Arch stuffing supporting technology by bricking arch apex for division of flue in coke oven

A technology of separating flue and vault, which is applied in the direction of coke oven bricklaying and other directions, can solve the problems of time-consuming and laborious installation of arch tires, narrow space for separating flue, low work efficiency, etc., so as to improve construction efficiency and reduce construction labor. Strength, easy to set up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

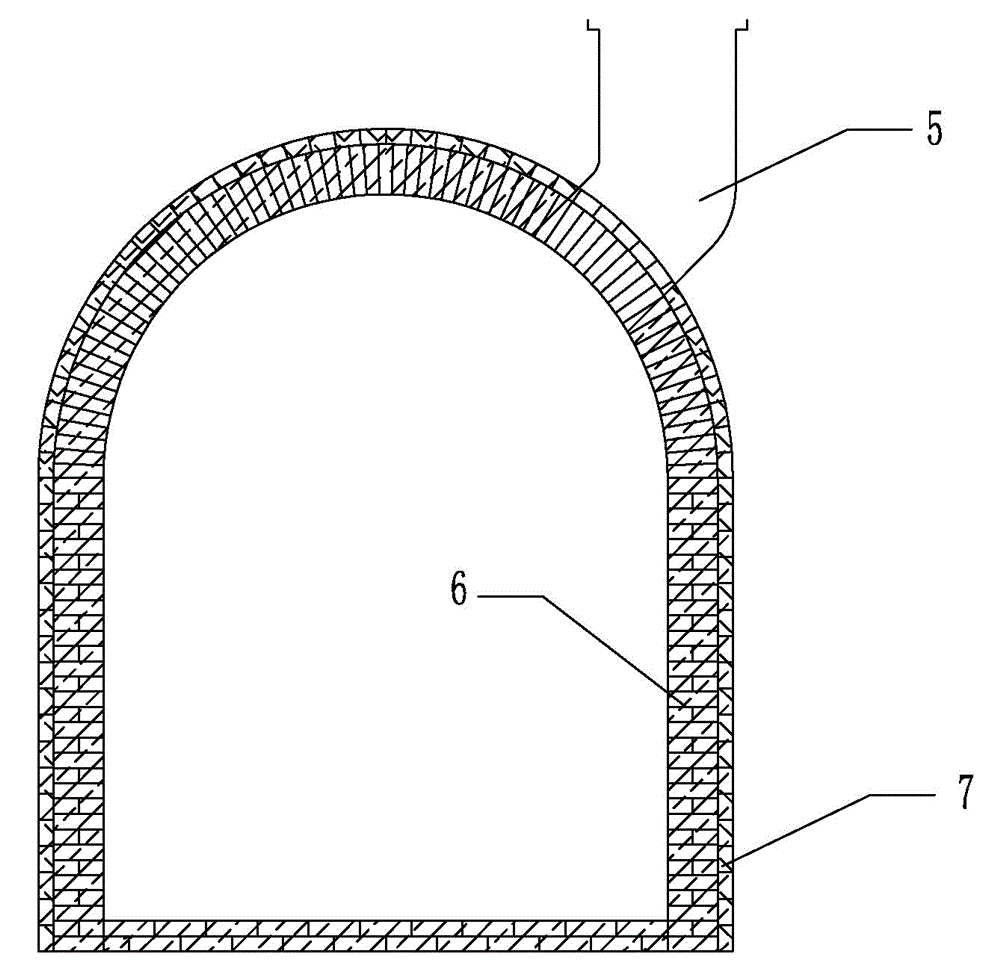

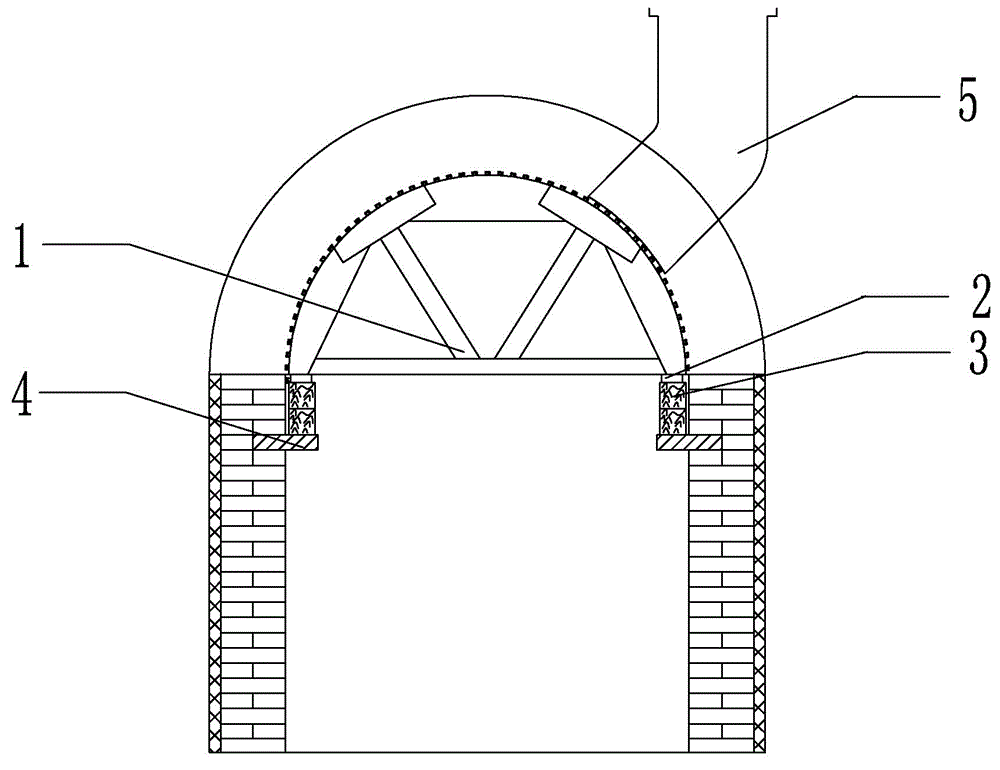

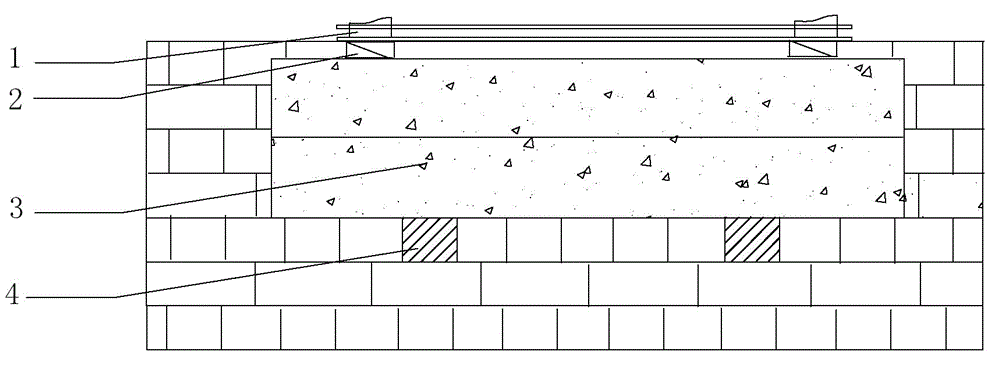

[0031] see now Figure 2 ~ Figure 4 , figure 2 It is a schematic diagram of the coke oven sub-flue vault masonry arch supporting arrangement according to the embodiment of the present invention, image 3 It is a schematic diagram of the installation and arrangement of support bricks, horizontal beams, wooden wedges and arch tires in the embodiment of the present invention, Figure 4 It is a schematic diagram of the masonry and arrangement of supporting bricks in the embodiment of the present invention.

[0032] The coke oven sub-flue vault masonry arch tire supporting process of the present invention is characterized in that it comprises the following steps:

[0033] a. Leave supporting bricks on the furnace wall

[0034] When building the two side walls of the flue, at the position of the fifth layer of bricks below the top of the two walls in the flue, first build half a piece of standard clay brick inside the side wall, and then use a standard clay brick to directly bui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com