Patents

Literature

37results about "Hydrogen production carbon capture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

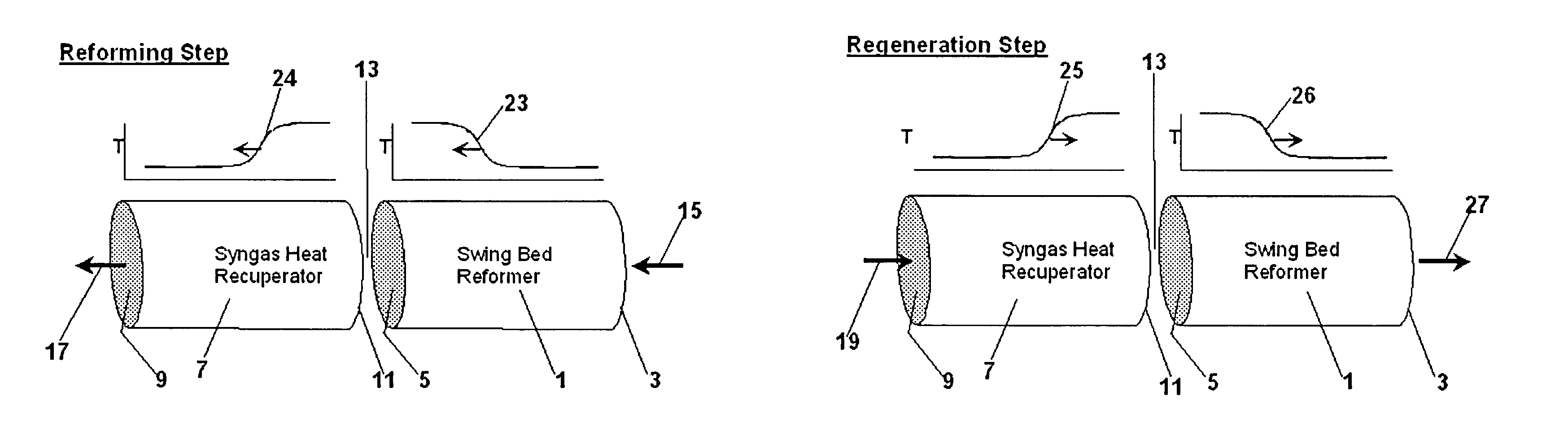

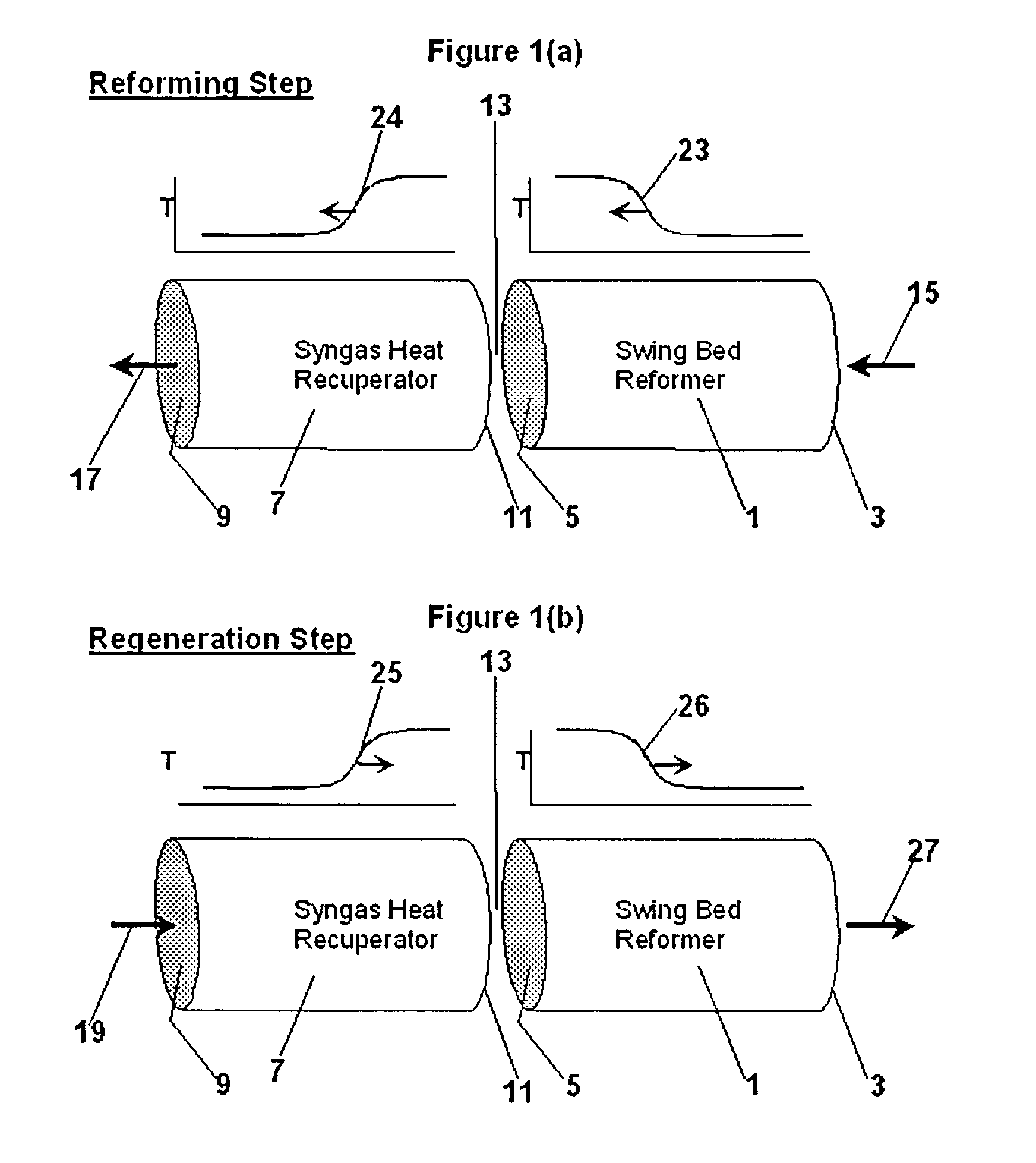

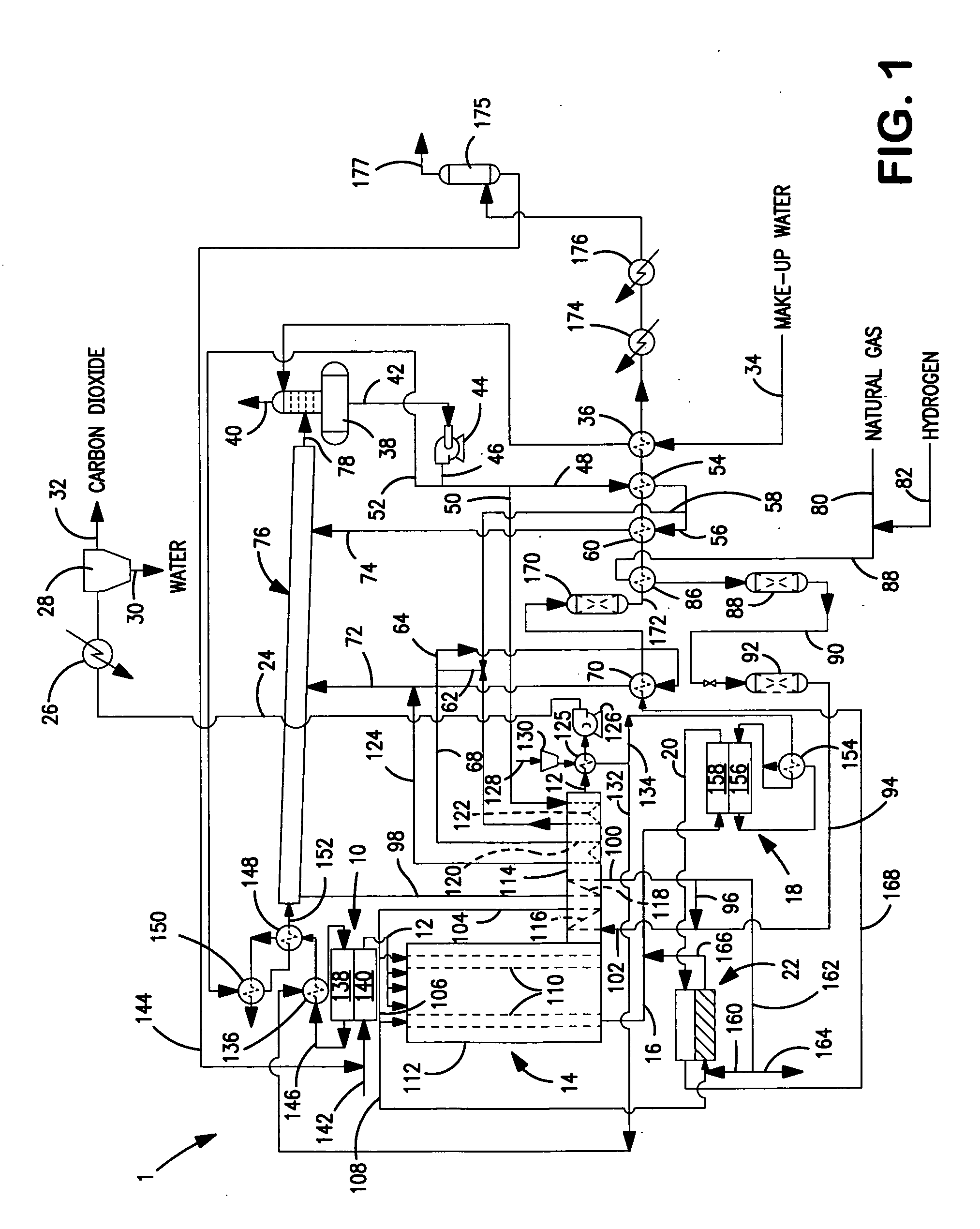

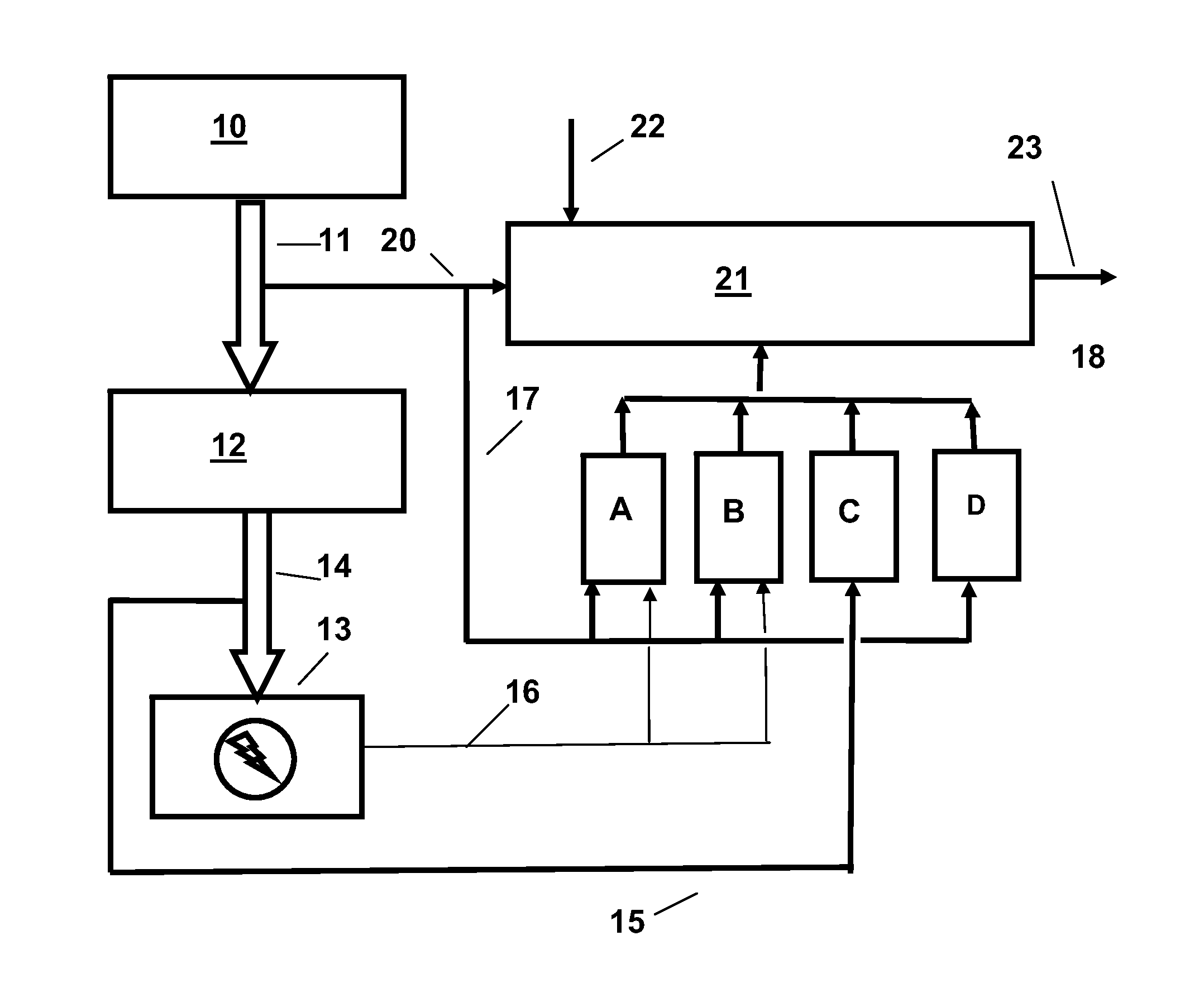

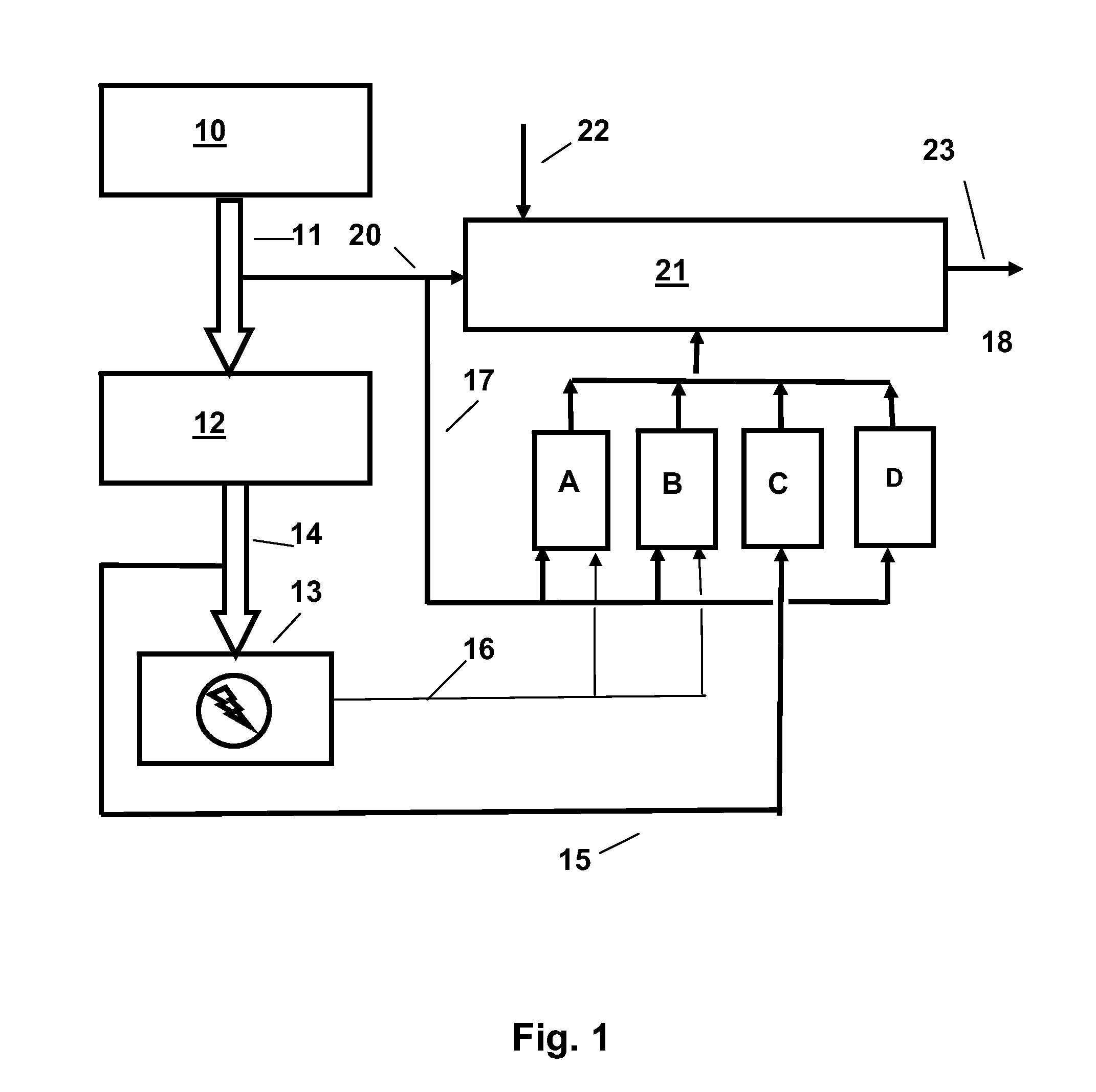

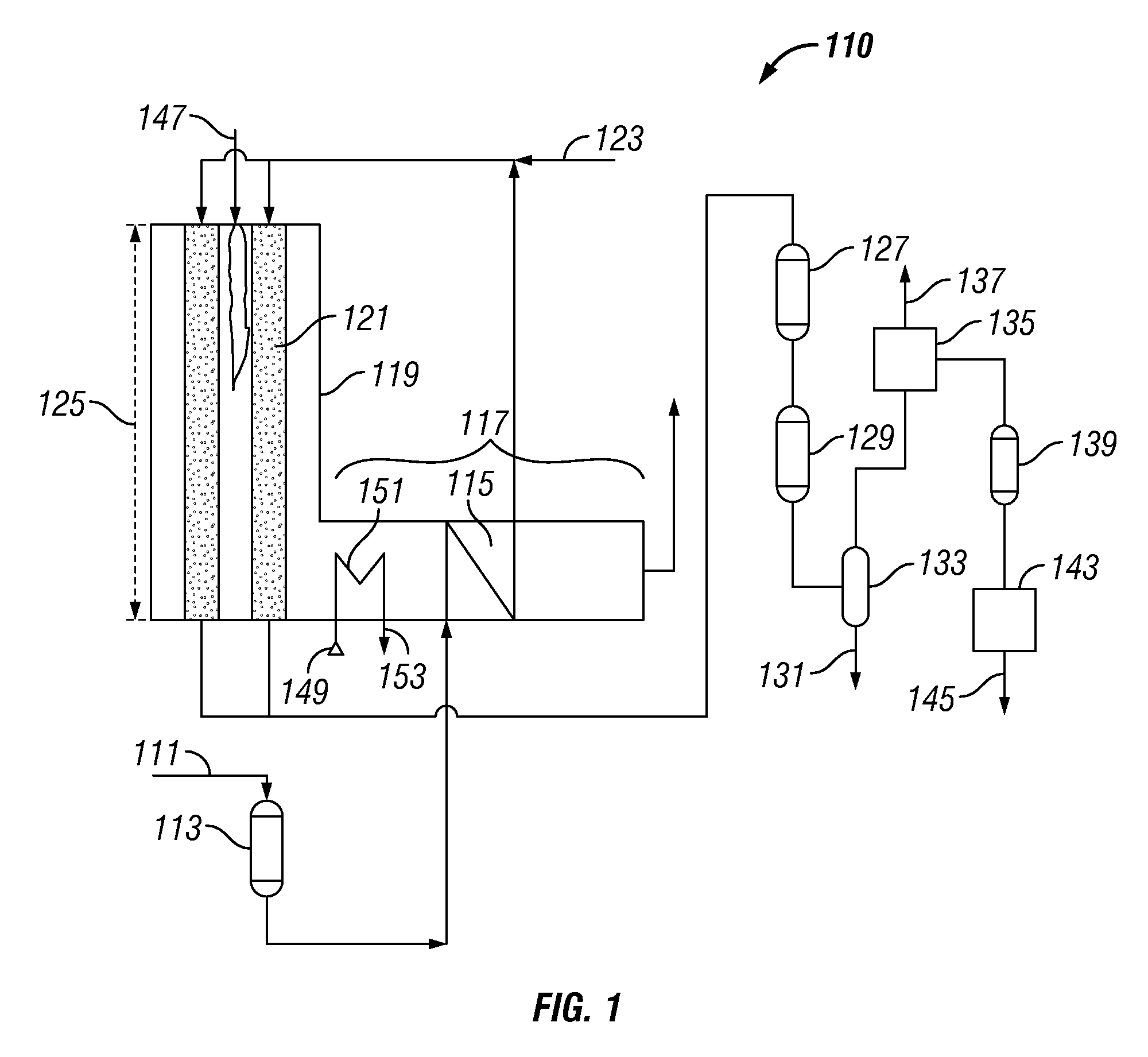

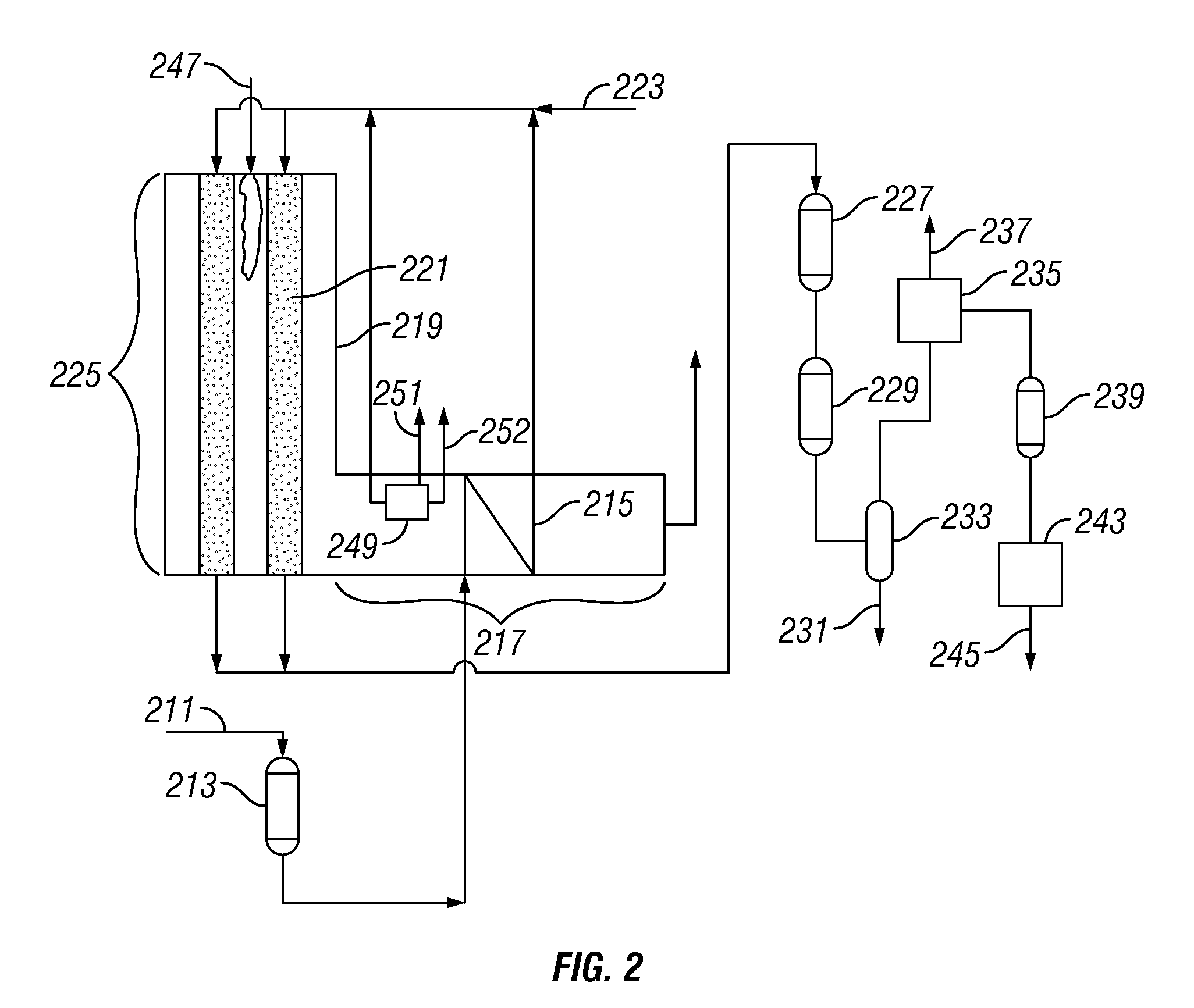

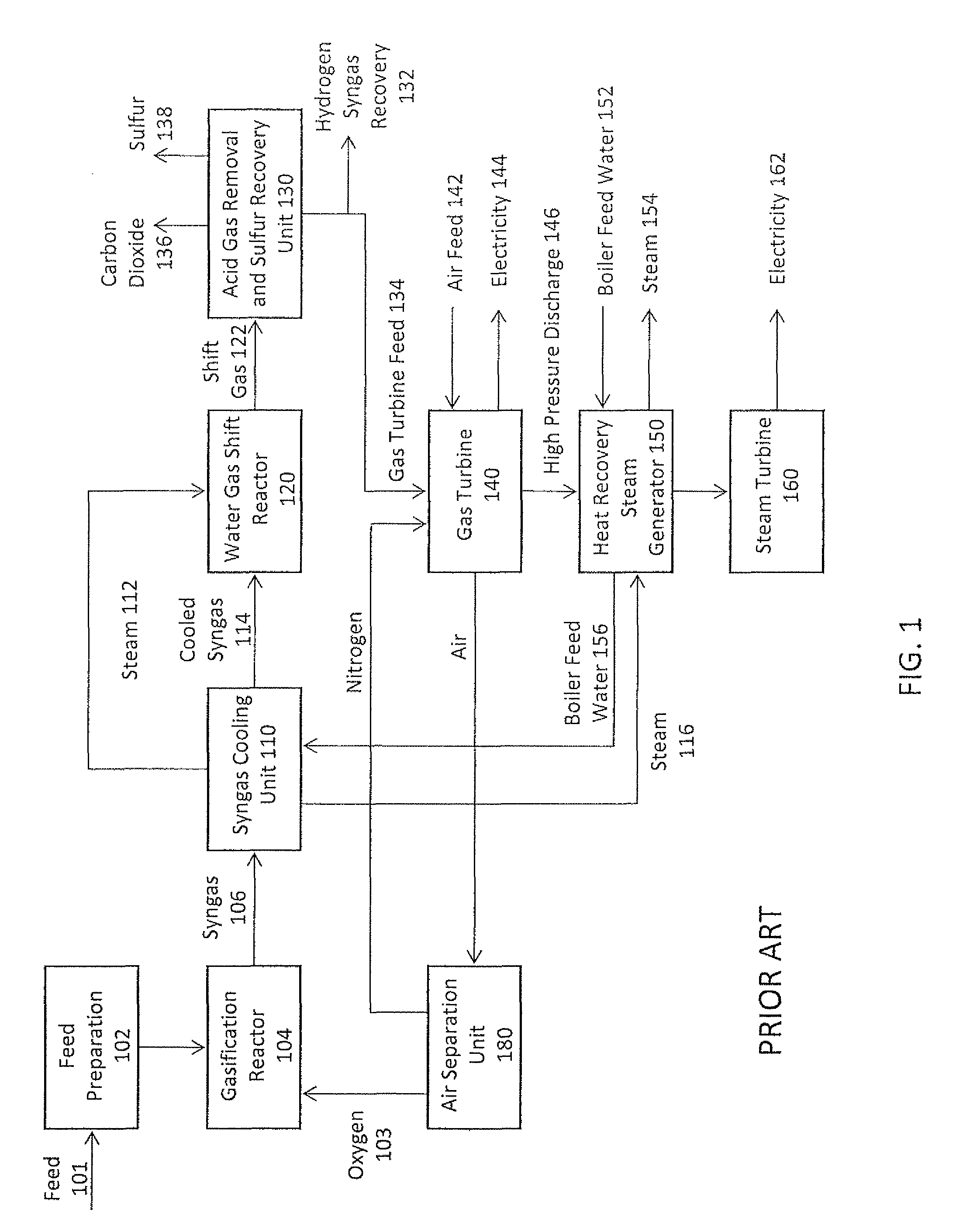

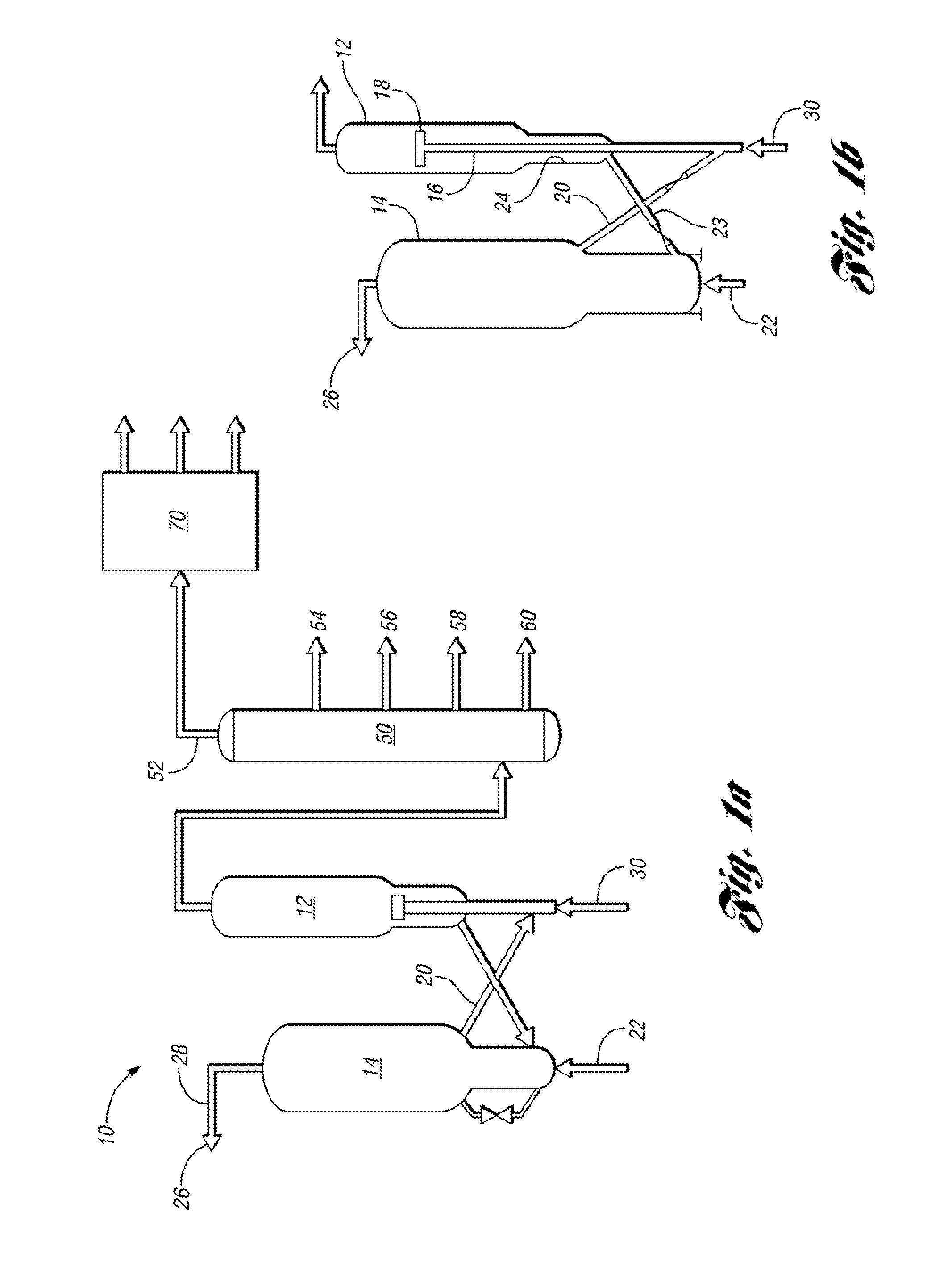

Integration of hydrogen and power generation using pressure swing reforming

ActiveUS7815892B2Improve processing efficiencyHydrogen separation using solid contactHydrogen production carbon captureHydrogenEngineering

The invention provides a method for generating power with a gas turbine which utilizes pressure swing reforming under conditions that facilitate CO2 capture. First a synthesis gas stream at a first pressure is produced in a pressure swing reformer. Next the synthesis gas stream is subjected to a high temperature water gas shift process to produce a CO2 containing hydrogen enriched stream from which hydrogen and CO2 each are separated. The separated hydrogen in turn is combusted with air to produce a gas turbine and the separated CO2 is easily sequestered.

Owner:EXXON RES & ENG CO

Synthesis gas and carbon dioxide generation method

A method of generating a synthesis gas product stream and carbon dioxide in which a fuel is combusted in an oxygen transport membrane combustor to produce a flue gas stream containing the carbon dioxide and water. Reforming duty is divided between a combined reforming process and a gas heated reformer to produce the product stream. The flue gas stream is used to supply heat to a primary, steam methane reforming stage of the combined reforming process. Residual methane, produced in the primary stage, is reacted in a secondary stage having an oxygen transport membrane reactor. Heat produced in the secondary stage is supplied to the gas heated reactor to support its operation. The flue gas stream is cooled and water is separated therefrom to produce the carbon dioxide at a concentration of at least 85 mol percent.

