Gas-liquid two-phase distributor and coke quenching furnace using the same

A technology of phase distribution and coke quenching oven, which is applied in coke ovens, coke cooling, and combustible gas production, etc., which can solve the problems of low coke quenching efficiency and uneven coke quality, and reduce coke quenching equipment and operating costs and avoid CDQ, small resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

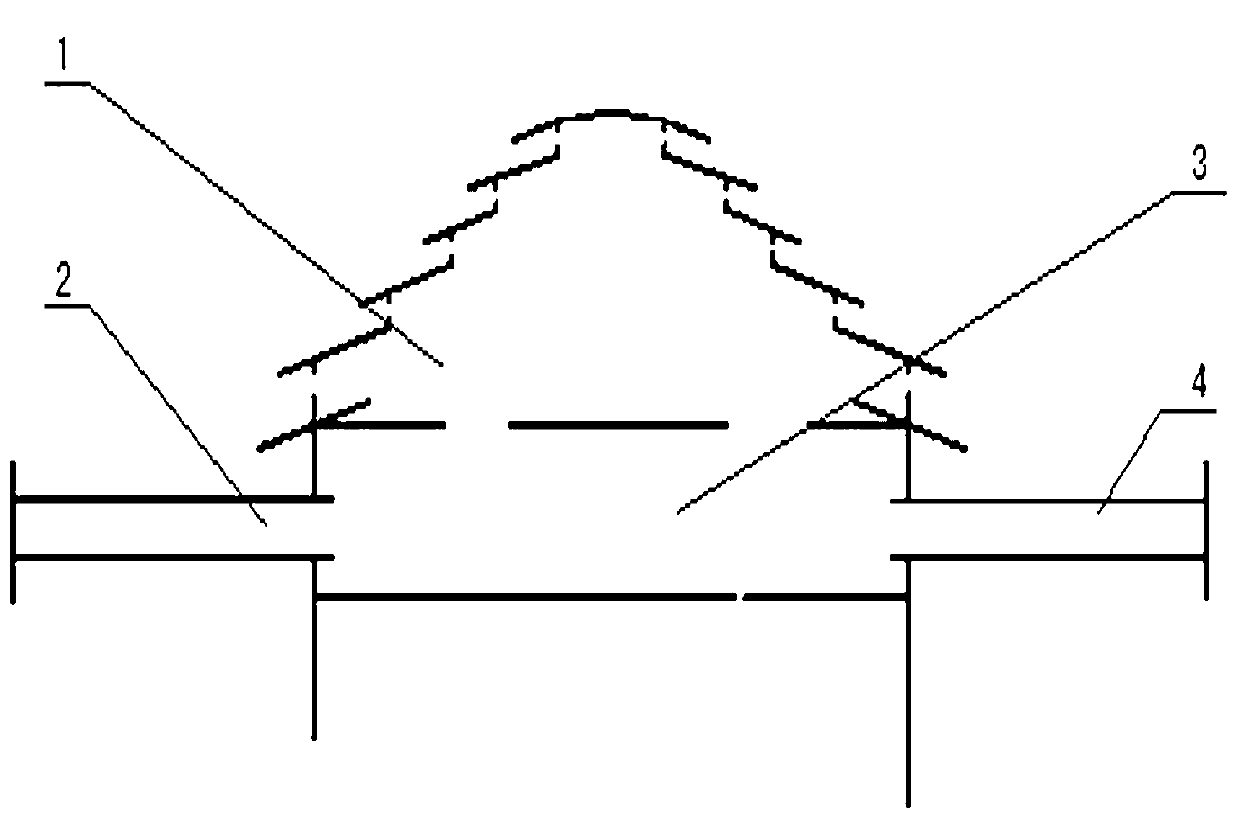

[0028] Implementation of a gas-liquid two-phase distributor provided by the present invention includes an existing gas distribution tower 1 and a liquid distribution plate 5; its specific implementation is as follows:

