Thermal-state non-stop production replacement method of lattice bricks in regenerative chamber of coke oven

A replacement method, checker brick technology, applied in coke oven bricklaying operations, etc., to achieve the effect of not being easily broken, reducing the difficulty of hot repair, and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

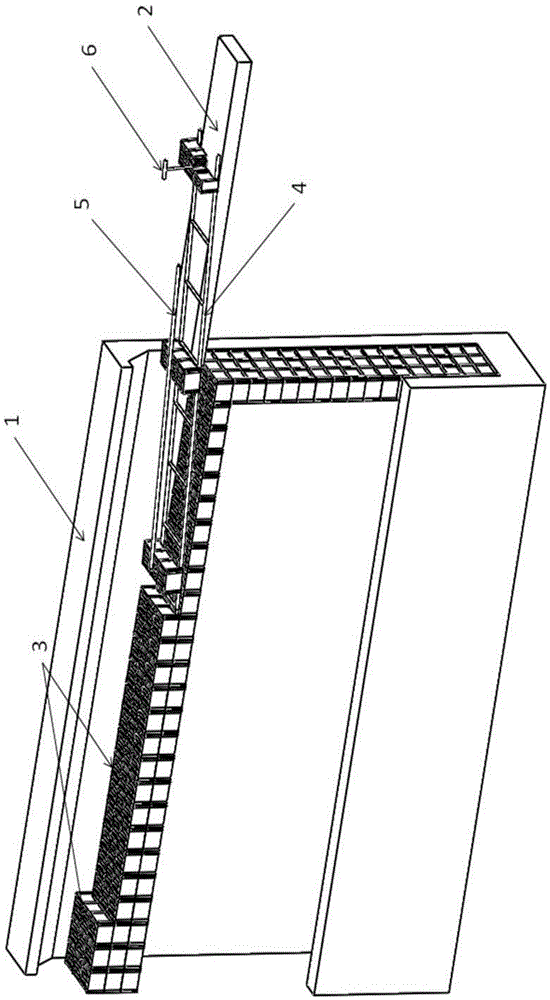

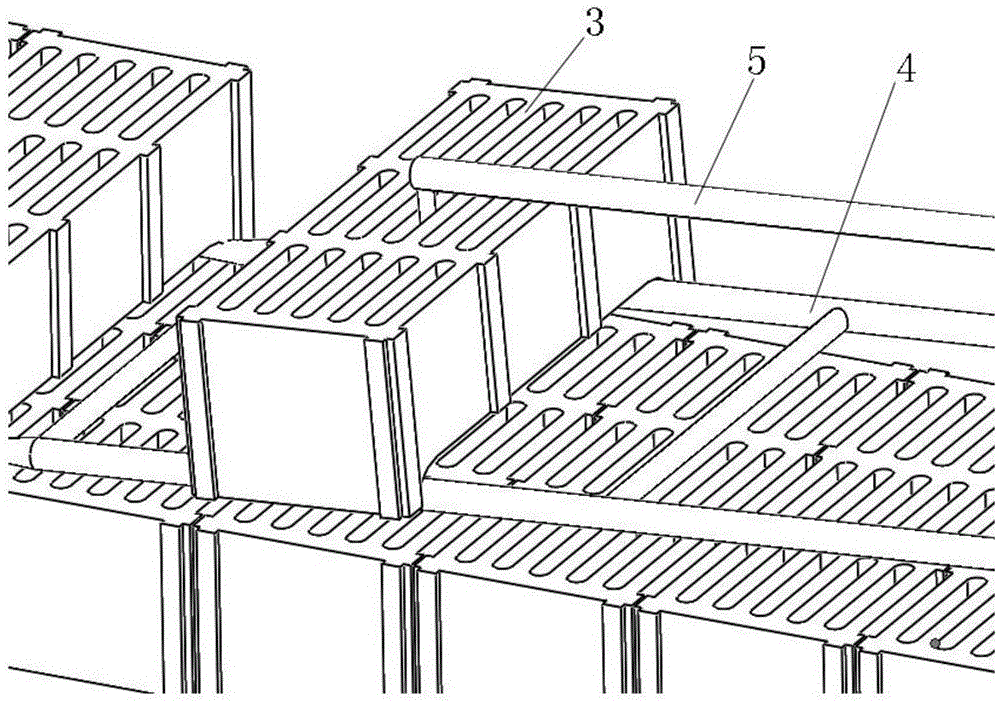

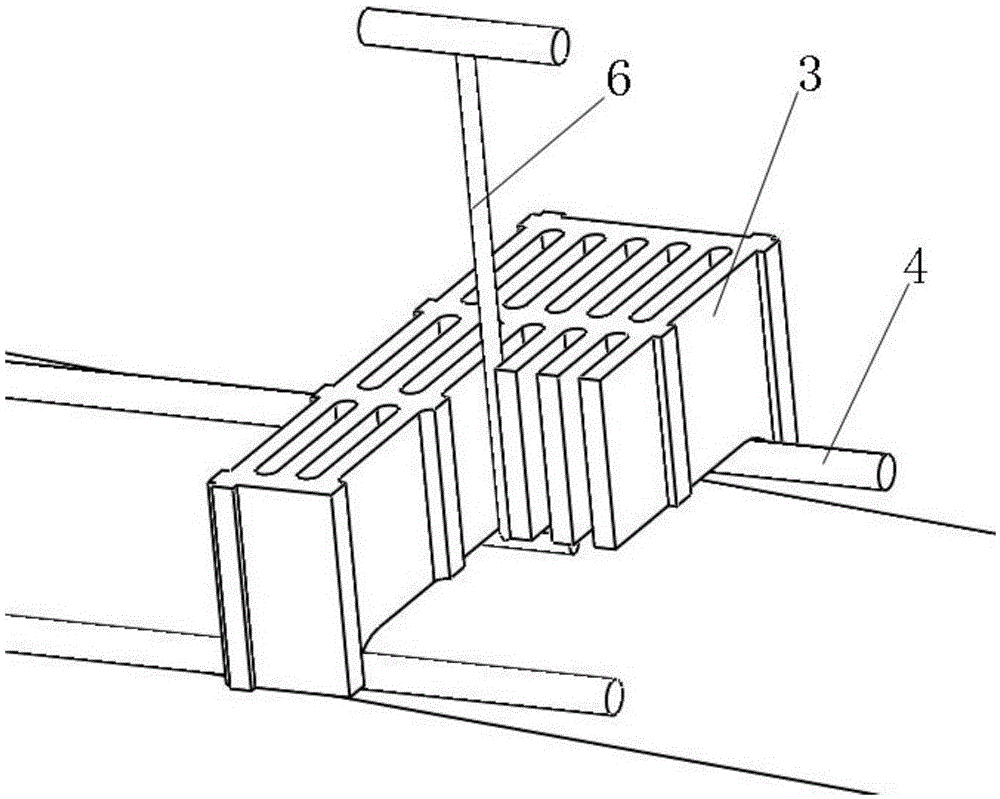

[0023] See figure 1 , is a schematic diagram of the checker brick replacement process in the present invention. The present invention a kind of coke oven regenerator checker brick thermal state non-stop replacement method, comprises the following steps:

[0024] 1) Remove the coke blocking plate in the chute area where the checker bricks need to be replaced, part of the sealing wall of the regenerator and its ancillary facilities. All the bricks can be exposed; install asbestos boards on the surface of the main wall and single wall of the regenerator within at least 3m near the edge of the demolition area to prevent the temperature of the regenerator 1 from cooling down too quickly;

[0025] 2) Set up the operation platform 2, insert the front end of the slideway 4 into the bottom of the checker brick 3 to be replaced, use the brick hook 5 to ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com