Owner:PRAXAIR TECH INC

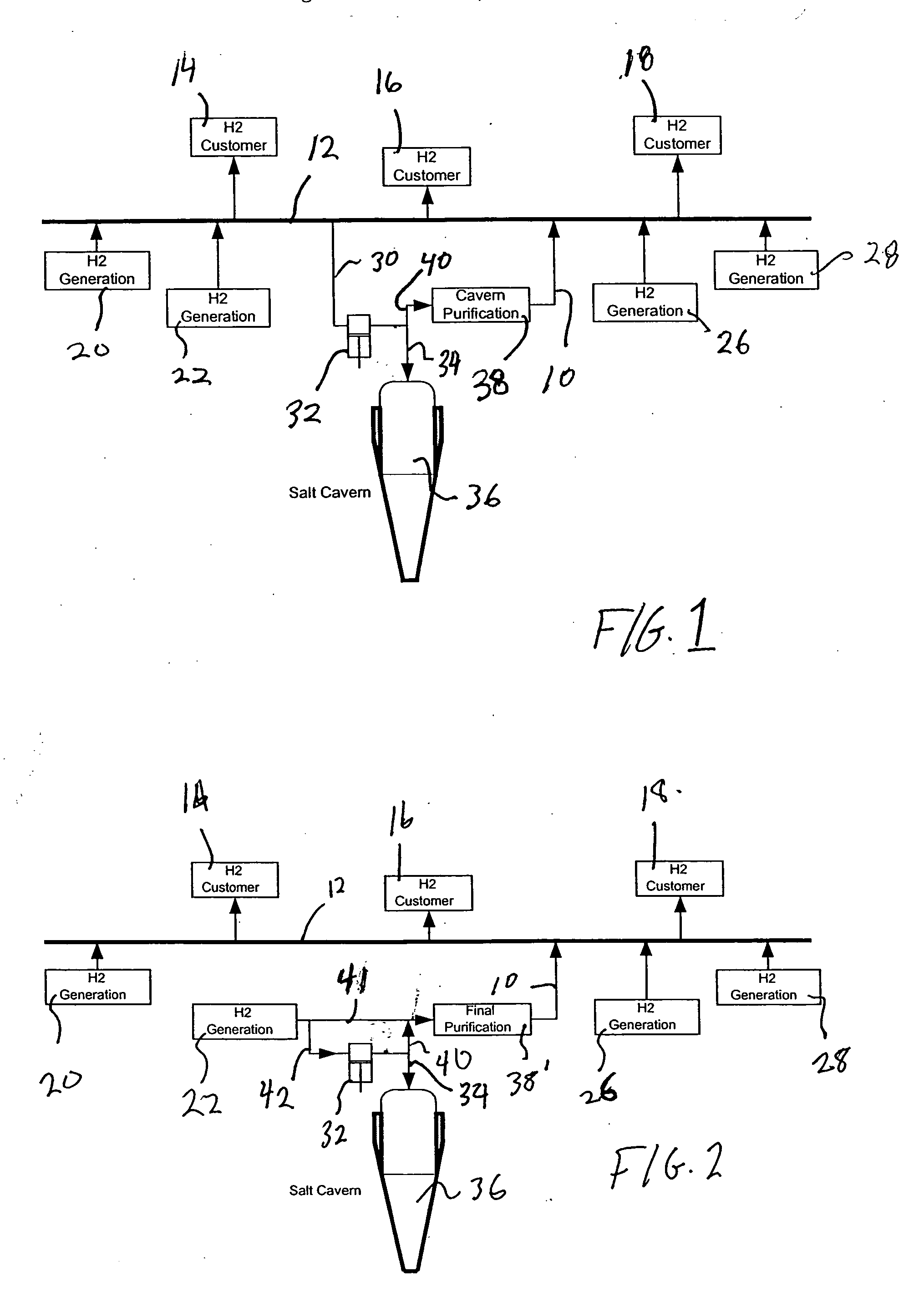

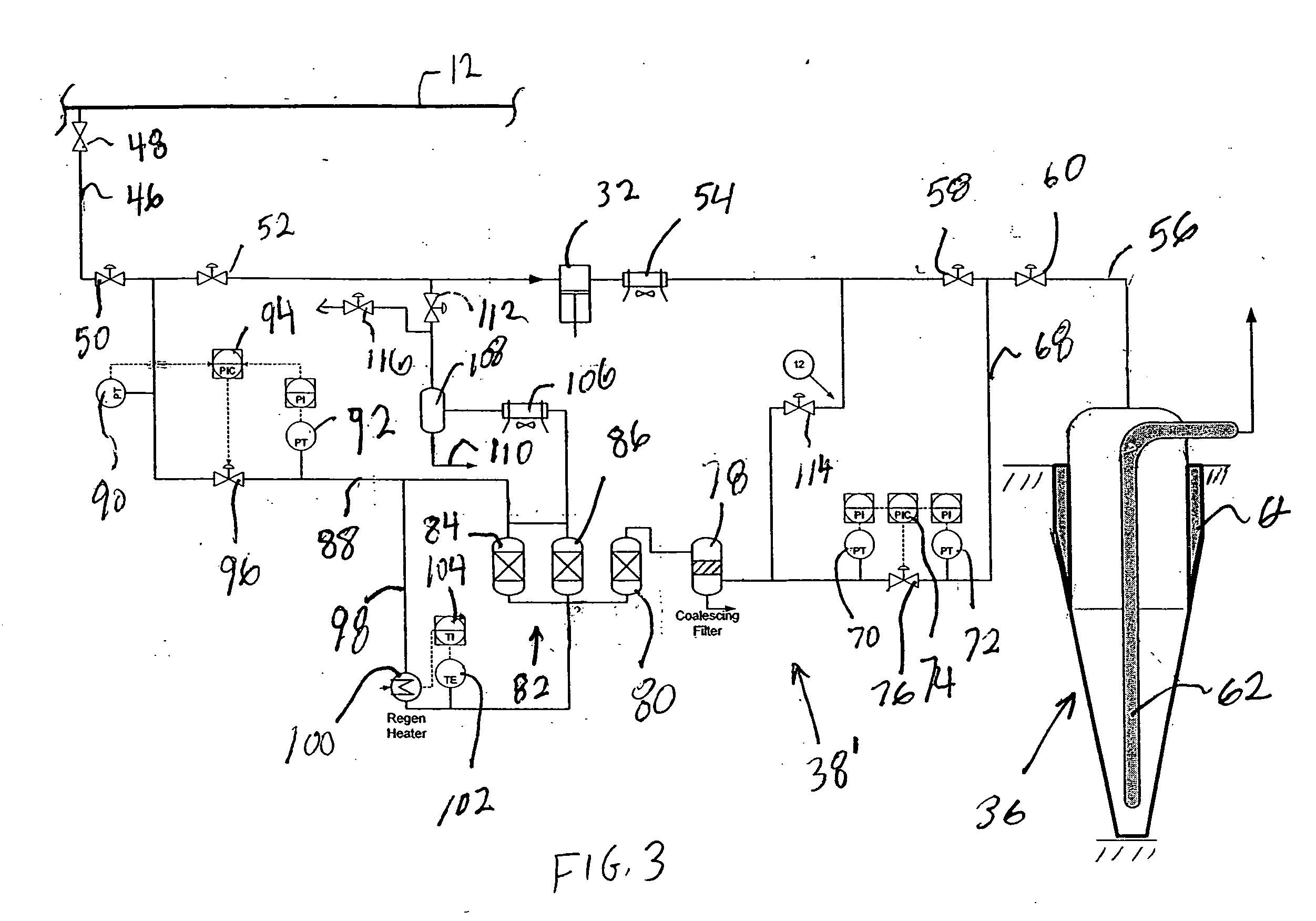

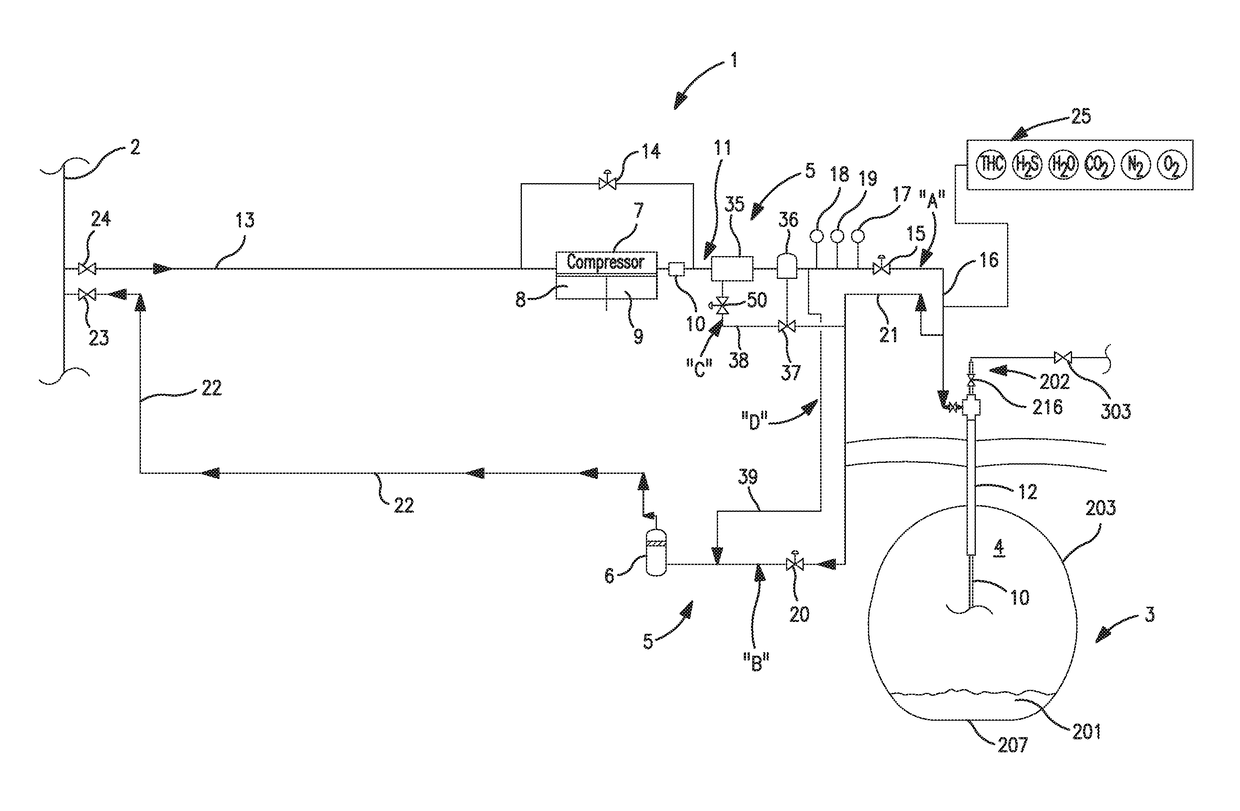

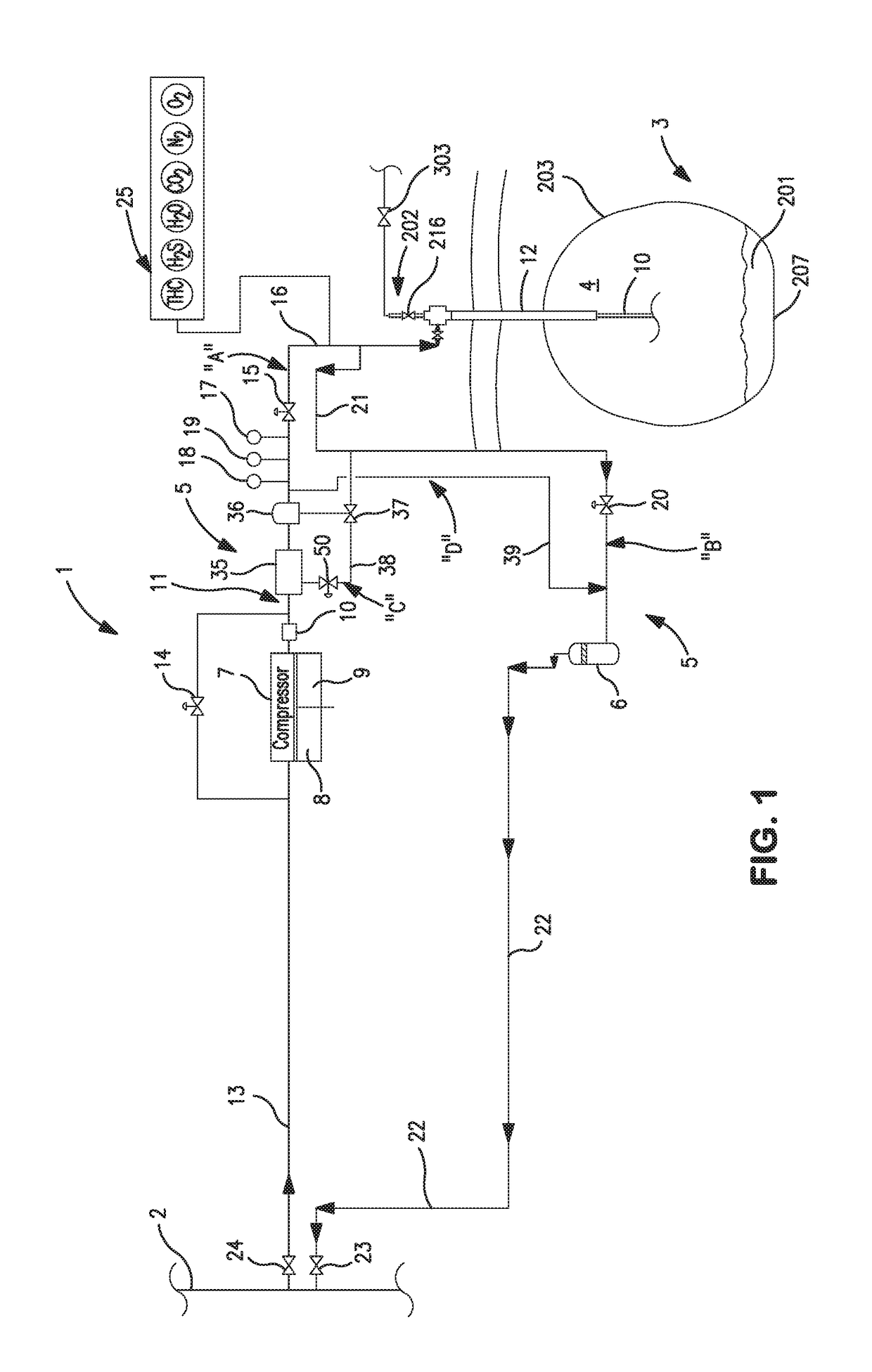

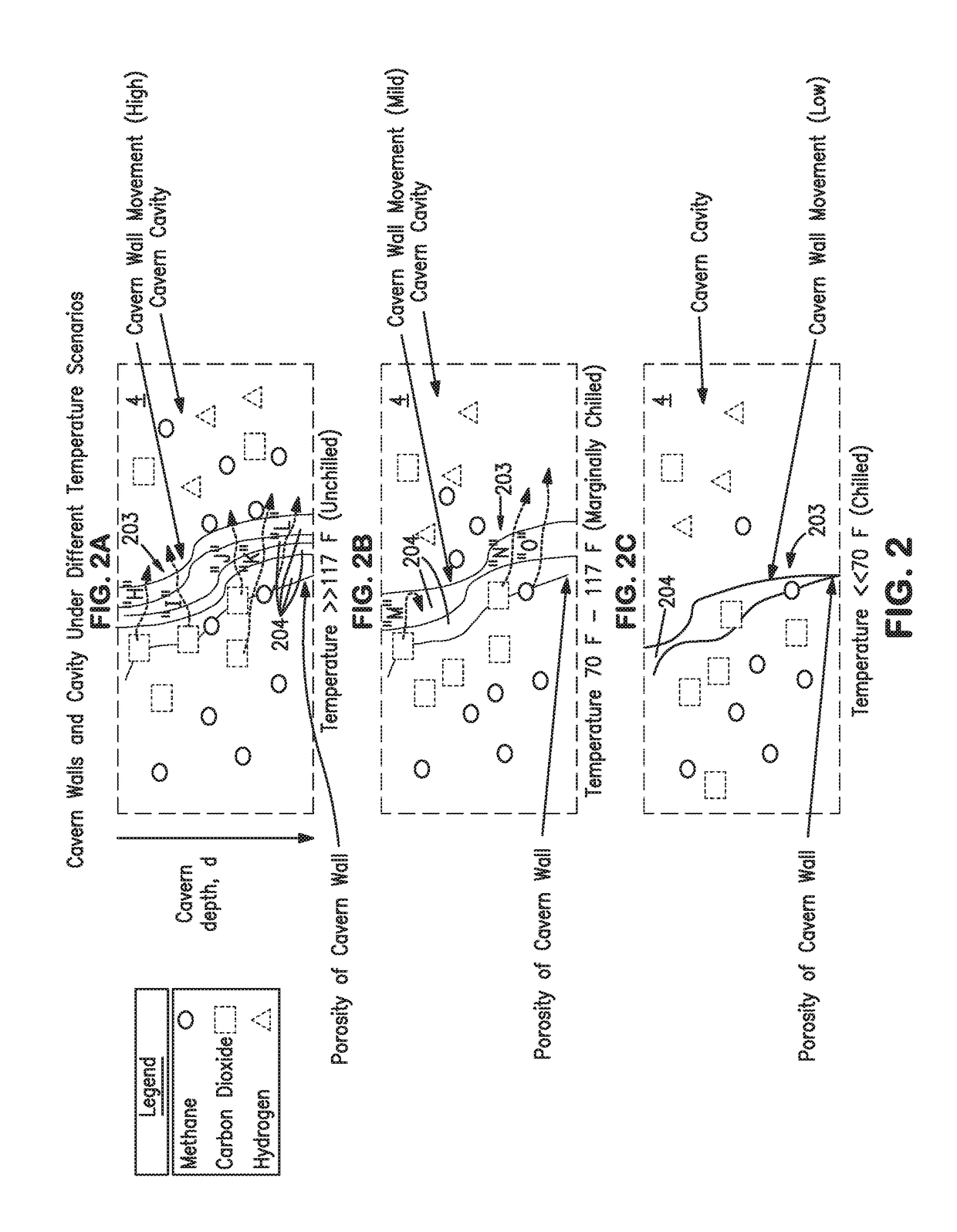

Method of storing and supplying hydrogen to a pipeline

A method of storing and supplying a gaseous hydrogen product to a pipeline under a product purity specification in which a hydrogen stream made up of gaseous hydrogen is compressed to form a compressed hydrogen stream and introduced into a salt cavern for storage. A crude hydrogen stream, contaminated from storage in the salt cavern is recovered and purified by sufficiently removing at least carbon dioxide and water vapor to produce a hydrogen product stream having an impurity level at or below the product purity specification. The hydrogen product stream is supplied back to the pipeline. Alternatively, during periods of low demand, hydrogen produced by a production facility is both purified and supplied to the pipeline and stored in the salt cavern. During high demand period, both the output of the production facility and hydrogen retrieved from the salt cavern are purified and supplied to the pipeline.

Owner:PRAXAIR TECH INC

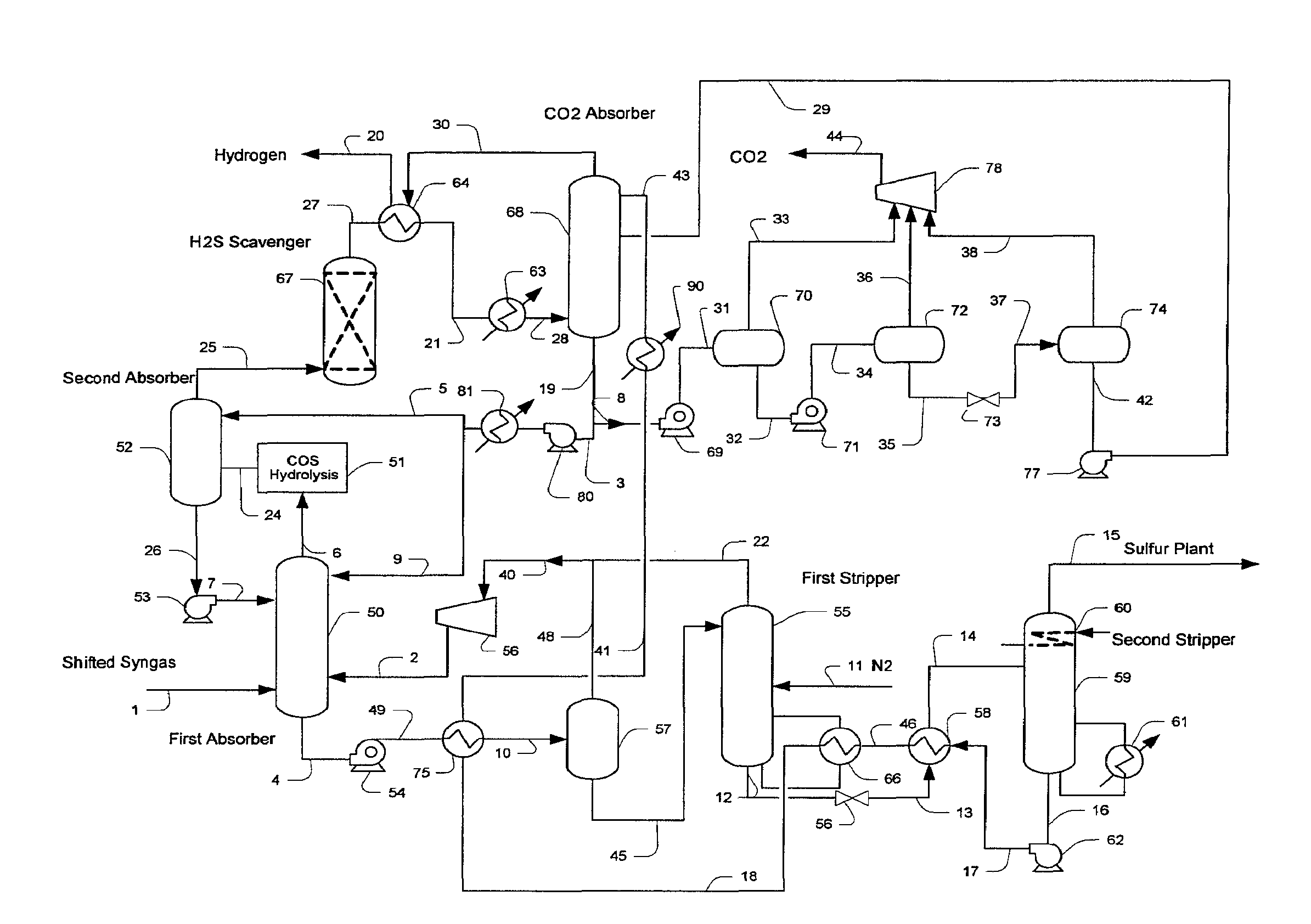

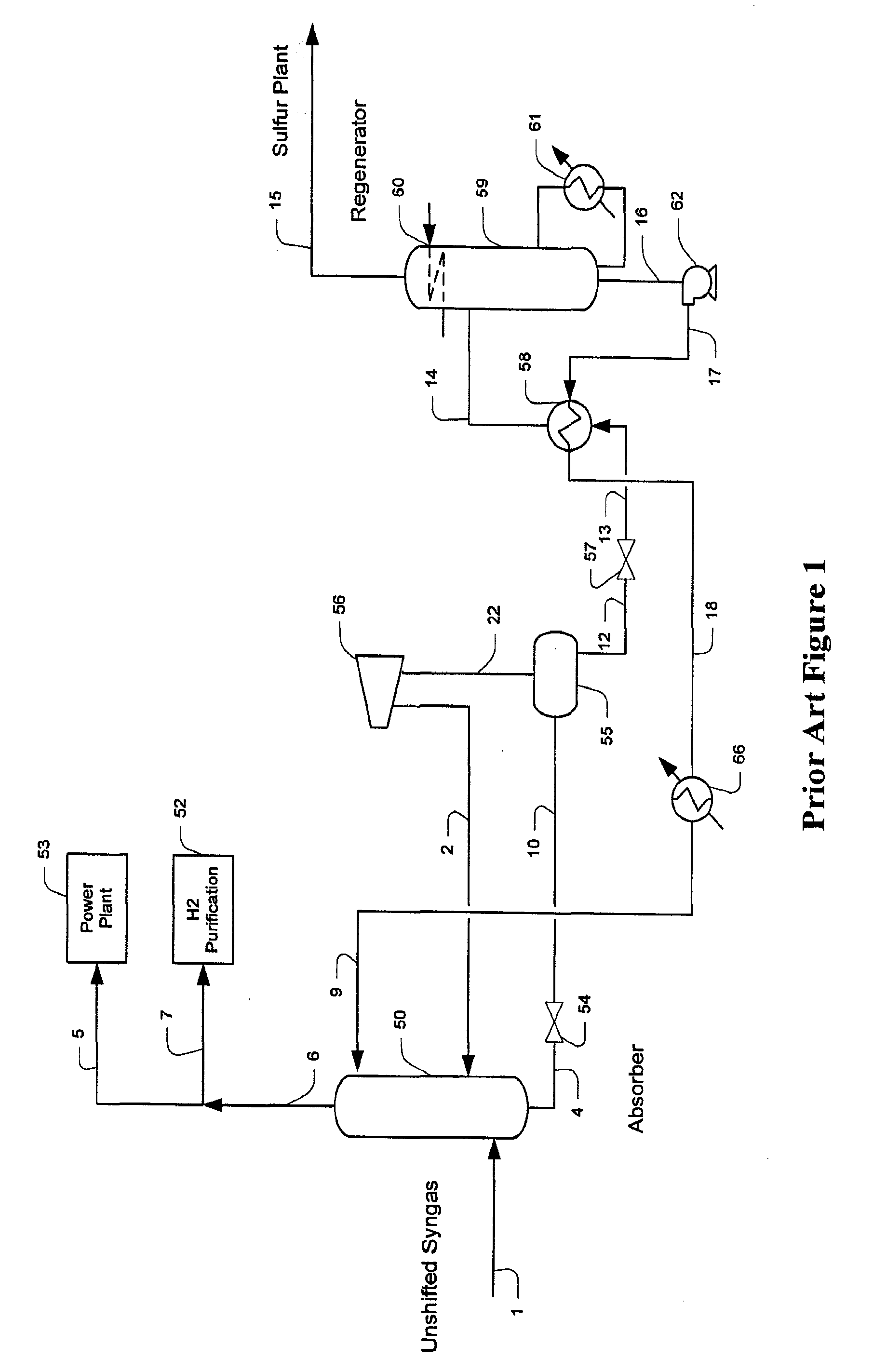

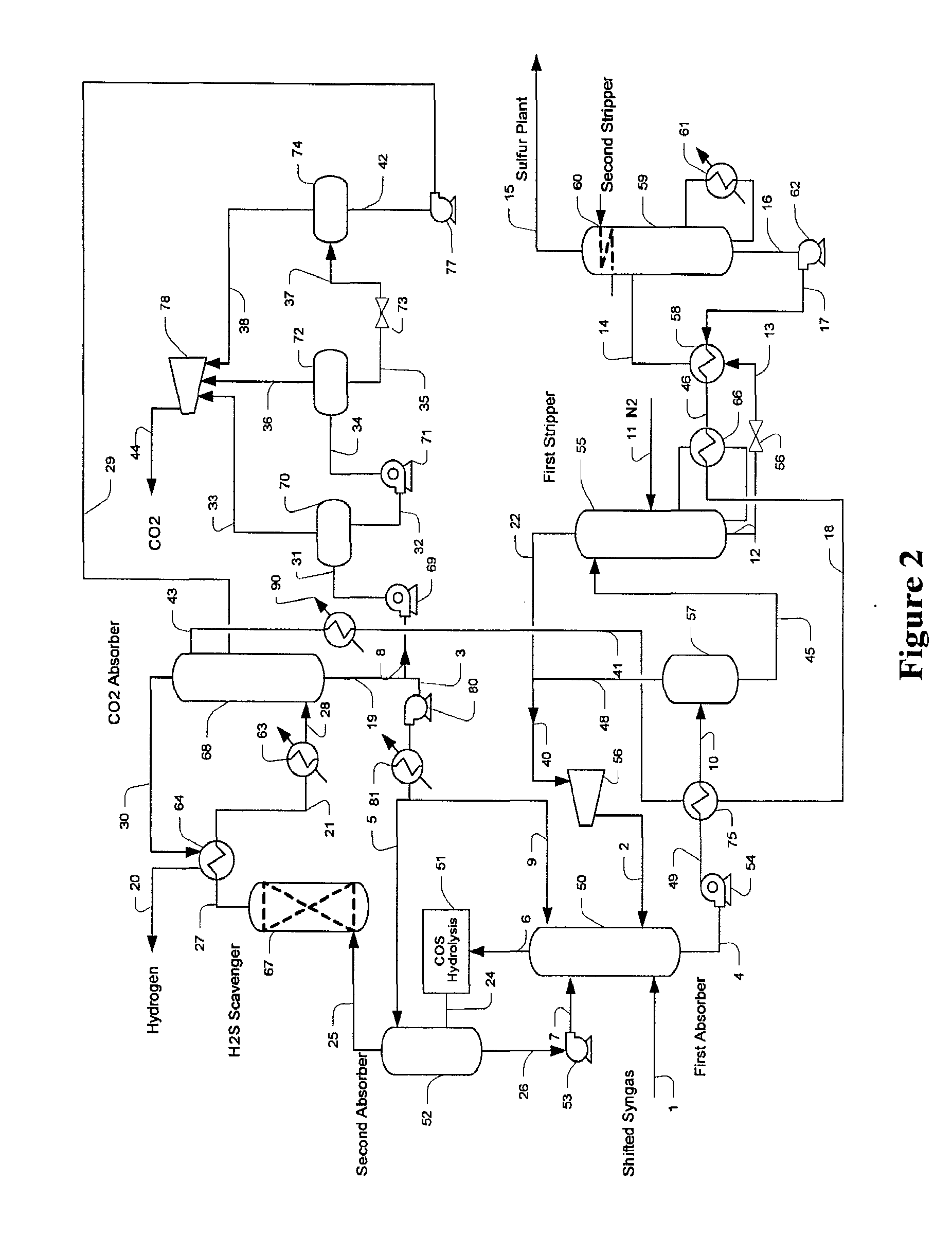

Configurations And Methods For Carbon Dioxide And Hydrogen Production From Gasification Streams

InactiveUS20100111784A1Significant energy savingSave energyCarbon compoundsHydrogen production carbon captureSyngasSolvent

A syngas treatment plant is configured to remove sulfurous compounds and carbon dioxide from shifted or un-shifted syngas in a configuration having a decarbonization section and a desulfurization section. Most preferably, the solvent in the decarbonization section is regenerated and cooled by flashing, while the solvent is regenerated in the desulfurization section via stripping using external heat, and it is still further preferred that carbonylsulfide is removed in the desulfurization section via hydrolysis, and that the so produced hydrogen sulfide is removed in a downstream absorber.

Owner:FLUOR TECH CORP

Integrated processes for generating carbon monoxide for carbon nanomaterial production

The integrated processes of the dry reforming or partial oxidation upstream of the carbon nanotube-producing reactor are described allowing the carbon monoxide to be produced on an as-needed basis, negating the need to transport carbon monoxide to the production site or store large quantities of carbon monoxide on-site. The apparatuses allowing to carry out such integrated processes are also provided. Carbon dioxide emissions may be eliminated from the carbon nanotube production process. This may be achieved by recycling the carbon dioxide byproduct and mixing it with the feed to the partial oxidation process.

Owner:MCKEIGUE KEVIN +2

Method and system for supplying synthesis gas

InactiveUS20100163804A1Increase the molar ratioReduce the amount requiredHydrogenHydrocarbon from carbon oxidesDownstream processingOxidizing agent

A method for supplying synthesis gas comprising reacting a carbonaceous feed with an oxidant, to generate synthesis gas; forwarding all or part of the generated synthesis gas to an underground storage location, to generate a synthesis gas buffer; and retrieving synthesis gas from the underground storage location and supplying the retrieved synthesis gas to a downstream processing unit, which downstream processing unit is substantially continuously converting synthesis gas.Conveniently the downstream processing unit can comprise a water-gas shift unit and the invention further provides a system for supplying synthesis gas comprising: a gasification unit, for generating synthesis gas from a carbonaceous feed and an oxidant, that is at least directly or indirectly connected to an underground storage location; an underground storage location, for generating a synthesis gas buffer, that is at least connected directly or indirectly to the gasification unit and at least connected directly or indirectly to a water-gas shift unit; and a water-gas shift unit, for generating a shifted synthesis gas, that is at least connected directly or indirectly to the underground storage location.

