Method for building vault lining of flue

A vaulting and masonry technology, applied in the direction of construction, building structure, scaffolding accessories, etc., can solve problems such as layoffs, and achieve the effect of simple control, strong bearing capacity, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

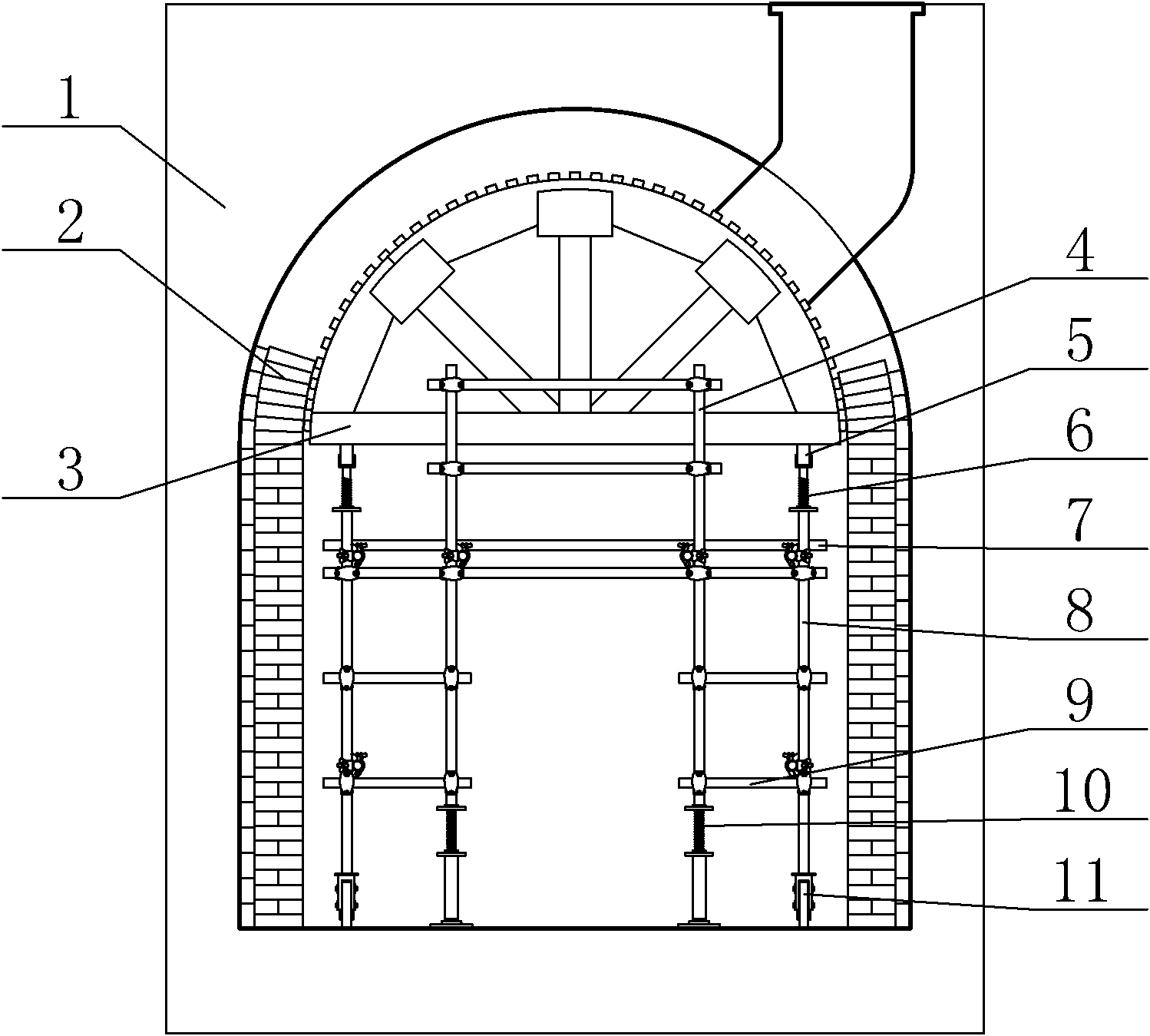

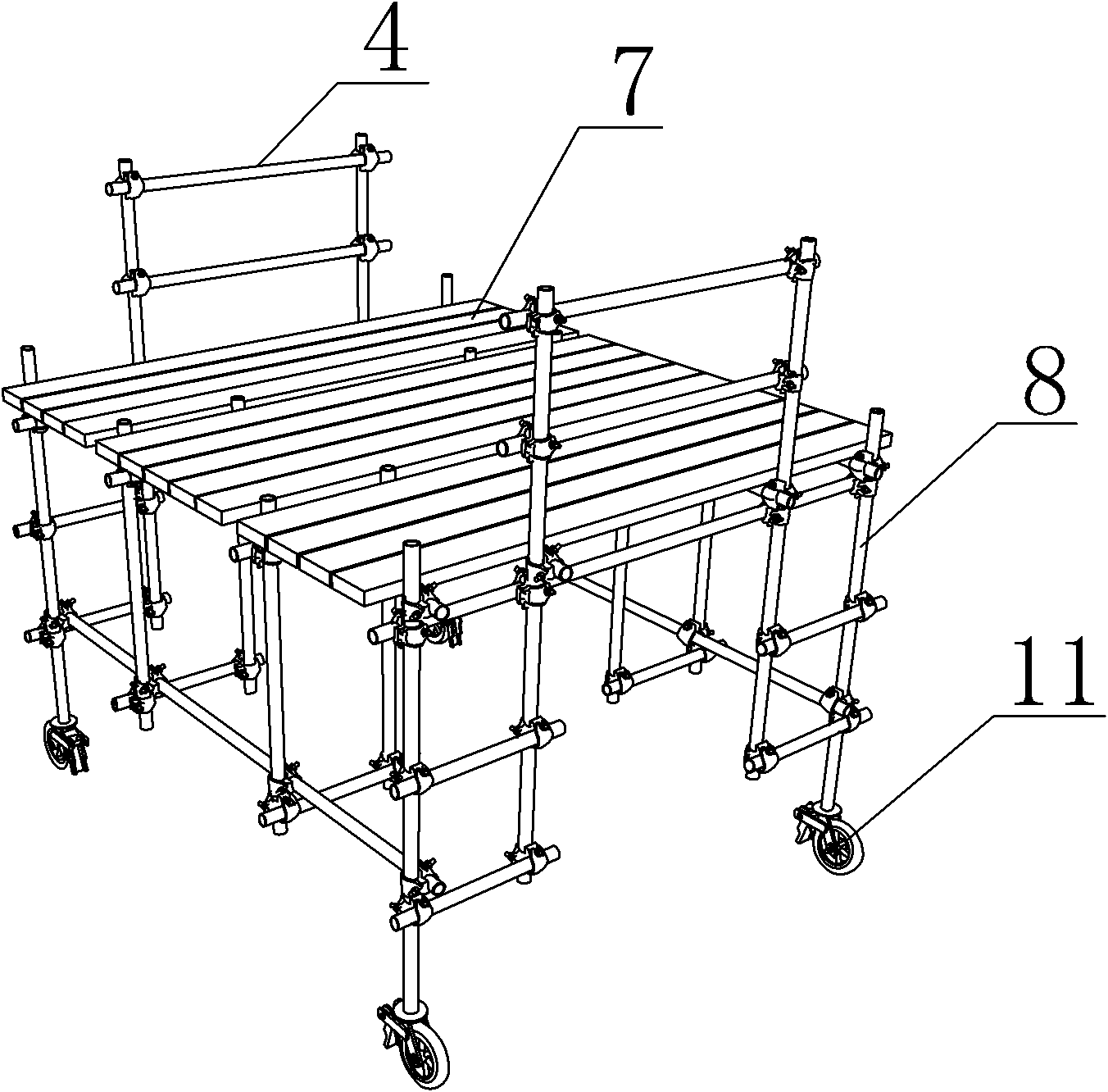

