Method for replacing safety valve of boiler drum of coke drying quenching boiler

A CDQ coke oven and coke CDQ technology, applied in the field of coking, to achieve the effect of reducing accident handling time and production loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment the embodiment of the present invention is further described:

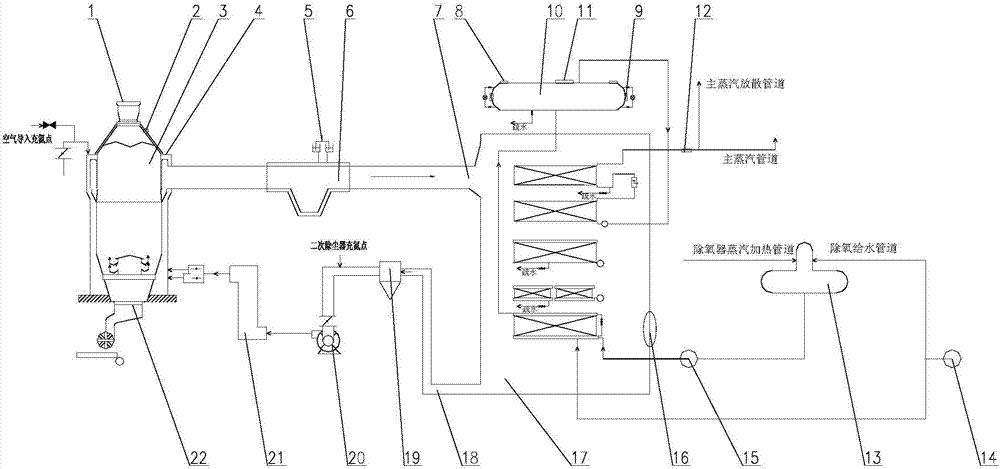

[0022] Such as figure 1 As shown, the coke CDQ-boiler system is composed of a coke CDQ oven 3, a boiler 17, a gas pipeline for connecting the two, and a water pipeline of the boiler 17. The high-temperature flue gas generated by the CDQ oven 3 enters the boiler 17 for heat exchange after being dedusted once, and the flue gas after heat exchange by the boiler 17 is subjected to secondary dedusting, then added nitrogen to cool down, and returns to the CDQ oven 3 as the bottom of the furnace CDQ cooling.

[0023] The boiler 17 is connected to the deaerator 13 through the boiler water pump 15 and the water supply pipeline. The circulating water in the boiler 17 needs to be deoxidized by the deaerator 13 and then re-enters the boiler 17 for circulation. Before entering the deaerator 13, the water needs to be heated by steam The pipe is heated to a certain temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com