Owner:SHELL OIL CO

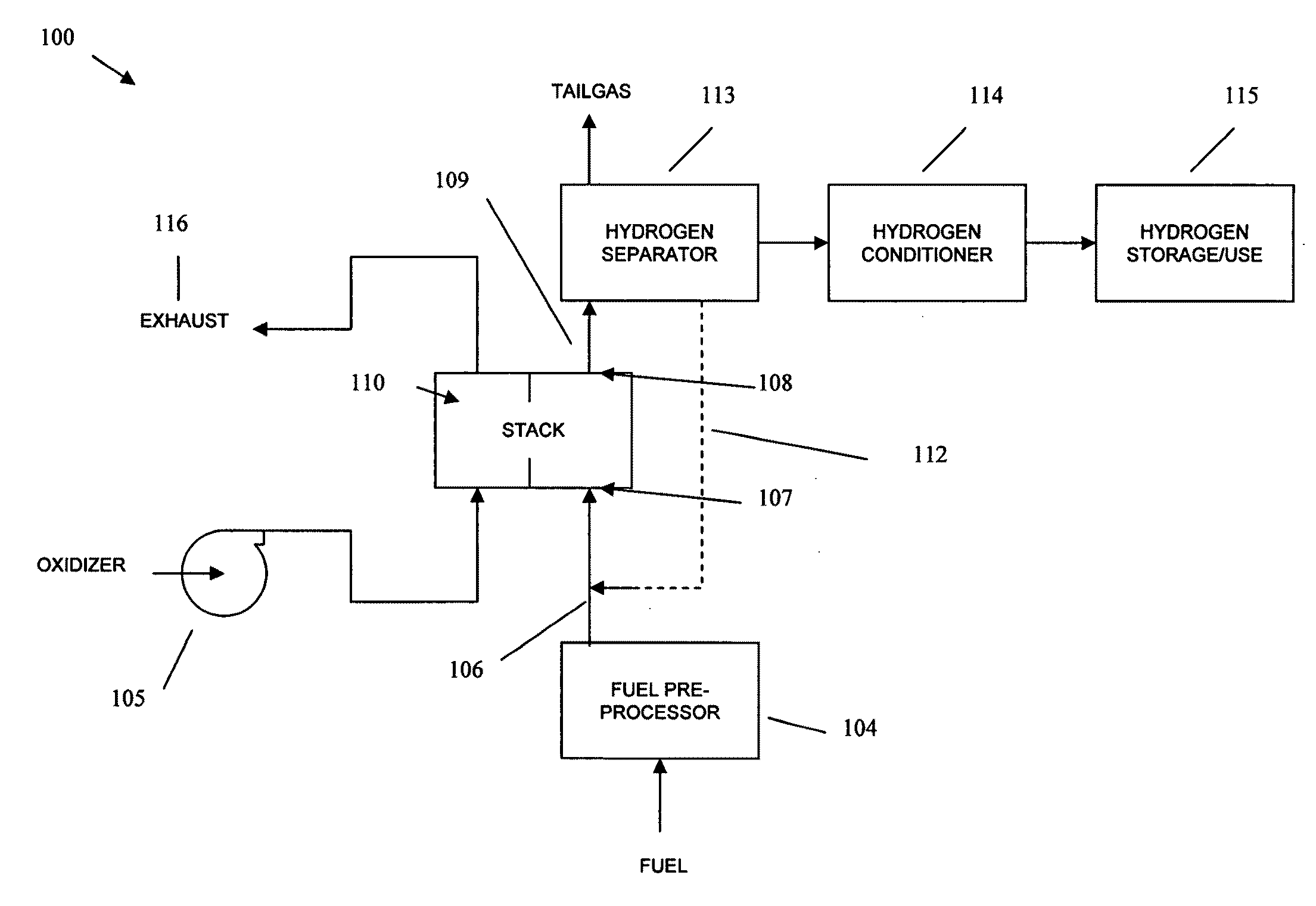

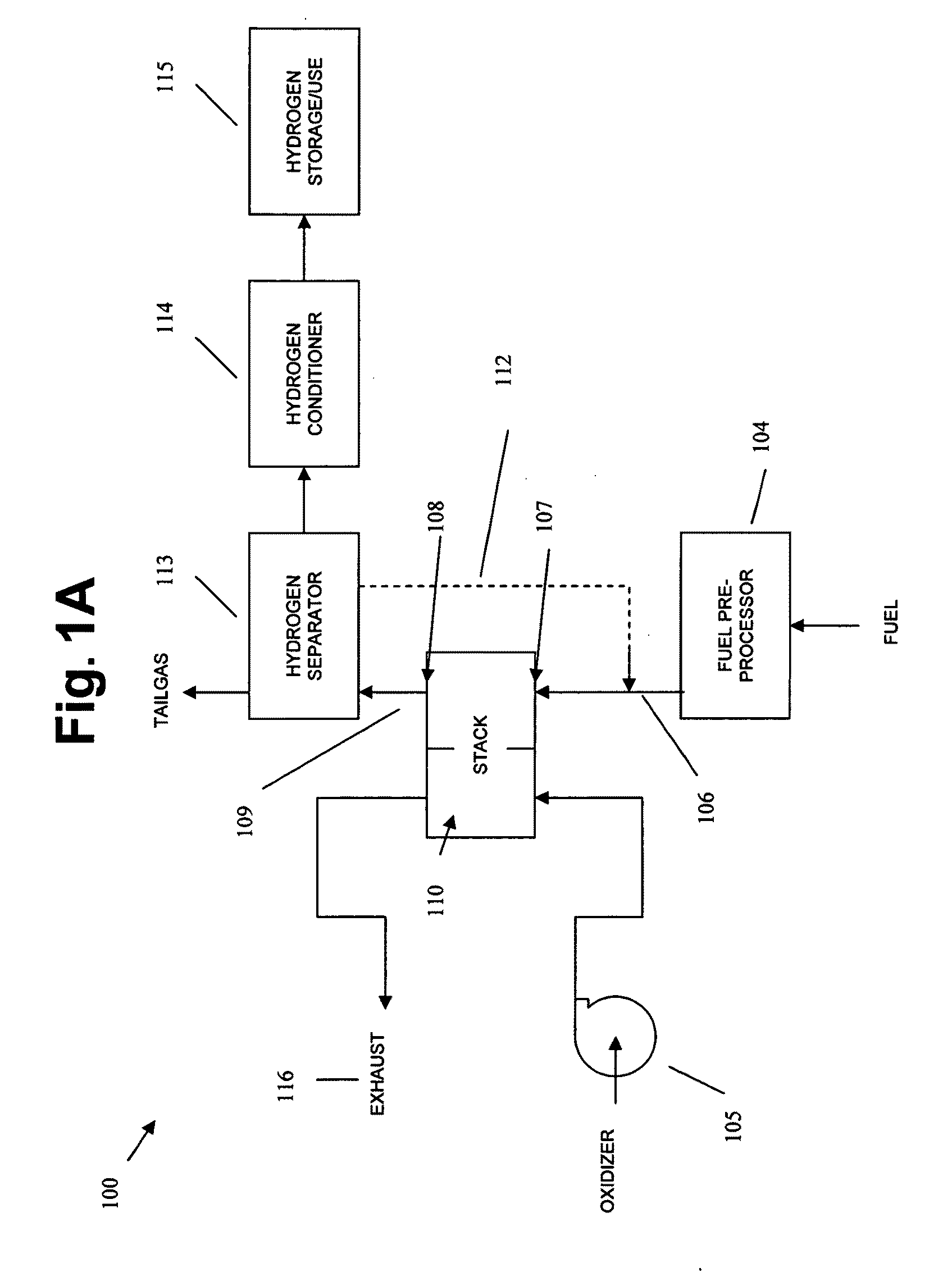

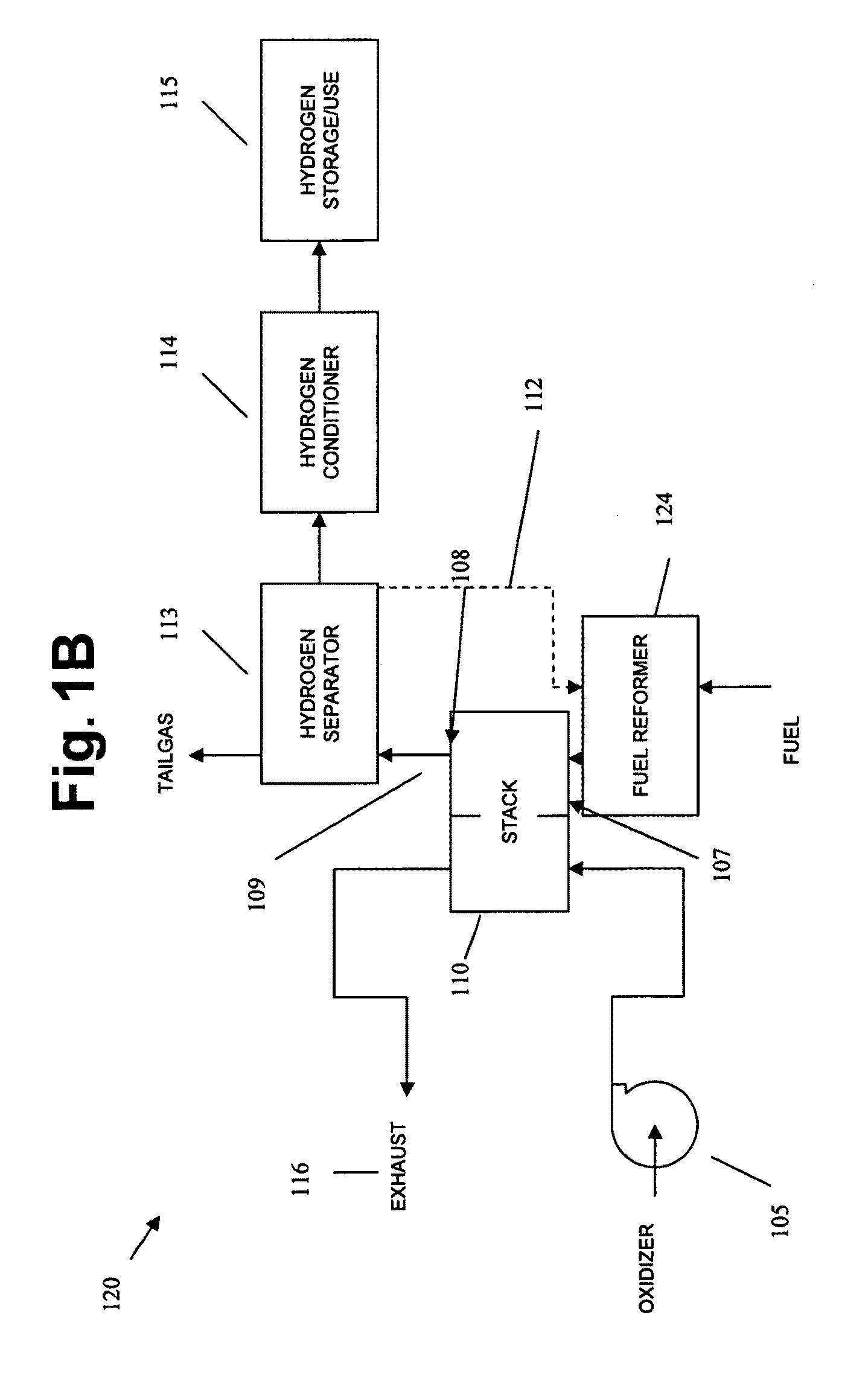

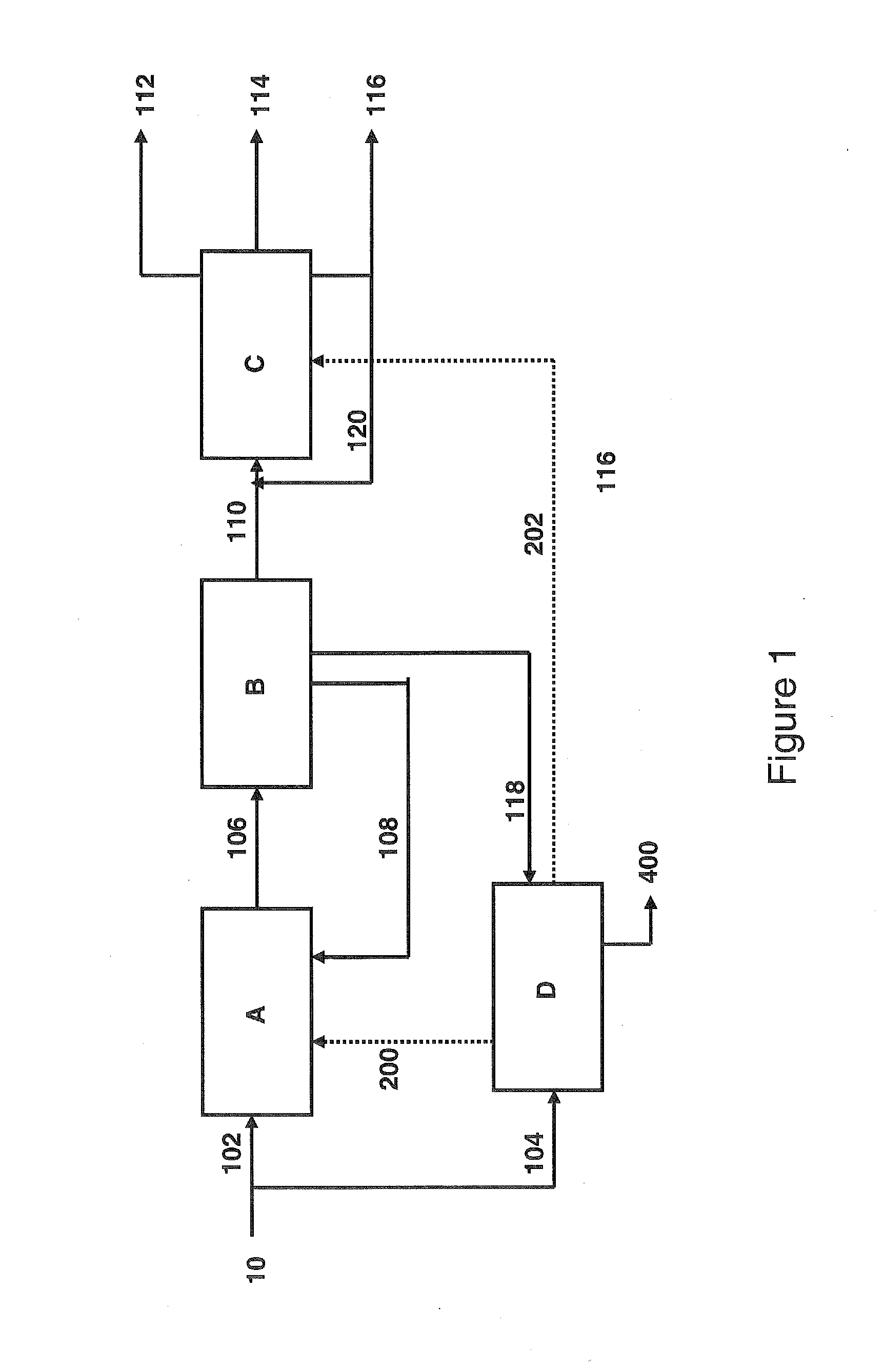

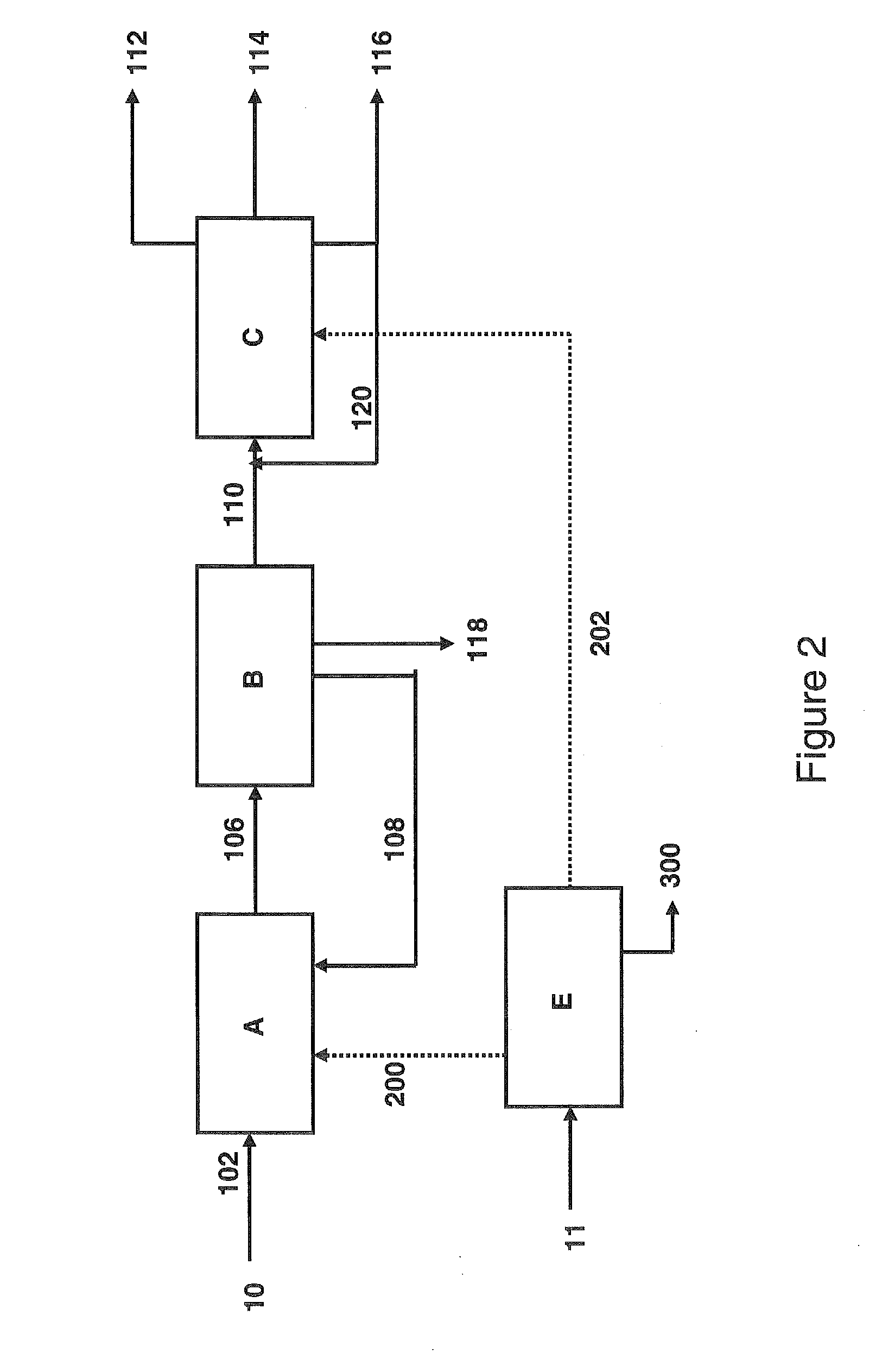

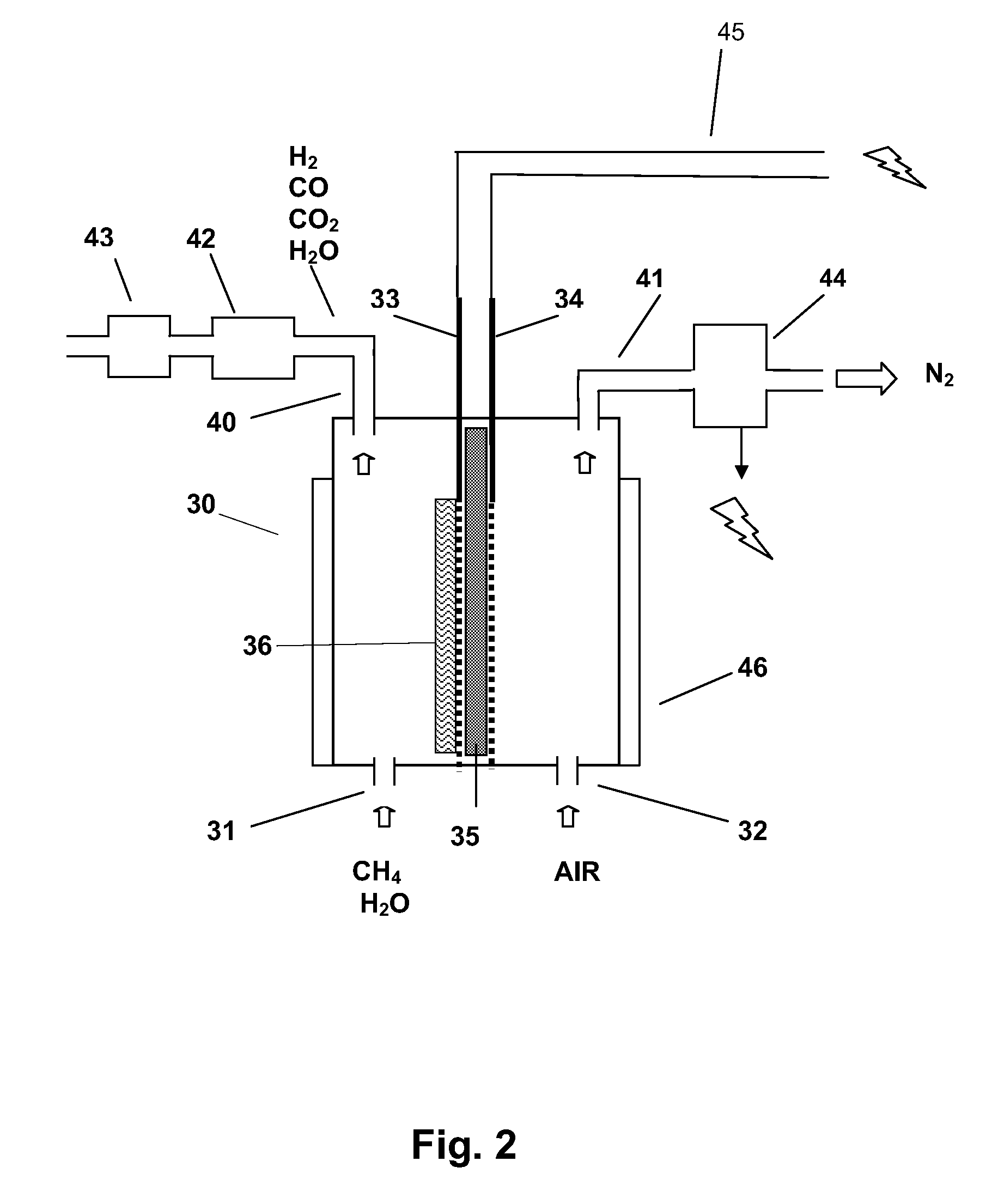

Co-production of hydrogen and electricity in a high temperature electrochemical system

A high temperature electrochemical system, such as a solid oxide fuel cell system, generates hydrogen and optionally electricity in a fuel cell mode. At least a part of the generated hydrogen is separated and stored or provided to a hydrogen using device. A solid oxide regenerative fuel cell system stores carbon dioxide in a fuel cell mode. The system generates a methane fuel in an electrolysis mode from the stored carbon dioxide and water by using a Sabatier subsystem. Alternatively, the system generates a hydrogen fuel in an electrolysis mode from water alone.

Owner:BLOOM ENERGY CORP

Carbon material conversion process comprising two liquefaction stages in a boiling bed in the presence of hydrogen generated by non-fossil sources

InactiveUS20120036764A1Limit greenhouse gas emissionEmission controlHydrogen production carbon captureLiquid hydrocarbon mixture productionOrganismal ProcessDecomposition

A process for converting carbon material into fuel bases comprising two liquefaction stages in the presence of hydrogen in a boiling-bed reactor containing a supported catalyst and integrating a hydrogen production stage generated by non-fossil sources that do not emit CO2. The hydrogen production stage comprises the gasification of biomass and / or the decomposition of water, hydrochloric acid, hydrogen chloride or hydrogen sulfide by thermal, electrolytic, chemical or biological processes. The thus produced hydrogen is sent into at least one of the liquefaction stages.

