Transporting and constructing method and device for coke-oven checker bricks

A checker brick and coke oven technology, which is applied in coke oven bricklaying operations, etc., can solve problems such as high labor intensity, and achieve the effects of reducing labor intensity, simple device structure, and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with specific embodiment, the present invention is further described:

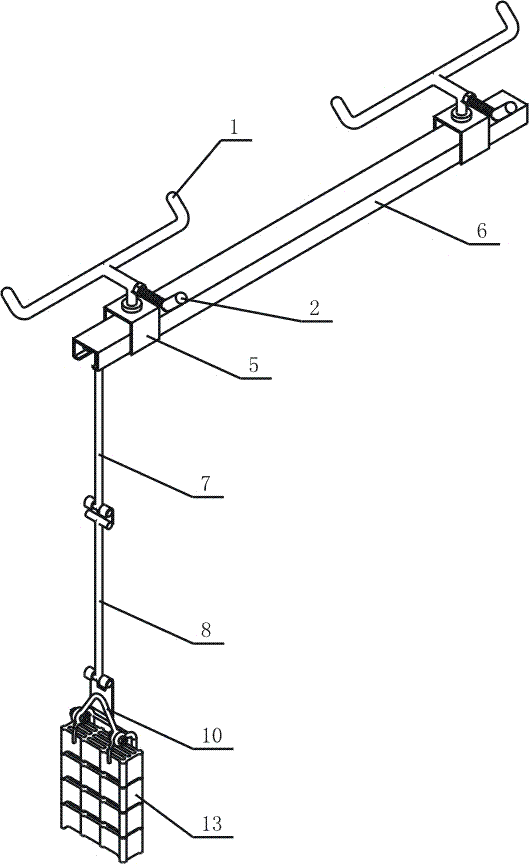

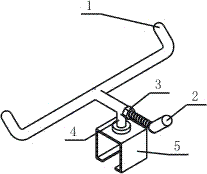

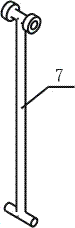

[0033] The transportation and masonry device of coke oven checker bricks in the embodiment of the present invention, such as Figure 1 to Figure 5 As shown, it is mainly composed of a fixed rod 1, an adjusting rod 2, an adjusting nut 3, a suspension shaft 4, a slide rail support 5, a slide rail 6, a first suspender 7, a second suspender 8 and a grid brick spreader, among which One end of the fixed rod 1 is connected with the adjusting rod 2, and the rod portion of the adjusting rod 2 is provided with a screw thread, and the adjusting nut 3 is installed on the adjusting rod 2; the lower part of the fixed rod 1 is provided with a suspension shaft 4 and a slide rail support 5; the first The upper end of the suspension rod 7 is provided with a slide rail wheel, and the lower part is provided with a suspension rod; the upper end of the second suspension rod 8 is provided with a hook,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com