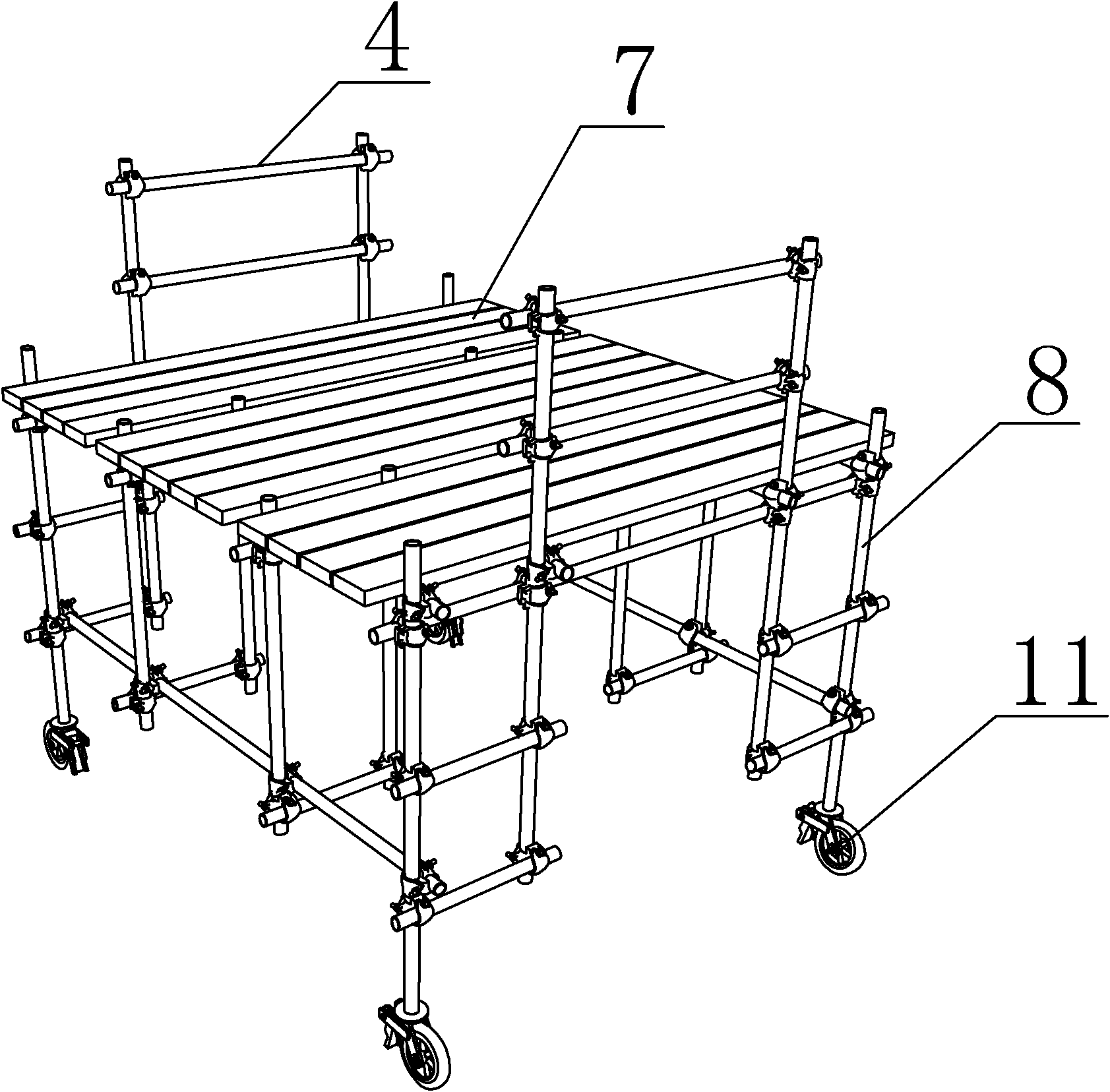

[0014] The method for building the lining of the flue vault provided by the invention, see figure 1 and figure 2 , the method is: in the process of using refractory bricks 2 to build the refractory lining of the vault of the coke oven flue 1, use the mobile operating platform and the mold support integrated support to support and move the mold 3 for the masonry vault , so that the construction personnel can construct on the operating platform on the bracket conveniently, and place refractory materials on the operating platform at the same time.

[0015] The mobile operation platform adopted by the present invention and the mold support integrated bracket have a structure such as figure 1 and figure 2 As shown: it is mainly composed of a mobile bracket, a mold adjust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com