Owner:INST FR DU PETROLE

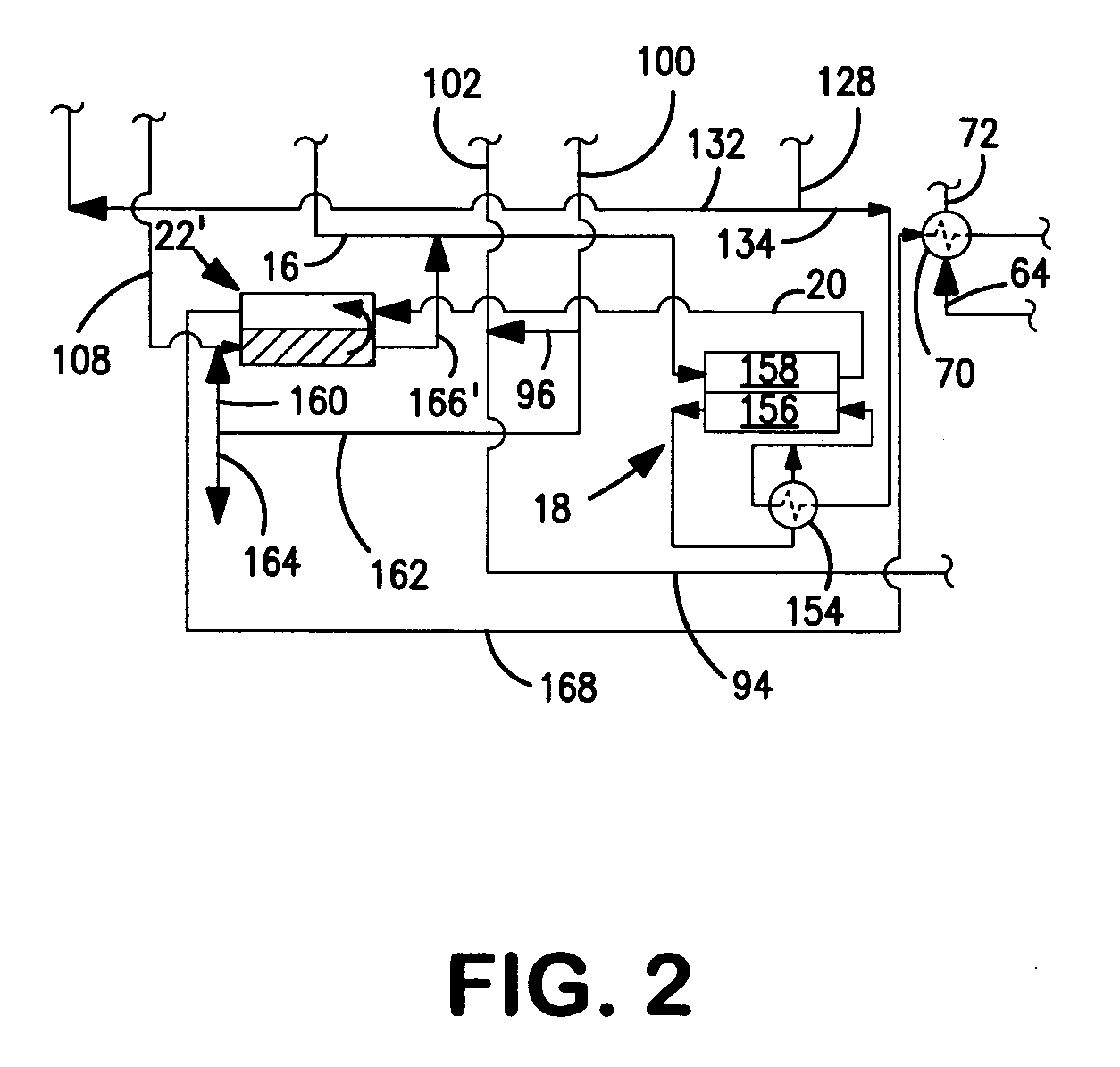

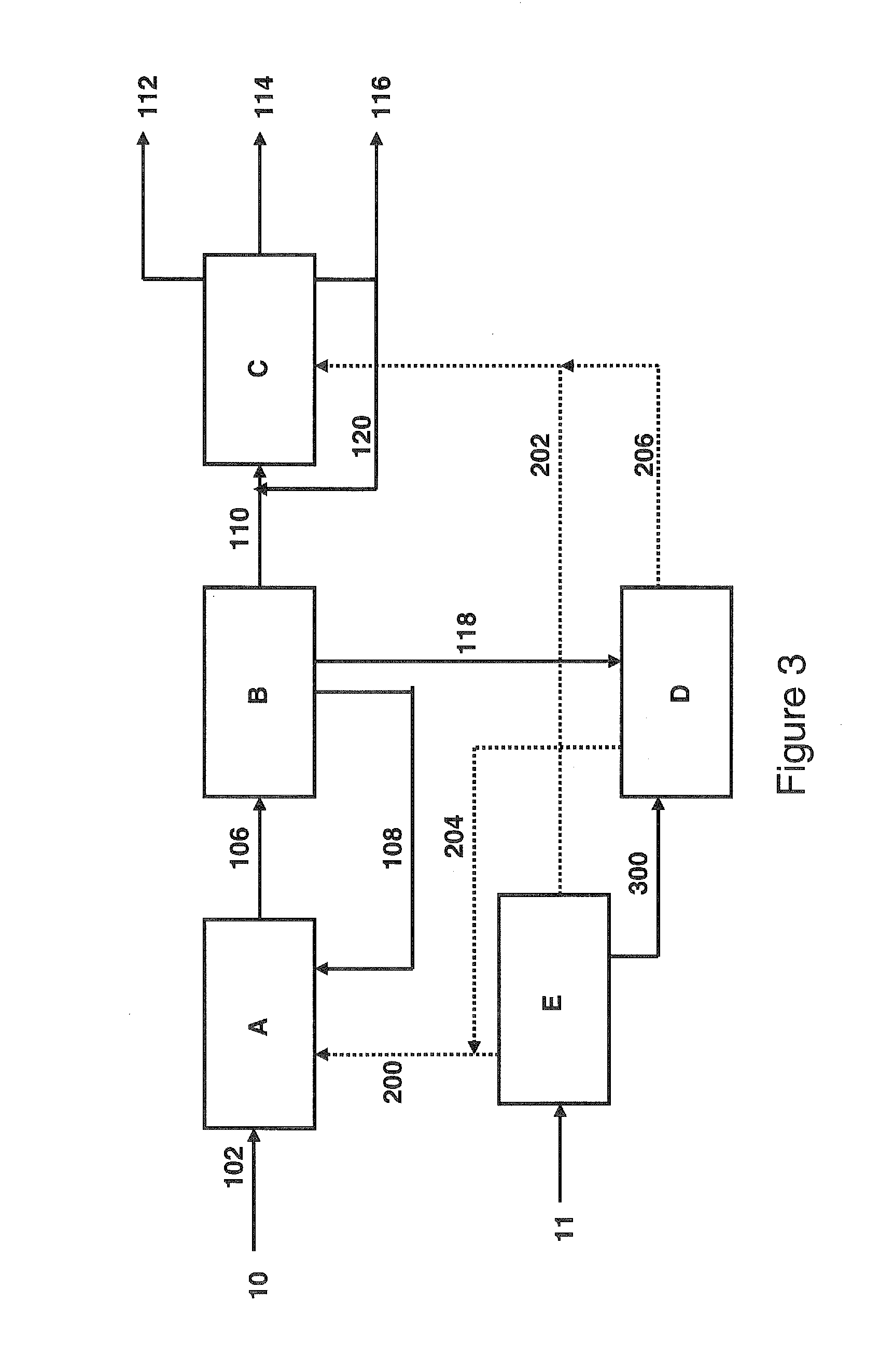

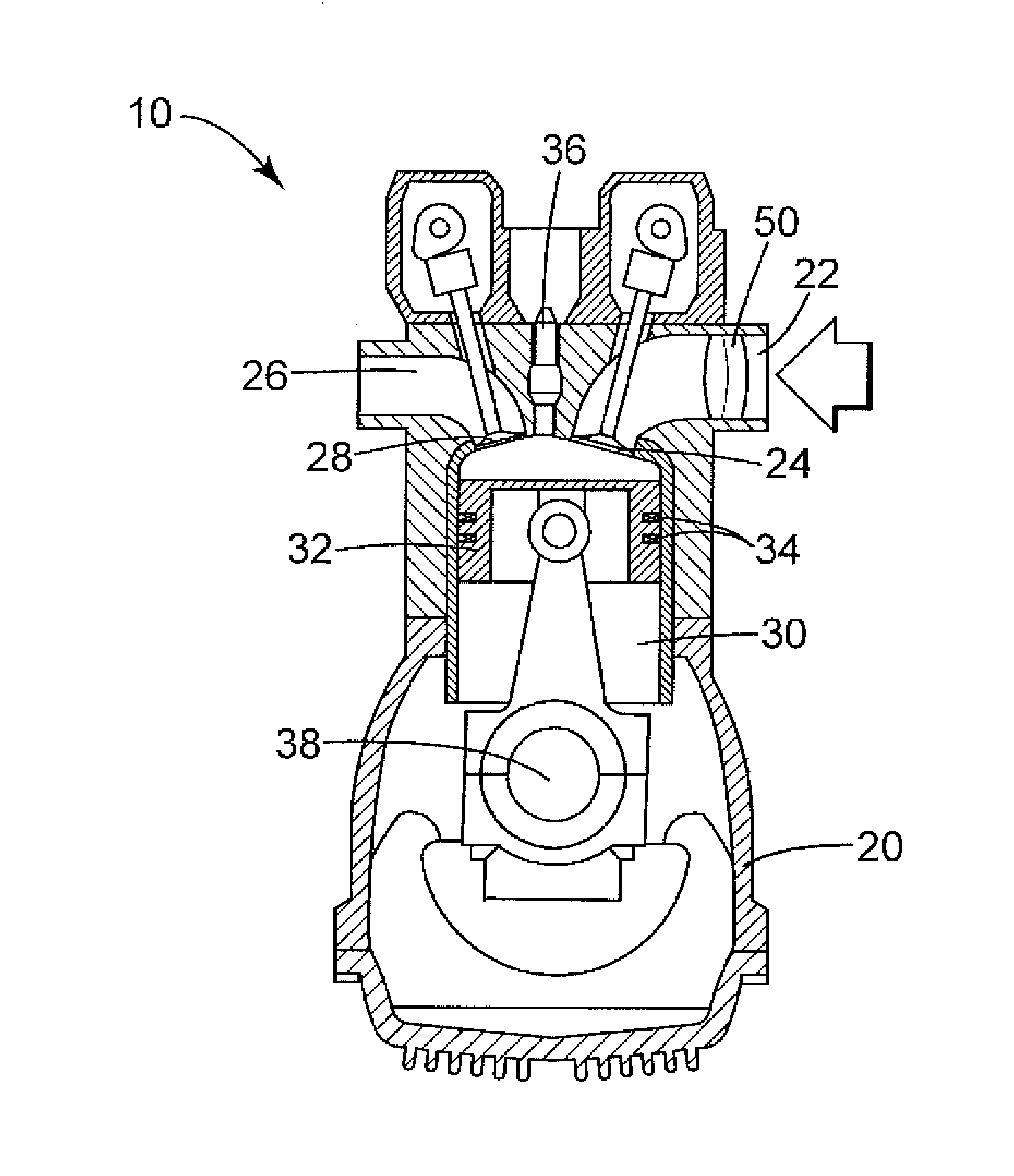

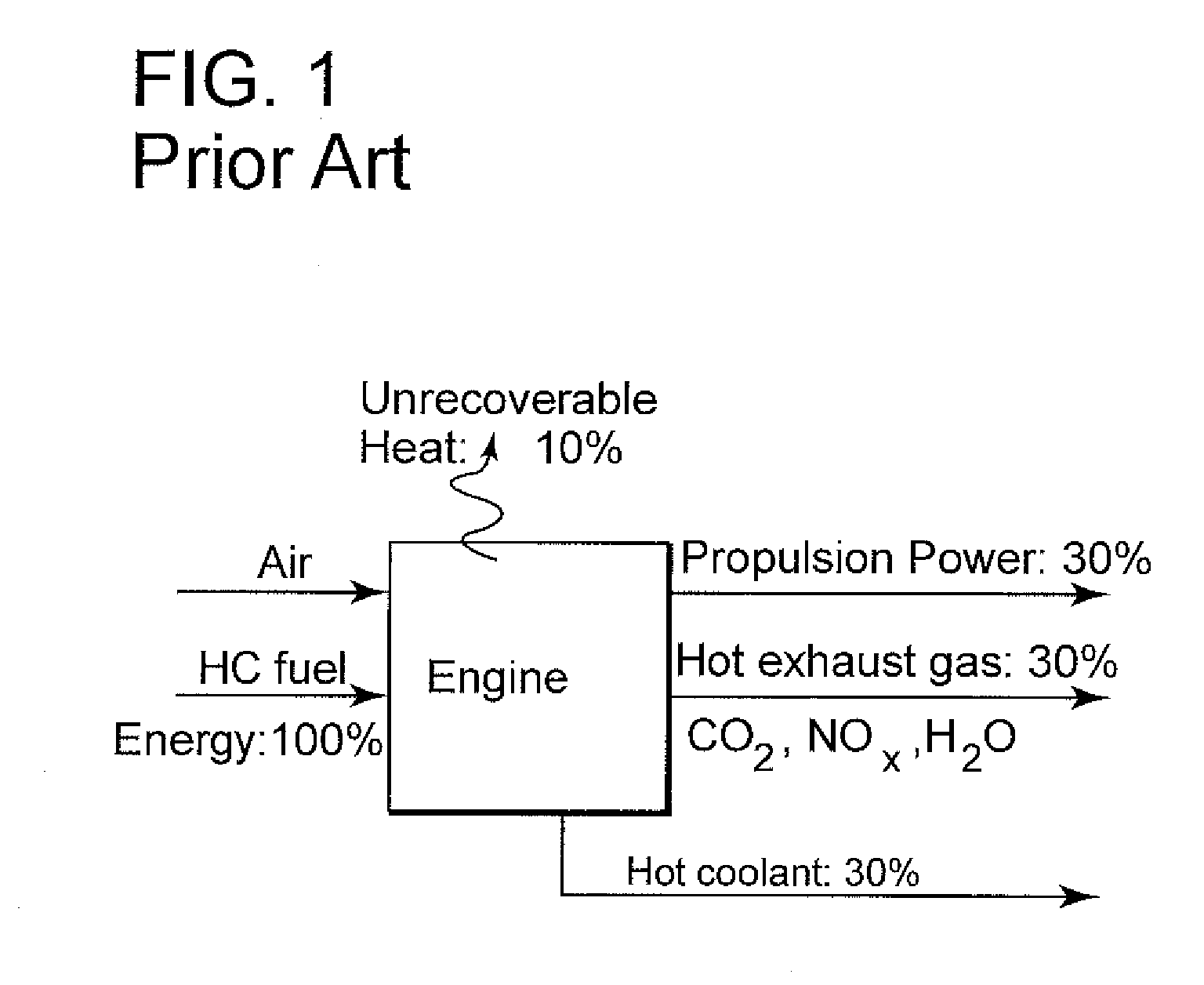

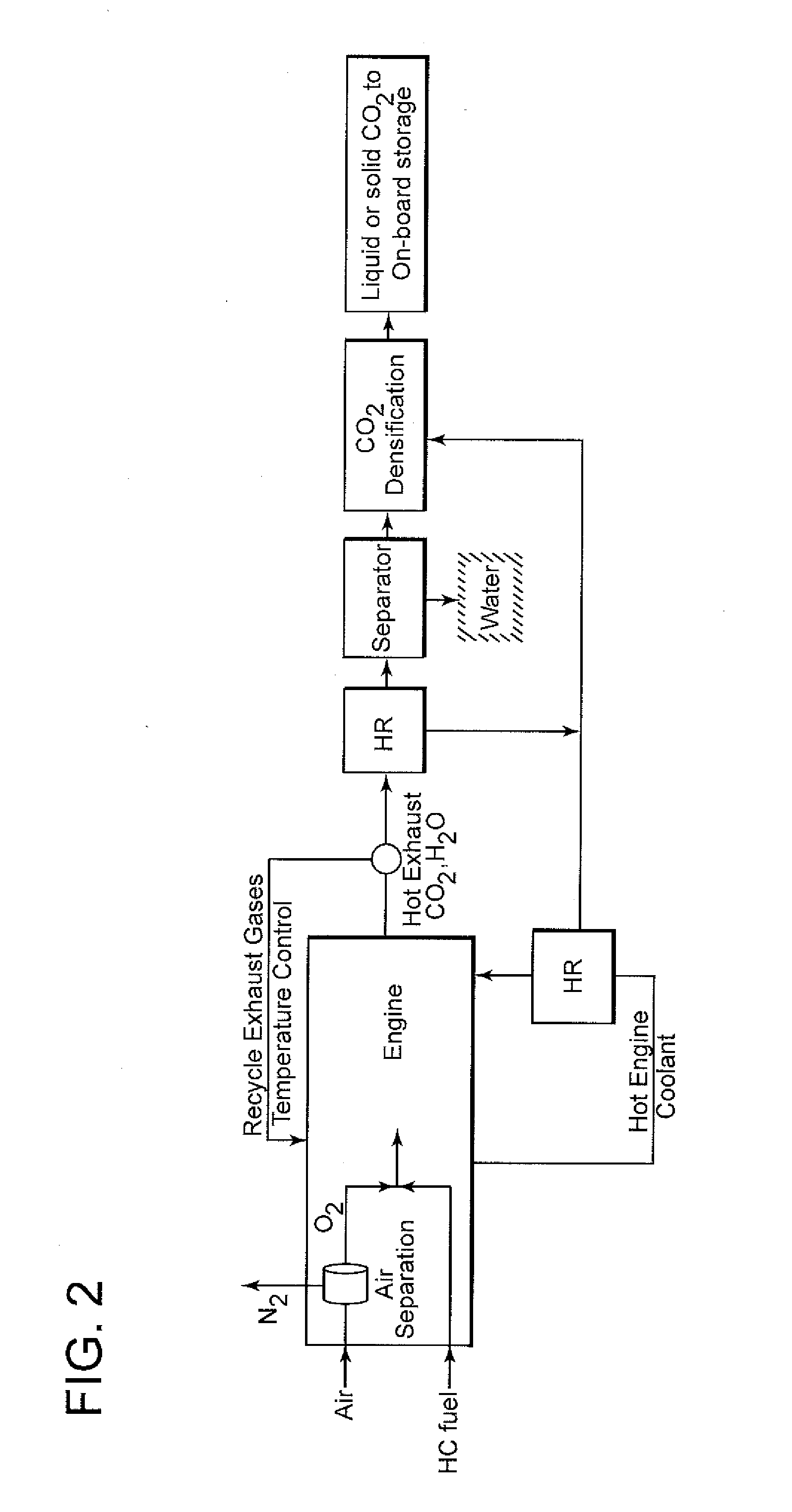

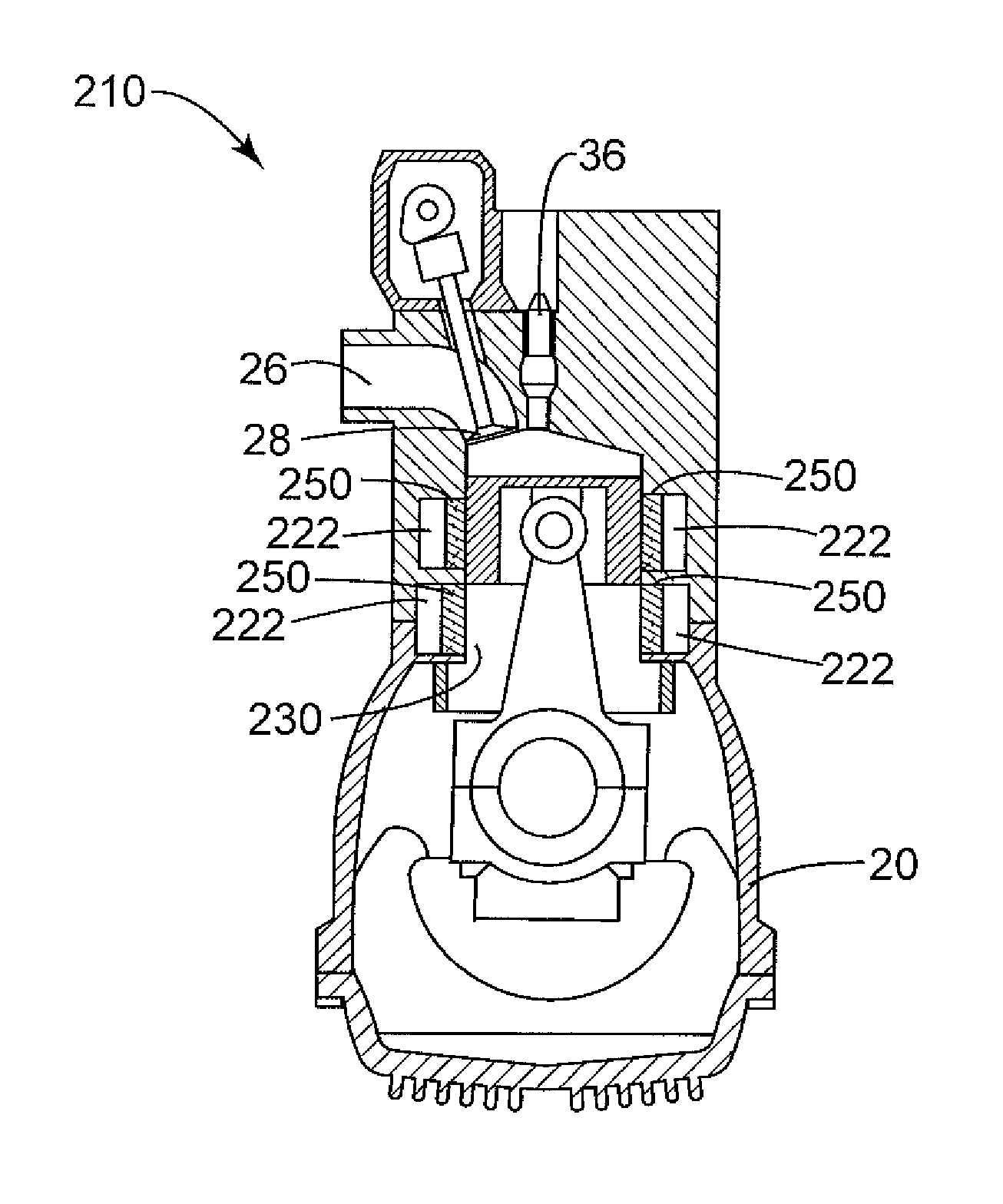

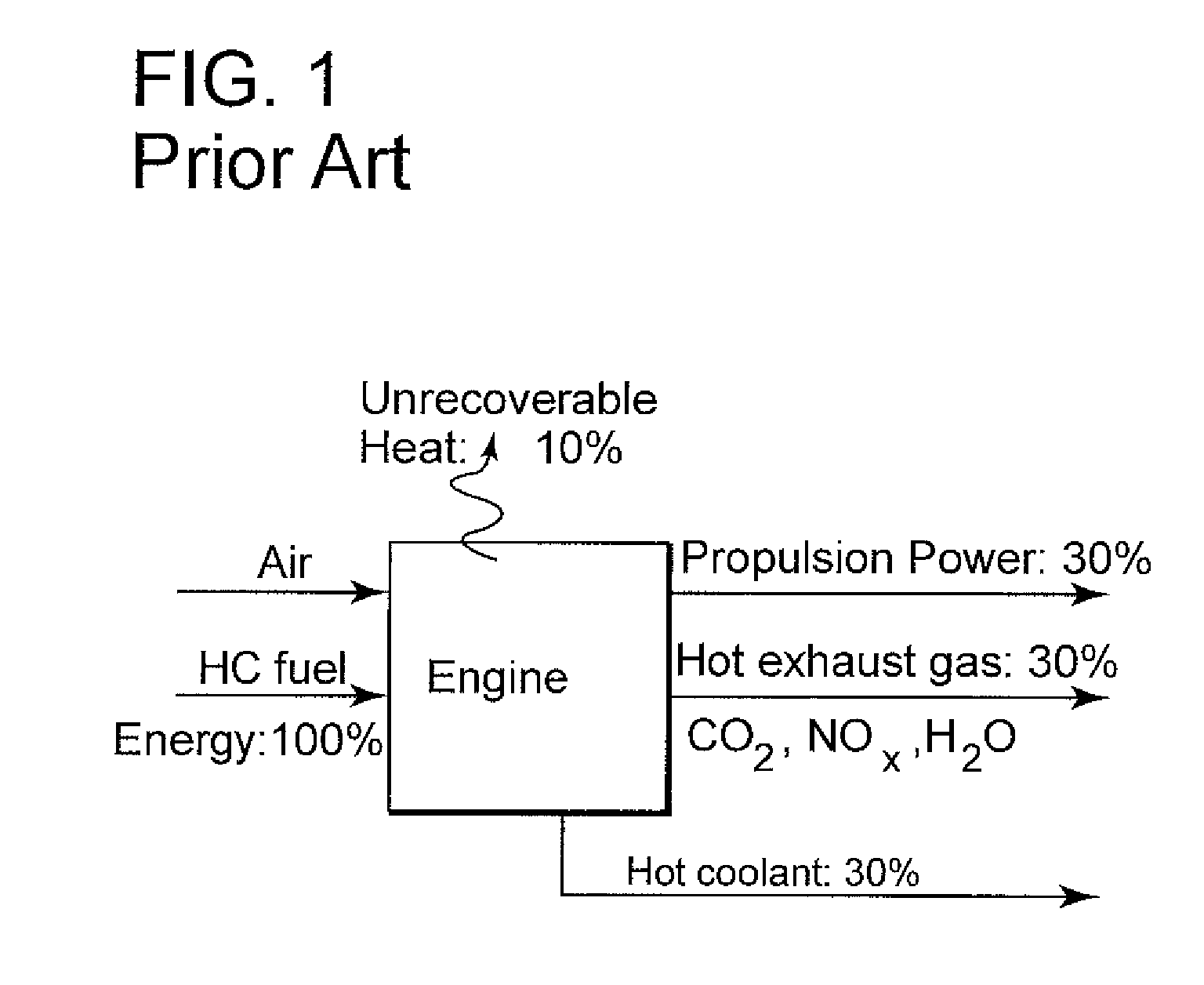

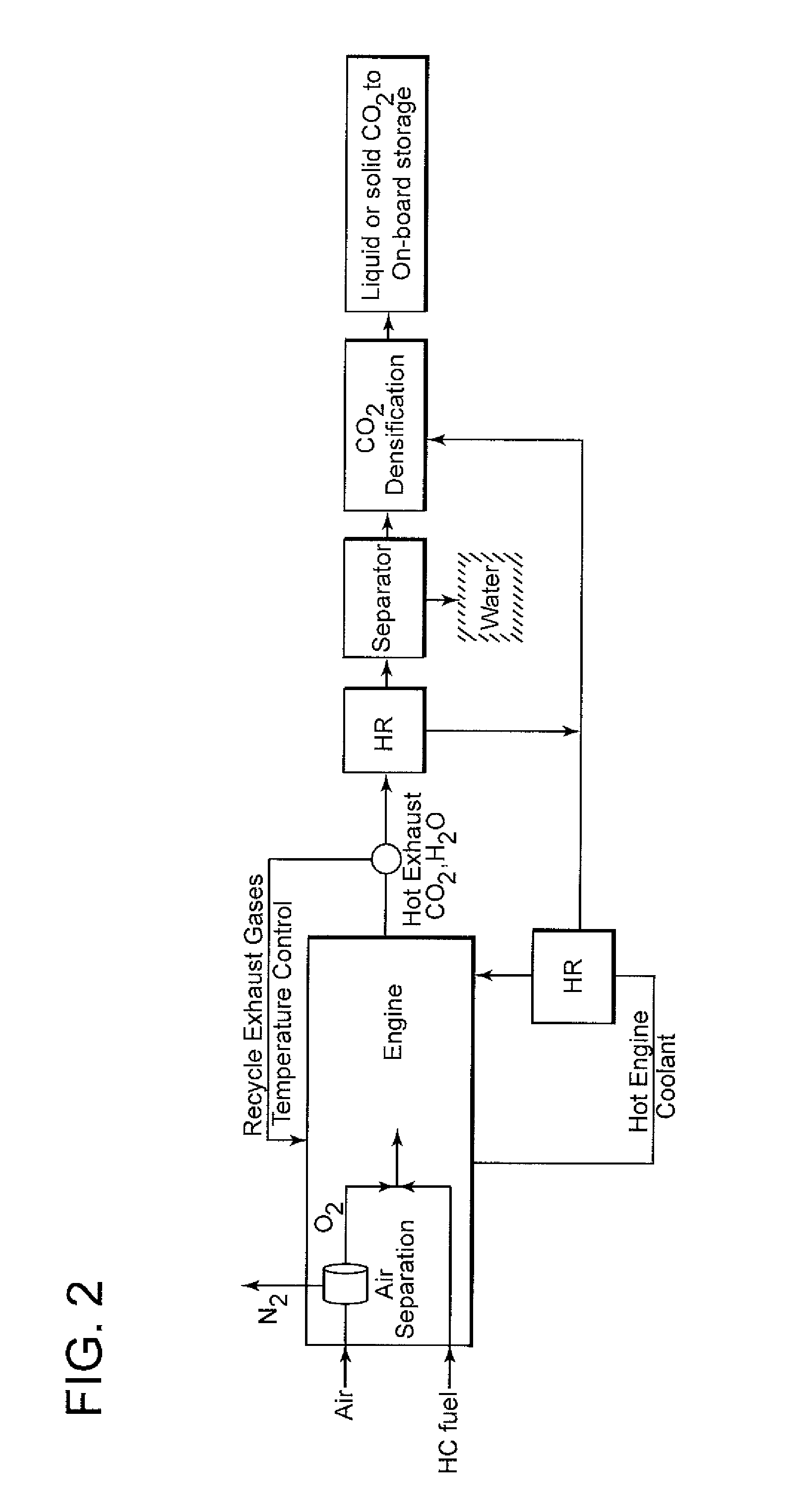

Apparatus and method for oxy-combustion of fuels in internal combustion engines

ActiveUS20130247886A1Lower the volumeElectrical controlInternal combustion piston enginesOn boardExternal combustion engine

A method and apparatus for the oxy-combustion of fuel in an internal combustion engine (ICE) used to power a vehicle converts the free energy available onboard the vehicle in the form of waste heat from the engine exhaust gas stream and coolant system into electrical and / or mechanical energy which energy is used to separate oxygen from air to eliminate or significantly reduce the volume of nitrogen entering the ICE's combustion chamber, and thereby reduce NOx pollutants released into the atmosphere and increase the concentration of CO2 in the engine exhaust stream for capture using an integrated system to compress and increase the density of the captured CO2 for temporary on-board storage until it is discharged at a recovery station, e.g., during vehicle refueling.

Owner:SAUDI ARABIAN OIL CO

High temperature hydropyrolysis of carbonaceous materials

InactiveUS20100314235A1Efficient supplyMinimizes problemCombustible gas coke oven heatingFuel cell heat exchangeSulphur iodideResource utilization

Heat from a concentrated solar power source is applied to the conversion of carbonaceous materials such as heavy petroleum crude oils, coals and biomass to liquid hydrocarbons. The solar heat is applied to provide at least a portion of the process heat used in the high temperature, short contact time hydropyrolysis of the carbonaceous material which is supplied with hydrogen generated by a high temperature process such as high temperature steam electrolysis, the sulfur-iodine cycle, the hybrid sulfur cycle, the zinc-zinc oxide cycle or by methane steam cracking. The heat from the solar source may be used to generate electricity to operate high temperature steam electrolysis used in generation of the hydrogen. By the use of solar thermal energy sources, hydrocarbon resource utilization for process heat is eliminated along with carbon dioxide evolution associated with burning of the hydrocarbon resource to generate process heat. The substitution of zero carbon emission sources therefore offers the potential for significant carbon emission reductions in refinery operations where external process heat can be applied and effectively utilized.

Owner:EXXON RES & ENG CO

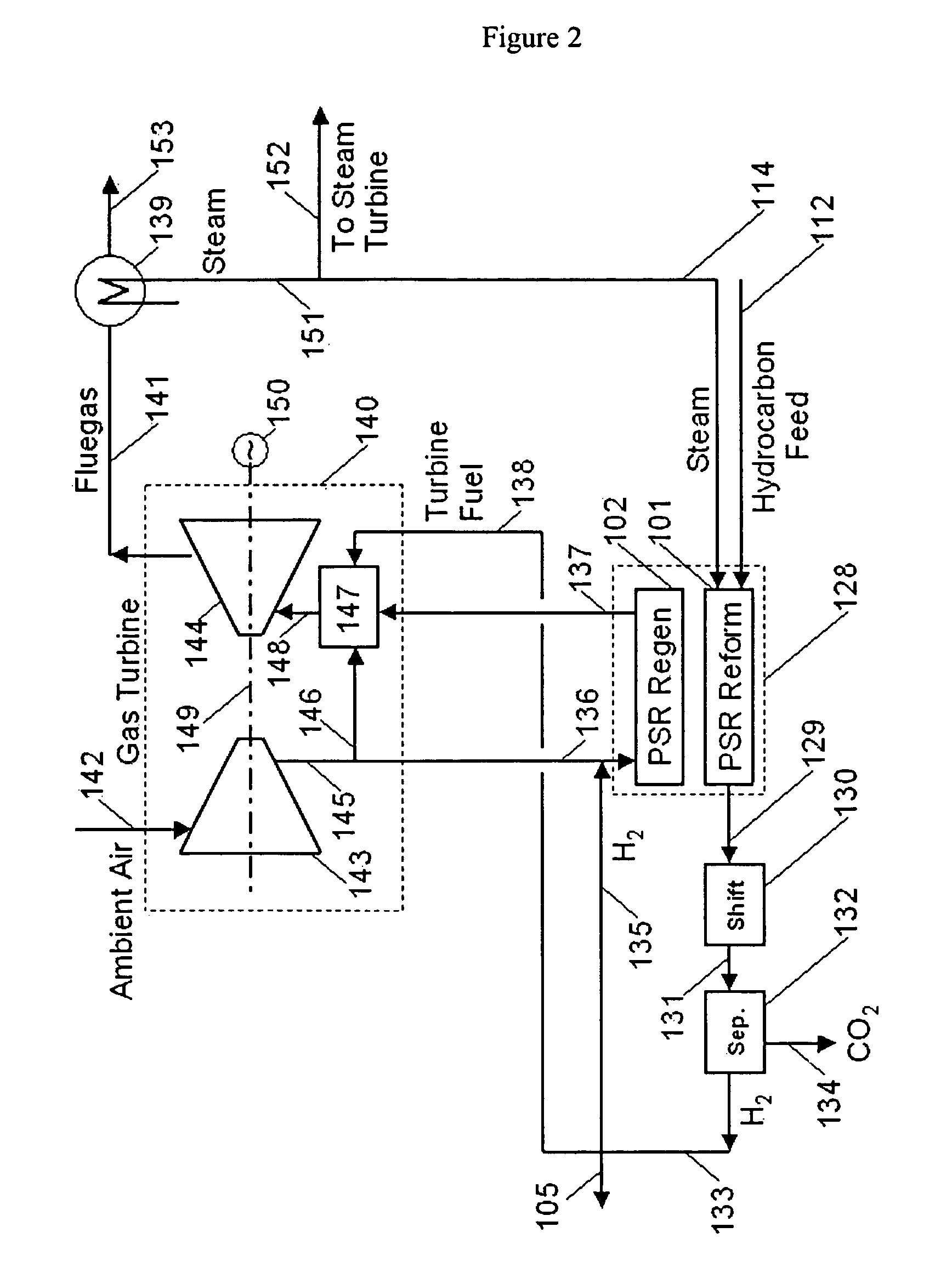

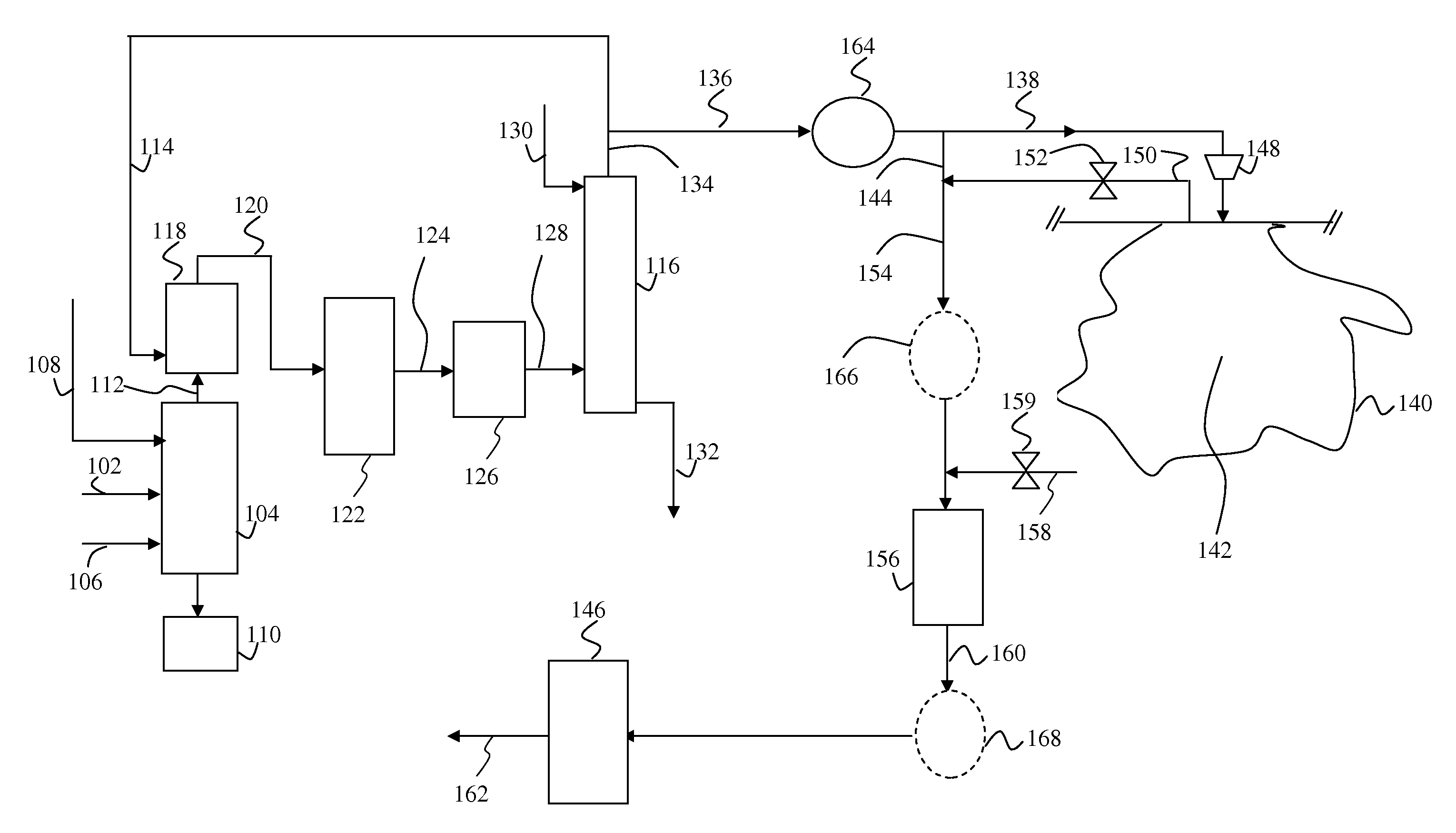

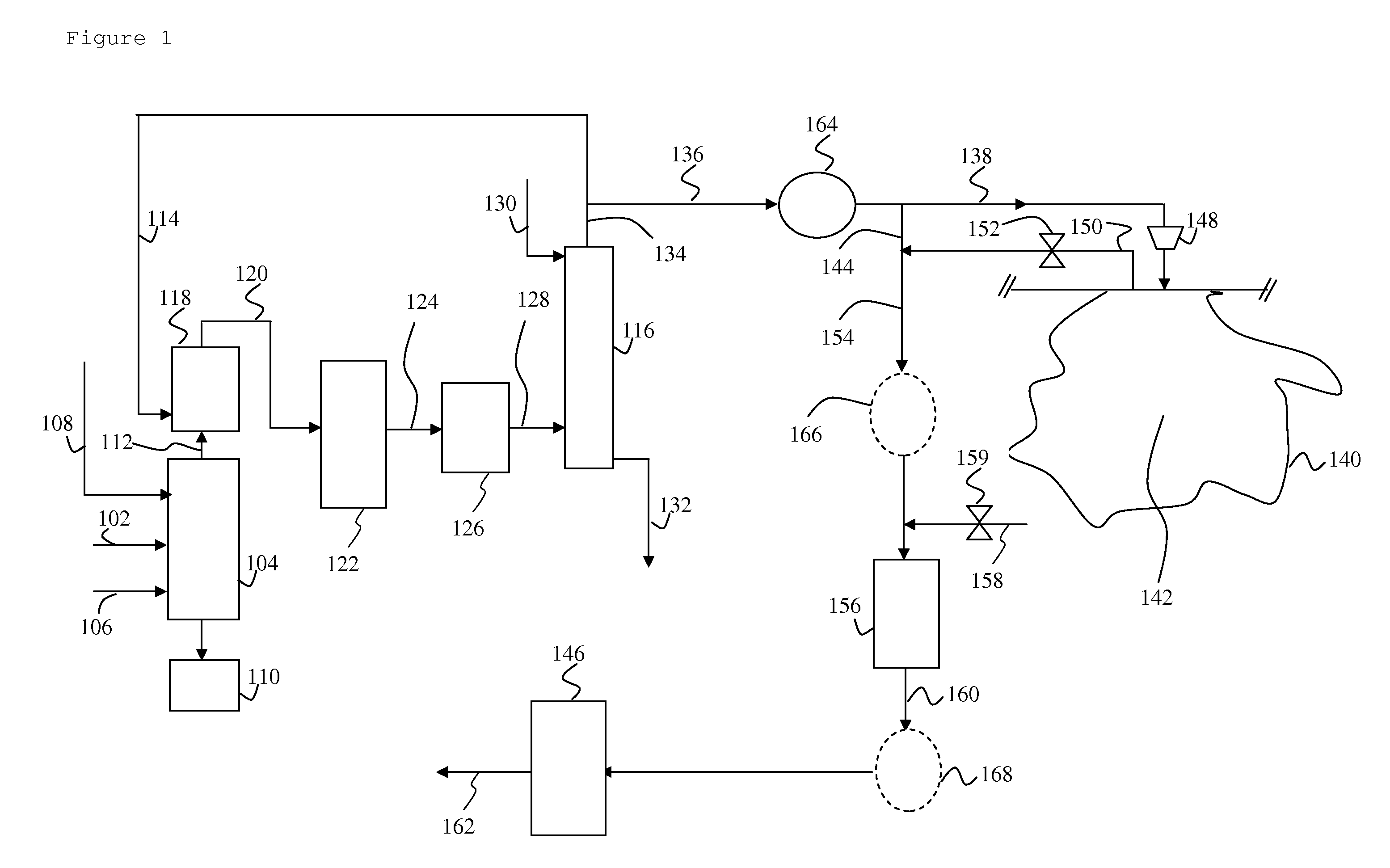

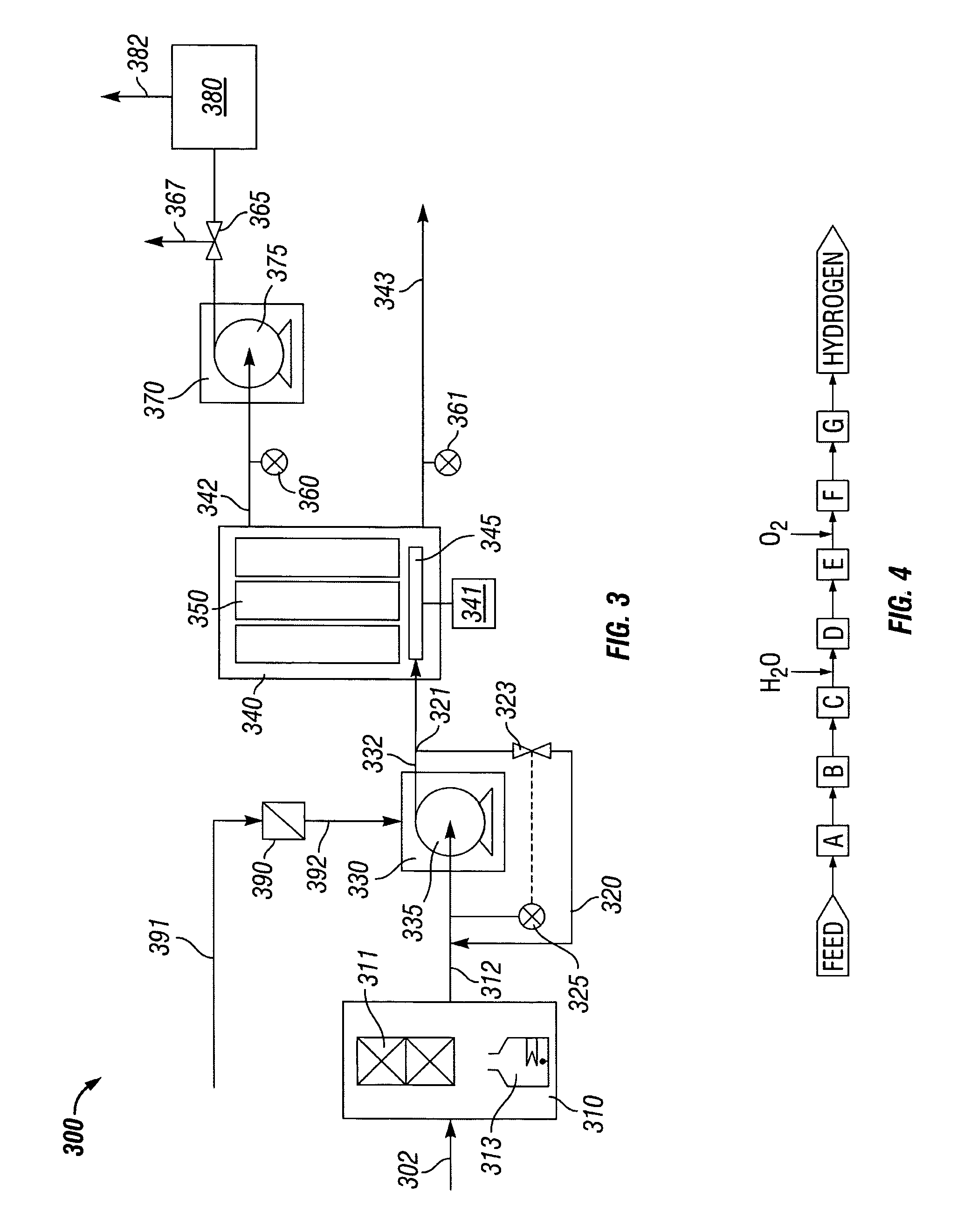

System and process for making hydrogen from a hydrocarbon stream

This invention relates to a process and apparatus for the production of pure hydrogen by steam reforming. The process integrates the steam reforming and shift reaction to produce pure hydrogen with minimal production of CO and virtually no CO in the hydrogen stream, provides for CO2 capture for sequestration, employs a steam reforming membrane reactor, and is powered by heat from the convection section of a heater.