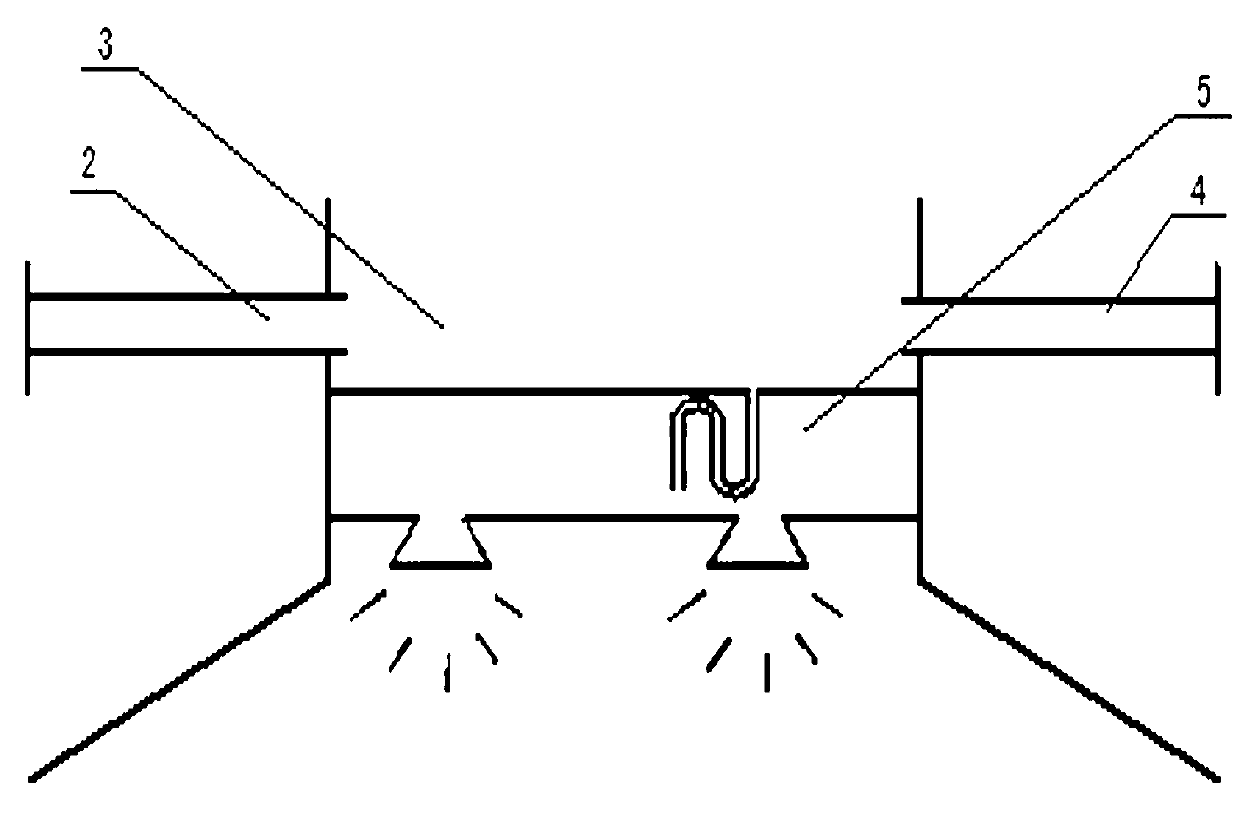

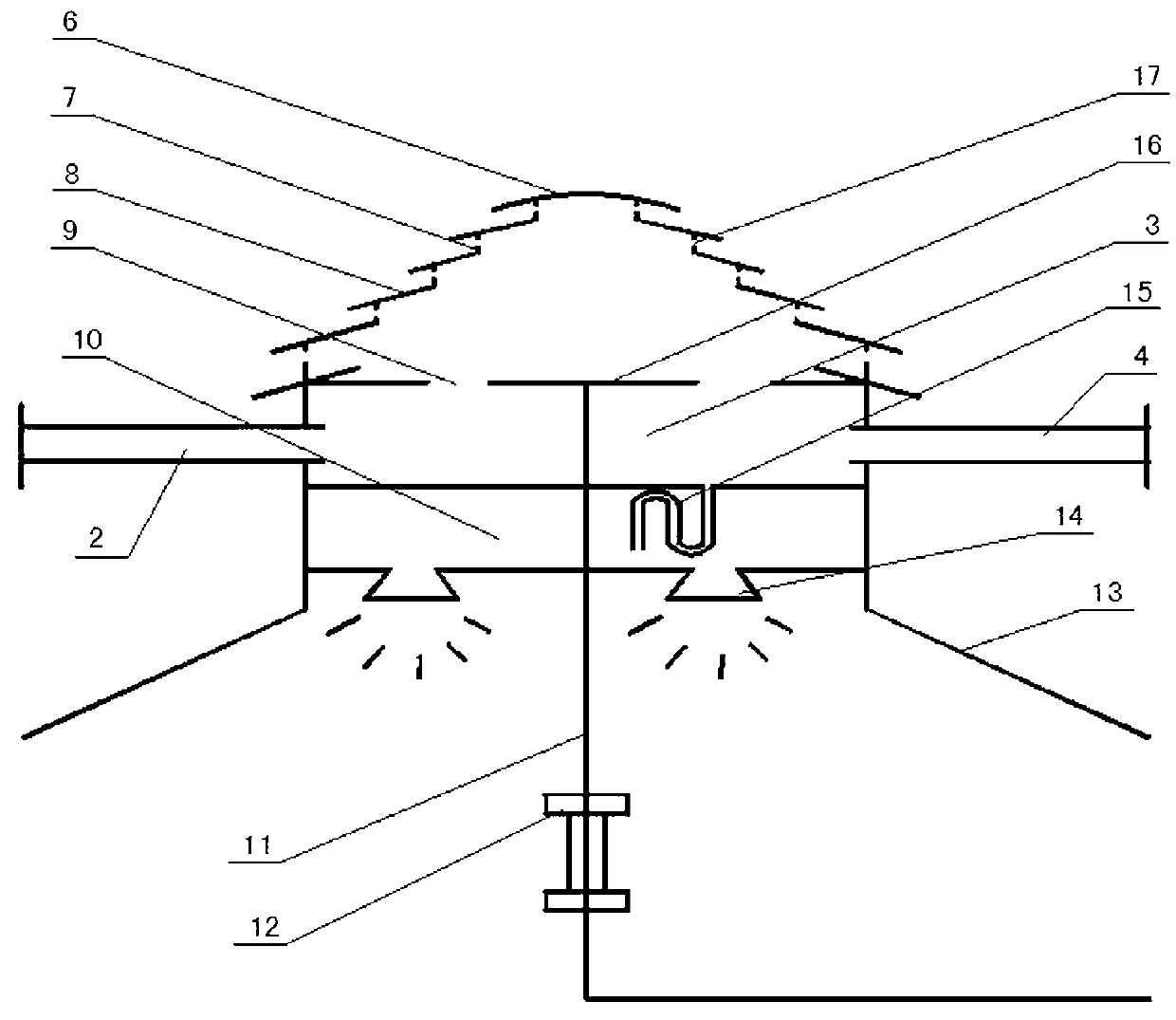

[0029] A gas-liquid two-phase distributor 22 is composed of a gas distribution tower 1 and a liquid distribution plate 5 connected through a gas-liquid separation tank 3; a number of " S" type liquid seal pipe 15, several cooling water nozzles 14 are evenly distributed on the lower end surface; circular liquid storage distribution tank 10 is used to store the liquid separated by "S" type liquid seal pipe 15, and passes through the small hole of the bottom plate The cooling water nozzle 14 connected to the hole is used for spraying distribution; the upper port of the "S" type liquid seal pipe 15 is connected to the lower liquid hole at the bottom of the gas-liquid separation tank 3, and the lower liquid hole is used for cooling water to enter the "S" type liquid ...

specific Embodiment approach

[0037] Implementation of a coke quenching oven that uses a gas-liquid two-phase distributor 22 provided by the present invention, the coke quenching oven is to apply the gas-liquid two-phase distributor 22 to a coke quenching oven, and the coke quenching oven is sequentially controlled by high temperature Coke pre-storage area 19, high-temperature coke and gaseous cooling medium reverse cross-flow contact first cooling area 21, cooling medium distribution area 29, hot coke co-flow liquid cooling medium uniformly sprayed radially, second cooling area 23 and discharge area 24 The