Method for removing heavy metals from activated sludge

A technology for activated sludge and heavy metal removal, applied in the field of heavy metal removal and activated sludge removal of heavy metals, can solve the problems of waste of organic components, high treatment cost, and high equipment investment, and achieves good effect, simple process, and low equipment investment requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

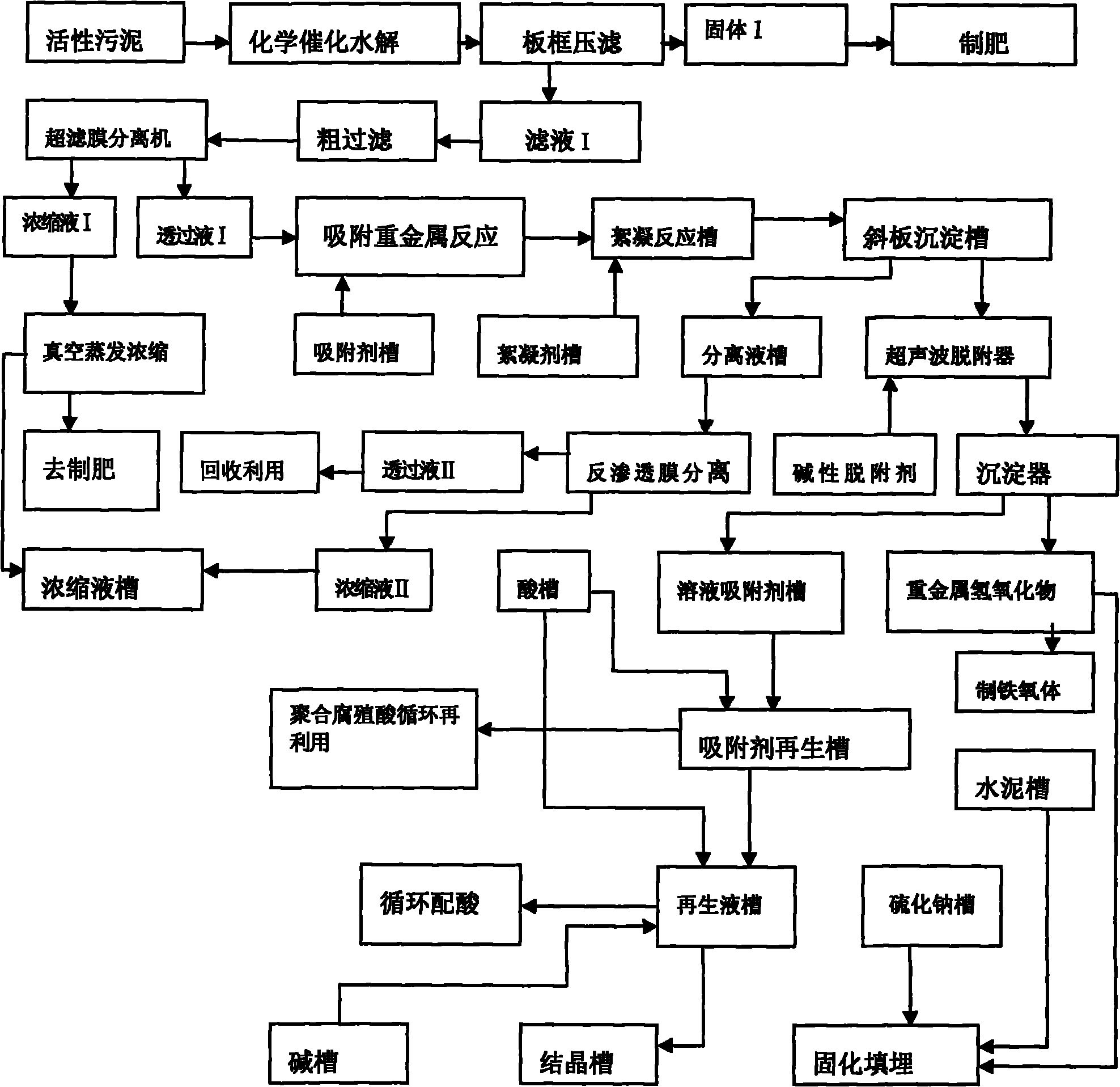

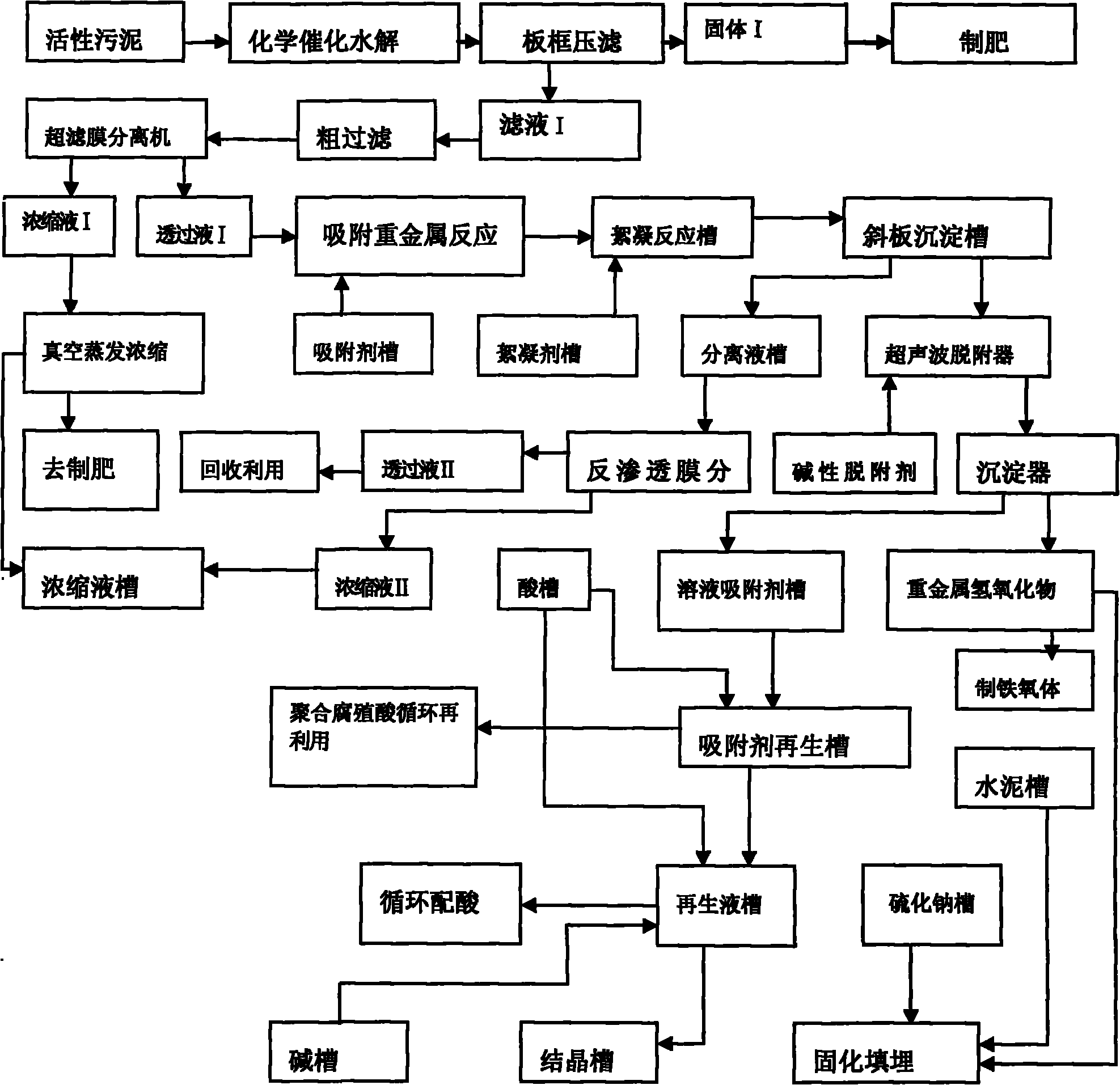

[0040] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0041] Such as figure 1 Shown, illustrate embodiment in conjunction with technical process of the present invention

[0042] A method for removing heavy metals from activated sludge, comprising the steps of:

[0043] (1) The activated sludge from the sewage treatment plant is used, and the activated sludge is firstly treated by chemical catalytic hydrolysis. For specific steps, refer to the chemical catalytic hydrolysis treatment method introduced in Chinese Patent Publication No. CN1868976. First, in the reaction tank, the organic solid waste is hydrolyzed and acidified by medium-temperature anaerobic fermentation or high-temperature anaerobic fermentation to produce organic acids; the generated organic acids are used as catalysts, and the activated s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com