Novel external heating type lignite pyrolysis quality increasing system and process

A pyrolysis upgrading and external heating technology, applied in the field of new external heating lignite pyrolysis upgrading system, can solve the problems of reduced desulfurization and denitrification load, hindering process development, low utilization value of solid products, etc. material ratio, reducing energy consumption, and the effect of large heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

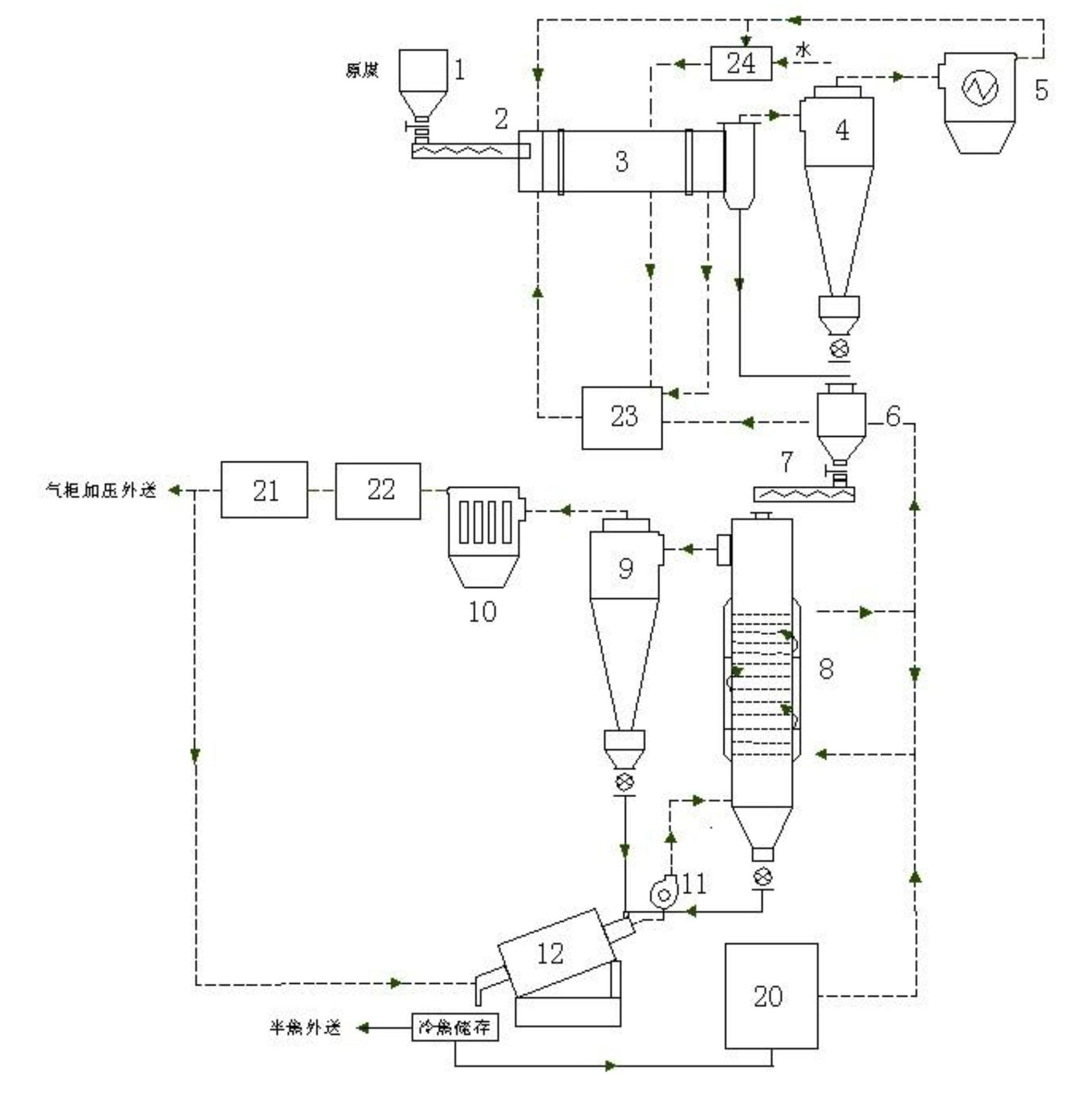

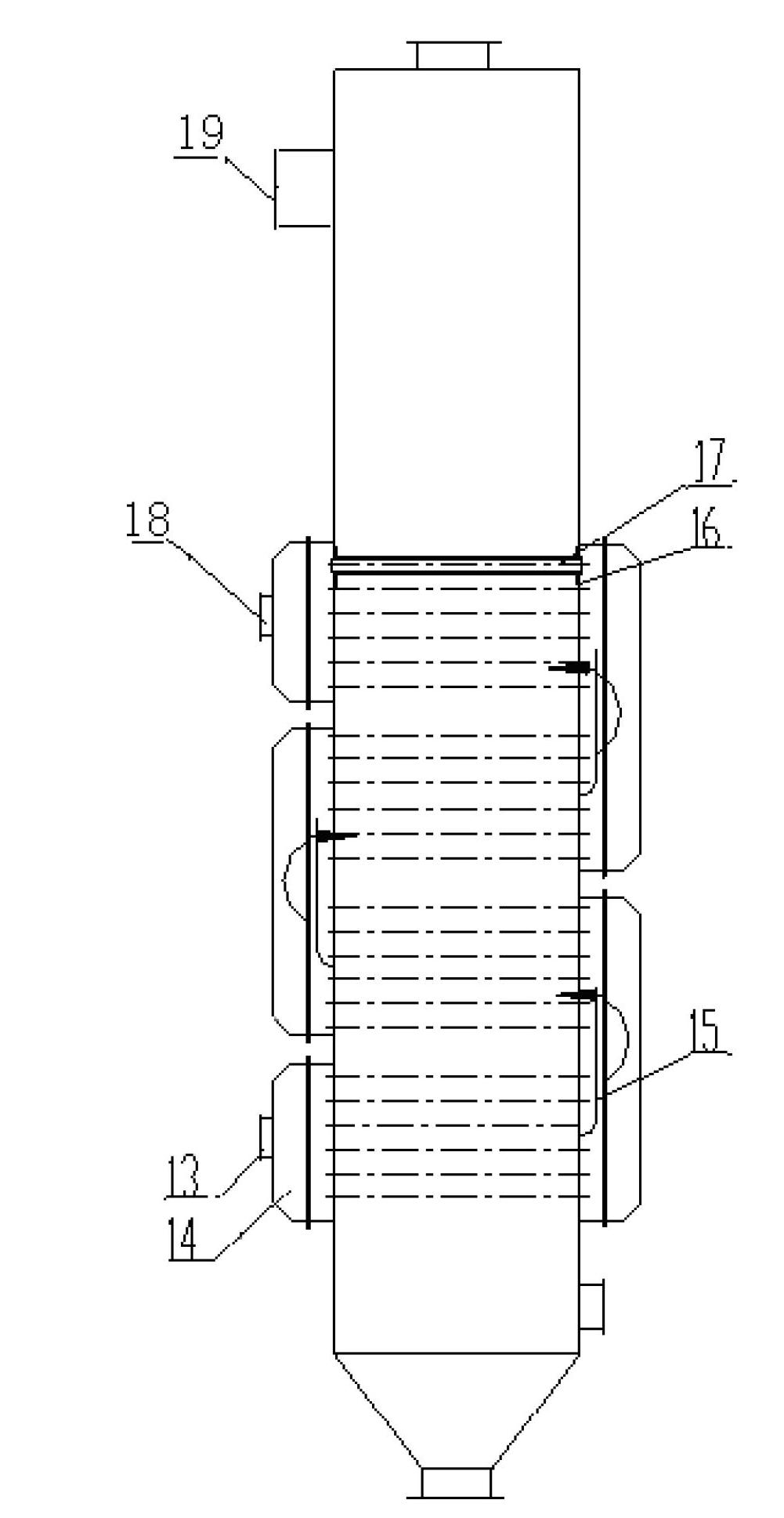

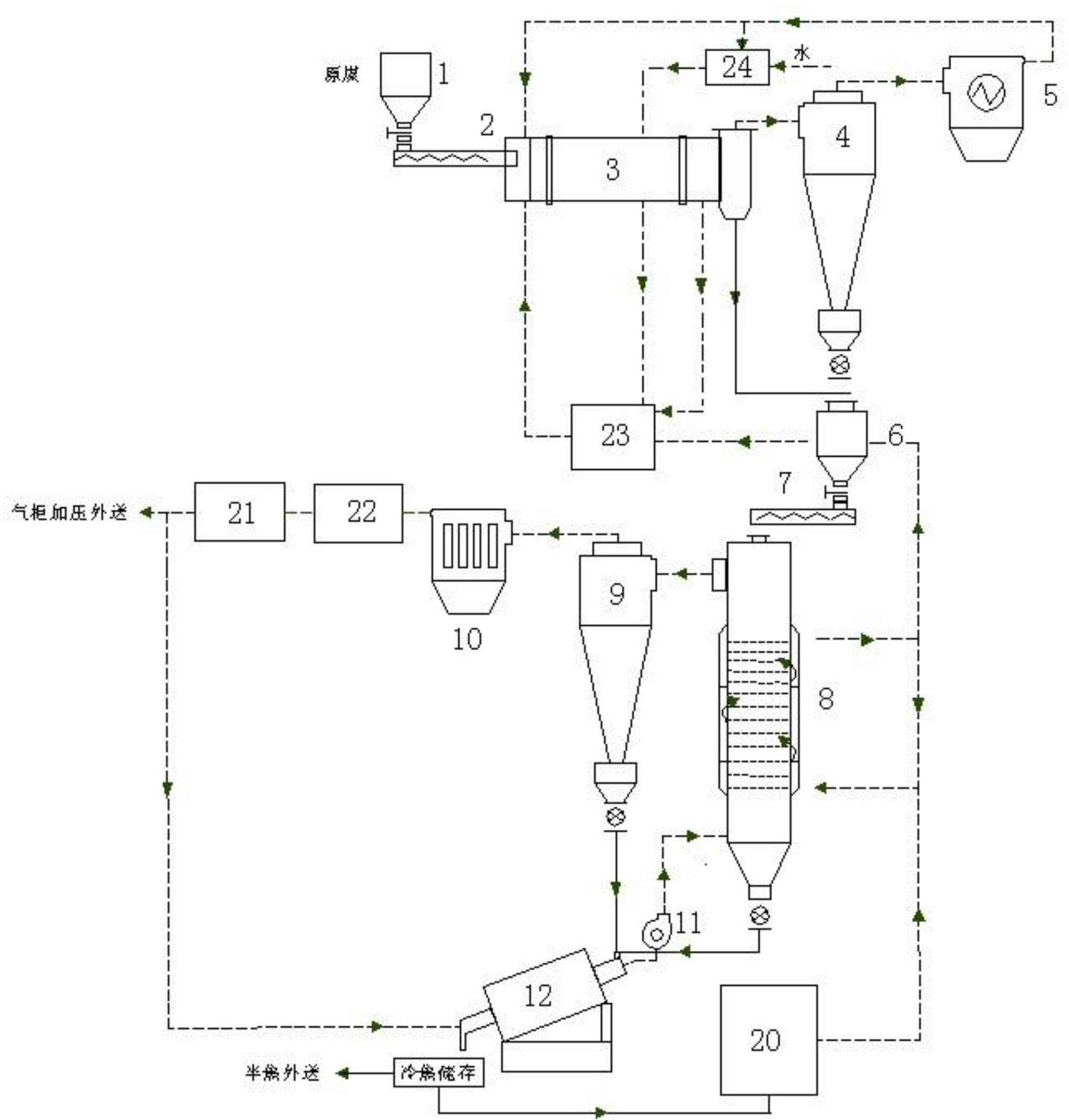

[0044] figure 1 Among them, a new type of external heating lignite pyrolysis upgrading system, the inner heating fluidized bed pyrolysis furnace 8 feed port is connected with the ring tube split type superheated steam rotary dryer 3 discharge port; the inner heating fluidized bed pyrolysis The discharge port of the furnace 8 is connected to the feed port of the semi-coke cooling chamber 12, and the discharge port of the semi-coke cooling chamber 12 is connected to the burner 20 and the finished product area respectively;

[0045] The tail gas outlet of internal heating fluidized bed pyrolysis furnace 8 is connected with the second dedusting device, tar collection 21, and desulfurization device 22. The pressurized fan 11 is connected with the internal heating fluidized bed pyrolysis furnace 8;

[0046] The flue gas outlet of the internal heating fluidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com