high-temperature mixed gas outlet 30 is arranged on the upper end of the upper mixed gas channel 20 where the high-temperature coke and the gaseous cooling medium cross-flow in reverse and contact the first cooling zone 21; the gas-liquid two-phase distributor 22, the mixed gas inlet 2 and the liquid inlet 4 are arranged on Coke quenching oven cooling medium distribution area 29. Its structure is to ins...

Embodiment approach 3

[0050]The conditions of the experimental device in this embodiment are: the height of the high-temperature coke pre-storage area 19 is 900 mm, the inner diameter is 600 mm, the top cover is lined with a steel plate of heat-insulating material, there is a valve at the connection between the high-temperature coke pre-storage area 19 and the cooling area, and the inner diameter of the valve is Ф300. There are 150mm high and 45°C sloping conical cylinders at the top and bottom, so that the gas can be better exported to the quenching oven; when coke is put into the high-temperature coke pre-storage area 19, the valve is closed, and a valve is opened 5mm below the valve. High-temperature mixed gas outlet 30; cooling zone height 1200mm, internal diameter 600mm, discharge zone 24 height 300mm, outlet diameter 150mm; the bottom of gas-liquid two-phase distributor 22 with three-layer conical carbon baffle plate 8 is located at 800mm from the upper valve, the gas The liquid two-phase dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com