Owner:SHELL OIL CO

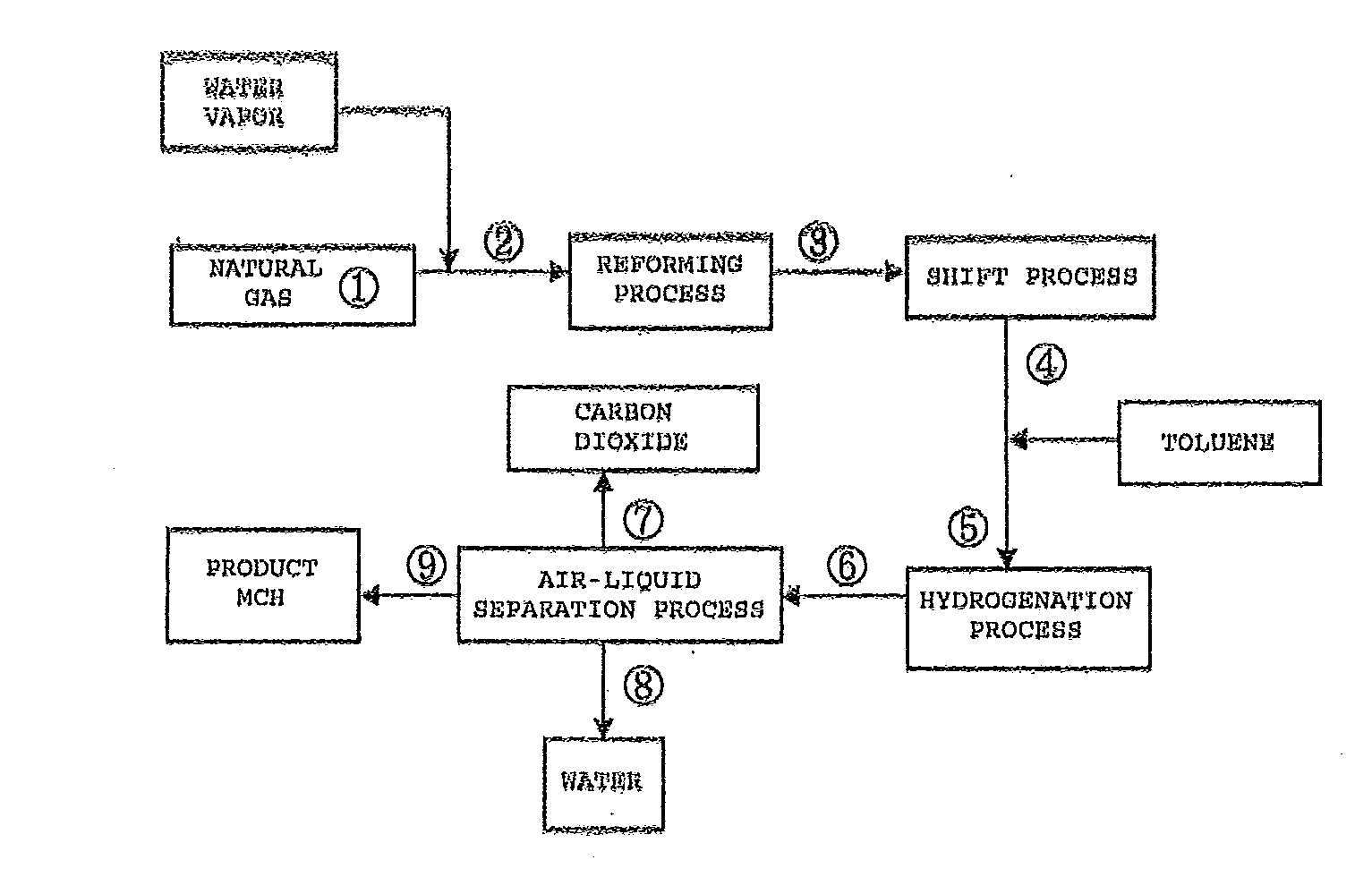

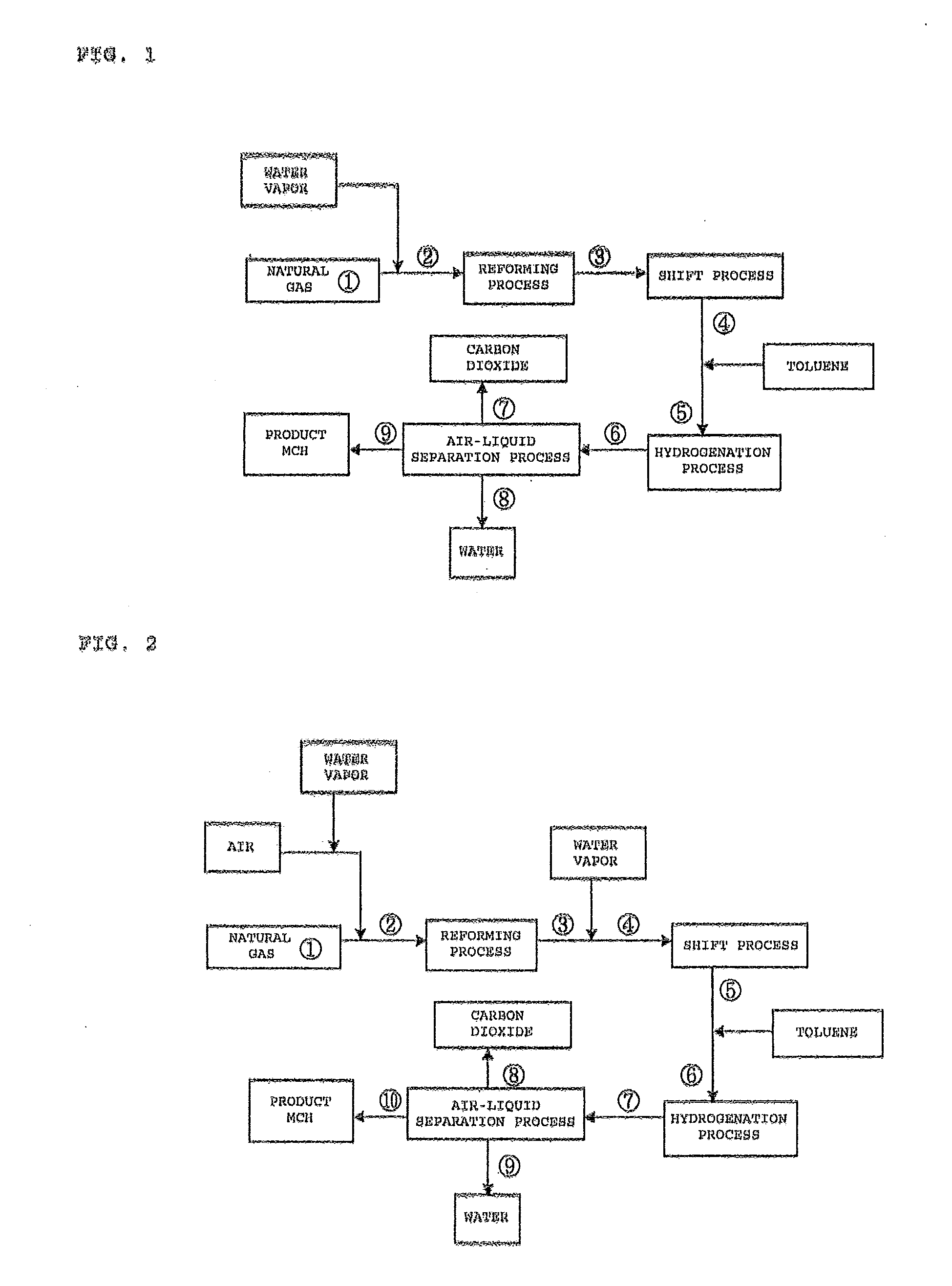

Method for producing hydrogen aimed at storage and transportation

ActiveUS20120321549A1Industrially produced efficientlyLow costReactant parameters controlHydrogen production carbon captureHydrogen concentrationHydrogenation process

Provided is a method for producing hydrogen aimed at storage and transportation, by which hydrogen for storage and transportation that is necessary for smoothly performing an organic chemical hydride method can be industrially produced efficiently at low cost. The method is a method for producing hydrogen aimed at storage and transportation in an organic chemical hydride method, in which: the hydrogenation process of an aromatic compound uses, as a hydrogen source for the reaction of the aromatic compound, a reaction gas is produced by a reforming reaction and adjusted a hydrogen concentration from 30 to 70 vol % by a shift reaction; and a hydrogenated aromatic compound is separated from a reaction mixture obtained in the hydrogenation process, which is followed by purification.

Owner:CHIYODA CORP

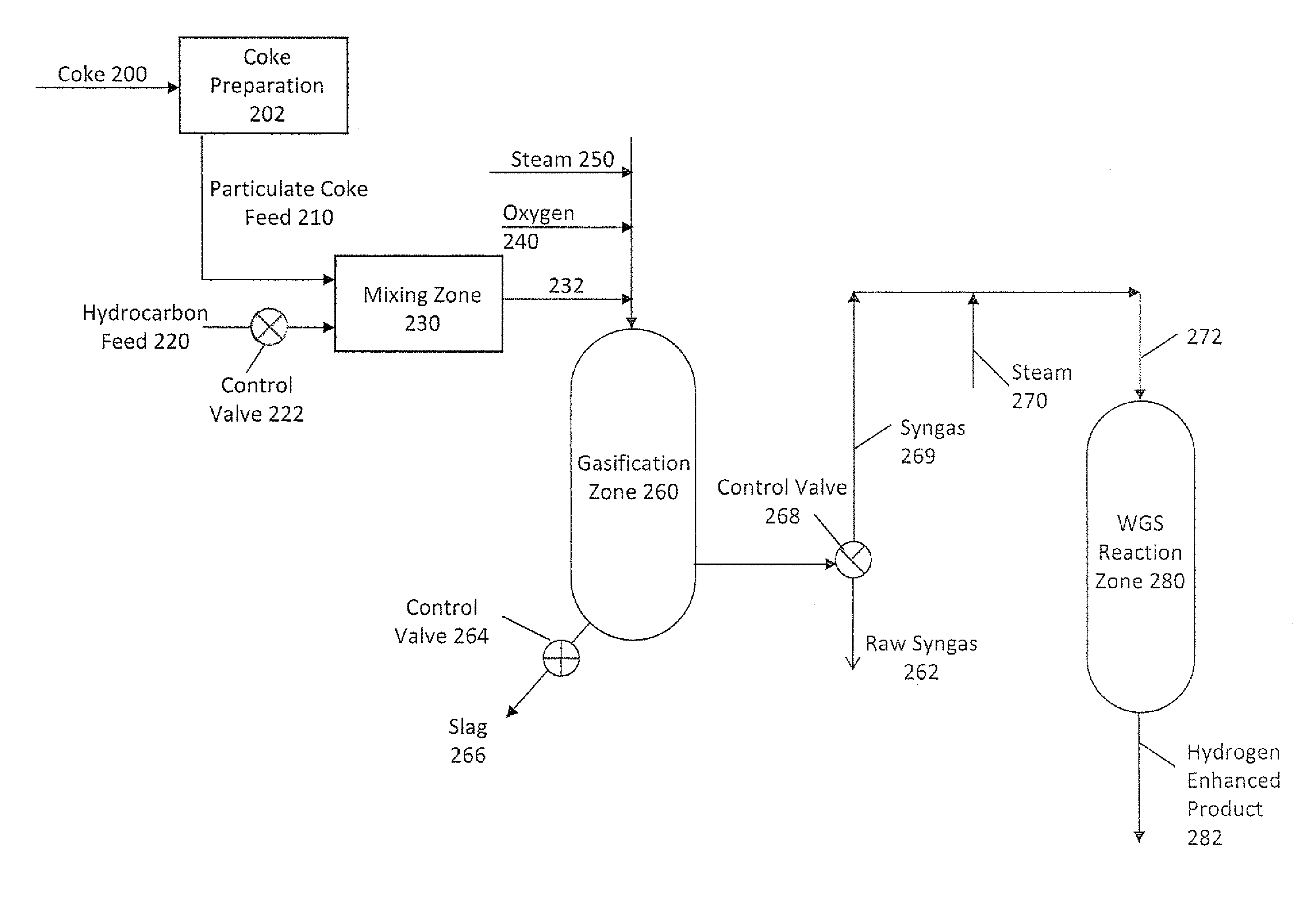

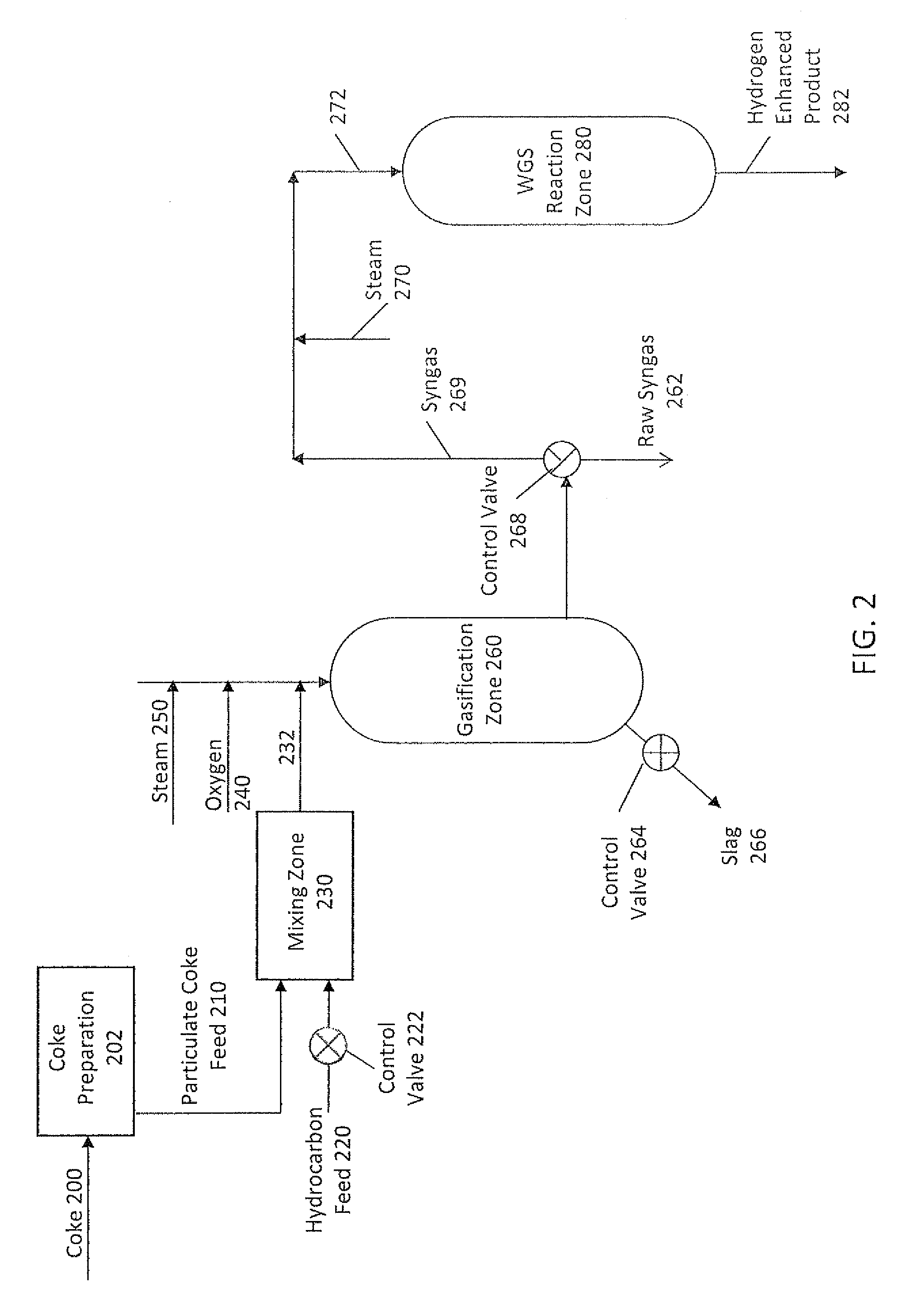

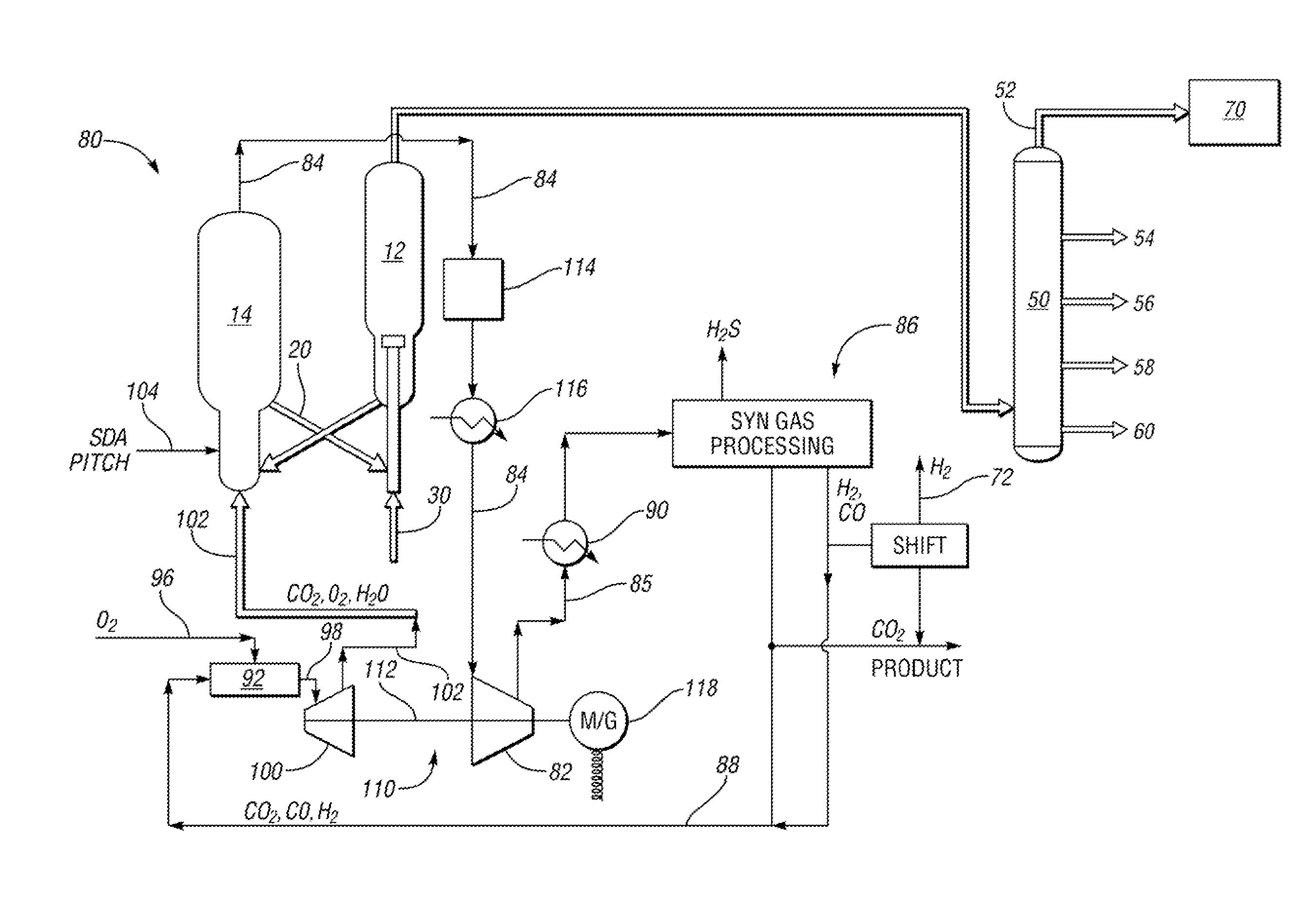

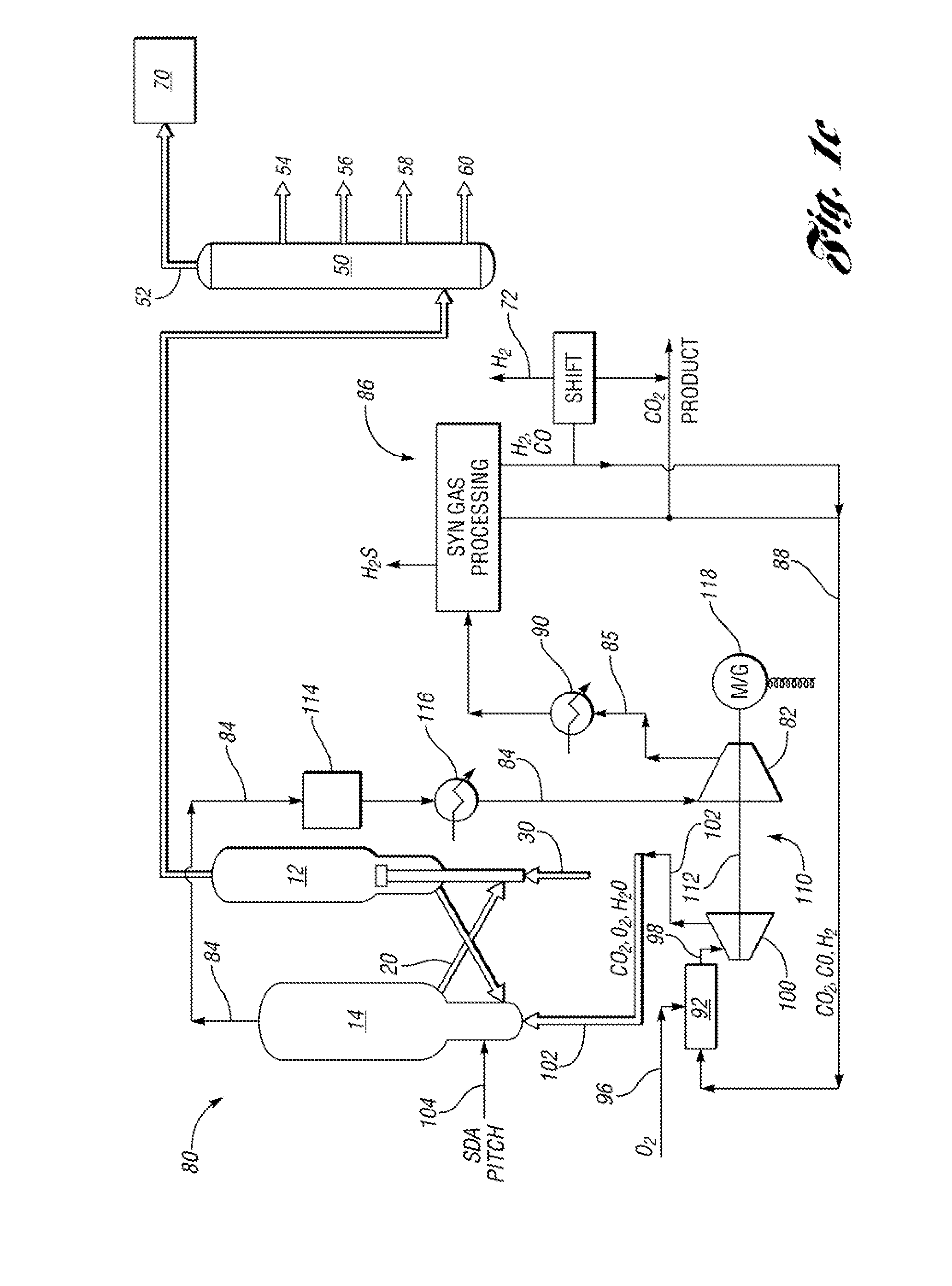

Process for the gasification of heavy residual oil with particulate coke from a delayed coking unit

ActiveUS9234146B2Energy efficient and economicalQuality improvementHydrogenHydrocarbon from carbon oxidesParticulatesPartial oxidation

A process for the production of a synthesis gas containing hydrogen and carbon monoxide utilizes ground coke having a predetermined ash content in combination with a refinery residual hydrocarbon oil feedstream for gasification in the combustion chamber of a tubular wall membrane partial oxidation gasification reactor in the presence of a predetermined amount of oxygen; the coke and residual oil can be mixed to form a single feedstream or introduced into the reactor as separate feeds. Optionally, the product synthesis gas is introduced as the feedstream to a water-gas shift reactor to enhance the hydrogen content of the final product stream.

Owner:SAUDI ARABIAN OIL CO

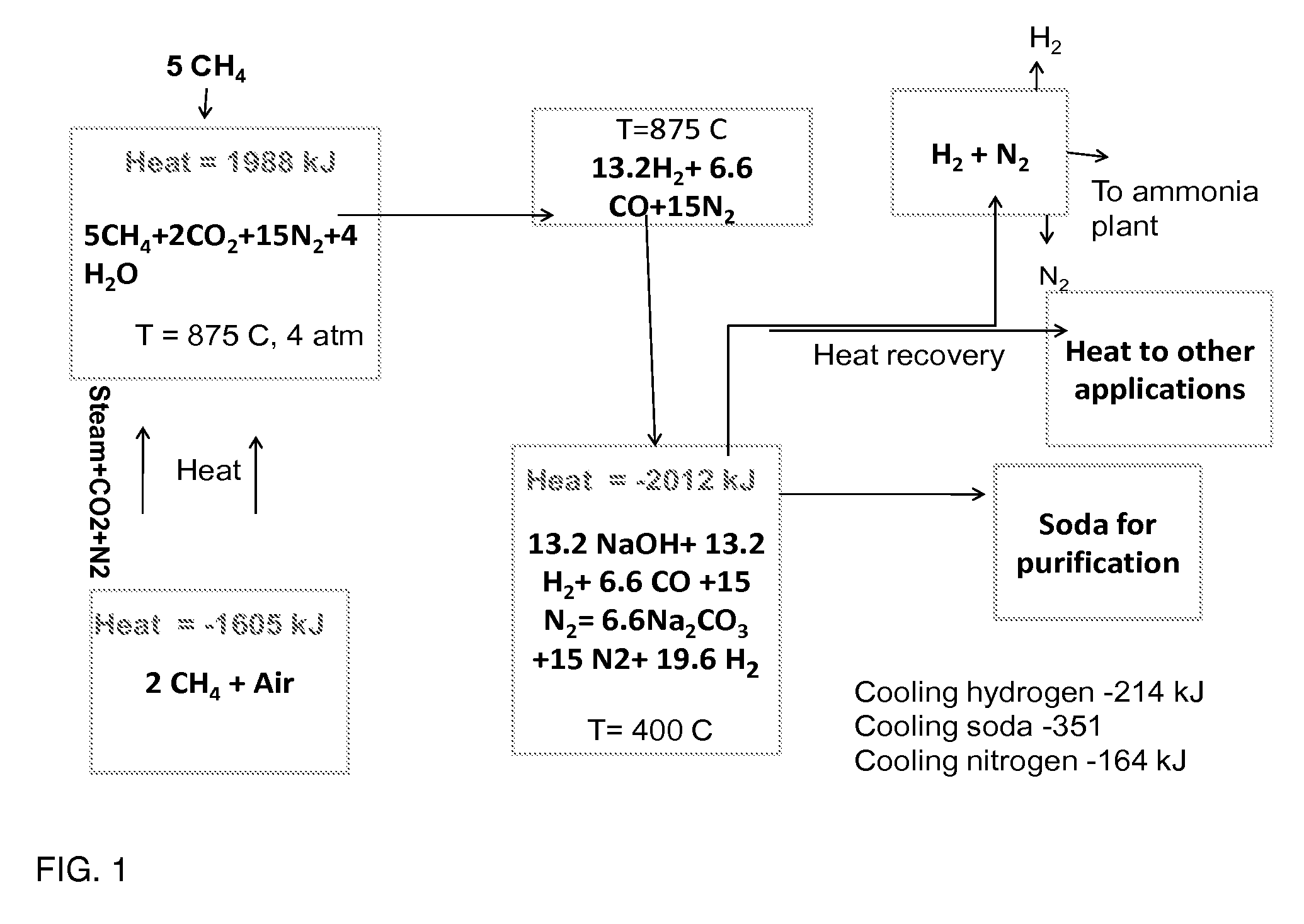

Modified steam-methane-reformation: Hydrogen production with carbon sequestration

Owner:SAXENA SURENDRA

Process and catalyst system for the production of high quality syngas from light hydrocarbons and carbon dioxide

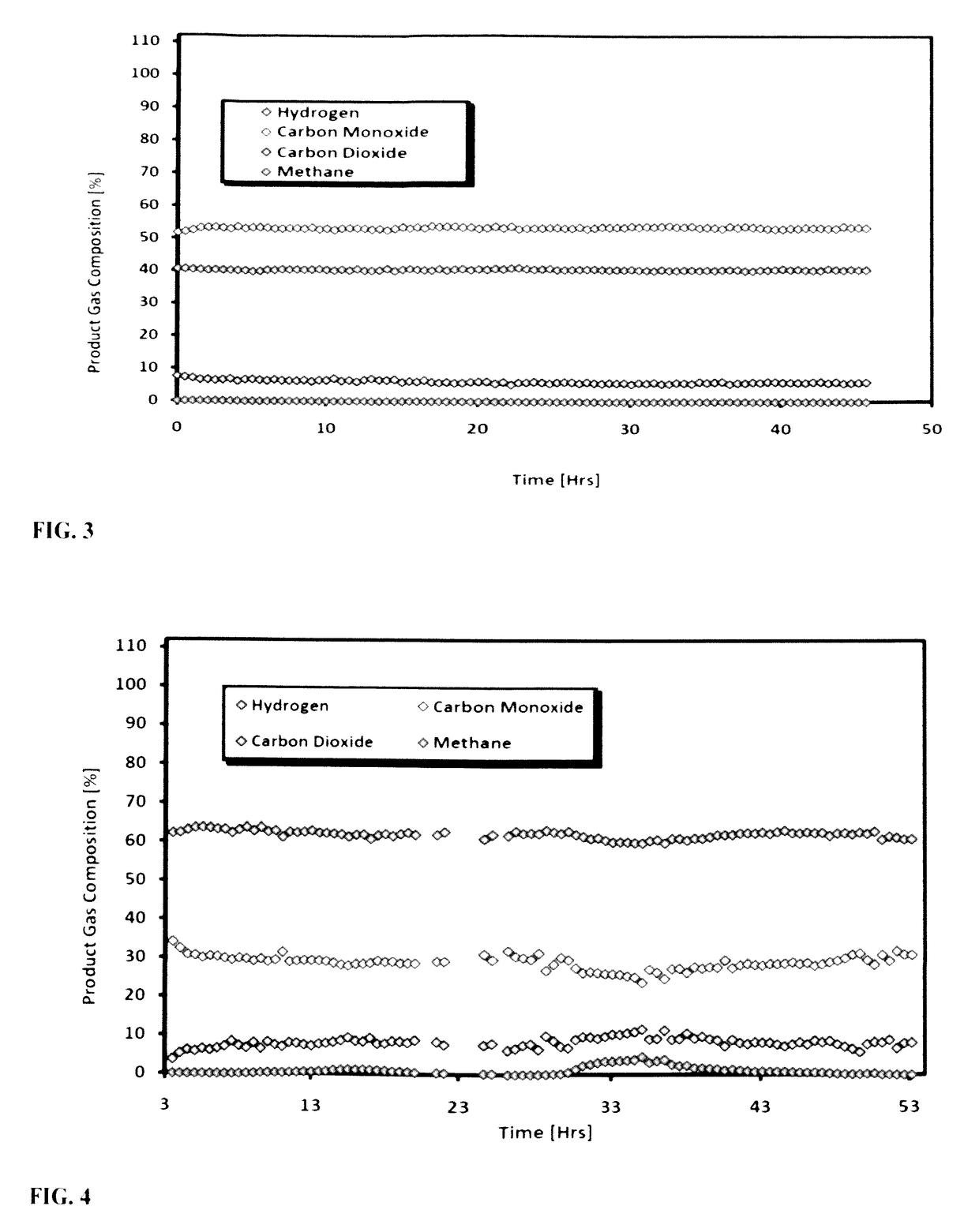

ActiveUS9611145B2Improve thermal stabilityImprove the immunityHydrogenCarburetting gasesSyngasCarbon dioxide production

The present invention describes a process and catalysts for the conversion of a light hydrocarbon and carbon dioxide input stream into high quality syngas with the subsequent conversion of the syngas into fuels or chemicals. In one aspect, the present invention provides an efficient, solid solution catalyst for the production of a carbon containing gas from carbon dioxide and light hydrocarbons. The catalyst comprises a single transition metal, and the transition metal is nickel.

Owner:INFINIUM TECH LLC

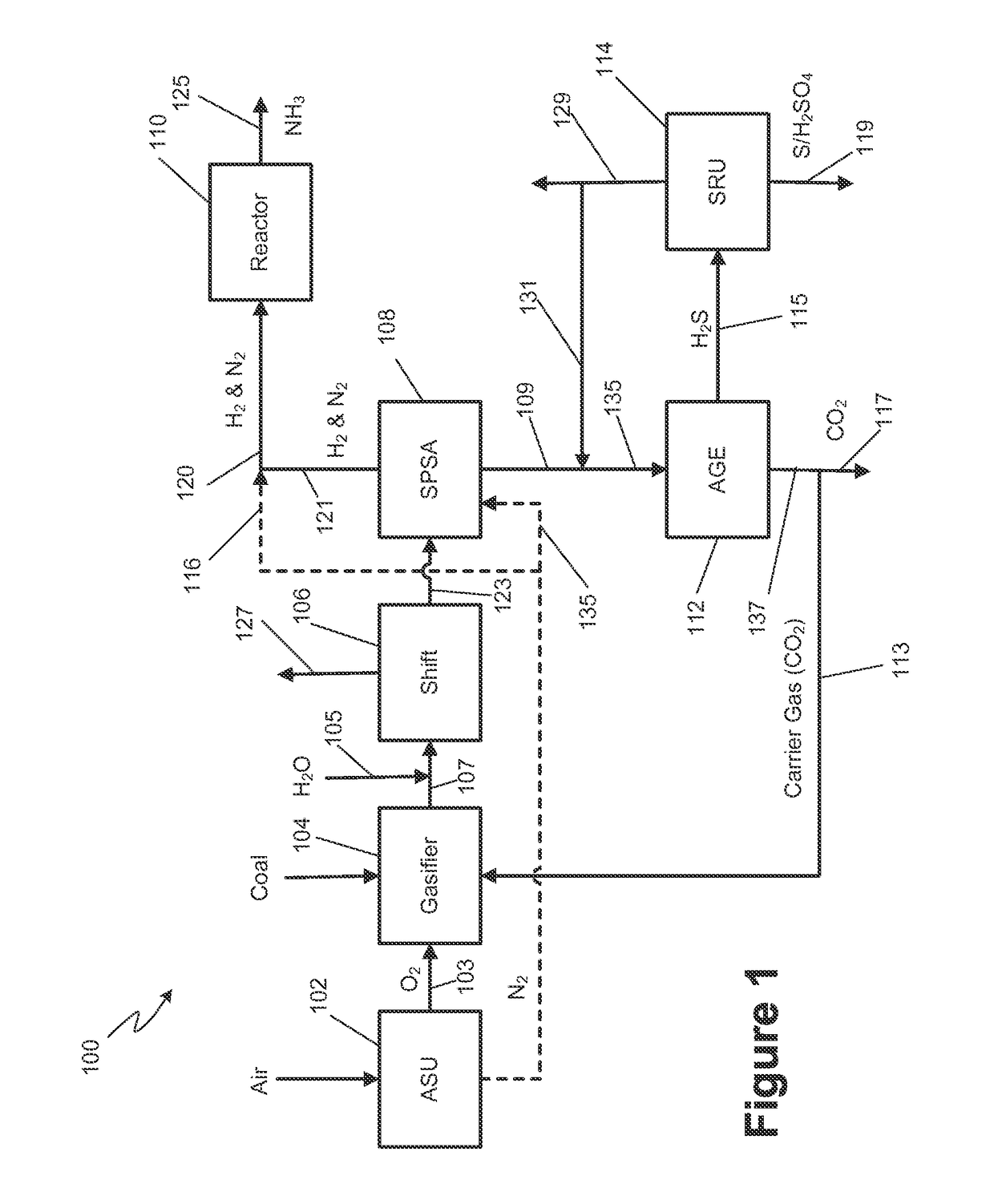

Polygeneration production of power and fertilizer through emissions capture

Method for the productioii of ammorsia, and optionally urea, from a flue gas effluent from an oxygen-fired, process, wherein the production of ammonia and optionally urea includes a net power production. Also provided is a method to effect cooling in an oxygen-fired process with air separation unit exit gases utilizing either closed or open cooling loop cycles.

