Perovskite solar cell preparation method

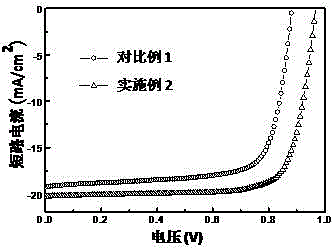

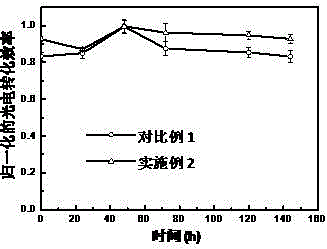

A solar cell and perovskite technology, applied in the field of solar cells, can solve problems such as high preparation requirements, low output voltage and short-circuit current, poor device performance and stability, etc., and achieve simple operation, increased open circuit voltage, and improved service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

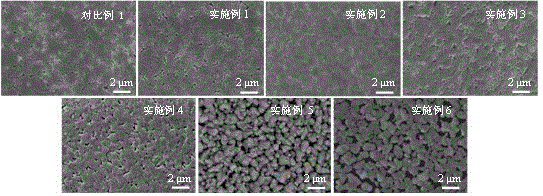

Embodiment 1

[0031] A preparation method for a perovskite solar cell, characterized in that the preparation steps are as follows:

[0032] (1) Cleaning and ozone treatment of ITO substrates: After scrubbing the ITO substrates with detergent, place the ITO substrates in deionized water, ethanol, acetone, and deionized water in sequence, ultrasonic cleaning for 12 minutes each time, and then Blow dry with a nitrogen gun, and then put the ITO substrate into an ozone machine for ozone treatment for 12 minutes;

[0033] (2) Spin coating of hole transport layer (PEDOT:PSS): Spin coat a layer of hole transport layer on the surface of the ITO substrate after ozone treatment, control the speed at 4000rpm, time is 40s, and then perform annealing treatment, controlled annealing The temperature is 100°C, the annealing time is 40min, and the substrate A is obtained;

[0034] (3) CH doped with water 3 NH 3 PB 3-x Cl x Precursor solution configuration: NH 3 CH 3 I and PbI 2 Mix and dissolve in N,...

Embodiment 2

[0040] The difference between Example 2 and Example 1 is that 2% by volume of water is added in step (3), and the rest of the steps are the same as in Example 1.

Embodiment 3

[0042] The difference between Example 3 and Example 1 is that 3% by volume of water is added in step (3), and the rest of the steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com