False corbel bracket and using method thereof during examining and repairing corbel bricks in dry quenching chute

A false corbel and CDQ technology, which is applied in coke cooling, coke oven brickwork, coke oven, etc., can solve the problems of safety hazards, high cost, and inconvenient maintenance methods for CDQ chute corbel bricks, etc. problem, to achieve the effect of simple structure and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

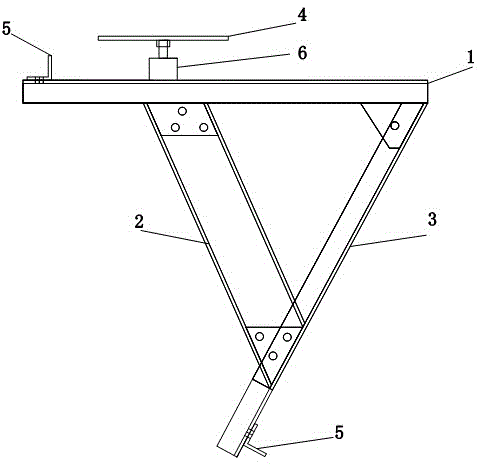

[0034] A kind of false corbel bracket built in Y shape

[0035] See now figure 1 , figure 1 It is a schematic diagram of the structure of the artificial corbel bracket according to the embodiment of the present invention. As shown in the figure, the load-bearing beam 1 is a horizontally arranged steel beam with a length of 935mm. The upper part of one end is provided with a screw hole for bolting with the angle steel 5, and the lower part of one end is fixedly welded to a stiffened plate with a screw hole. , The lower part of the other end is also fixedly welded to a stiffened plate with screw holes;

[0036] The supporting member 2 has a length of 810mm, both ends of which are provided with screw holes, one end is bolted to the stiffened plate of the load-bearing beam 1, and the other end is provided with screw holes;

[0037] The length of the chute contact piece 3 is 894mm, one end is provided with a screw hole for bolting to the load-bearing beam 1, and the lower part of the oth...

Embodiment 2

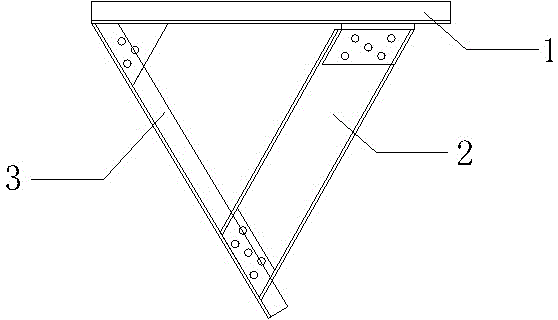

[0039] A kind of false corbel bracket built in V shape

[0040] This embodiment is the same as the embodiment 1 except that the false corbel bracket is constructed under the load-bearing beam 1 by the supporting member 2 and the chute contact member 3 in a V shape.

Embodiment 3

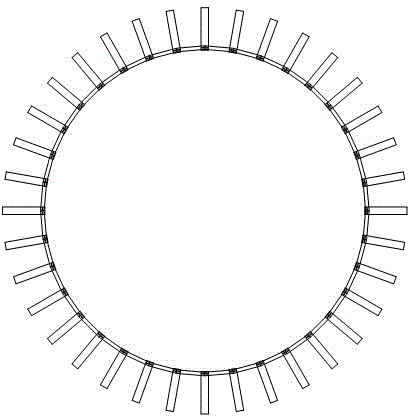

[0042] A method for using a fake corbel bracket in the overhaul of corbel bricks for CDQ chute is characterized by comprising the following steps:

[0043] a, prefabricated false corbel bracket parts

[0044] According to the structural characteristics of the CDQ chute, the force analysis is carried out to determine that the bracket meets the actual force requirements, calculate the size of the bracket, prefabricated fake corbel bracket parts, manufactured fake corbel bracket and CDQ corbel quantity, The external dimensions are the same; the false corbel bracket parts include load-bearing beam 1, support 2 and chute contact 3.

[0045] b. Assemble the false corbel bracket into a single whole in the furnace

[0046] The false corbel bracket parts including the load-bearing beam 1, the support member 2 and the chute mouth contact member 3 are transported into the furnace in single pieces from the furnace mouth, and assembled into a single body of the false corbel bracket in the furnace;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com