Owner:GRANNUS

Conversion of biomass, organic waste and carbon dioxide into synthetic hydrocarbons

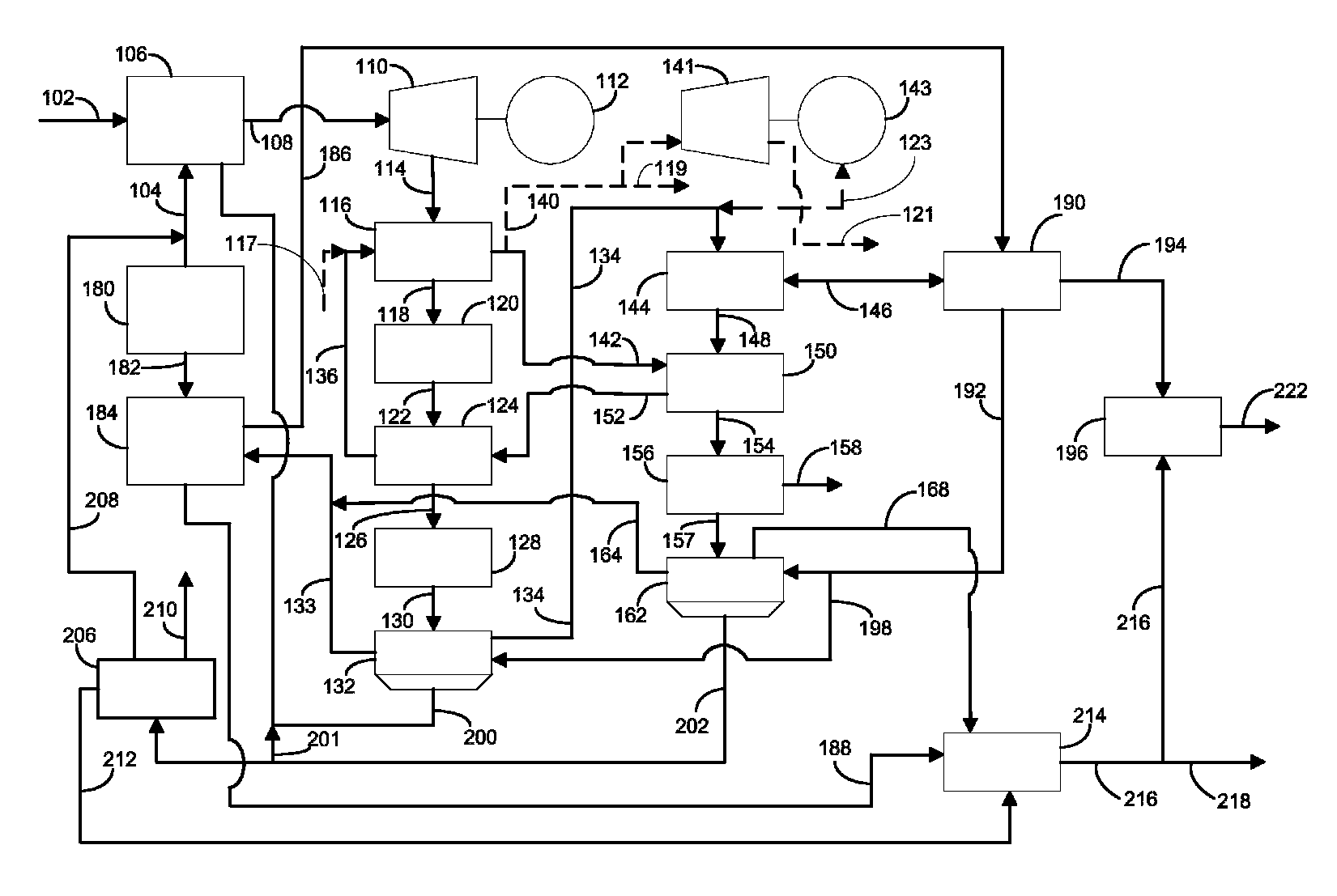

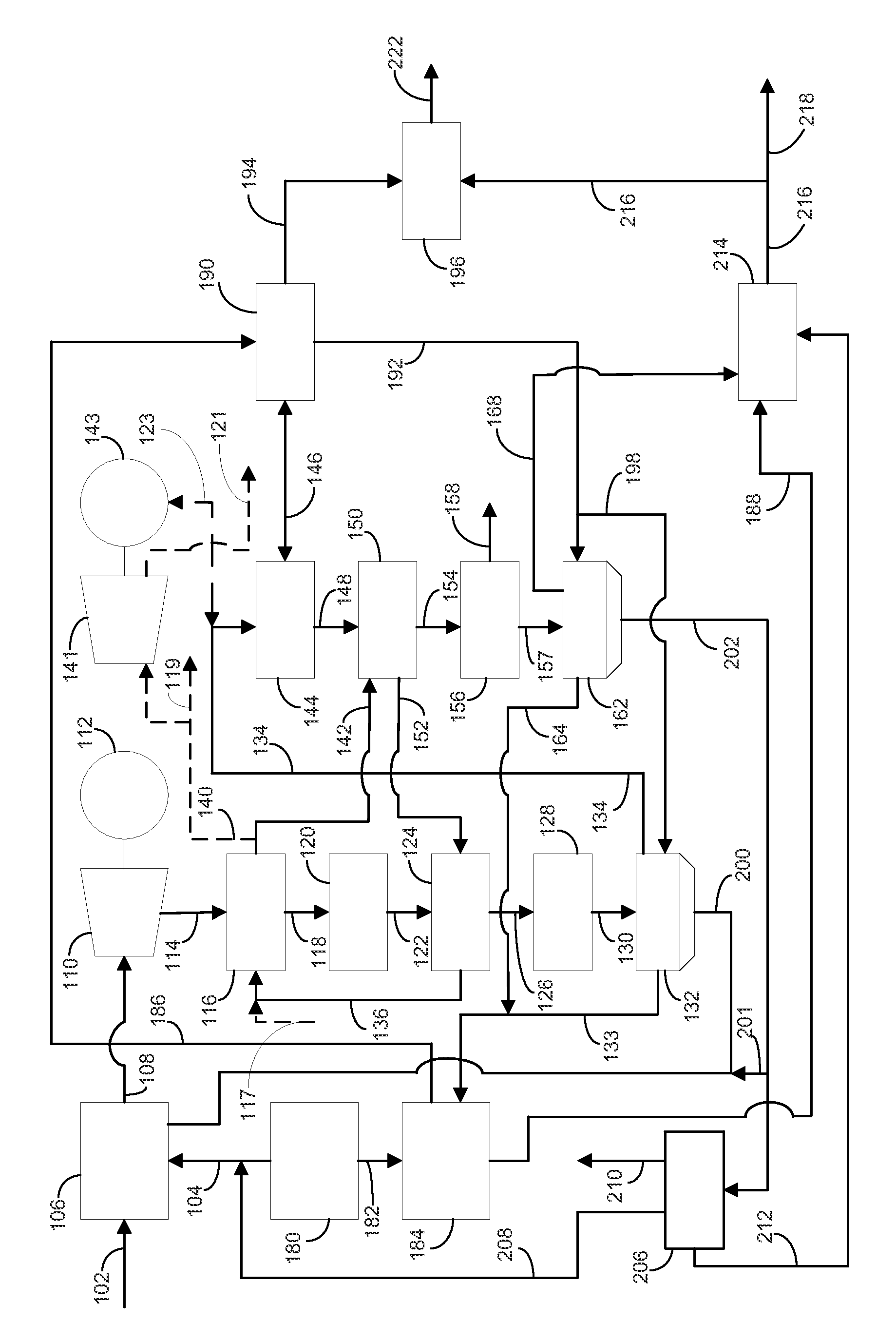

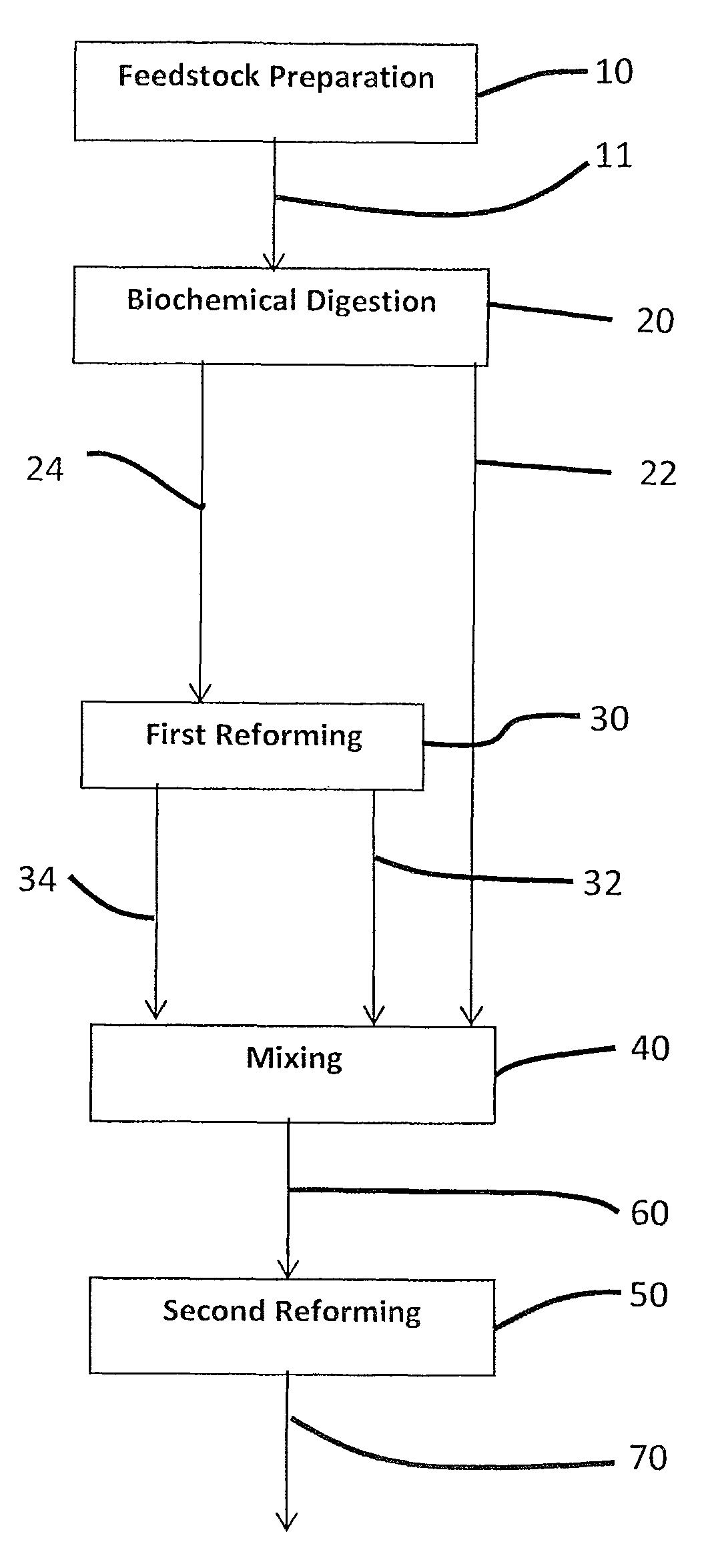

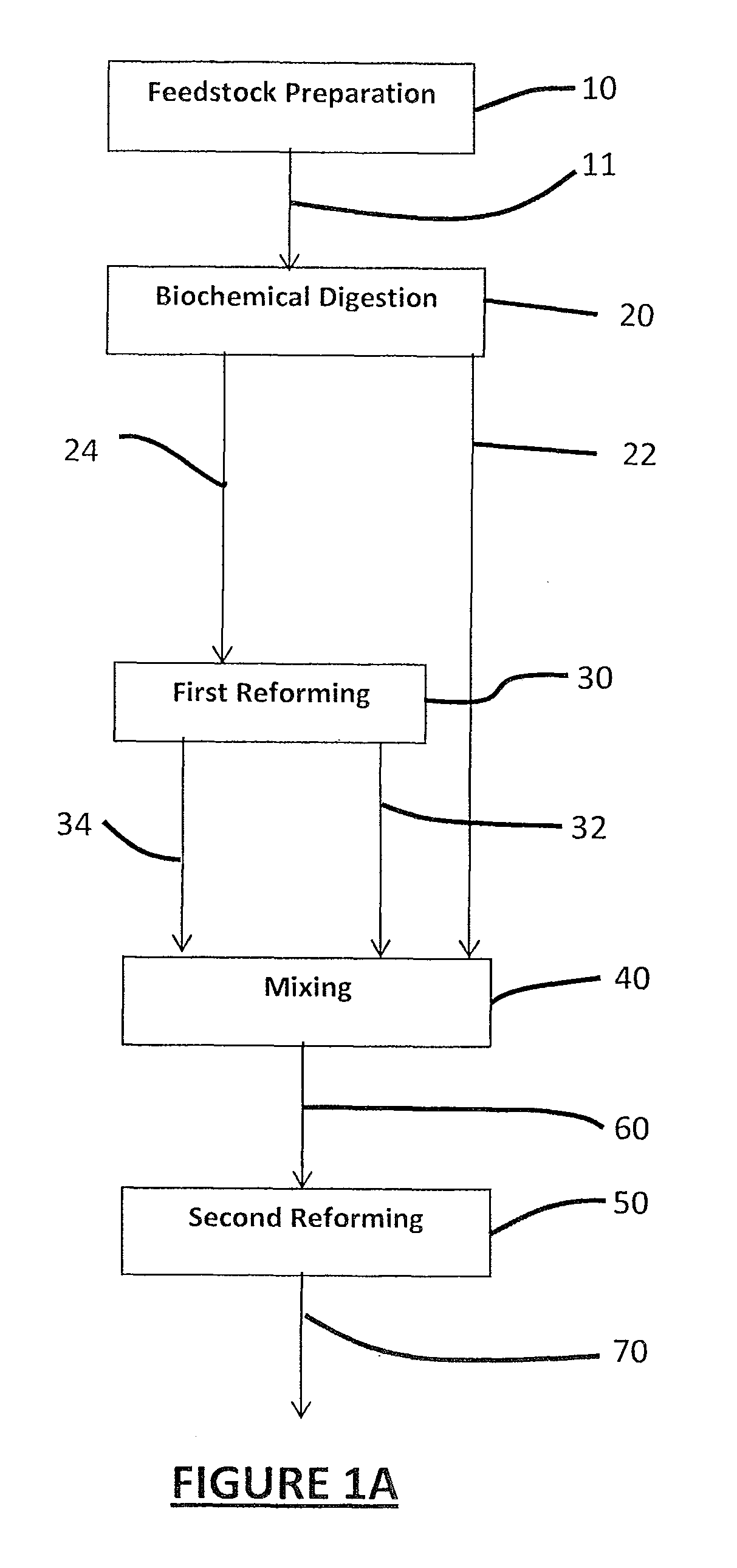

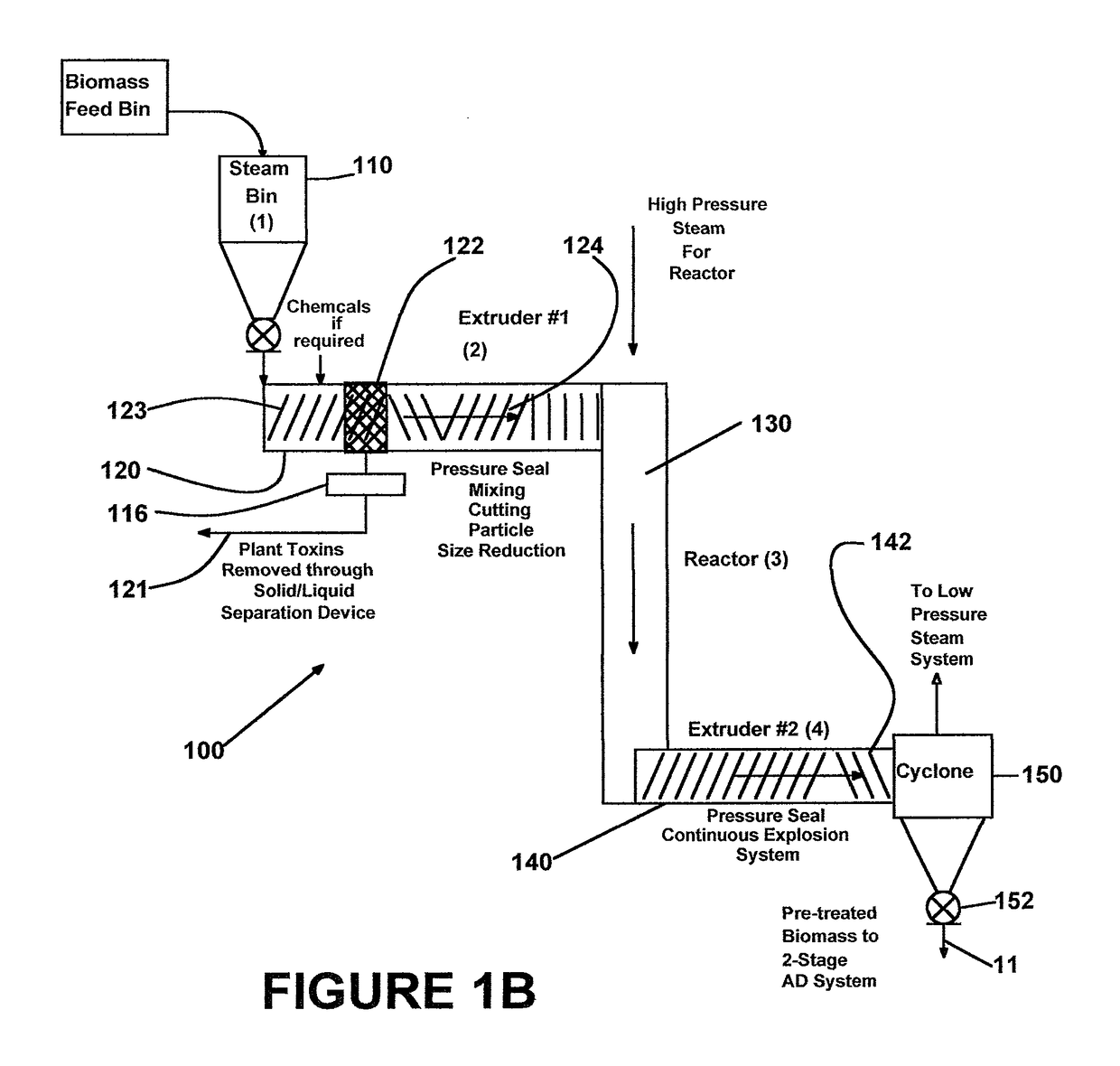

InactiveUS9816035B2Promote reformWell mixedBioreactor/fermenter combinationsBiological substance pretreatmentsSyngasOrganic matter

A process and system for producing a synthetic hydrocarbon having a desired H / C ratio is disclosed. Organic material is biochemically digested in a two stage biodigester for separately producing a hydrogen containing biogas substantially free of methane in a first stage and a methane containing biogas in a second stage. The methane containing biogas is reformed in a first reformer to generate hydrogen gas and carbon monoxide gas, which are then combined in a mixer with the hydrogen containing biogas into a syngas in amounts to achieve in the syngas an overall H / C ratio substantially equal to the desired H / C ratio. The syngas is reacted with a catalyst in a second reformer, a Fischer-Tropsch (FT) reactor, to produce the hydrocarbon. Using a two stage biodigester allows for the generation of separate hydrogen and methane streams, a more economical generation of the FT syngas and reduced fouling of the FT catalyst.

Owner:GREENFIELD SPECIALTY ALCOHOLS

Method and system of heating a fluid catalytic cracking unit for overall CO2 reduction

In at least one embodiment of the present invention, a method of heating a FCC unit having a regenerator and a reactor for over CO2 reduction is provided. The method comprises compressing syngas to define compressed syngas. CO2 is separated from the compressed syngas to provide a first stream of gas comprising CO2. The first stream of gas is expanded with a second stream of gas comprising O2 to define a feed gas. The feed gas and an injected hydrocarbon feed are introduced to the regenerator having spent catalyst from the reactor. The regenerator is at gasification conditions to burn the injected hydrocarbon feed and coke from the spent catalyst producing the syngas and heat for operating the reactor at reaction temperatures.

Owner:UOP LLC +1

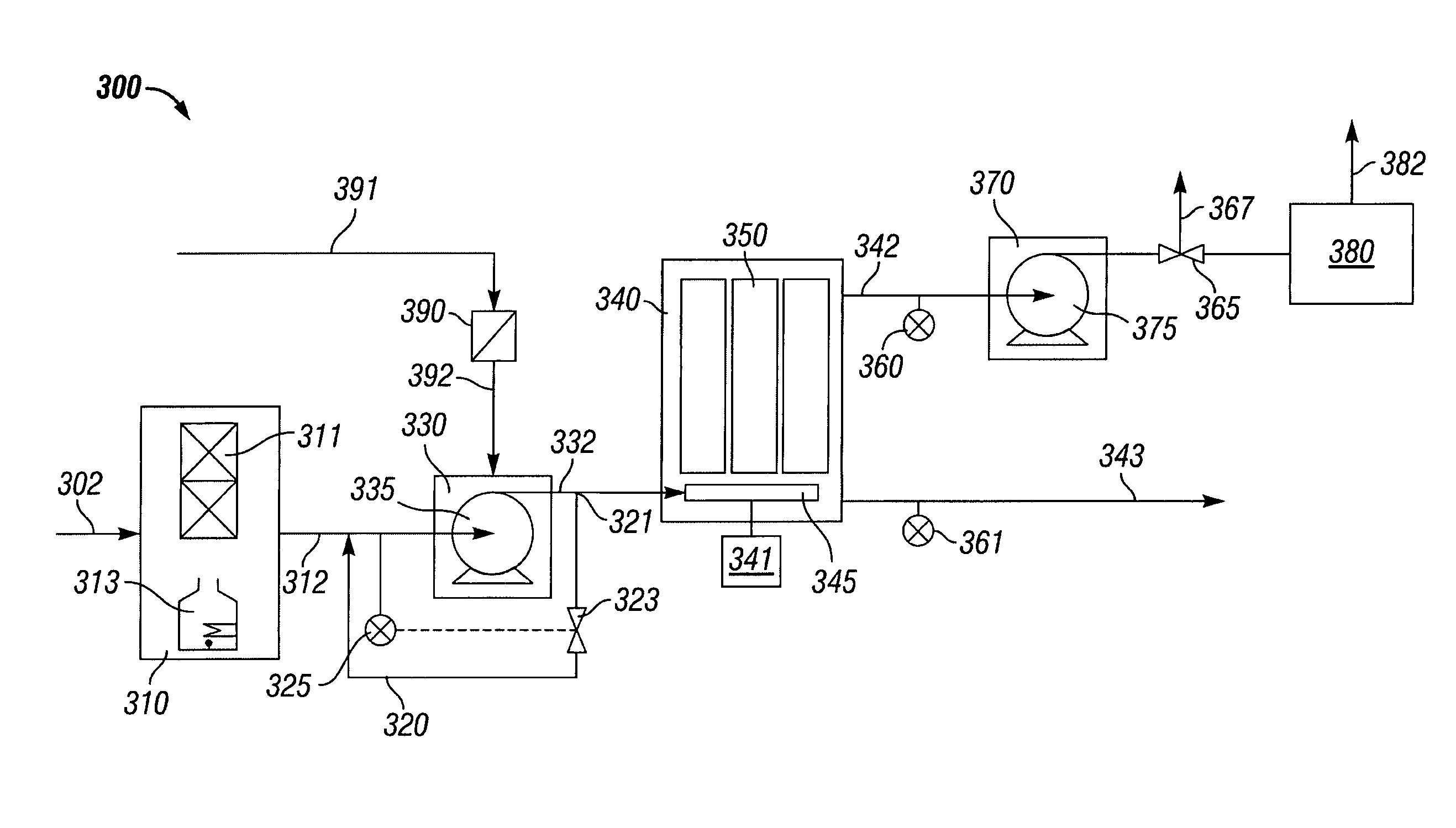

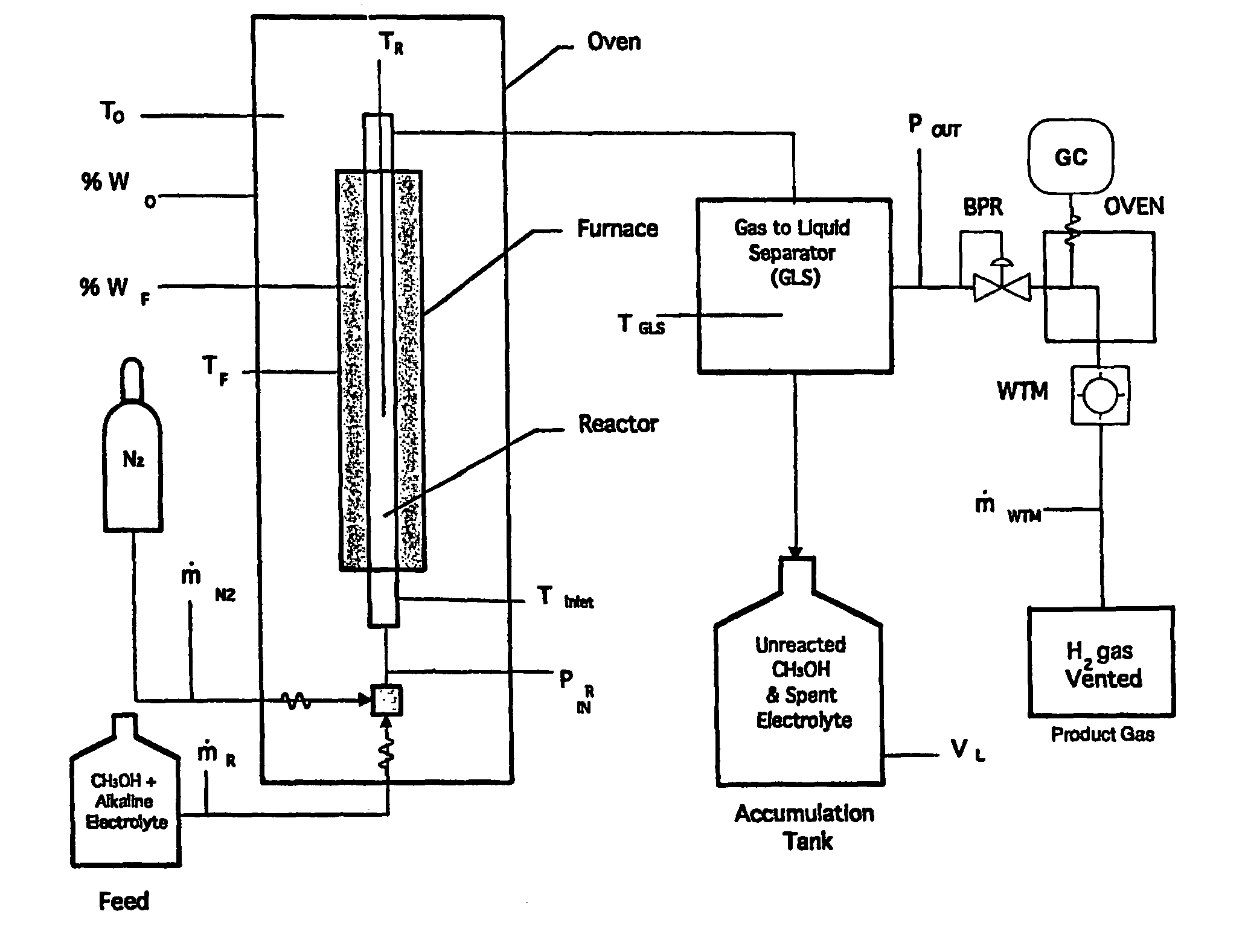

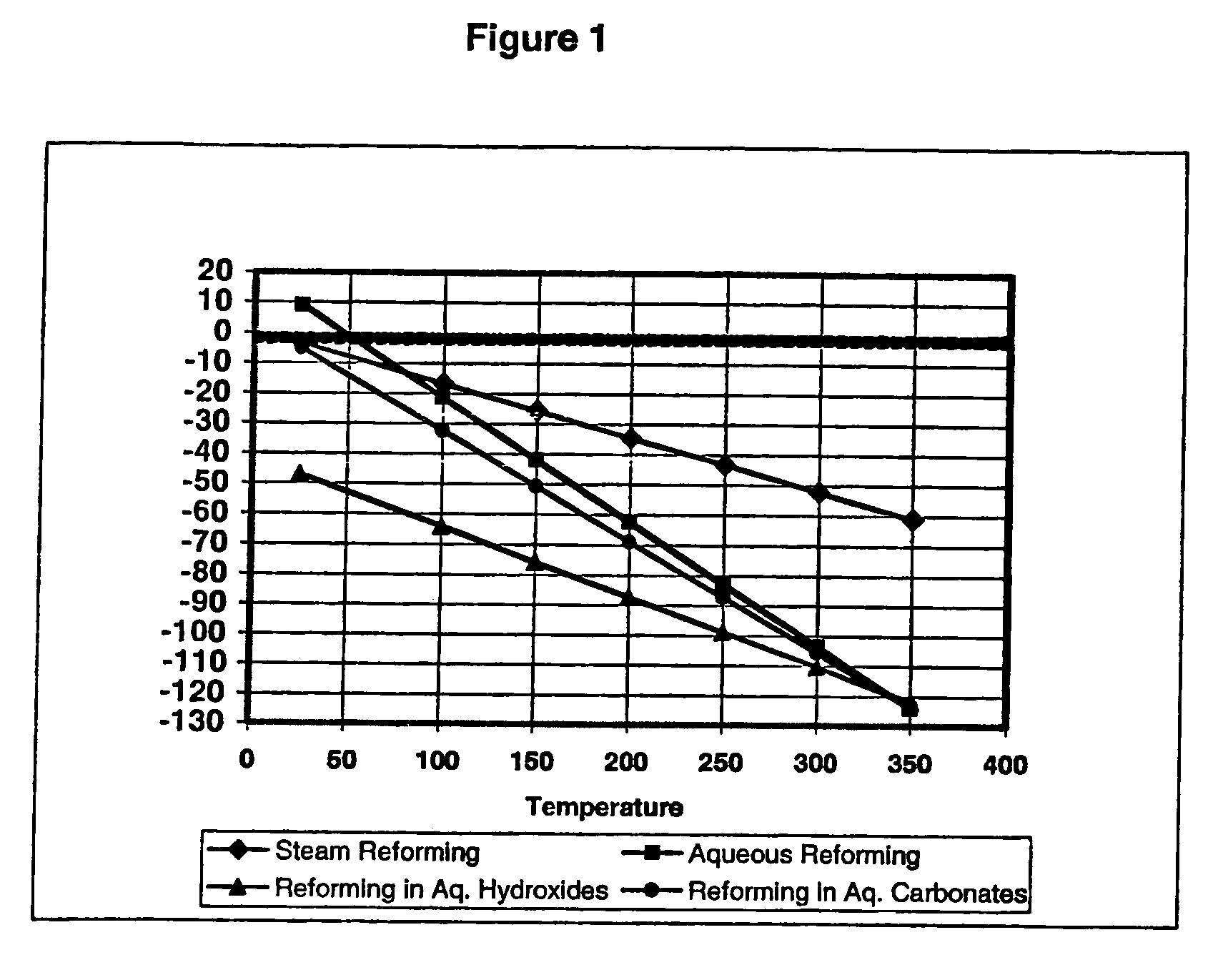

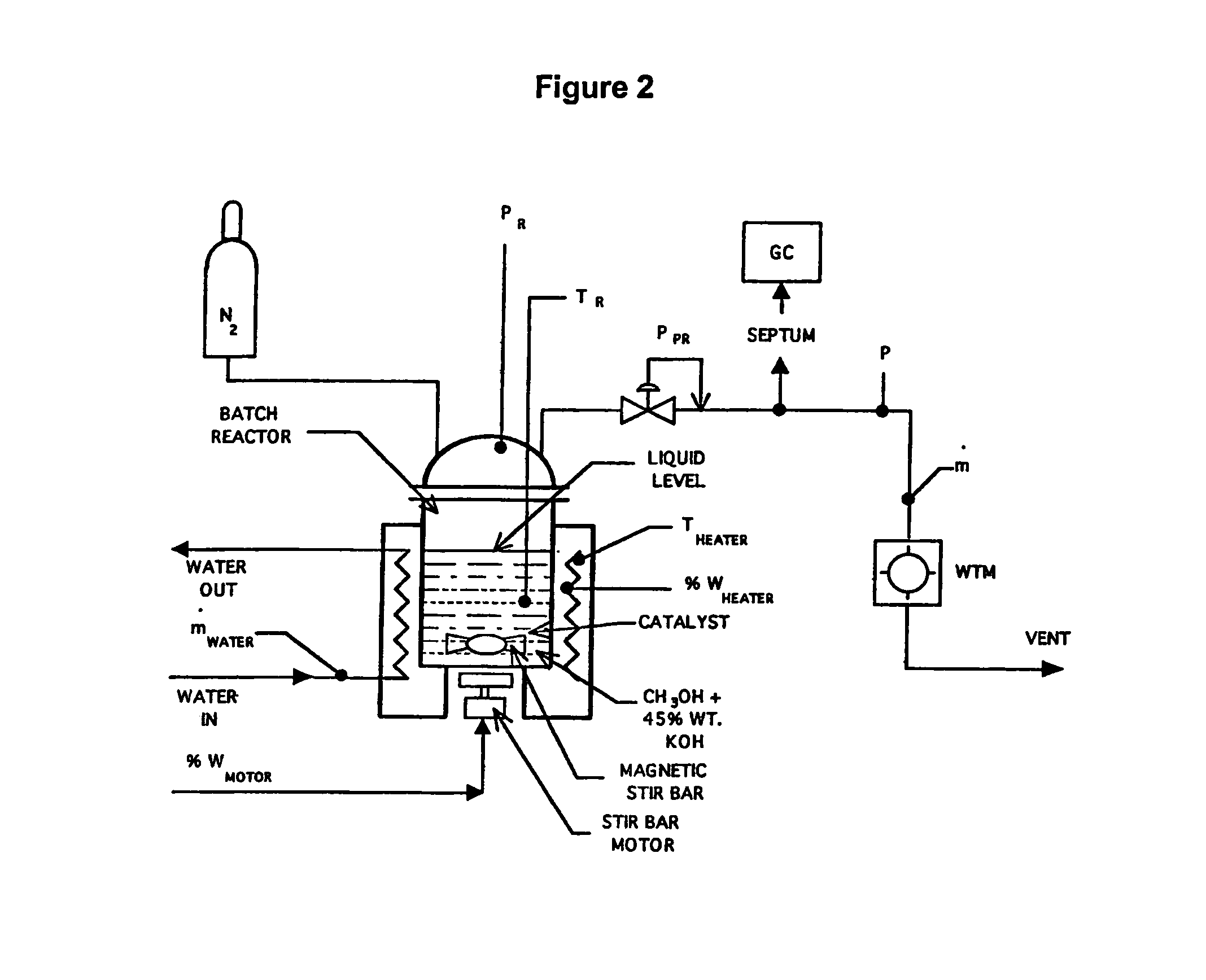

Hydrogen production using electrochemical reforming and electrolyte regeneration

ActiveUS8318130B2Effective and economical regenerationLower in carbon monoxide and carbon dioxideBicarbonate preparationElectrolysis componentsStream flowElectrochemistry

A process, preferably continuous, for producing hydrogen gas comprising contacting in the liquid phase at least one oxidizable organic substance in the presence of a mixture comprising at least one conductive catalyst and an aqueous alkaline carbonate electrolyte, wherein at least one bicarbonate composition produced by reaction of the electrolyte is regenerated and the at least one oxidizable organic substance comprises a oxygenated hydrocarbon, for example methanol and / or dimethyl ether. In a preferred embodiment the alkaline electrolyte is regenerated using steam. Various advantageous reaction schemes are described, utilizing, e.g., co-current and countercurrent stream flow and alternative tower sequence arrangements.

