Method for repairing fusion holes in wall of carbonization chamber without cooling

A carbonization chamber and melting hole technology, which is applied in the field of coke oven repair, can solve the problems of long repair time, damage to the wall of the carbonization chamber, and a large reduction in furnace temperature, so as to shorten the repair time, prolong the service life, and improve the gunning speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below through embodiment.

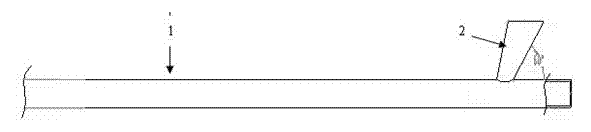

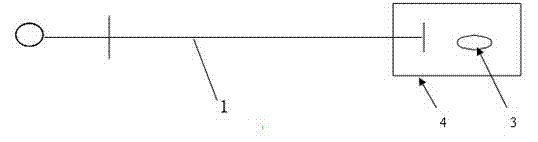

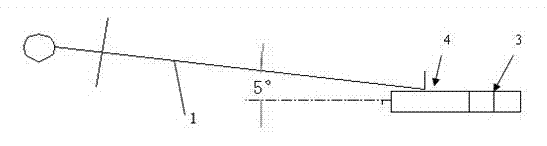

[0017] A method for repairing a melting hole on the wall of a carbonization chamber without cooling down, comprising the following process: ①Use detection tools to detect the melting hole on the wall of the carbonization chamber that needs to be repaired, and determine the specific location of the melting hole that needs to be repaired; ②The karst hole in the carbonization chamber needs to be repaired The furnace top vertical fire channel corresponding to the position stops heating, which is convenient for gunning operation; ③Fix the baffle plate in the carbonization chamber, and the baffle plate is close to the wall of the carbonization chamber to cover the entire melting hole; the pressure relief hole is set on the material baffle plate , the pressure relief hole is facing the mouth of the melting hole; ④ observe the melting hole in the furnace wall of the carbonization chamber from the fire vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com