Method and device for recovering waste heat of coke oven crude gas

A technology for coke oven gas and waste gas, which is applied in the application field of industrial waste heat recovery and can solve the problems of recovering waste heat of coke oven waste gas and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

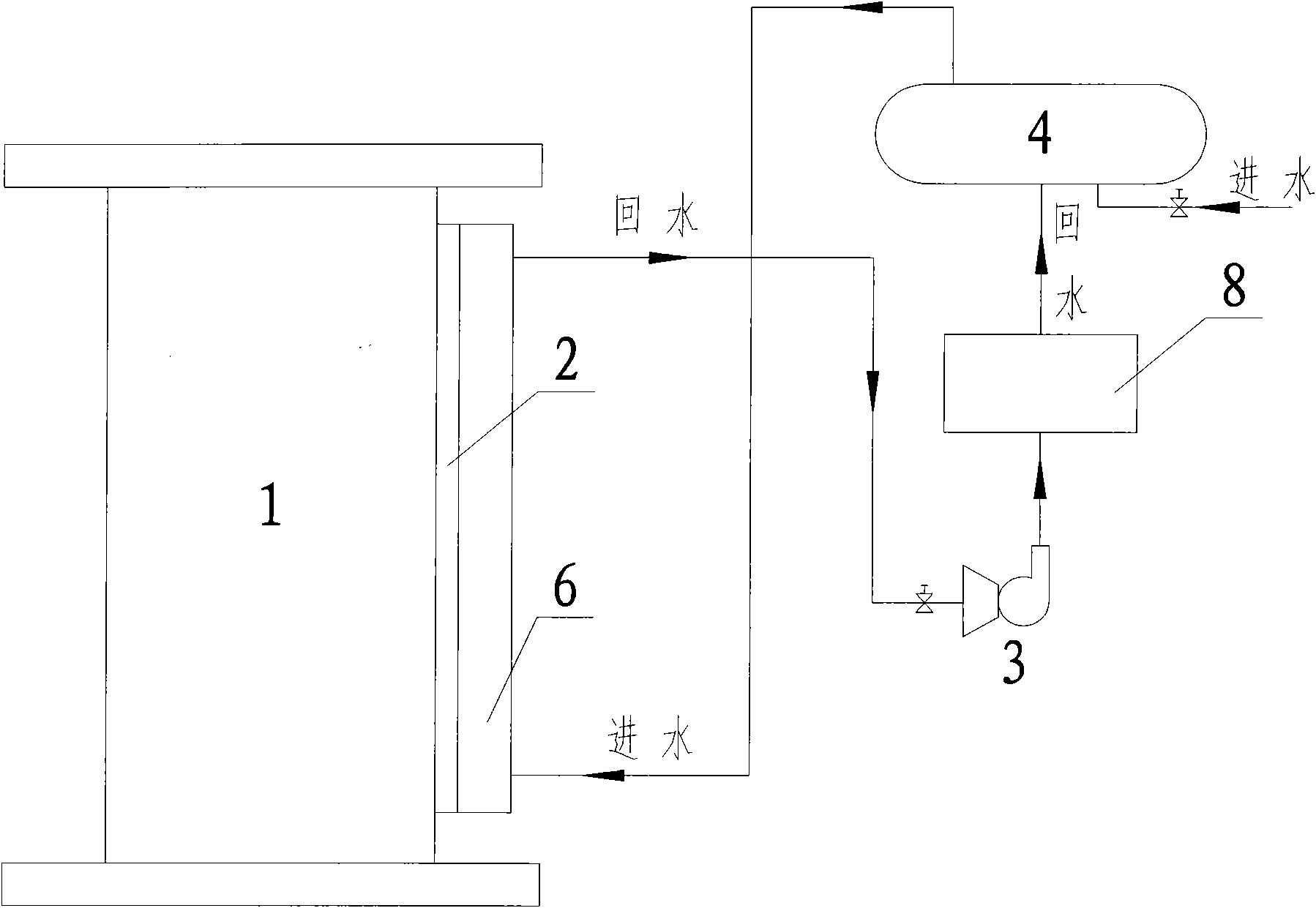

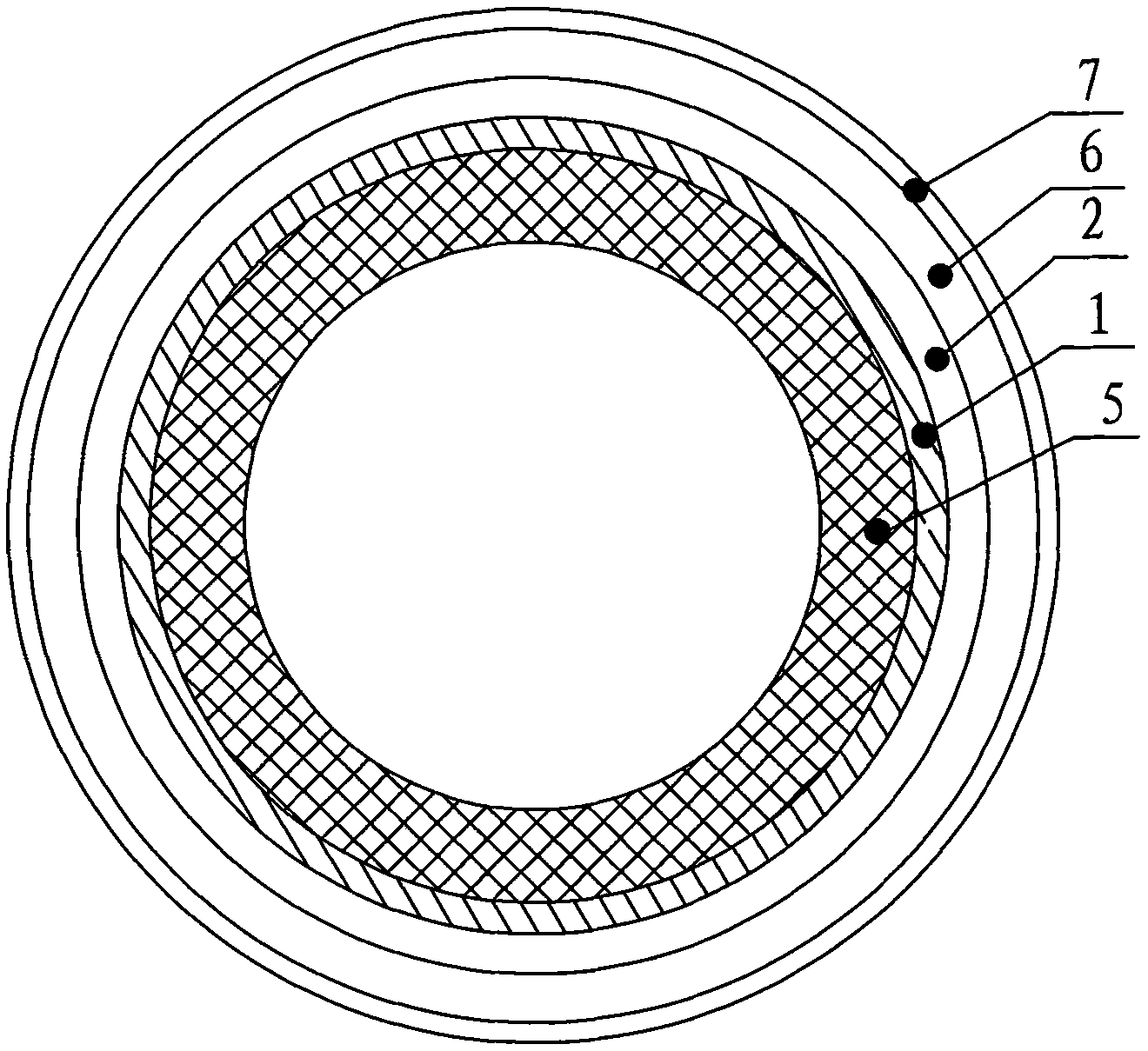

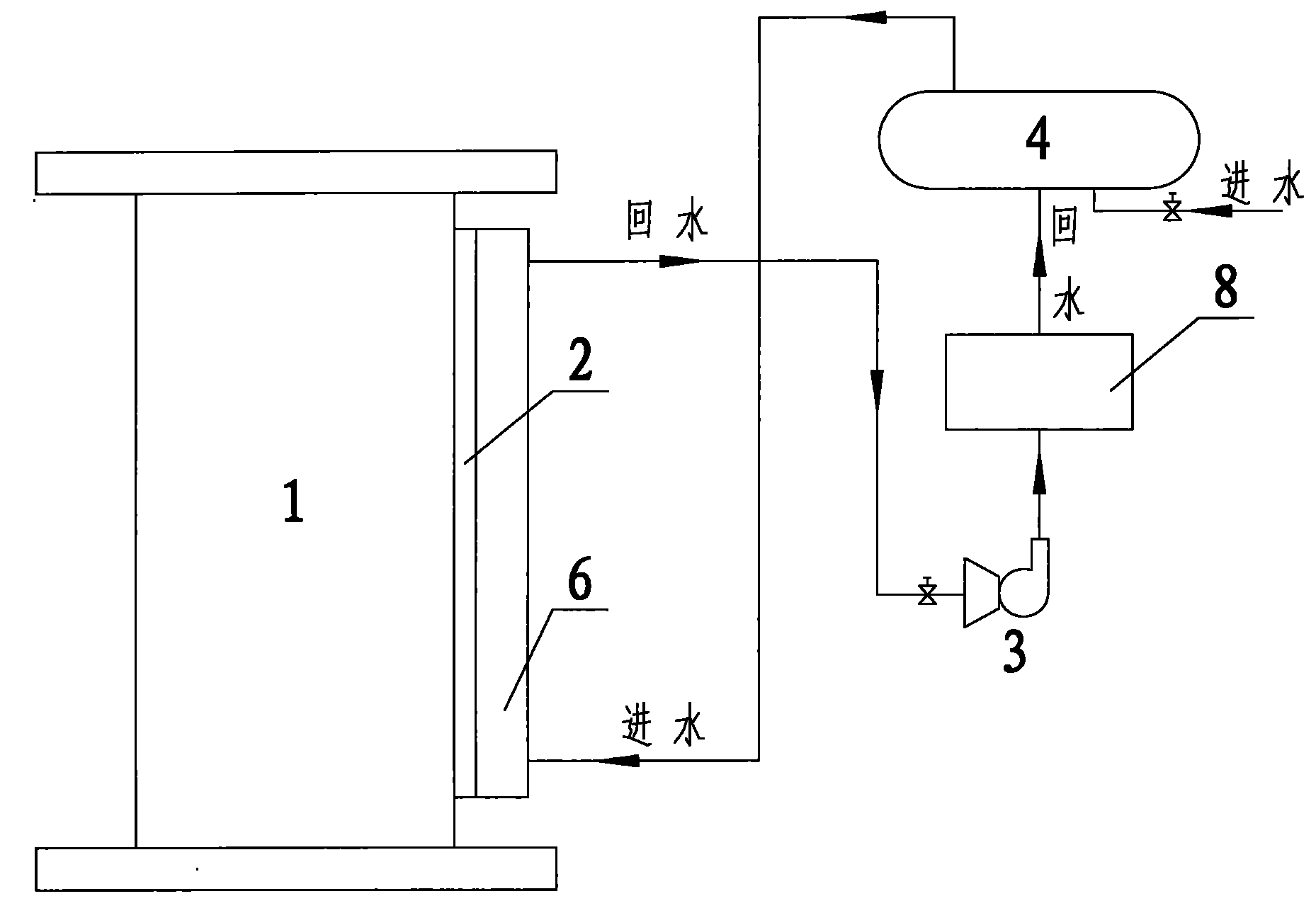

[0016] See figure 1 , a method for recovering the waste heat of coke oven raw gas, the method is to transform the coke oven riser 1, install a semiconductor thermoelectric power generation module 2 on the outer wall of the riser 1, and recover the waste heat of coke oven waste gas to generate electricity.

[0017] Improve the refractory bricks of the riser, use silicon carbide refractory lining bricks to replace the original refractory lining bricks, install the semiconductor thermoelectric power generation module 2 on the outer wall of the riser 1, and use the raw coke oven gas in the riser 1 as the heat of the semiconductor thermoelectric power generation source, to realize waste heat recovery of coke oven raw gas in the rising pipe. Since the thermal conductivity of silicon carbide refractory lining bricks is higher than that of refractory lining bricks, the heat of coke oven raw gas can be quickly transferred to the wall of riser 1, so riser 1 becomes the heat collector of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com