Owner:CONOCOPHILLIPS ENERGY TECH +1

Carbon capture in fermentation

InactiveUS20200048665A1Improve efficiencyImprove processing efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyMicroorganism

The invention relates to methods of capturing carbon by microbial fermentation of a gaseous substrate comprising CO into one or more first products which, in turn, may be incorporated into an article of manufacture or one or more second products.

Owner:LANZATECH NZ INC

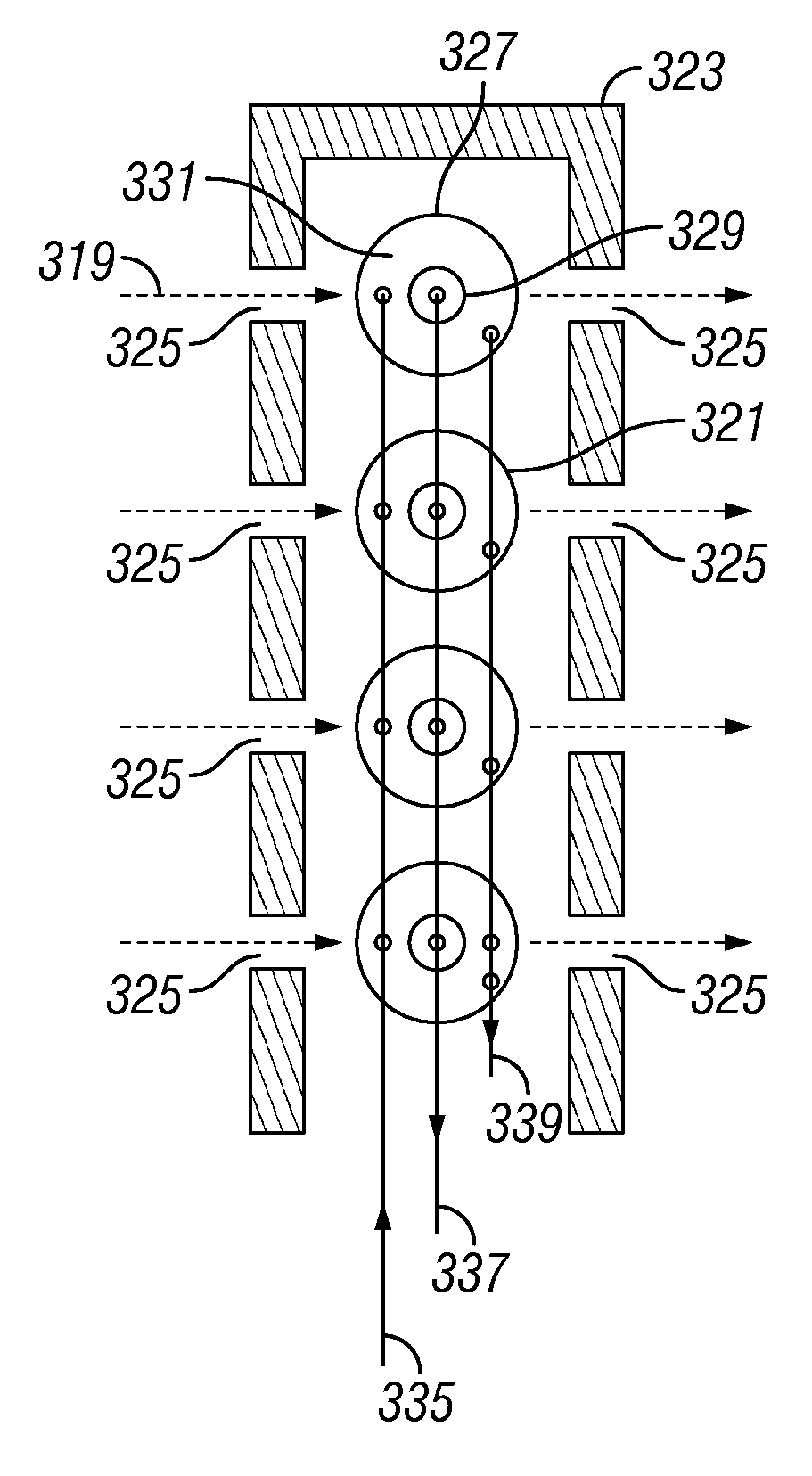

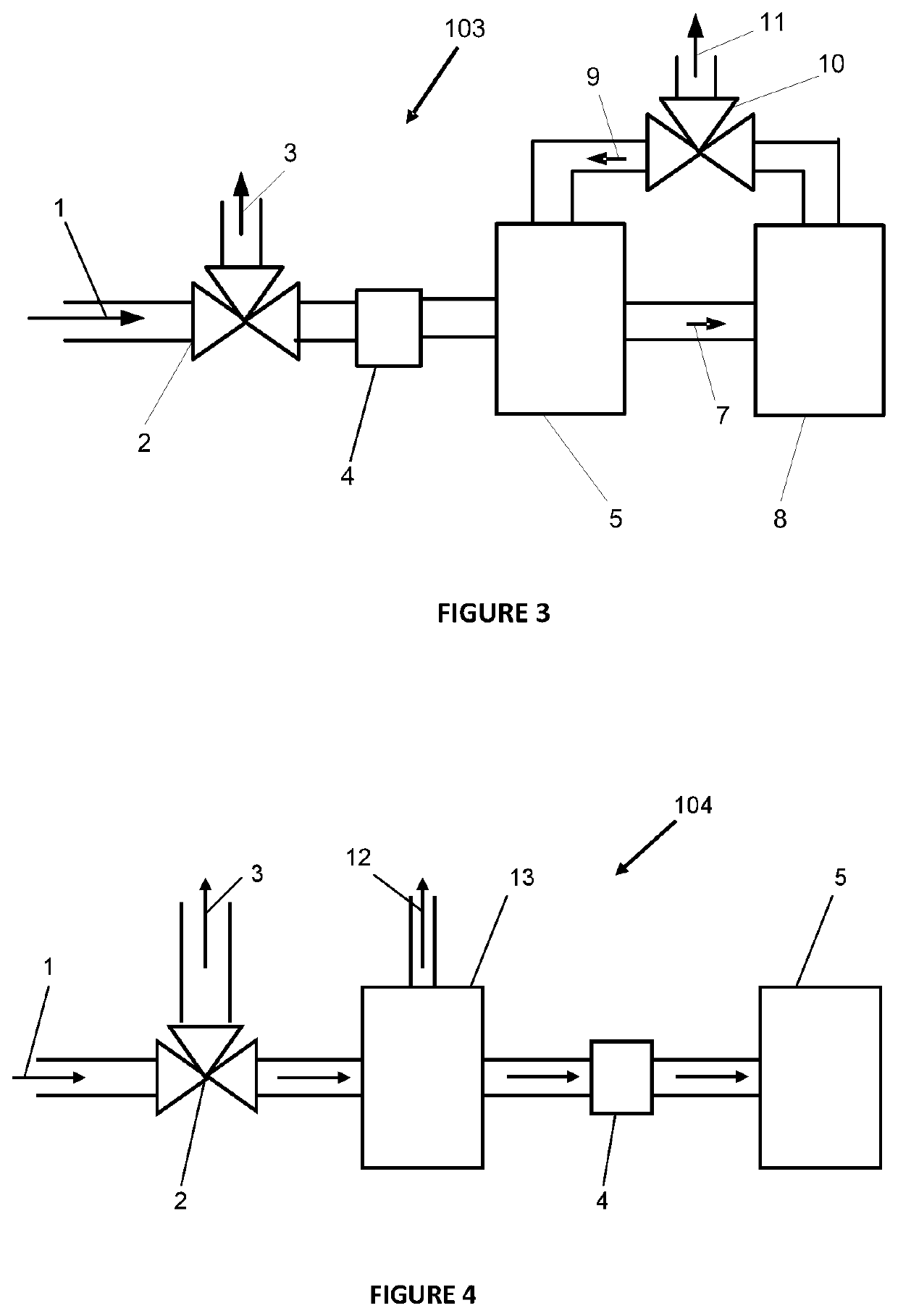

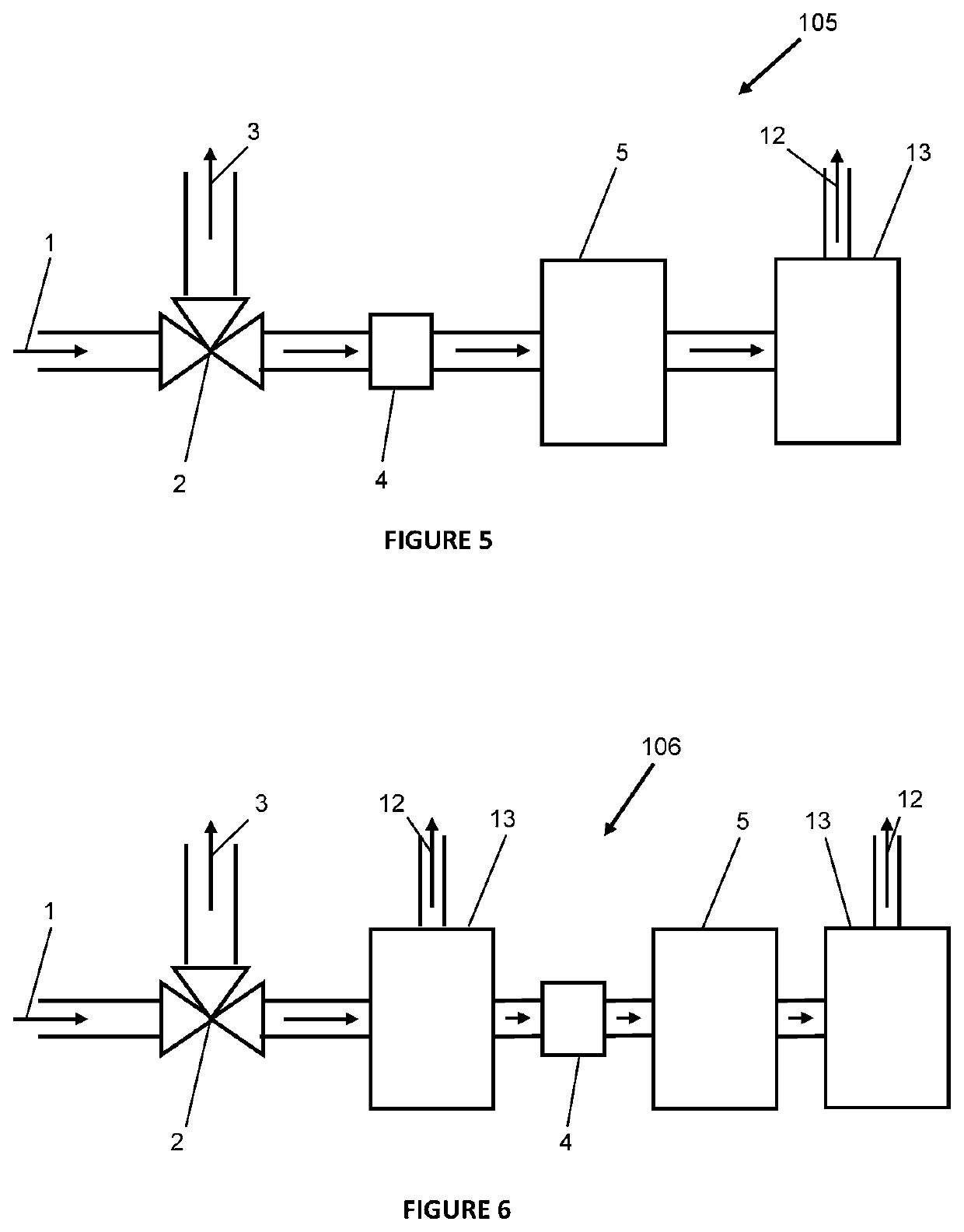

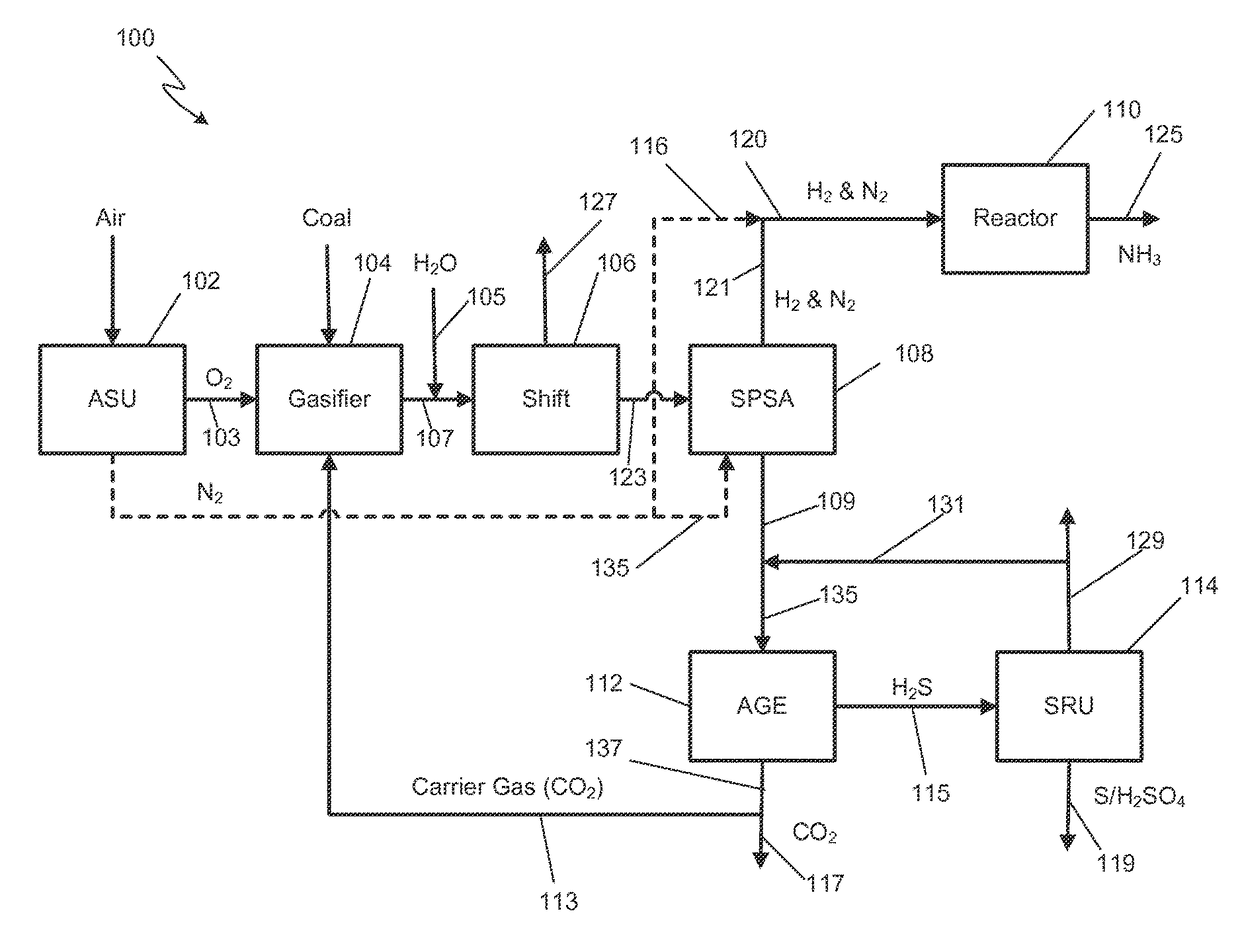

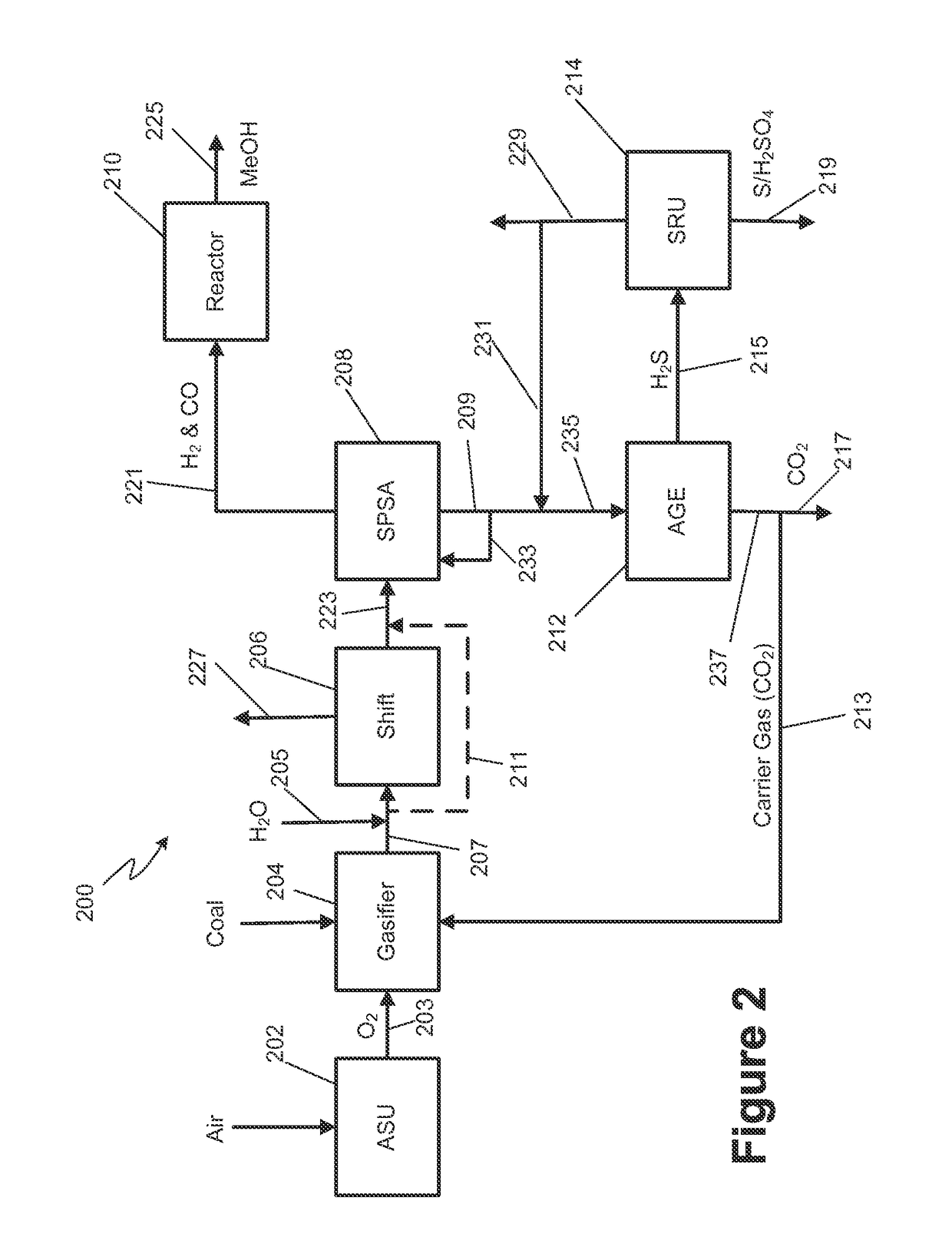

Sour pressure swing adsorption process

Methods and apparatuses for separating CO2 and sulfur-containing compounds from a synthesis gas obtained from gasification of a carbonaceous feedstock. The primary separating steps are performed using a sour pressure swing adsorption (SPSA) system, followed by an acid gas enrichment system and a sulfur removal unit. The SPSA system includes multiple pressure equalization steps and a rinse step using a rinse gas that is supplied from a source other than directly from one of the adsorber beds of the SPSA system.

Owner:AIR PROD & CHEM INC

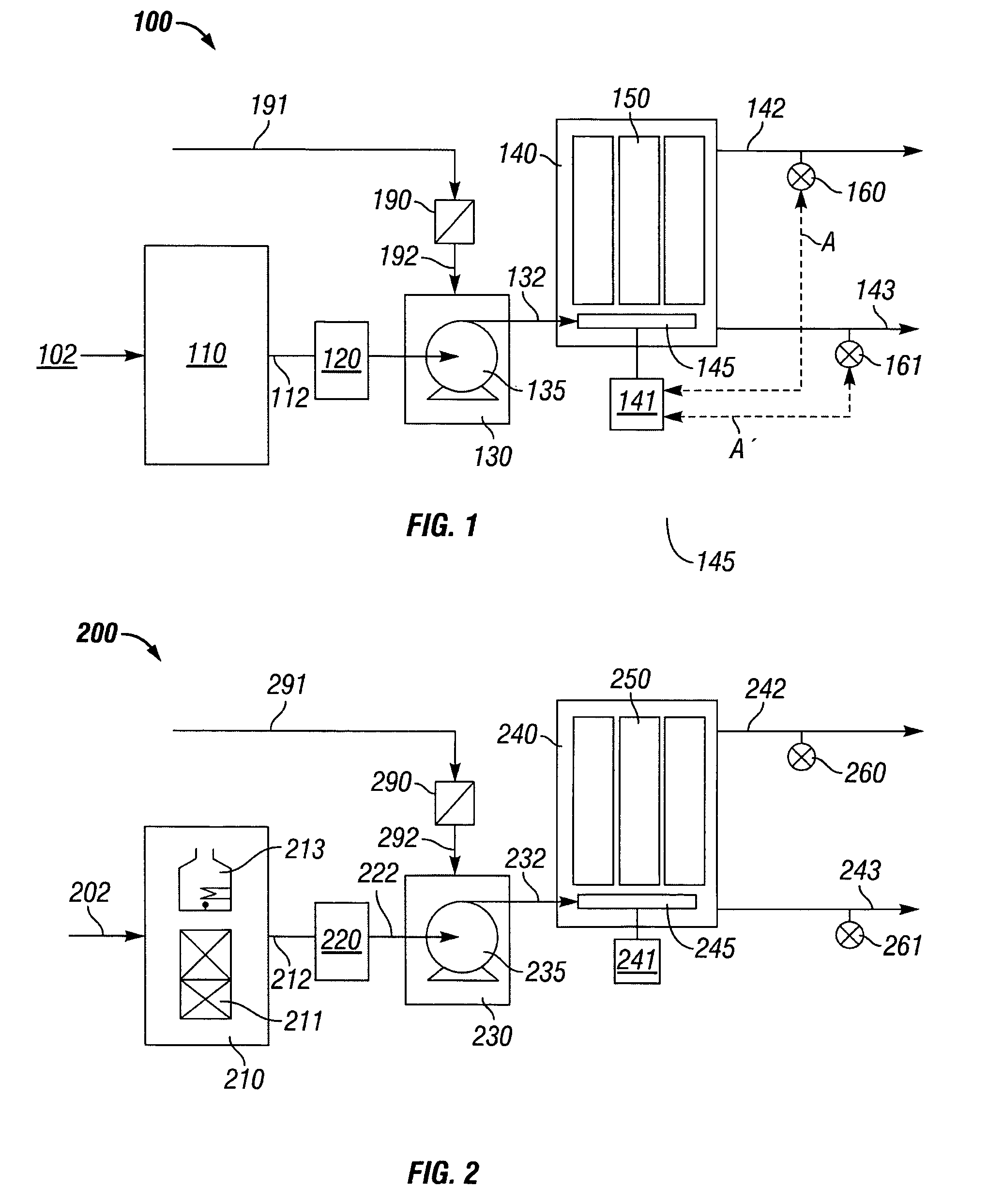

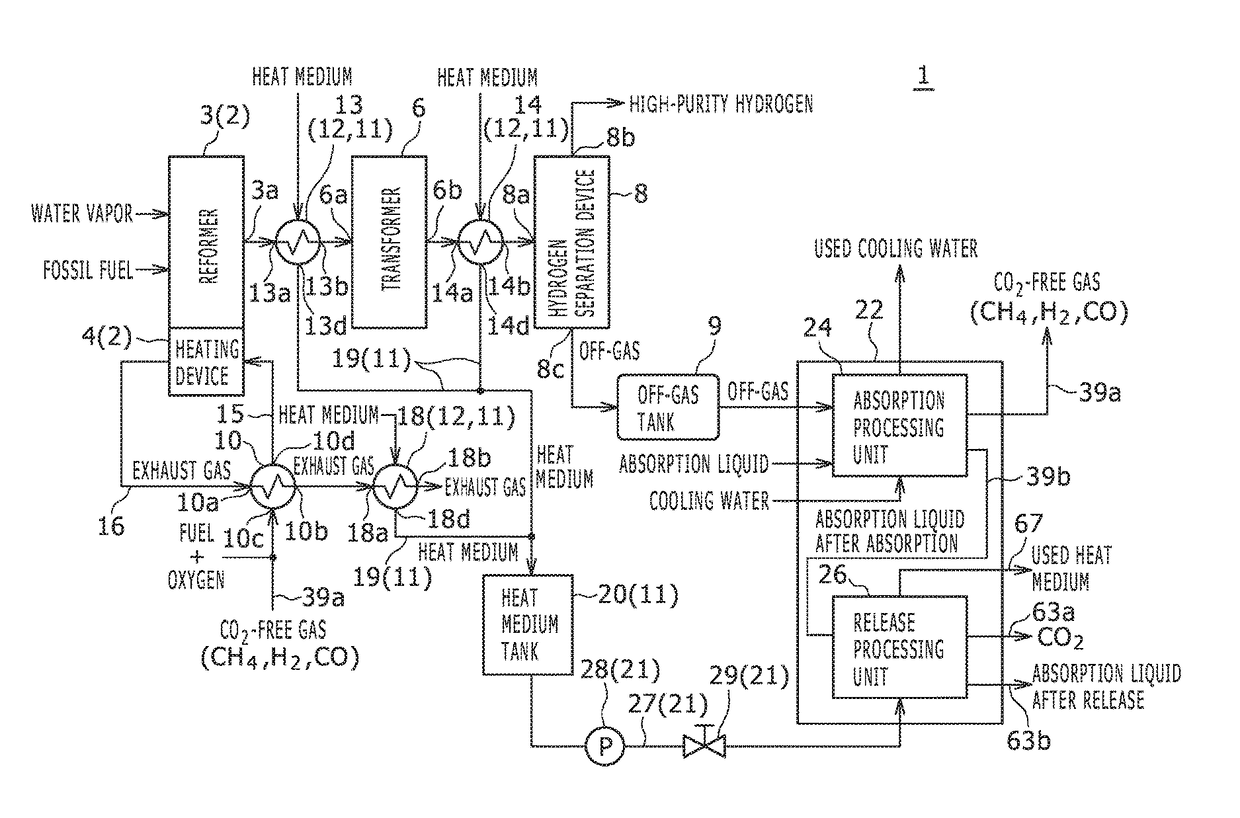

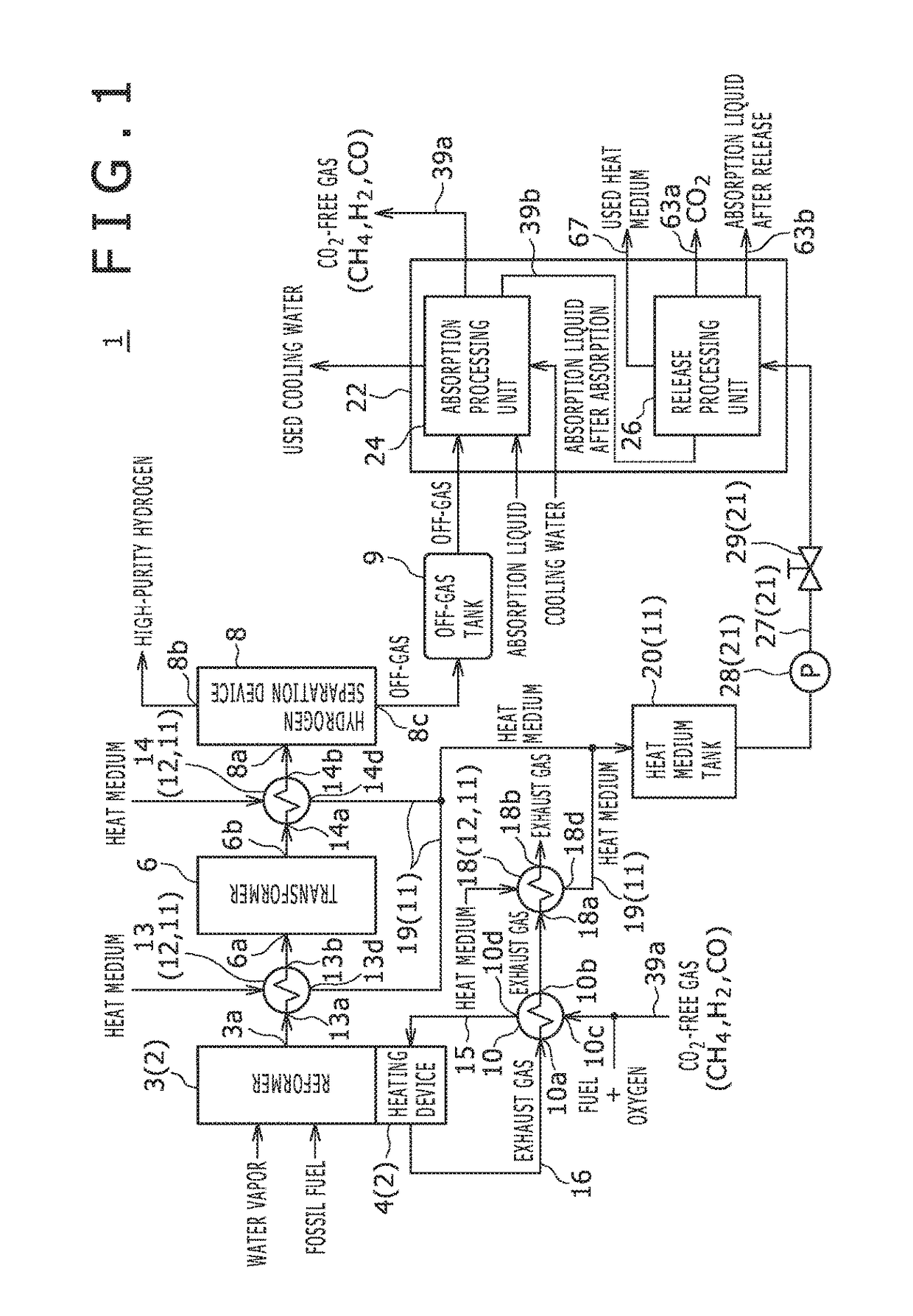

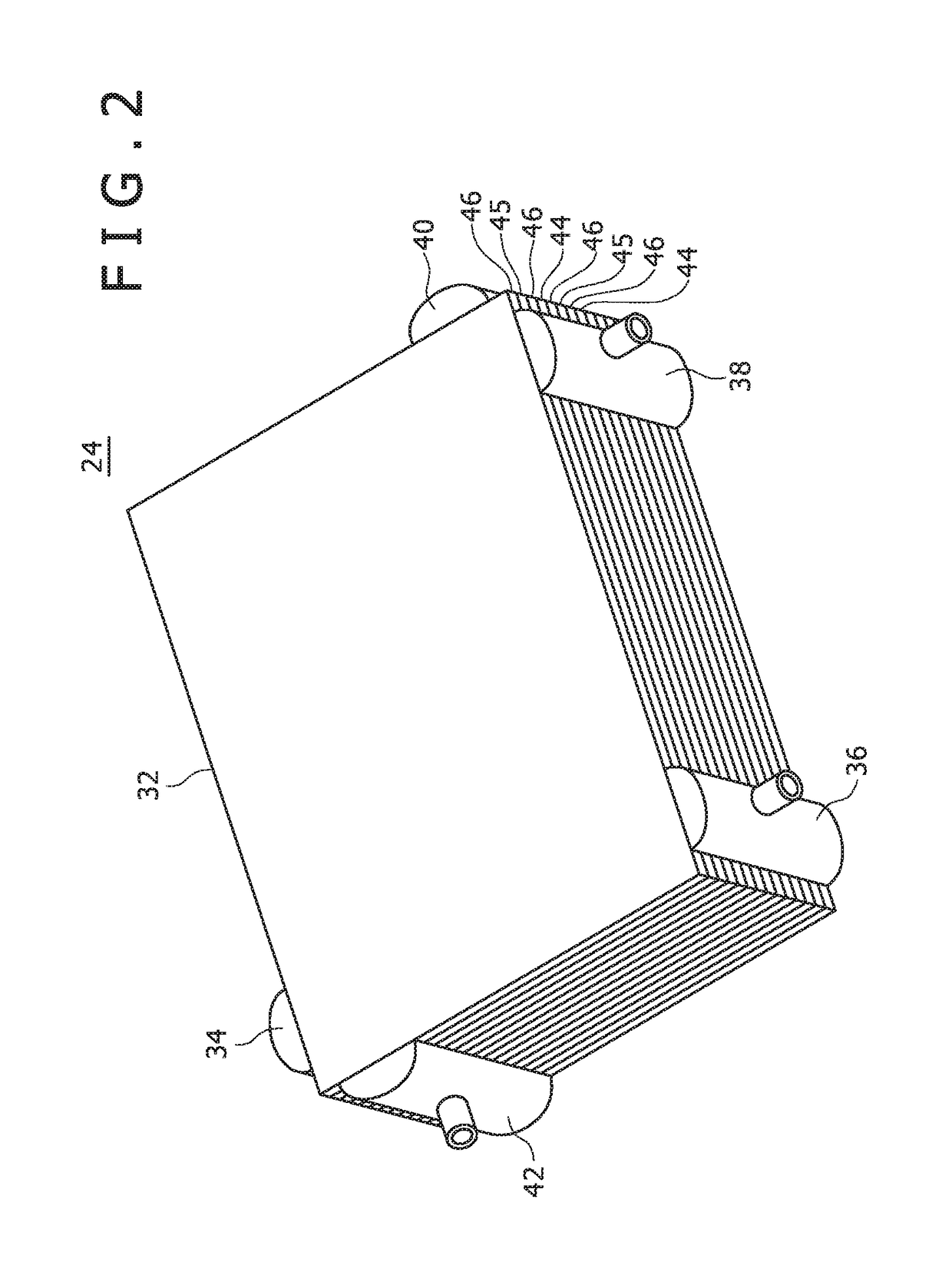

Hydrogen production apparatus and hydrogen production method

ActiveUS9776862B2Save energyCarbon compoundsHydrogen production carbon captureTransformerProduct gas

Provided is a hydrogen production apparatus enabling reduction of energy needed for separation and collection of CO2 in the hydrogen production. The hydrogen production apparatus includes a reformer, a heating device heating the reformer, a transformer, a hydrogen separation device separating and taking out hydrogen from transformed gas, a CO2 separation device separating and taking out CO2 from off-gas from which hydrogen was separated by the hydrogen separation device, a heat collecting device collecting heat of the reformed gas, heat of the transformed gas, and waste heat from the heating device, and a heat medium supply device supplying the heat medium having absorbed heat collected by the heat collecting device to the CO2 separation device. The absorption liquid having absorbed CO2 in off-gas is heated by the heat medium heated with collected heat, thereby releasing CO2.

