Method for cleaning coke oven chute

A chute and coke oven technology, which is applied to coke ovens, coke oven bricklaying operations, furnace prevention/removal of fouling, etc., can solve problems such as large damage to furnace walls, heavy workload, and impact on the service life of coke ovens. Improvement of operation safety, reduction of resistance, beneficial effect of temperature regulation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

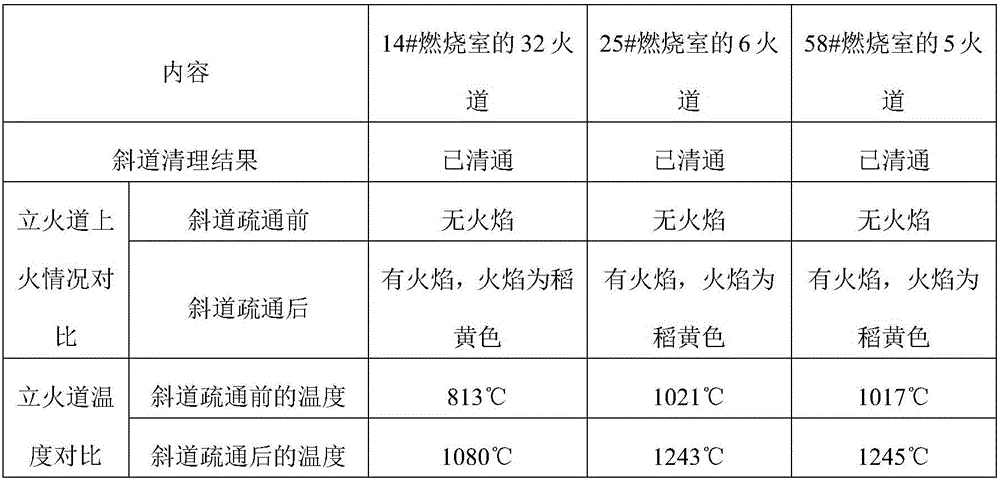

Examples

Embodiment 1

[0041] A method for cleaning the coke oven chute in the present embodiment consists of the following steps:

[0042] 1. Preparatory work

[0043] (1) According to different coke oven models, transport the required checker bricks to the coke oven area in advance and place them in the drying area of the second floor of the coke oven or the end platform;

[0044] (2) Prepare fiber felt and asbestos felt insulation materials, and prepare 3 to 4 sets of heat insulation clothing;

[0045] (3) Prepare the tools needed for cleaning;

[0046] 2. Cooling treatment

[0047] (1) Set up the carbonization chamber and buffer furnace of the braising furnace: when one of the ramps of the coke oven combustion chamber needs to be cleaned, according to the characteristics of the double-connected fire channel, if the combustion chamber where the ramp is located has two eyes, the combustion chamber The previous carbonization chamber adjacent to the braising furnace is set as the braising furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com