7.63m coke oven upper spanning hole masonry method

A coke oven and masonry technology, which is applied in the field of masonry across a 7.63m coke oven to achieve the effects of improving the working environment, preventing heat transfer and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

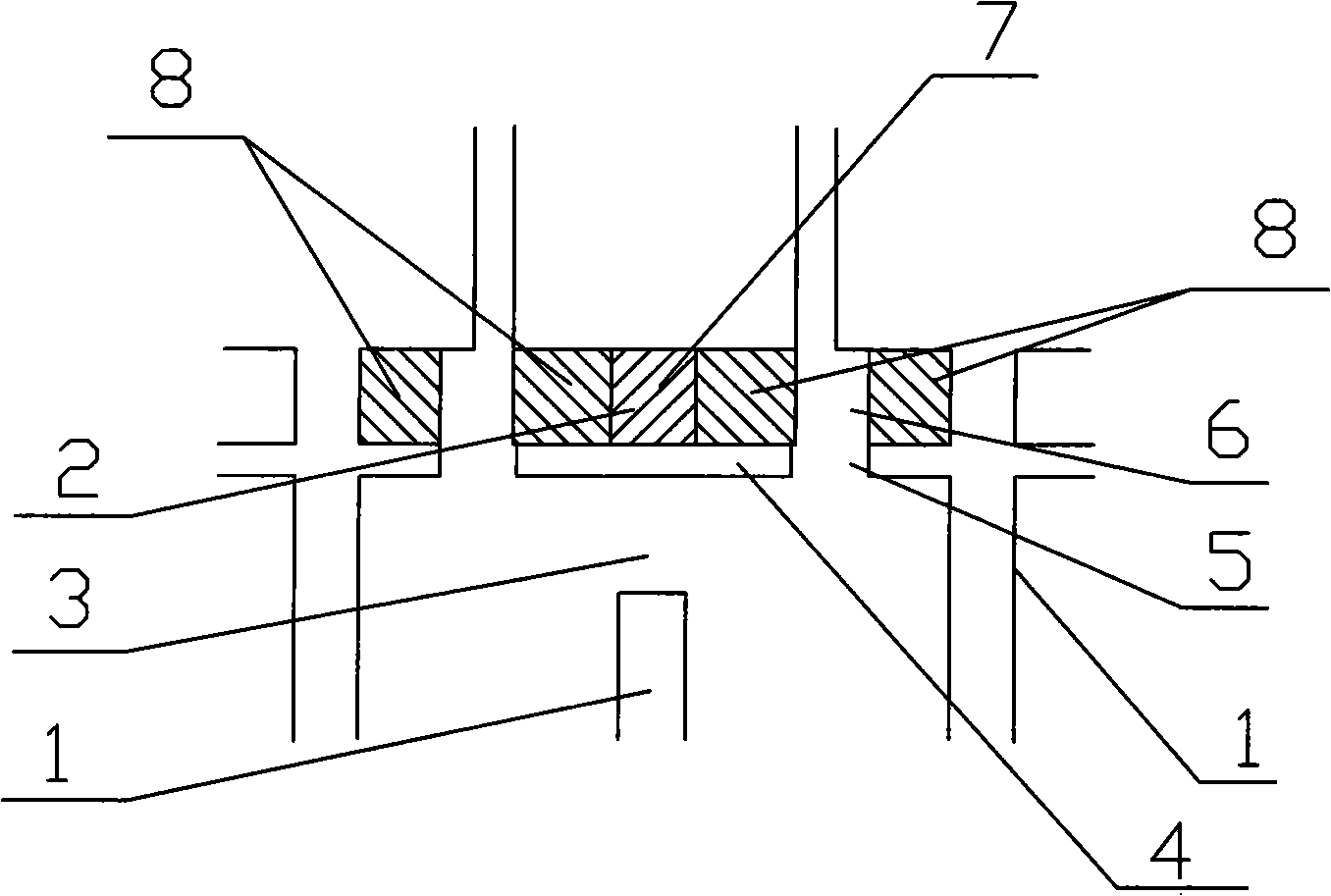

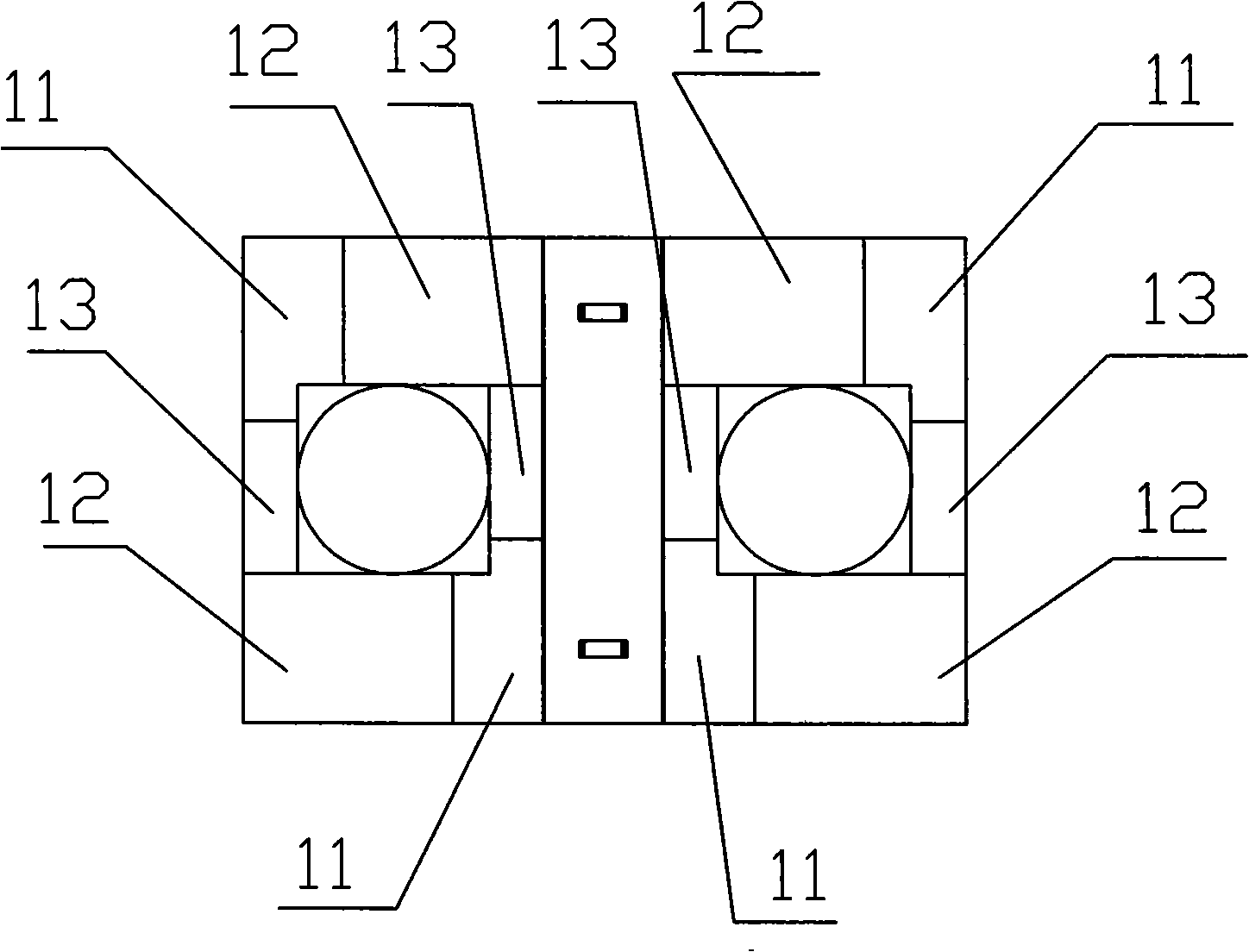

[0015] Such as figure 1 As shown, a method for building spanning holes on a 7.63m coke oven of the present invention includes a 7.63m coke oven 1 and a spanning hole on the coke oven. An interlayer 4 is arranged between the layer spanning holes, and two through holes 5 are arranged on the interlayer, and the upper and lower two layer spanning holes form interpenetrating passages 6 through the interlayer through holes. The upper spanning hole is divided into five areas, which are respectively the area 7 above the middle of the interlayer and the four areas 8 on both sides of the through hole of the interlayer. The area above the middle of the interlayer is all built with silica bricks to completely block the upper span. The holes preve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com