Furnace opening vault laying control device and method for heat recovery coke furnace

A control device and heat recovery technology, applied in coke oven bricklaying operations, etc., can solve problems such as difficult adjustment of furnace mouth bricks, loose vaults, and burning of brick joint mud, etc., and achieve the effect of simple structure and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

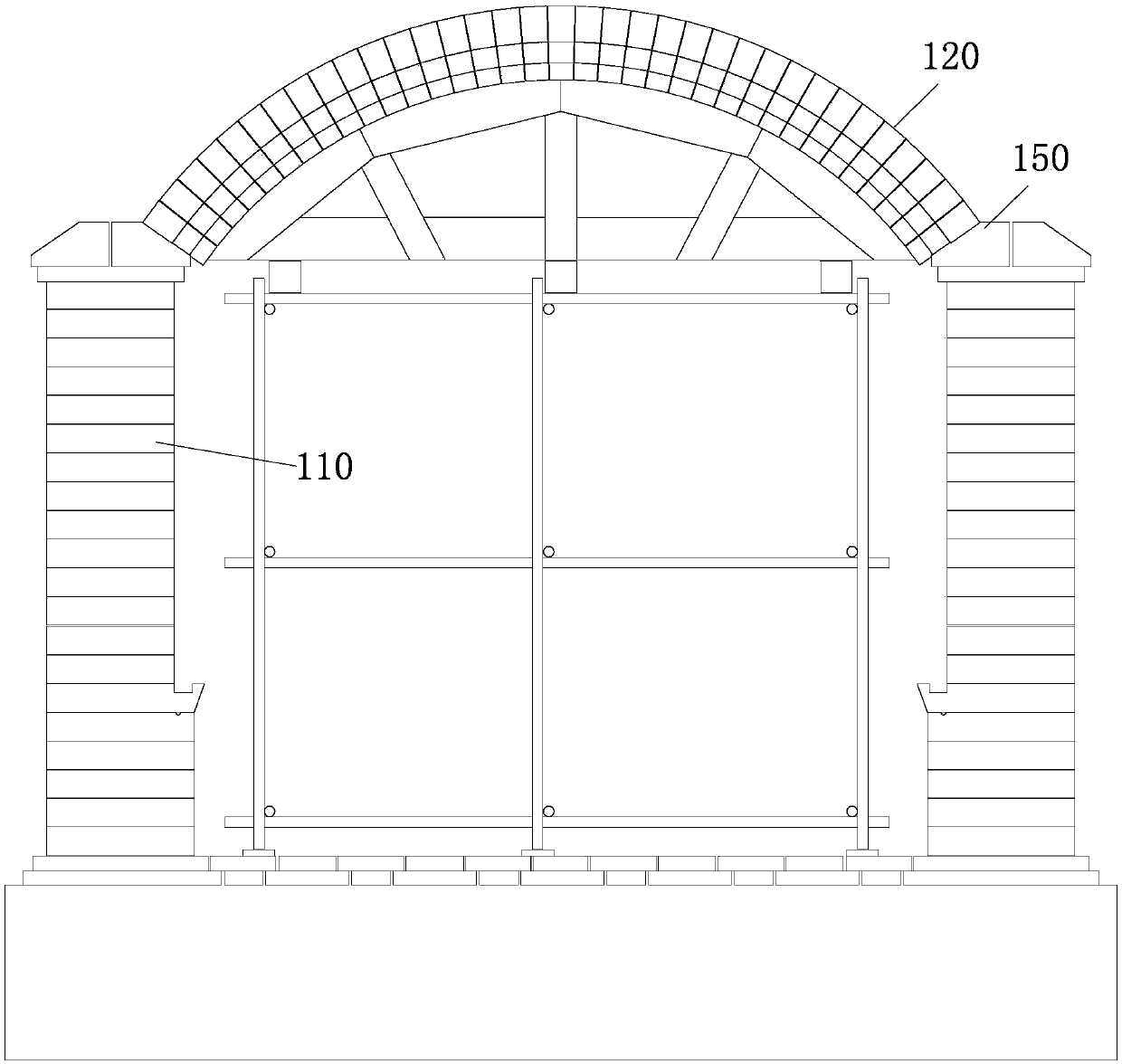

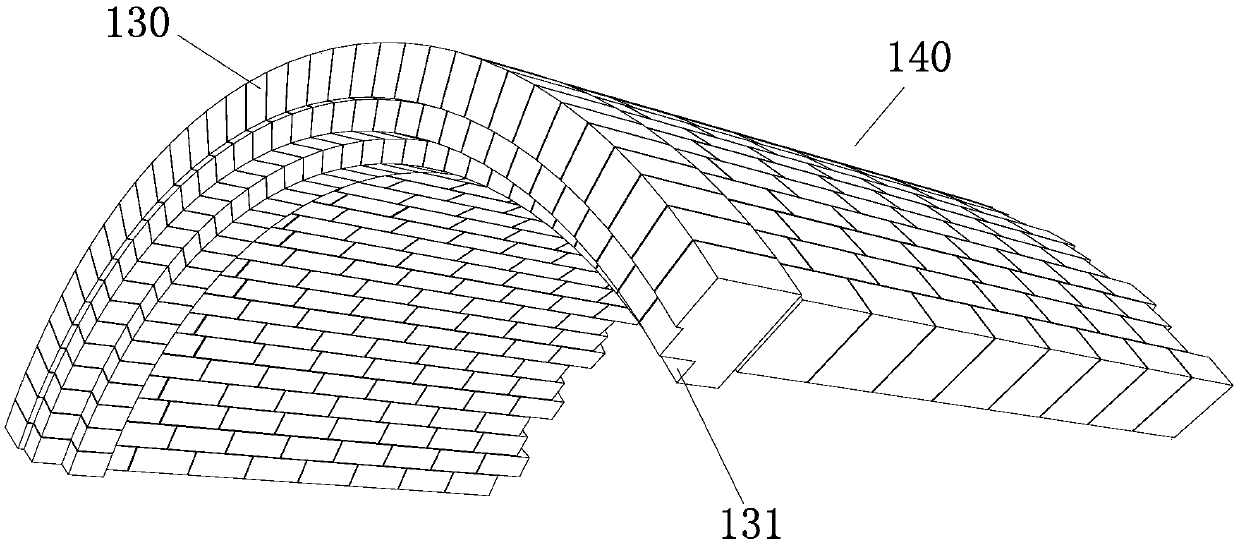

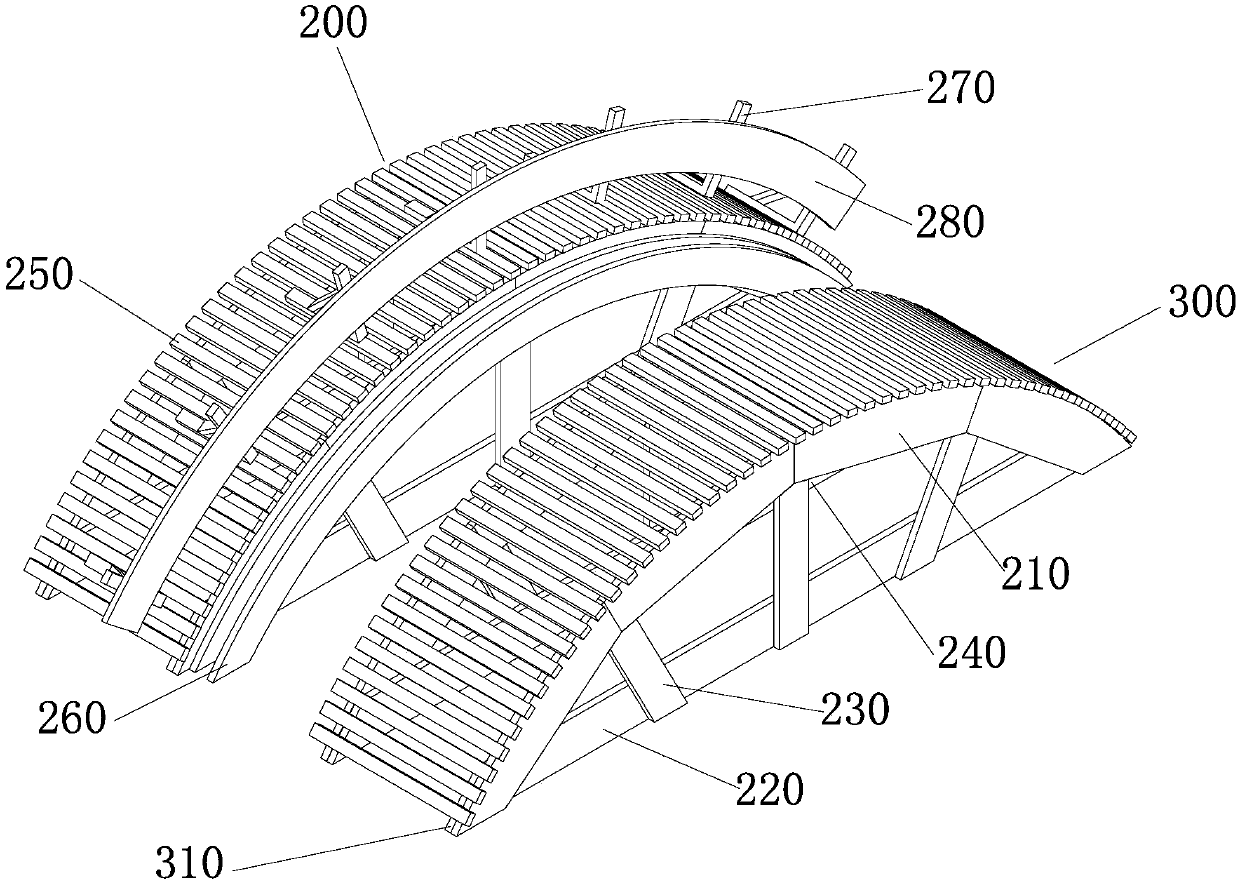

[0032] Such as Figure 3-5 As shown, it is a heat recovery coke oven mouth vault masonry control device according to a preferred embodiment of the present invention, which includes a tire outside the furnace mouth 200 and a hearth tire 300, and both tires include tire strips 250 and are installed on The arch tire under the tire strip 250, the side of the arch tire 200 outside the furnace mouth close to the furnace arch tire 300 is provided with a boss tire plate 260, the upper surface of the boss tire plate 260 is arc-shaped, used to support the furnace mouth The bottom surface of the brick 130, the boss tire plate 260 and the tire strip 250 of the outer arch tire 200 of the furnace mouth form a staggered platform struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com