Method and device for co-production of synthetic ammonia and LNC (liquefied natural gas) by coke gas

A technology for synthesizing ammonia and coke oven gas, which is applied in the field of coal chemical industry, can solve the problems of low investment cost, short process flow, and low utilization rate of raw material gas, and achieve the effect of high utilization rate and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

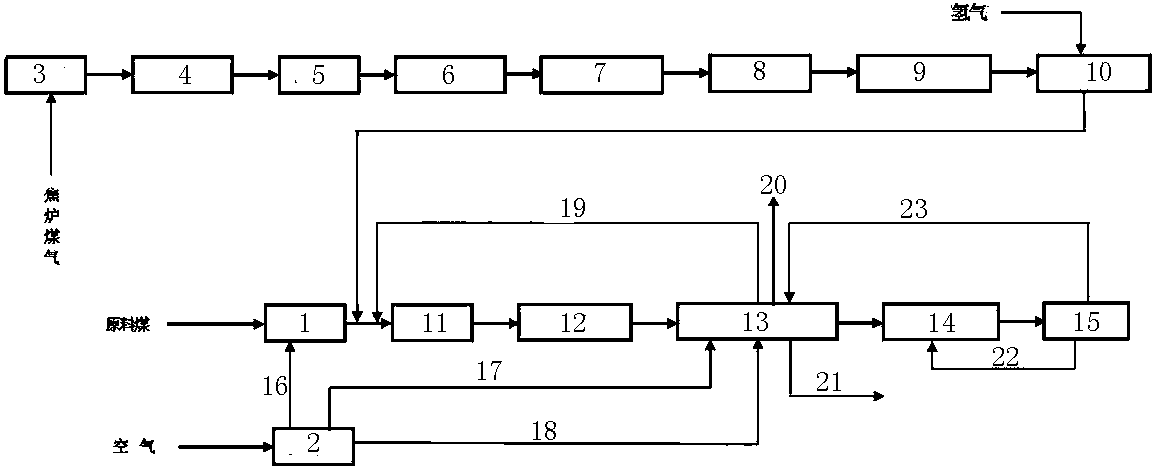

[0018] In order to enable those skilled in the art to better understand the present invention, the present invention will be further clearly and completely described below in conjunction with the accompanying drawings.

[0019] A coke oven gas production method for synthesizing ammonia and co-producing LNG provided by the present invention is to mix the semi-water gas and the purified coke oven gas into the conversion unit, and then enter the low-temperature methanol washing unit for purification treatment, and the purified gas after purification treatment enters the In the two-in-one cold box composed of liquid nitrogen washing device and cryogenic device, the purified gas is further purified in the two-in-one cold box, and finally configured into H 2 / N 3 =3:1 pure synthesis gas, the pure synthesis gas enters the synthetic ammonia unit to produce synthetic ammonia, and the purge gas produced by the synthetic ammonia unit returns to the two-in-one cold box device to produce L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com