High-temperature-resistant and corrosion-resistant nano self-cleaning coating and preparation method and application thereof

A high-temperature-resistant and corrosion-resistant technology, applied in corrosion-resistant nano-self-cleaning coatings and high-temperature-resistant fields, can solve problems such as easy blockage, poor heat transfer effect, easy cracking and coking of the coke oven riser heat exchanger, and achieve excellent firmness , Improve production capacity, good heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

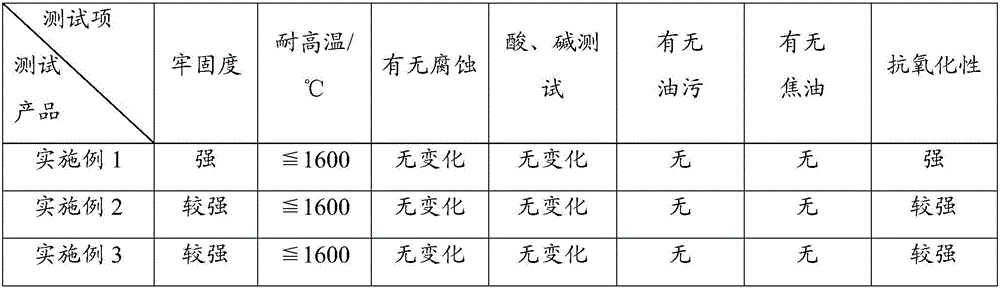

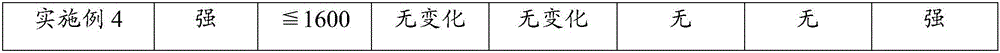

Examples

Embodiment 1

[0018] Embodiment 1: get nano-silica 7kg, nano-zirconia 4kg, nano-scale ceramic powder 8kg, nano-titanium dioxide 6kg, nano-silicon nitride 2kg, nano-iron oxide 2kg, nano-magnesia 2kg, triphenyl phosphate 4kg, no 8kg of water ethanol, 2kg of aminosilane, and 50kg of water; wherein, the particle size of the nanoscale ceramic powder is 4nm.

[0019] Prepare high-temperature-resistant, corrosion-resistant nano self-cleaning coatings according to the following steps:

[0020] S01, 7kg nano-silica, 4kg nano-zirconia, 8kg nano-scale ceramic powder, 6kg nano-titanium dioxide, 2kg nano-silicon nitride, 2kg nano-iron oxide, 2kg nano-magnesia, 8kg absolute ethanol are added to 50kg water, While stirring at a stirring speed of 60r / min, use microwave heating to 55°C, keep stirring for 2-3 hours to obtain product A;

[0021] S02. Slowly add 4 kg of triphenyl phosphate to product A, heat to 75° C. with microwave while stirring at a stirring speed of 40 r / min, keep stirring for 2-3 hours to...

Embodiment 2

[0023] Embodiment 2: Get nano-silica 5kg, nano-zirconia 3kg, nano-scale ceramic powder 6kg, nano-titanium dioxide 5kg, nano-silicon nitride 1kg, nano-iron oxide 1kg, nano-magnesia 1kg, triphenyl phosphate 3kg, no 6kg of water ethanol, 1kg of aminosilane, and 30kg of water; wherein, the particle size of the nanoscale ceramic powder is 3nm.

[0024] Prepare high-temperature-resistant, corrosion-resistant nano self-cleaning coatings according to the following steps:

[0025] S01, 5kg nano-silica, 3kg nano-zirconia, 6kg nano-scale ceramic powder, 5kg nano-titanium dioxide, 1kg nano-silicon nitride, 1kg nano-iron oxide, 1kg nano-magnesia, 6kg absolute ethanol are added to 30kg water, Heat at 55°C in a water bath while stirring at a stirring speed of 60r / min, keep stirring for 2-3 hours to obtain product A;

[0026] S02. Slowly add 3 kg of triphenyl phosphate to product A, heat to 75° C. in a water bath while stirring at a stirring speed of 40 r / min, keep stirring for 2-3 hours to ...

Embodiment 3

[0028] Embodiment 3: Get nano-silica 8kg, nano-zirconia 5kg, nano-scale ceramic powder 10kg, nano-titanium dioxide 7kg, nano-silicon nitride 3kg, nano-iron oxide 3kg, nano-magnesia 3kg, triphenyl phosphate 5kg, no 10kg of water ethanol, 3kg of aminosilane, and 70kg of water; wherein, the particle size of the nanoscale ceramic powder is 5nm.

[0029] Prepare high-temperature-resistant, corrosion-resistant nano self-cleaning coatings according to the following steps:

[0030] S01, 8kg nano-silica, 5kg nano-zirconia, 10kg nano-scale ceramic powder, 7kg nano-titanium dioxide, 3kg nano-silicon nitride, 3kg nano-iron oxide, 3kg nano-magnesia, 10kg absolute ethanol are added to 70kg water, While stirring at a stirring speed of 60r / min, use electric heating to heat to 55°C, keep stirring for 2-3 hours under continuous stirring, and obtain product A;

[0031] S02. Slowly add 5 kg of triphenyl phosphate to product A, heat to 75° C. with electric heating while stirring at a stirring spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com