Method for retaining cleaning of 7.63m coke oven in building process

A technology for maintaining furnaces and coke ovens, which is applied in coke oven bricklaying operations, etc., can solve problems such as complex structural design, and achieve the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

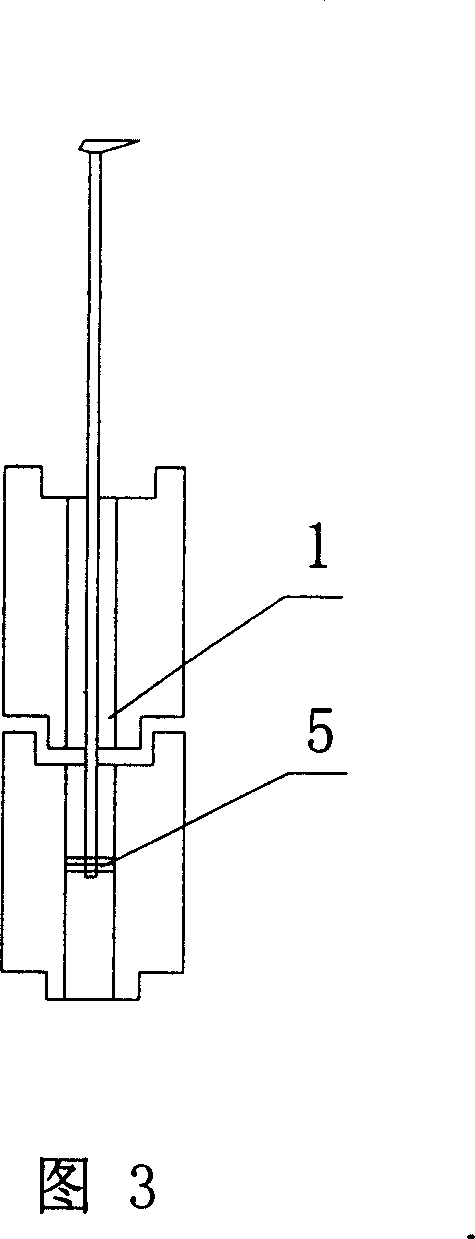

[0035] 1. The method for keeping the furnace body clean during the masonry process of the 7.63m coke oven includes the following steps:

[0036] (1) Cleaning of brick gas channels:

