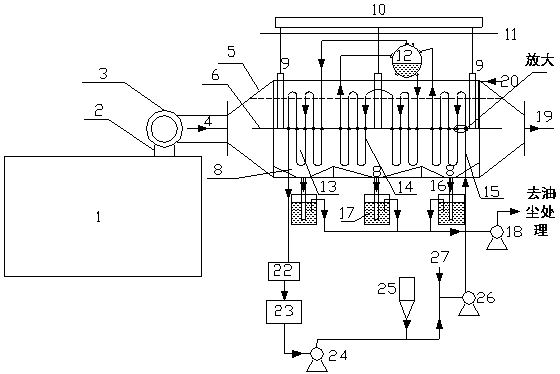

High-temperature raw gas waste heat and tar recovery device and recovery method therefor

A waste heat recovery device and tar recovery technology are applied to clean heat transfer devices, dry distillation gas discharge devices, coke ovens, etc., which can solve the problems of large cooling water consumption, low heat recovery efficiency, and low heat exchange efficiency, and achieve The effect of reducing sewage discharge, simplifying system operation process and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be further described below.

[0034] Implementation of a high-temperature raw gas waste heat and tar recovery device and recovery method thereof provided by the present invention is based on the following ideas:

[0035] One is on-site recovery, avoiding the setting of collection and conveying pipes to avoid coking and sealing safety issues caused by cooling;

[0036] Second, the structure is compact, the limited space is rationally used, and the equipment is arranged to maximize the recovery of waste heat from raw gas;

[0037] The third is safe and reliable, avoiding damage to the existing furnace body due to waste heat recovery, affecting the normal operation of the coke oven;

[0038] The fourth is to prevent tar from condensing and coking on the surface of the condensation pipe, and reduce the efficiency of waste heat recovery of high-temperature raw gas;

[0039] Fifth, the structure is simple, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com