Method for raising temperature in coke dry quenching furnace

A technology of CDQ and heating speed, applied in coke oven, coke cooling, petroleum industry, etc., can solve the problems of high labor intensity, inability to deal with it well, and small amount of refractory repair of CDQ system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

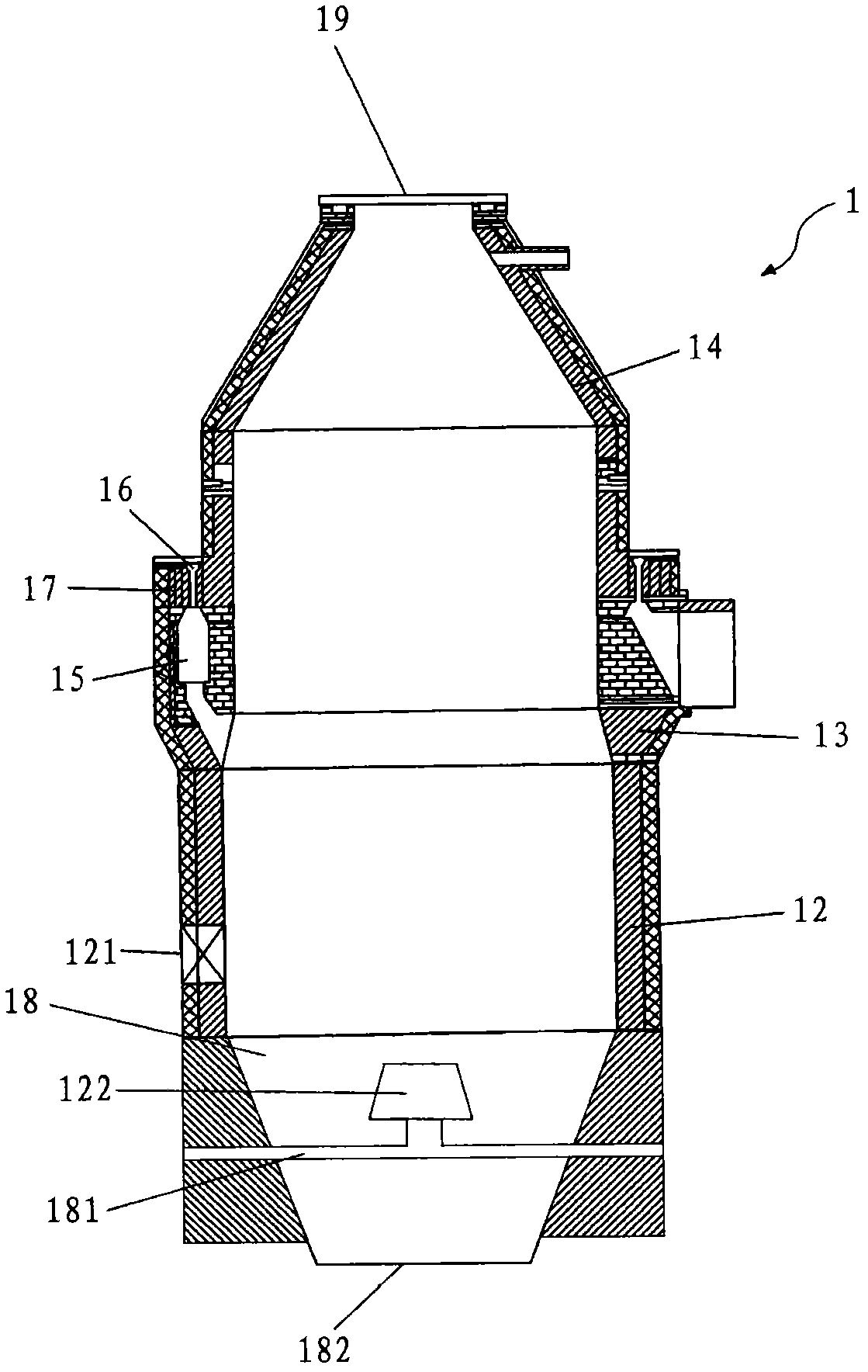

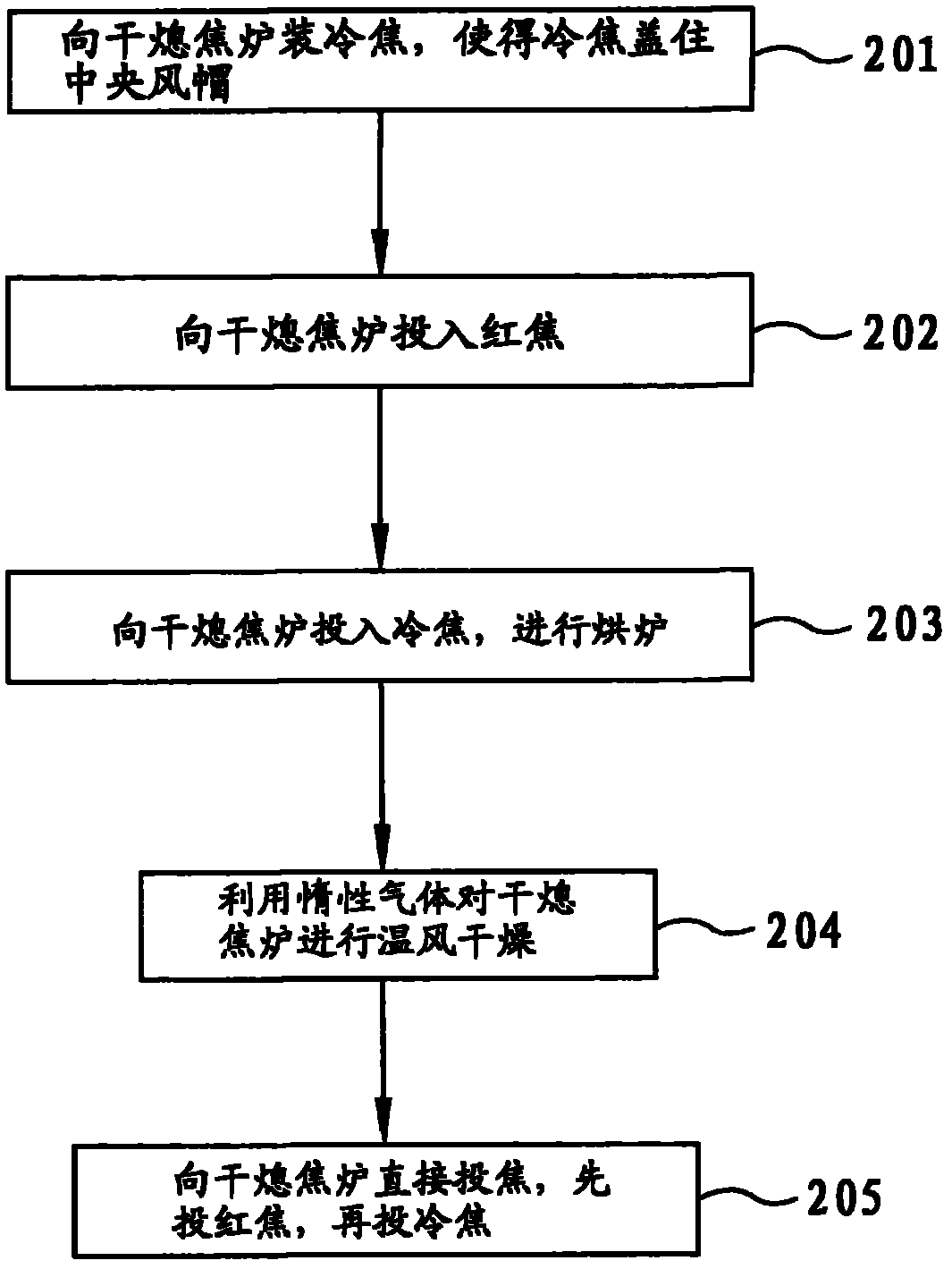

[0021] figure 1 is a schematic diagram of a CDQ oven of a CDQ system according to an embodiment of the present invention, figure 2 It is a schematic flow chart of the method for raising the temperature of red coke according to an embodiment of the present invention.

[0022] For the convenience of description, in this embodiment, the dry quenching coke oven 1 is formed as figure 1 The cylindrical shaft kiln structure is shown, but the shape of the CDQ oven 1 is not limited thereto, and the CDQ oven 1 can be formed into other suitable structures, for example, a polygonal structure.

[0023] Such as figure 1 As shown, the CDQ coke oven 1 includes an outer ring masonry 12 , a corbel 13 and an inner ring masonry 14 .

[0024] Wherein, the outer ring masonry 12 is located at the lower part of the dry quenching coke oven 1, and the outer ring masonry 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com