Bimetal ferromanganese low-temperature catalyst for selective catalytic reduction (SCR) denitration as well as preparation method and application of catalyst

A denitration catalyst and bimetal technology, applied in the field of denitration catalysts, can solve the problems of poor stability and low destocking efficiency, and achieve the effects of good stability, not easy to fall off, and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The method for preparing a bimetal ferromanganese low-temperature SCR denitration catalyst of this embodiment includes the following steps: using Fe(NO 3 ) 3 , Mn(NO 3 ) 2 With citric acid as raw materials, the active components are physically and chemically mixed by sol-gel method through water bath magnetic stirring. The mass ratio of each component Mn: Fe: citric acid is 0.05: 1: 0.5, and the required weight of iron nitrate is calculated , The quality of manganese nitrate solution and citric acid crystals. Then pour the weighed ferric nitrate and manganese nitrate solution into a beaker containing citric acid crystals, add deionized water, and after magnetically stirring in a 50℃ water bath for 3 hours, place it in a 105℃ blast drying oven to dry for 3 hours, and finally After roasting in a closed air atmosphere at 350° C. for 4 hours, and then cooling in the furnace, the bimetallic ferromanganese catalyst of this embodiment is obtained.

Embodiment 2

[0030] The method for preparing a bimetal ferromanganese low-temperature SCR denitration catalyst of this embodiment includes the following steps: using Fe(NO 3 ) 3 , Mn(NO 3 ) 2 With citric acid as raw materials, the active components are physically and chemically mixed by sol-gel method through water bath magnetic stirring. The mass ratio of each component Mn: Fe: citric acid is 0.1: 1: 1.5, and the required weight of iron nitrate is calculated , The quality of manganese nitrate solution and citric acid crystals. Then pour the weighed ferric nitrate and manganese nitrate solution into a beaker containing citric acid crystals, add deionized water, and after magnetically stirring in a 50℃ water bath for 3 hours, place it in a 105℃ blast drying oven to dry for 3 hours, and finally After roasting in a closed air atmosphere at 450°C for 3 hours, and then cooling in the furnace, the bimetallic ferromanganese catalyst of the present embodiment is obtained.

Embodiment 3

[0032] The method for preparing a bimetal ferromanganese low-temperature SCR denitration catalyst of this embodiment includes the following steps: using Fe(NO 3 ) 3 , Mn(NO 3 ) 2 With citric acid as raw materials, the active components are physically and chemically mixed by sol-gel method through water bath magnetic stirring. The mass ratio of each component Mn: Fe: citric acid is 0.2: 1: 2, and the required weight of iron nitrate is calculated , The quality of manganese nitrate solution and citric acid crystals. Then pour the weighed ferric nitrate and manganese nitrate solution into a beaker containing citric acid crystals, add deionized water, and after magnetically stirring in a 50℃ water bath for 3 hours, place it in a 105℃ blast drying oven to dry for 3 hours, and finally After calcination in a closed air atmosphere at 550° C. for 2 hours, followed by cooling in the furnace, the bimetallic ferromanganese catalyst of this example was obtained.

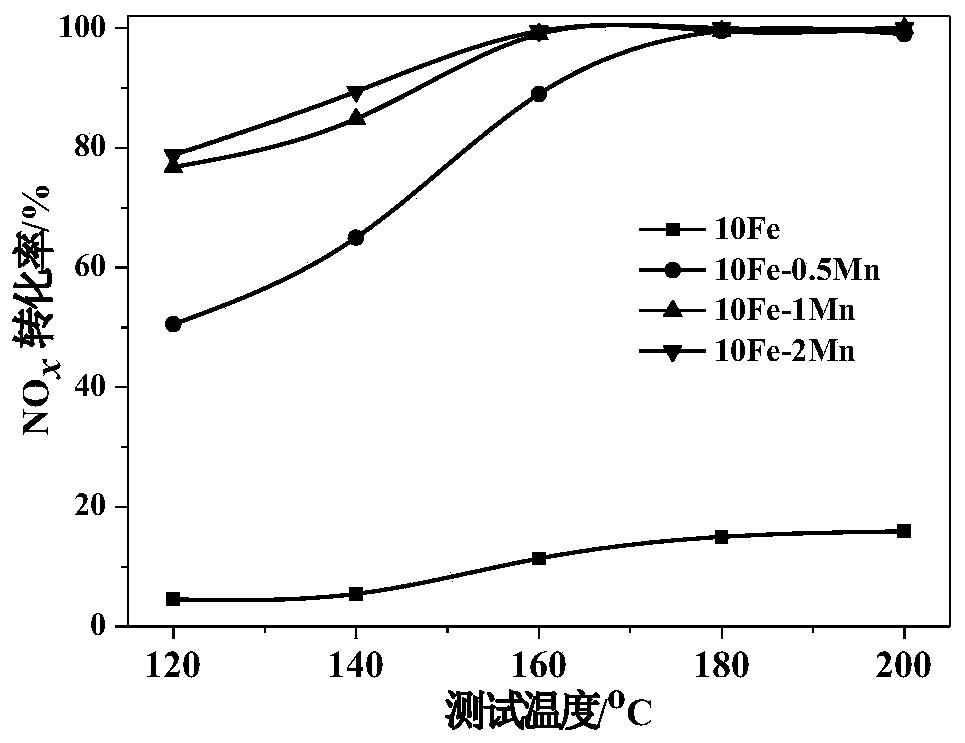

[0033] Examples of the effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com