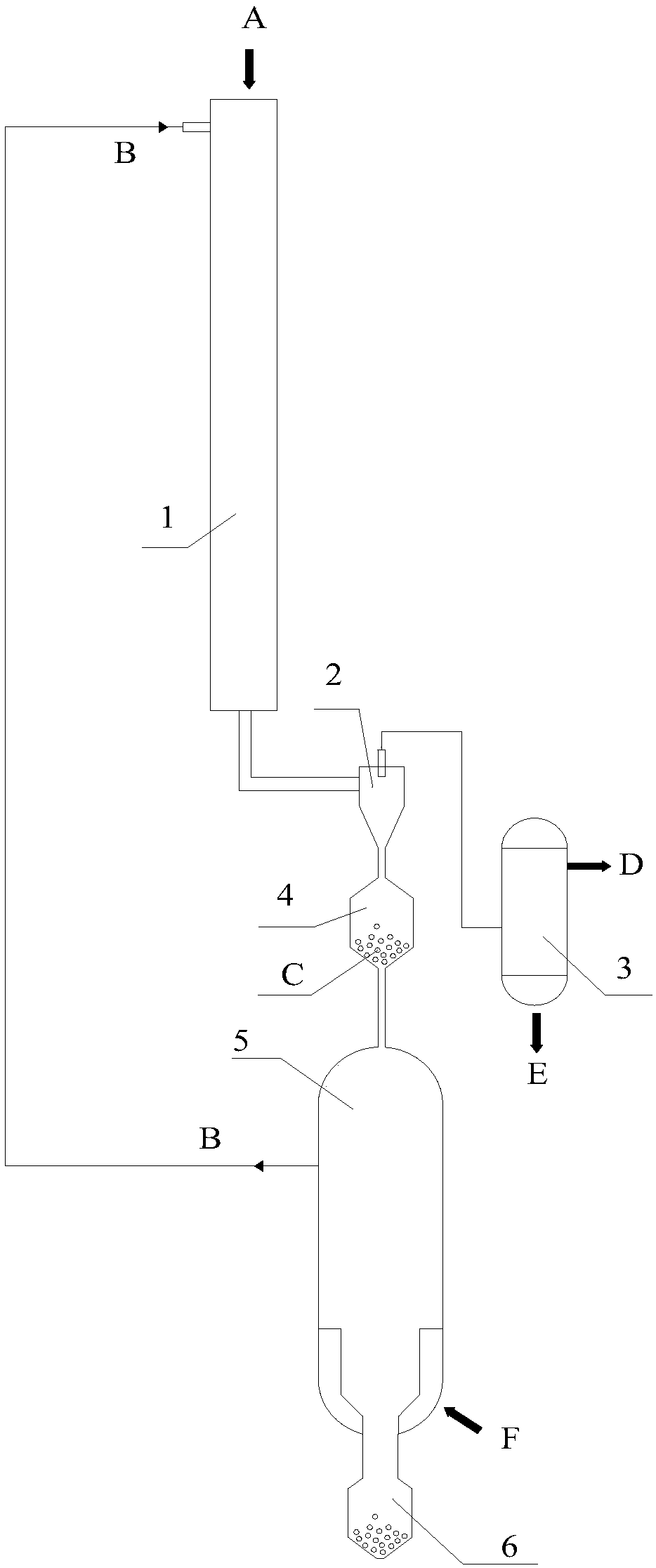

Downer-fixed bed pyrolysis-gasification integrated method and device

A fixed-bed gasifier and fixed-bed technology, which are applied in fixed-bed gasification, gasification process, manufacture of combustible gas, etc., can solve the problem of difficulty in utilizing tar yield of low-rank coal, and achieve good application prospects and energy utilization. High efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