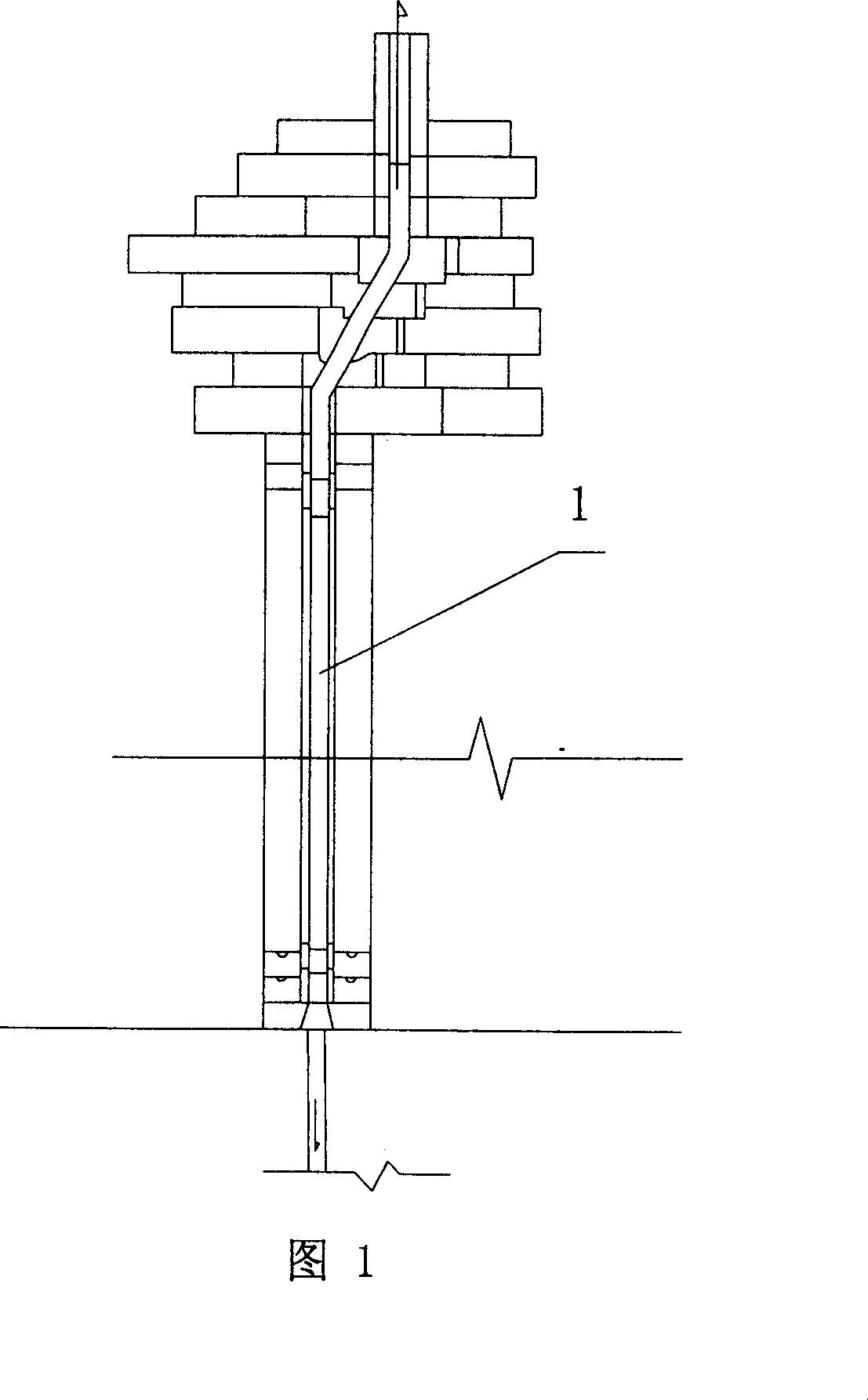

[0037] The structure of the brick gas channel of the 7.63m coke oven is shown in Figure 1.

[0038] 1. Preparations

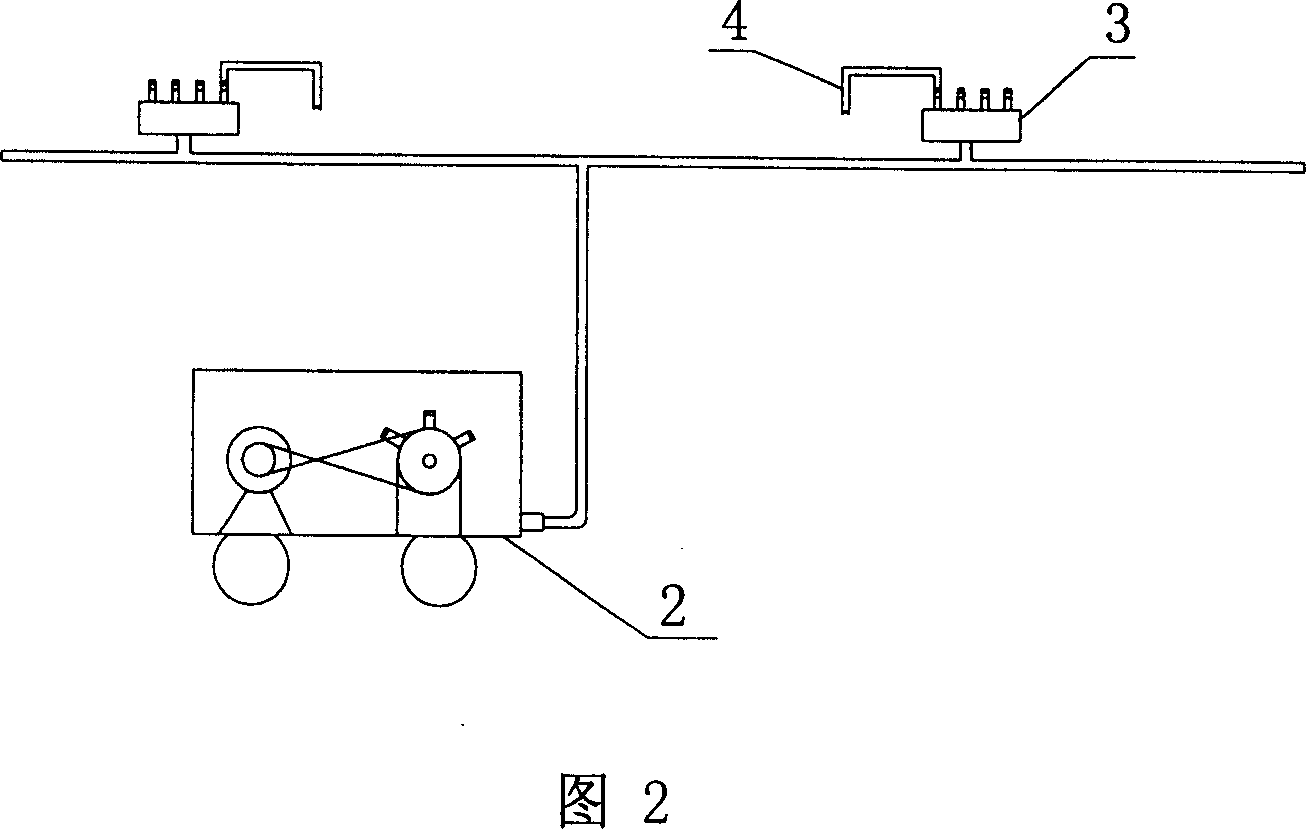

[0039] (1) Mechanical configuration

[0040] According to the test before construction, each 9m 3 / min air compressor can meet the blowing requirements of 4-5 blowing pipes, then 10 mutual aid groups blowing at the same time, at least two 9m 3 / min air compressor.

[0041] (2) Preparation of materials and tools

[0042] The materials and tools to be prepared mainly include: high-pressure air pipe, steel pipe with two ends of wire, small wind bag, small butterfly valve, three-way pipe fittings, special pulling barrel, etc. See Table 1 for details:

[0043] serial number

name specification

unit

quantity

1

High pressure air pipe, φ50

M

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com