System and method for treating benzene-contained separating water of coking benzol

A technology for separating water from crude benzene and coking crude benzene is applied in the field of coke oven gas purification, can solve problems such as benzene gas pollution, and achieve the effects of improving the environment and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

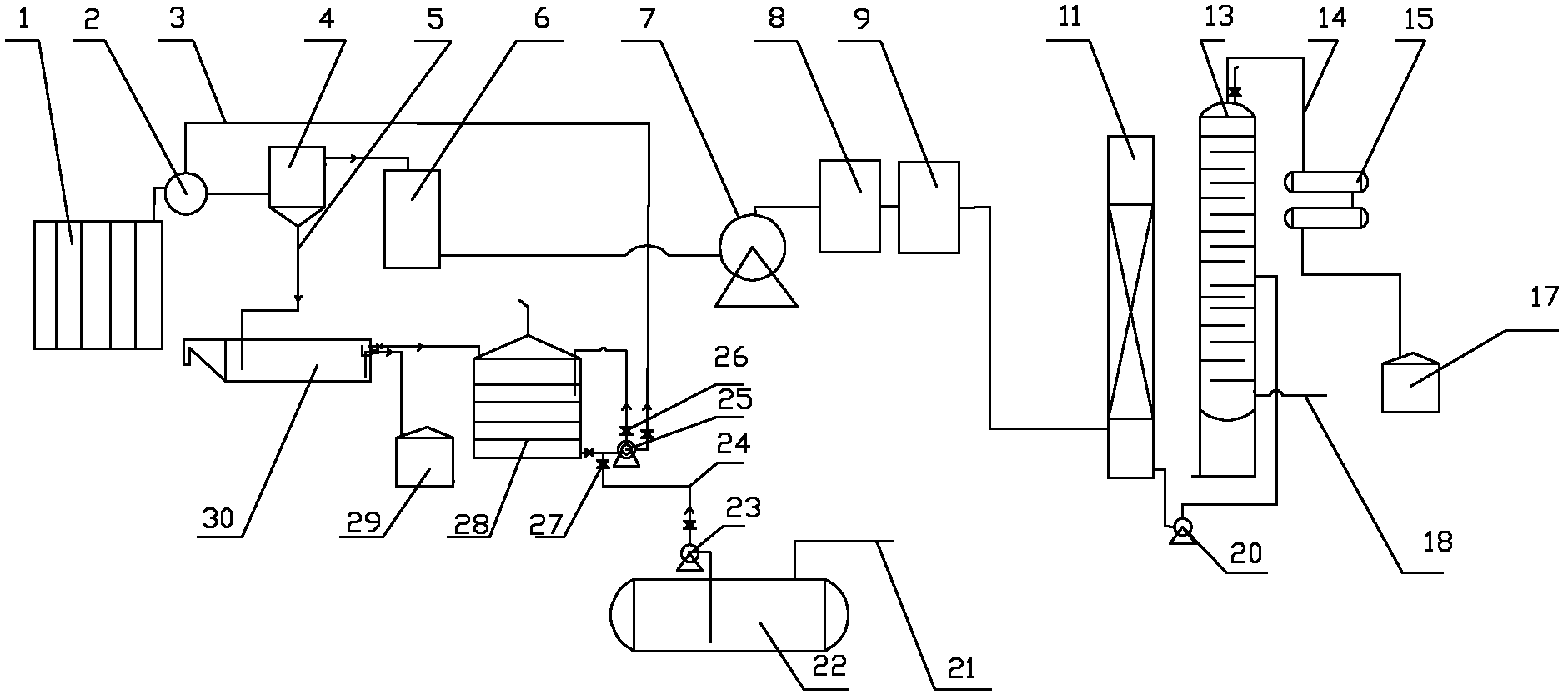

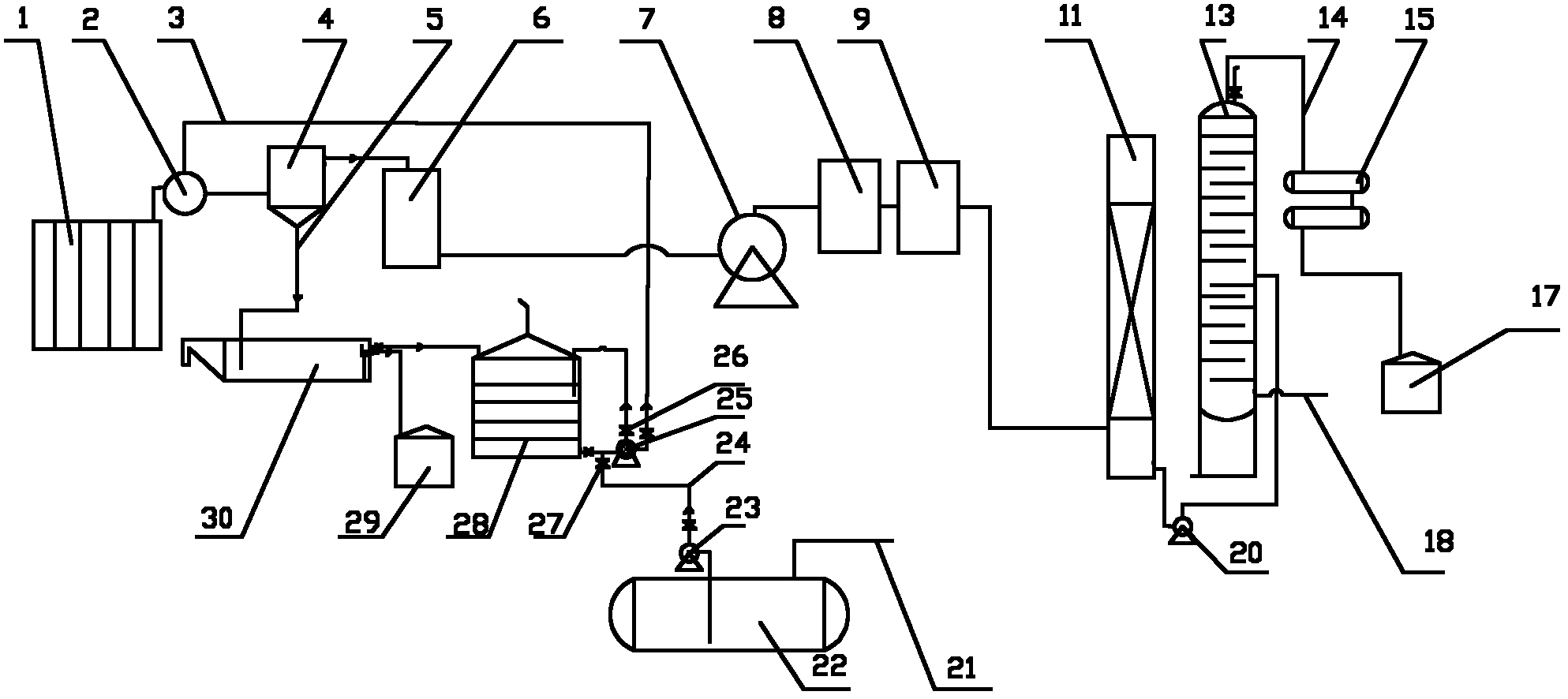

[0018] In this embodiment, a coking crude benzene-containing benzene separation water treatment system is connected such as figure 1 As shown, a coking crude benzene-containing benzene separation water treatment system includes an underground vent tank 22, a circulating ammonia water tank 28, a coke oven gas collecting pipe 2 and a circulating ammonia water pump 25, the coke oven gas collecting pipe 2 is connected to the coke oven 1, and the circulating ammonia water pump 25 is set on the circulating ammonia water tank 28 connected to the coke oven gas collecting pipe 2 on the circulating ammonia water pipe 3, the circulating ammonia water pump 25 on the circulating ammonia water pipe 3 is provided with valves before and after, and the liquid inlet of the underground emptying tank 22 is connected to the crude benzene separation Water venting pipe 21, crude benzene separation water venting pipe 21 transports the crude benzene separation water containing benzene and oil separated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com