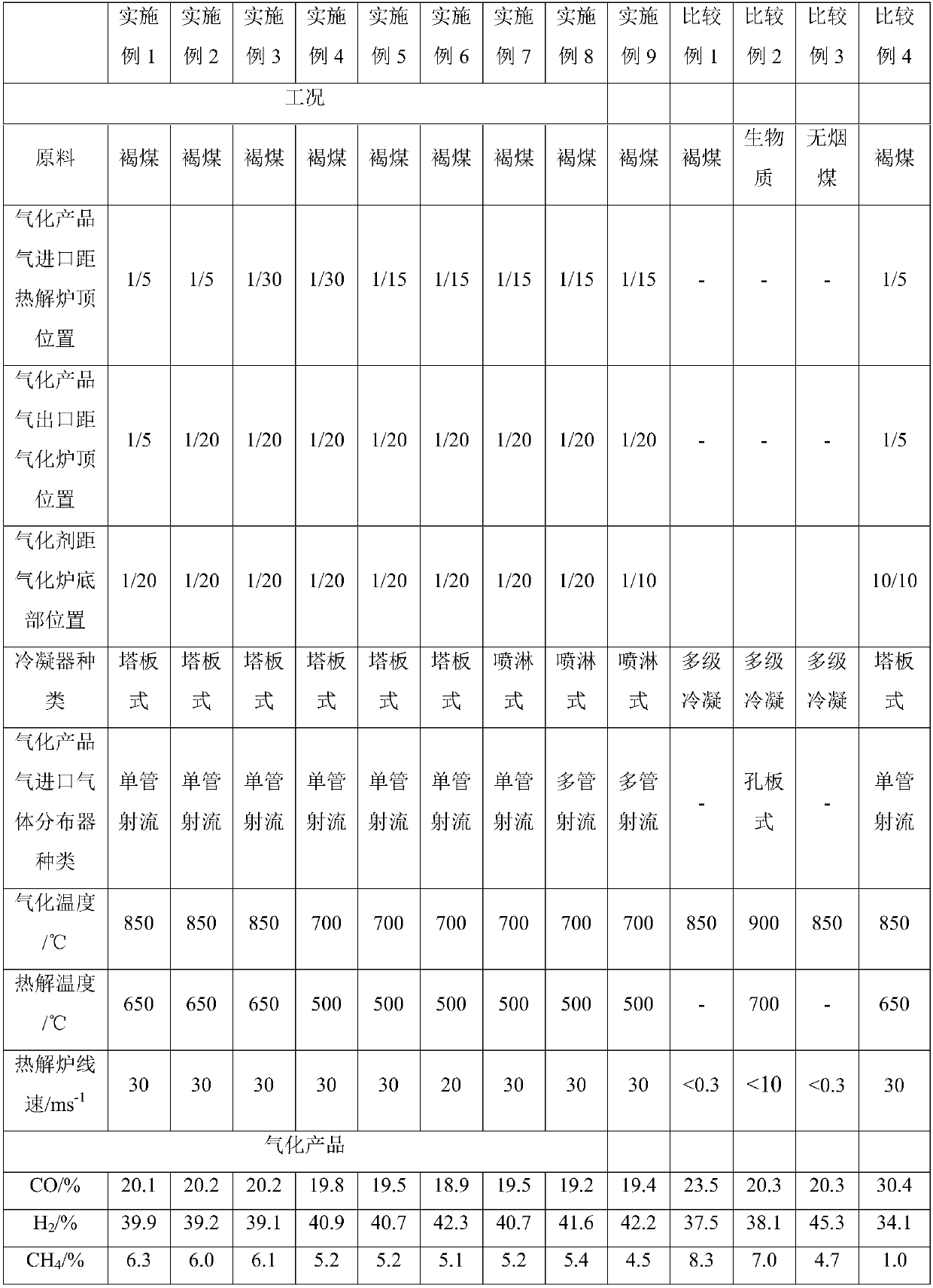

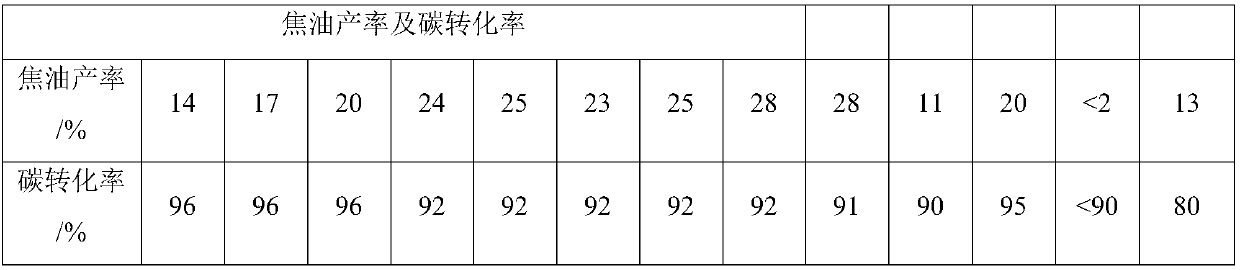

Embodiment 1

[0030]The lignite with a particle size of 2 , CO and CH 4 The contents are respectively 39.9%, 20.1%, and 6.3%, and the results are shown in Table 1.

Embodiment 2

[0032] The lignite with a particle size of 2 , CO and CH 4 The contents are respectively 39.2%, 20.2%, and 6.0%, and the results are shown in Table 1.

Embodiment 3

[0034] The lignite with a particle size of 2 , CO and CH 4 The contents are respectively 39.1%, 19.9%, and 6.1%, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com