Coal solid heat carrier pyrolysis method and system for guide type stripping reinforced oil gas accelerated introduction

A solid heat carrier, guided technology, applied in the field of coal chemical industry, can solve the problems of reduced coal pyrolysis tar yield, intensified secondary cracking reaction, and increased oil and vapor export resistance, so as to improve yield and overcome easy damage. , the effect of improving the yield of coal pyrolysis tar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Using the above-mentioned system to implement the coal solid heat carrier pyrolysis method of guided gas stripping and accelerated export of oil and gas, the percentages involved in the following examples are all mass percentages (%). The properties of the powdered coal used in the experiment are shown in Table 1.

[0040] Table 1 Properties of powdery coal (air dry basis)

[0041]

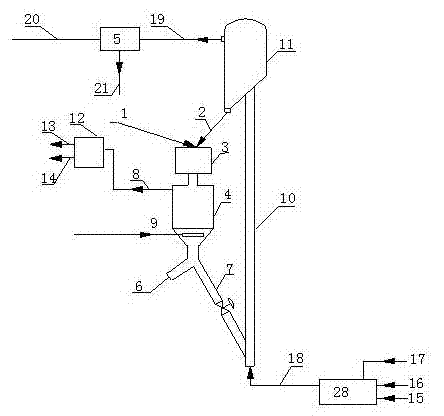

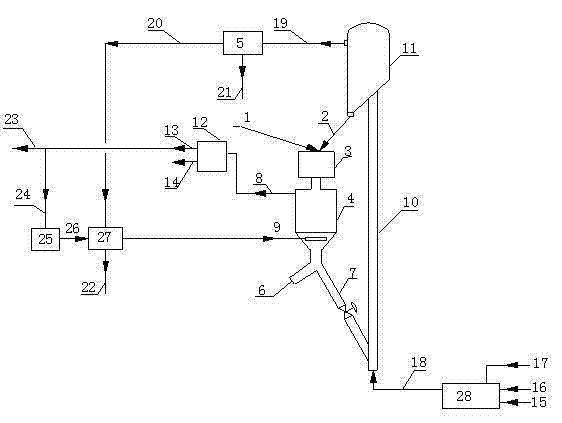

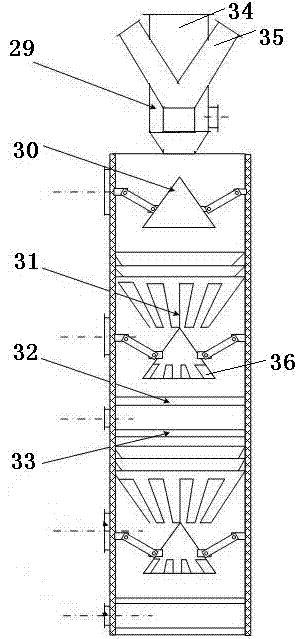

[0042] The raw material used in this embodiment is bituminous coal 1. The coal solid heat carrier pyrolysis method using guided gas stripping to strengthen the accelerated export of oil and steam is 0.24 tons / day pyrolysis test device. The specific operation process is shown in the appendix figure 2 ; The dried powdery bituminous coal 1 and heat carrier 2 are imported into the mixer 3 at a mixing ratio of 1:2.5, and the powdery bituminous coal 1 and the heat carrier 2 are mixed into a uniform powder in the mixer 3, and the powder It enters the moving bed reactor 4 from the bottom of t...

Embodiment 2

[0048] In this example, the raw material is lignite 2, and a 0.24 ton / day pyrolysis test device is used for coal solid heat carrier pyrolysis method using guided gas stripping to strengthen the accelerated export of oil and vapor. The specific operation process is shown in the appendix figure 2 . The dried powdery lignite 1 and the heat carrier 2 are introduced into the mixer 3 at a mixing ratio of 1:4, and the powdery lignite 1 and the heat carrier 2 are evenly mixed into a uniform powder in the mixer 3, and the powder It enters the moving bed reactor 4 from the bottom of the mixer, and a pyrolysis reaction occurs in the moving bed reactor. The pyrolysis reaction temperature is 550° C., and the residence time is 20 minutes. To generate pyrolysis gas 8 and semi-coke, a stripping gas inlet pipe is provided at the lower part of the reaction section of the moving bed reactor, from which the stripping gas 9 enters the moving bed reactor and is evenly distributed in the material l...

Embodiment 3~7

[0054] The specific raw materials used are lignite 1,2 and bituminous coal 1,2. The coal solid heat carrier pyrolysis method 0.24 tons / day pyrolysis test device using the guided gas stripping enhanced oil vapor accelerated export method, the operating process is the same as the above-mentioned embodiment 2, and the specific process parameters and product yield are shown in Table 4.

[0055] Table 4 Process parameters and product yield

[0056]

[0057] Note: 1 Coal-to-coke ratio refers to the mass ratio of the amount of hot semi-coke to the dried coal sample;

[0058] 2 The increase percentage of tar yield refers to the comparison with the non-gas stripped gas under the same production conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com