Owner:KOBE STEEL LTD

Apparatus and method for oxy-combustion of fuels in internal combustion engines

ActiveUS9488100B2Lower the volumeElectrical controlInternal combustion piston enginesAtmospheric airOn board

A method and apparatus for the oxy-combustion of fuel in an internal combustion engine (ICE) used to power a vehicle converts the free energy available onboard the vehicle in the form of waste heat from the engine exhaust gas stream and coolant system into electrical and / or mechanical energy which energy is used to separate oxygen from air to eliminate or significantly reduce the volume of nitrogen entering the ICE's combustion chamber, and thereby reduce NOx pollutants released into the atmosphere and increase the concentration of CO2 in the engine exhaust stream for capture using an integrated system to compress and increase the density of the captured CO2 for temporary on-board storage until it is discharged at a recovery station, e.g., during vehicle refueling.

Owner:SAUDI ARABIAN OIL CO

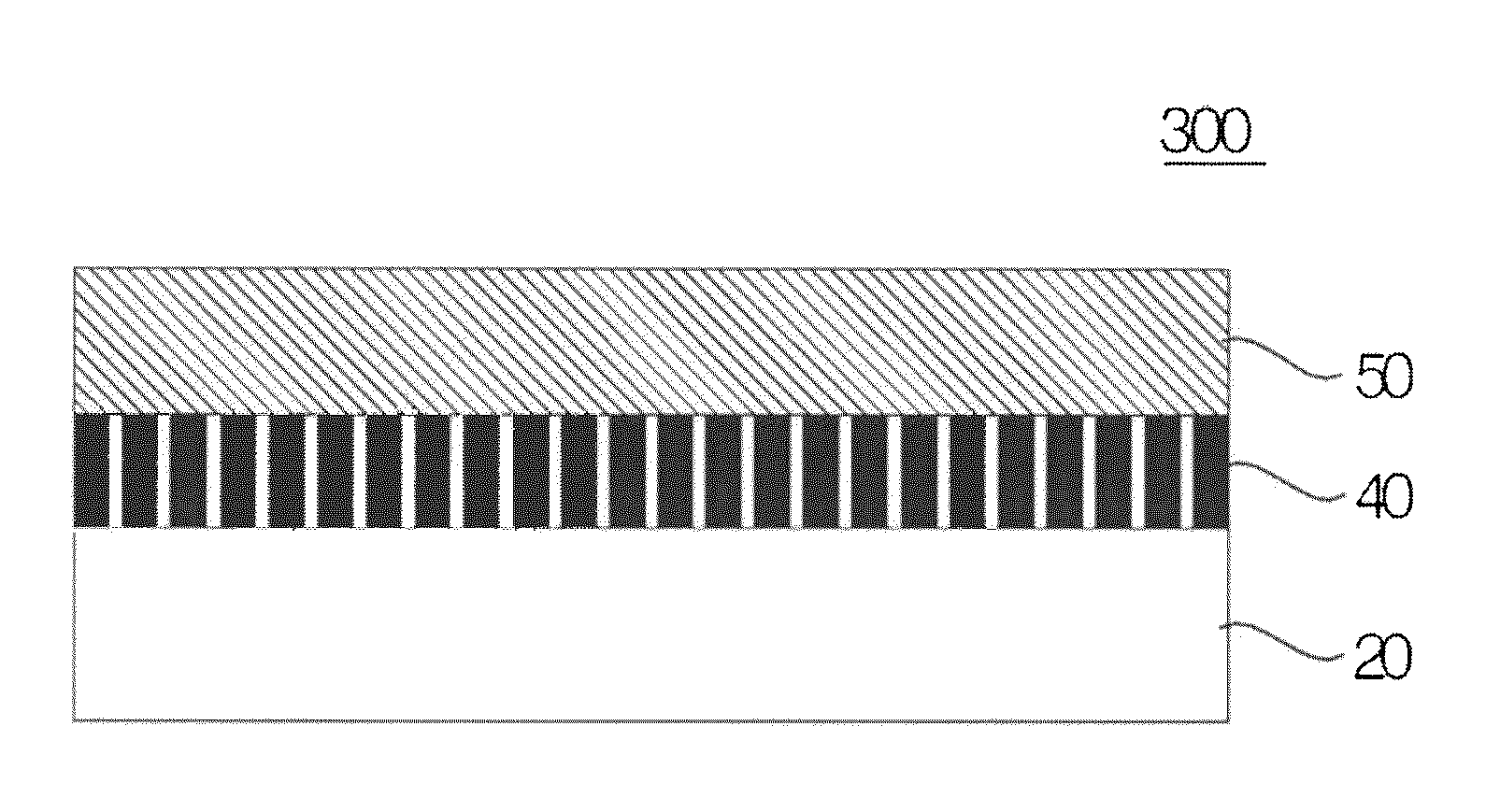

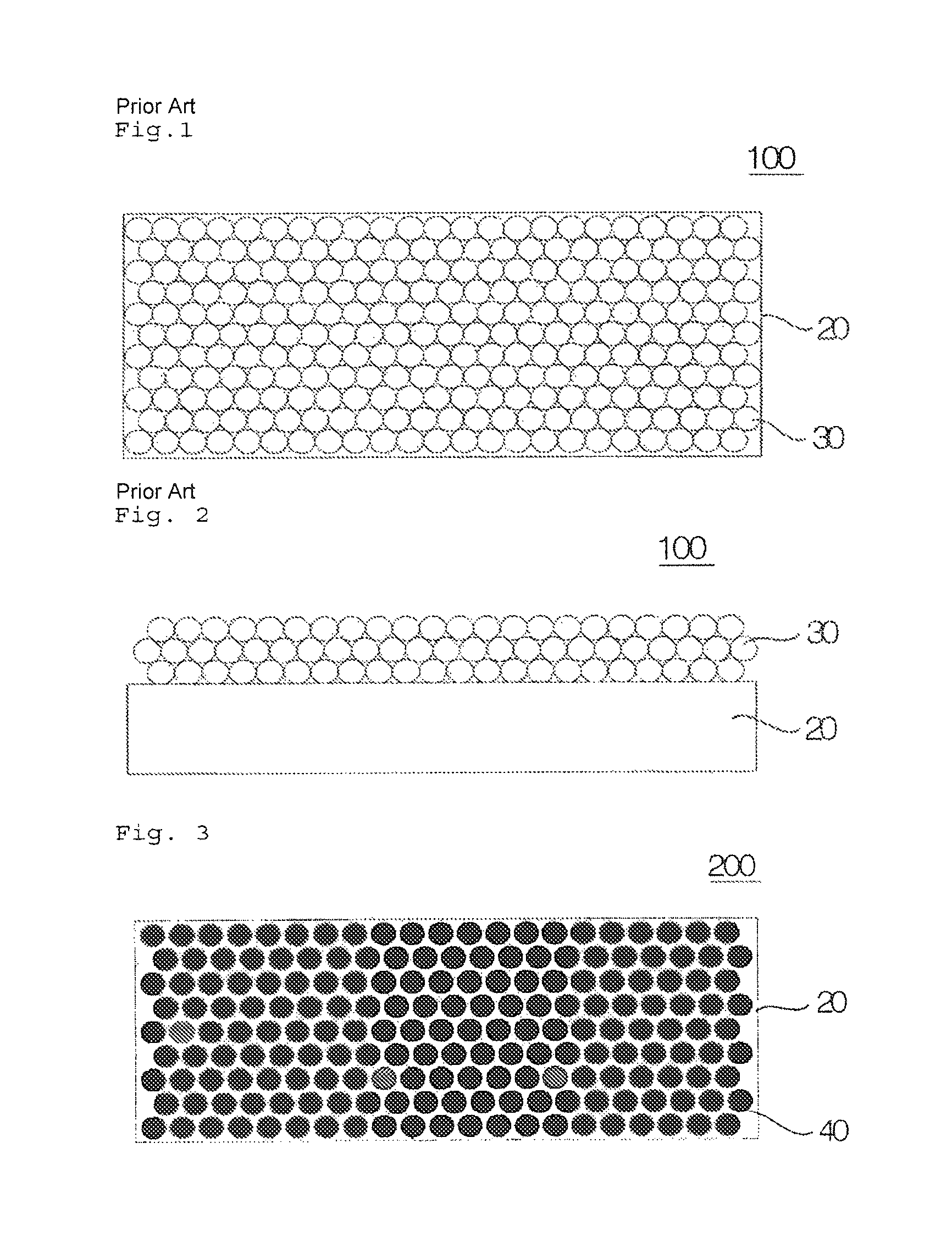

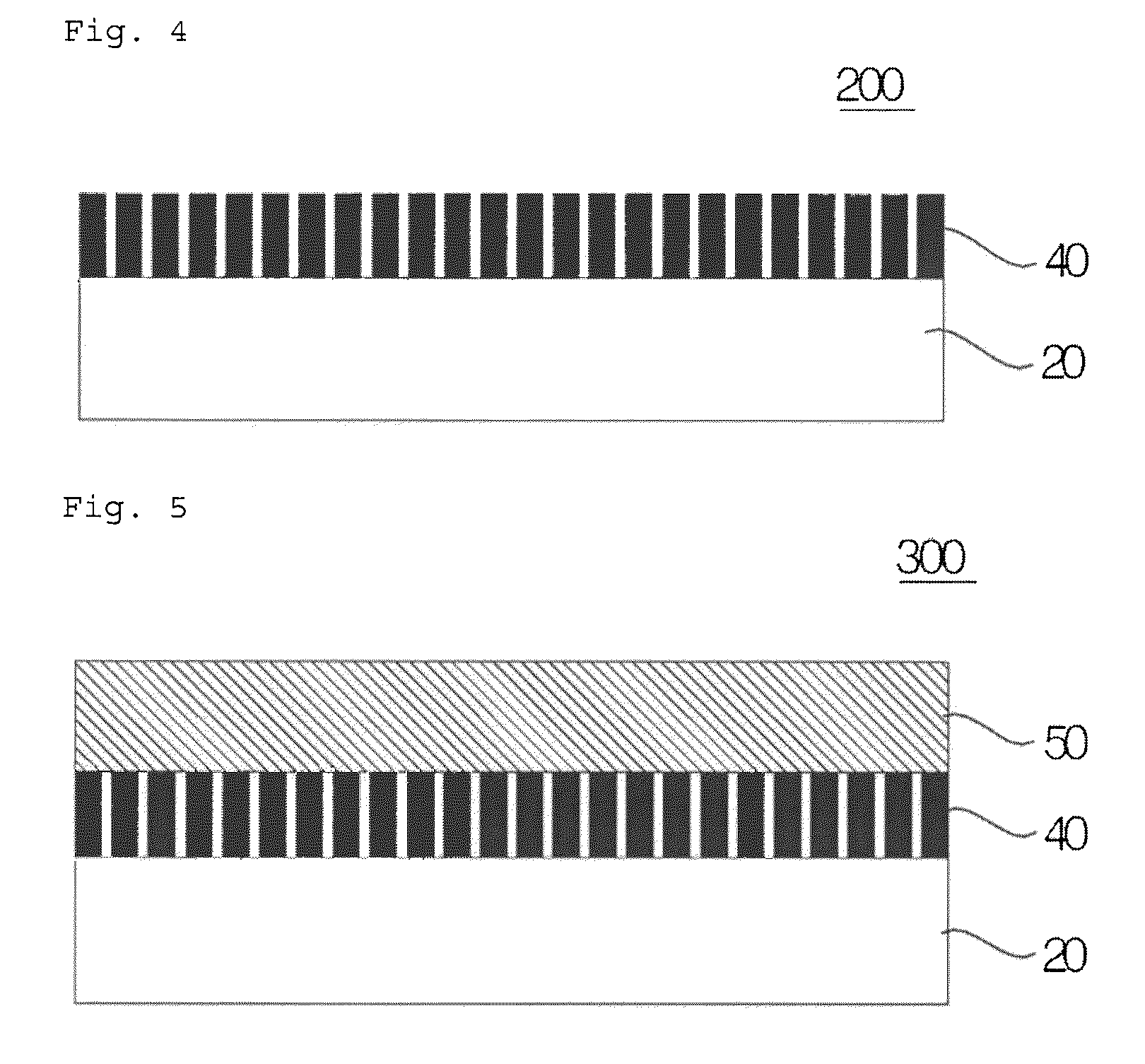

Heat resistant hydrogen separation membrane and method for manufacturing same

ActiveUS9415343B2Increased durabilityEasy to modularizeSemi-permeable membranesMembranesHydrogenHydrogen permeation

The present invention relates to a hydrogen separation membrane which coats granular ceramic onto the surface of a porous metal support and which coats a hydrogen permeation metal thereon so as to inhibit diffusion between the support and a hydrogen separation layer, and to a method for manufacturing same. As a result, the metal support can be modularized with ease, the hydrogen permeation layer can be made thinner to increase the amount of hydrogen permeation, the use of a separation material can be minimized, and the hydrogen separation membrane can have higher competitiveness.

Owner:KOREA INST OF ENERGY RES

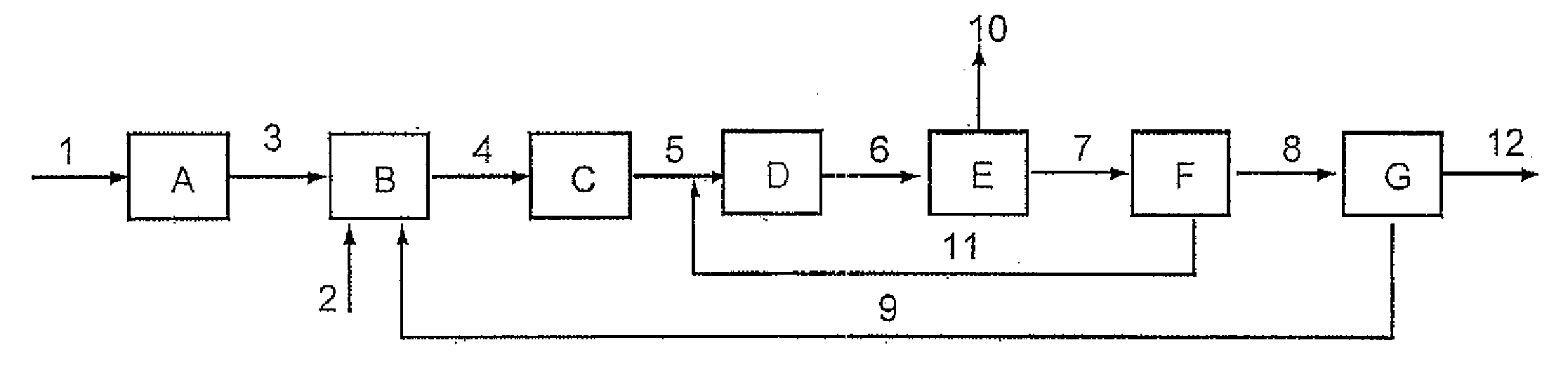

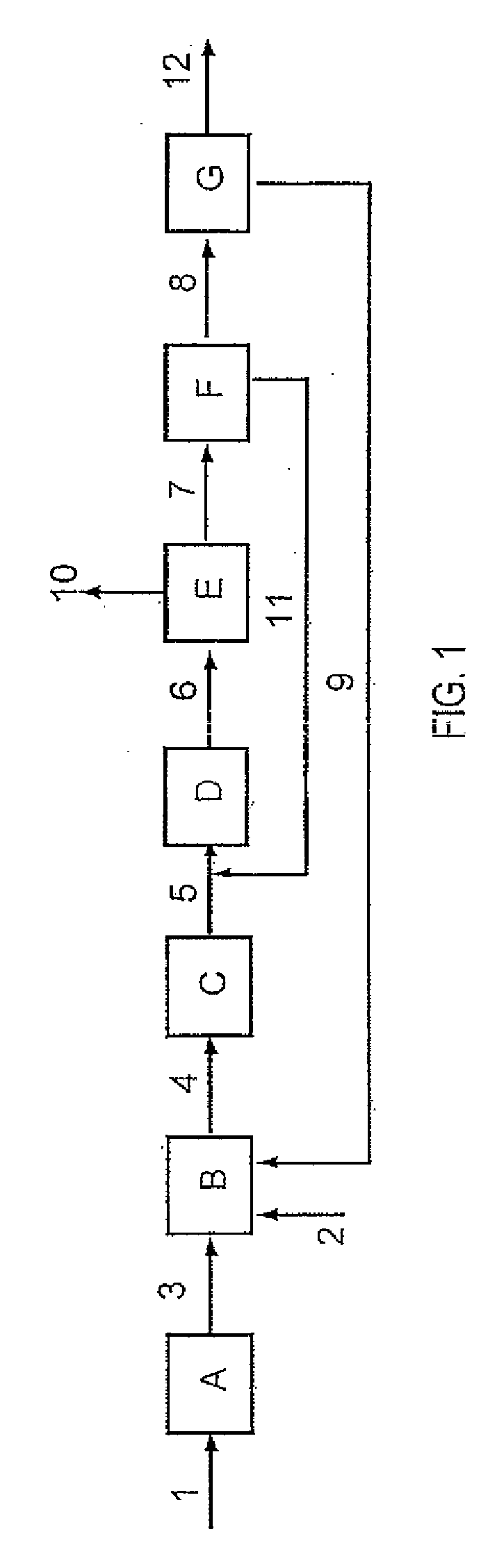

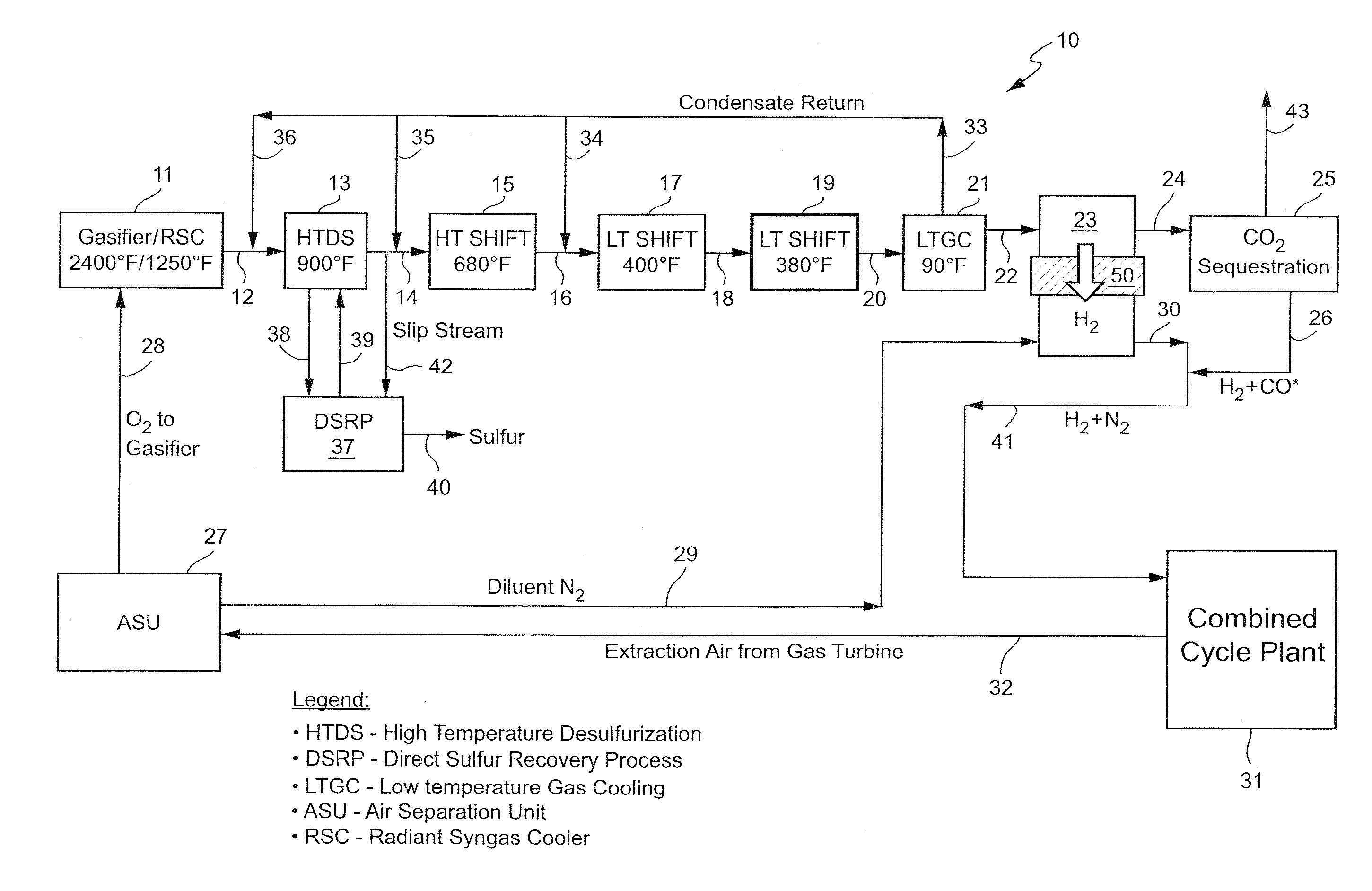

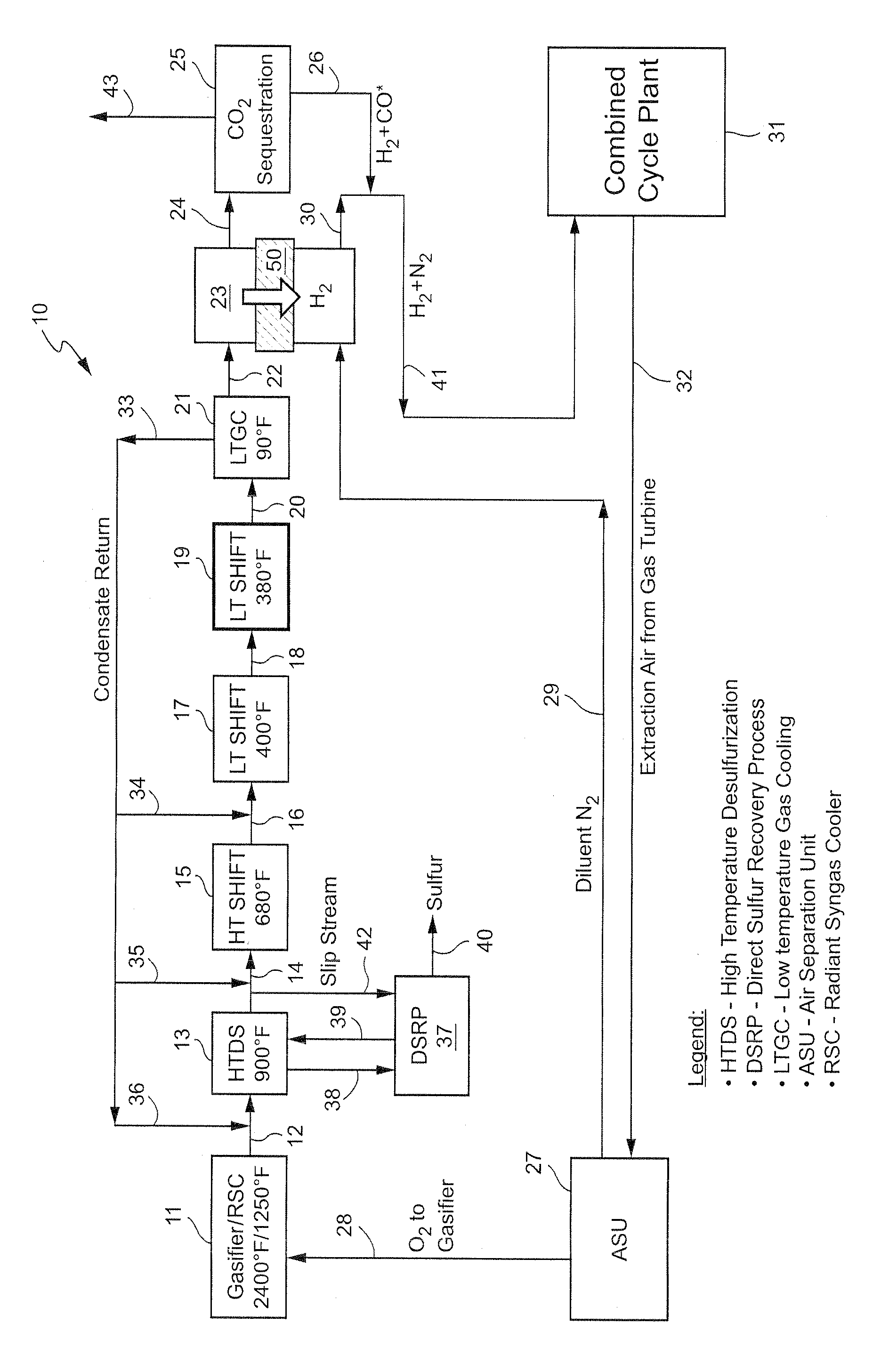

Sytems and method for CO2 capture and H2 separation with three water-gas shift reactions and warm desulfurization

Owner:GE INFRASTRUCTURE TECH INT LLC

Method for treating waste gases from plants for pig iron production

InactiveUS9377242B2Improve overall utilizationHigh hydrogen contentHydrogenEnergy inputWater vaporEnvironmental engineering

A method and a system for treating waste gases (4) from plants (32, 33) for pig iron production, wherein a first sub-stream (51) of the waste gas is subjected to an at least partial conversion of CO into CO2 after the addition of water and / or water vapor (10) and the waste gas (4) is then subjected to CO2 capture. To be able to set a variable H2 / CO ratio in the waste gas, a further sub-stream (52) of the waste gas is not subjected to a conversion of CO into CO2, but is subjected to CO2 capture separately from the first sub-stream (51).

Owner:PRIMETALS TECH AUSTRIA GMBH

System and method for treating hydrogen to be stored in a salt cavern and supplying therefrom

ActiveUS9718618B2Suppresses intrusion of and moreHigh purityHydrogen separation at low temperatureDispersed particle separationStable stateAbsorption capacity

Owner:PRAXAIR TECH INC

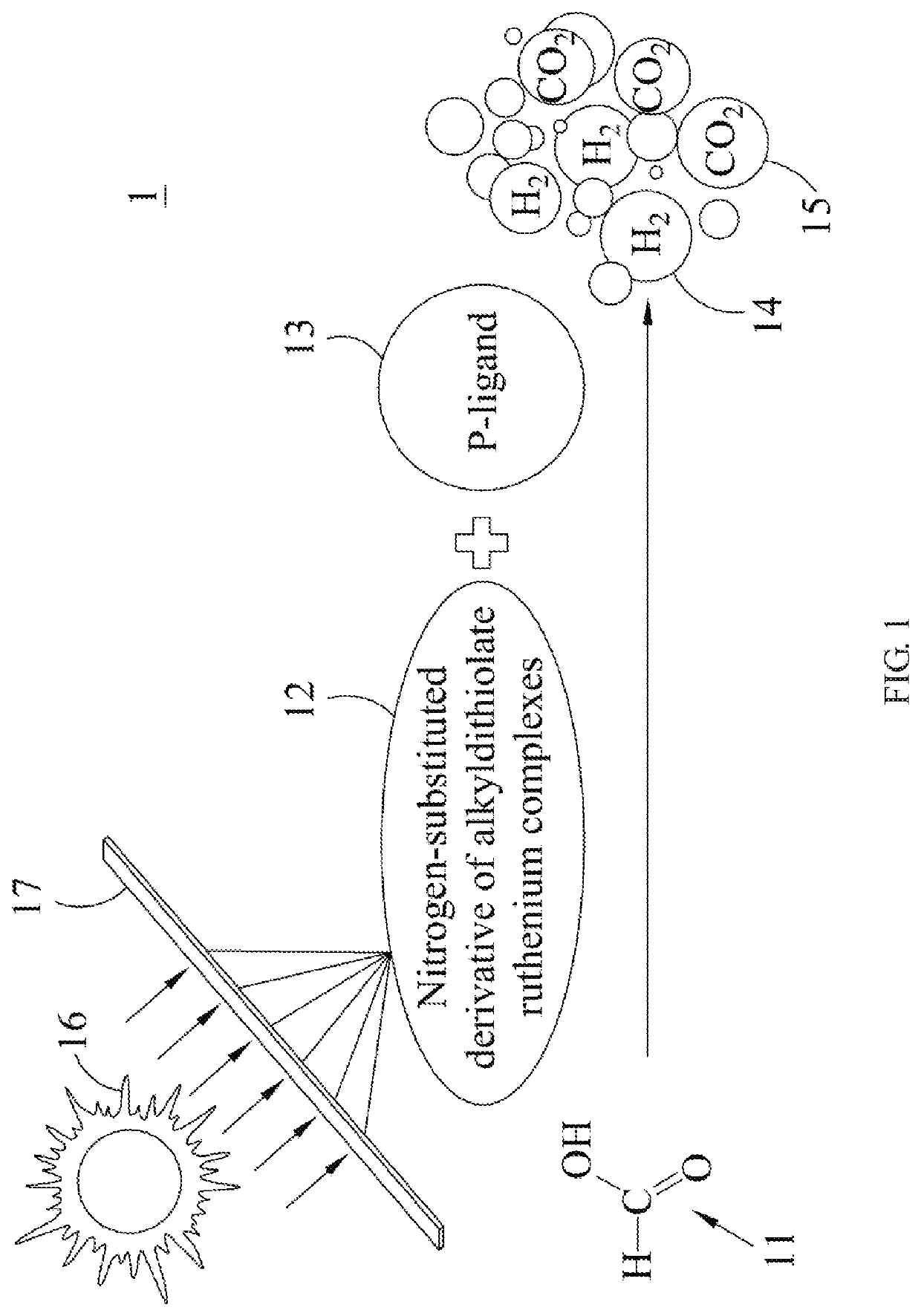

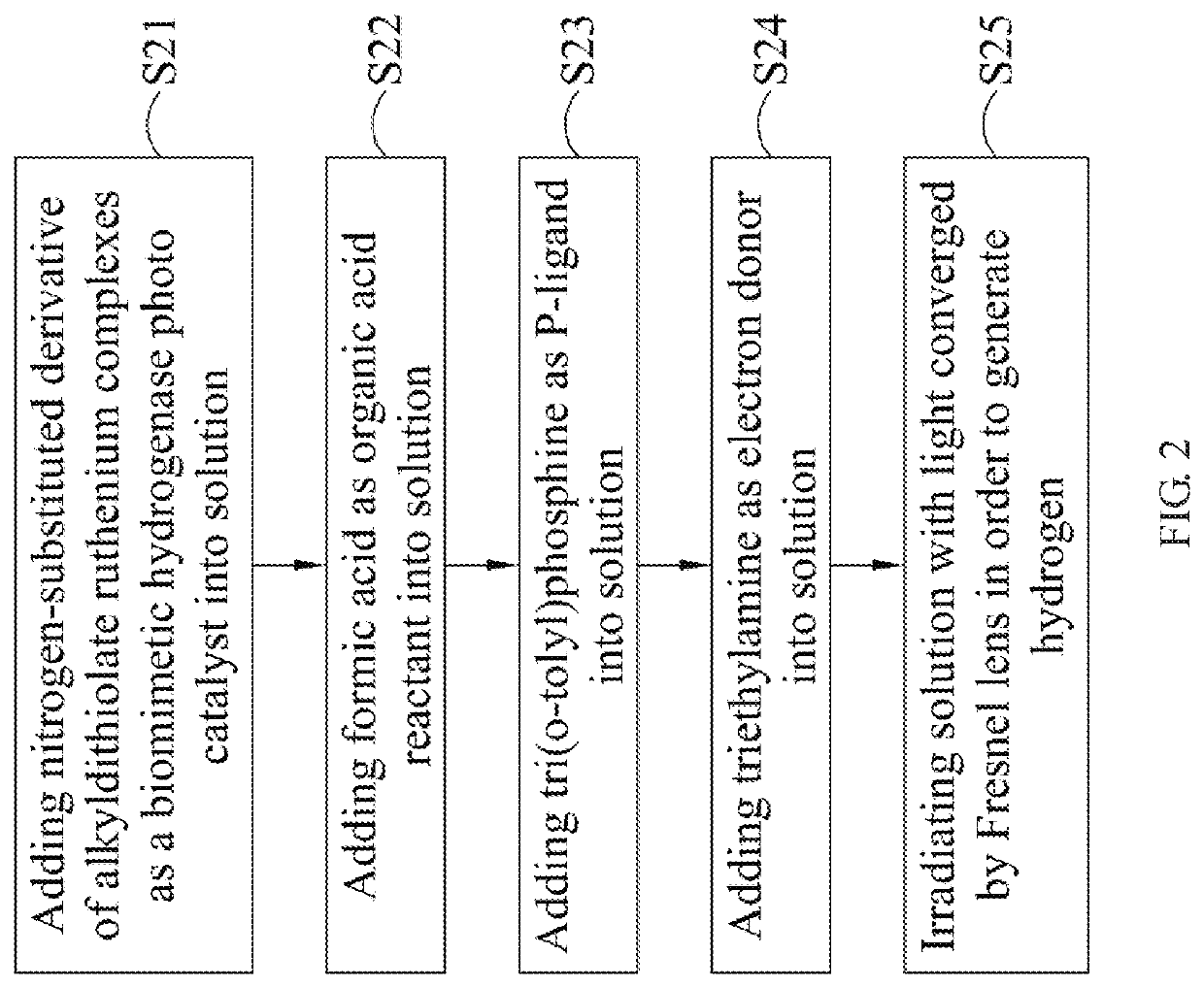

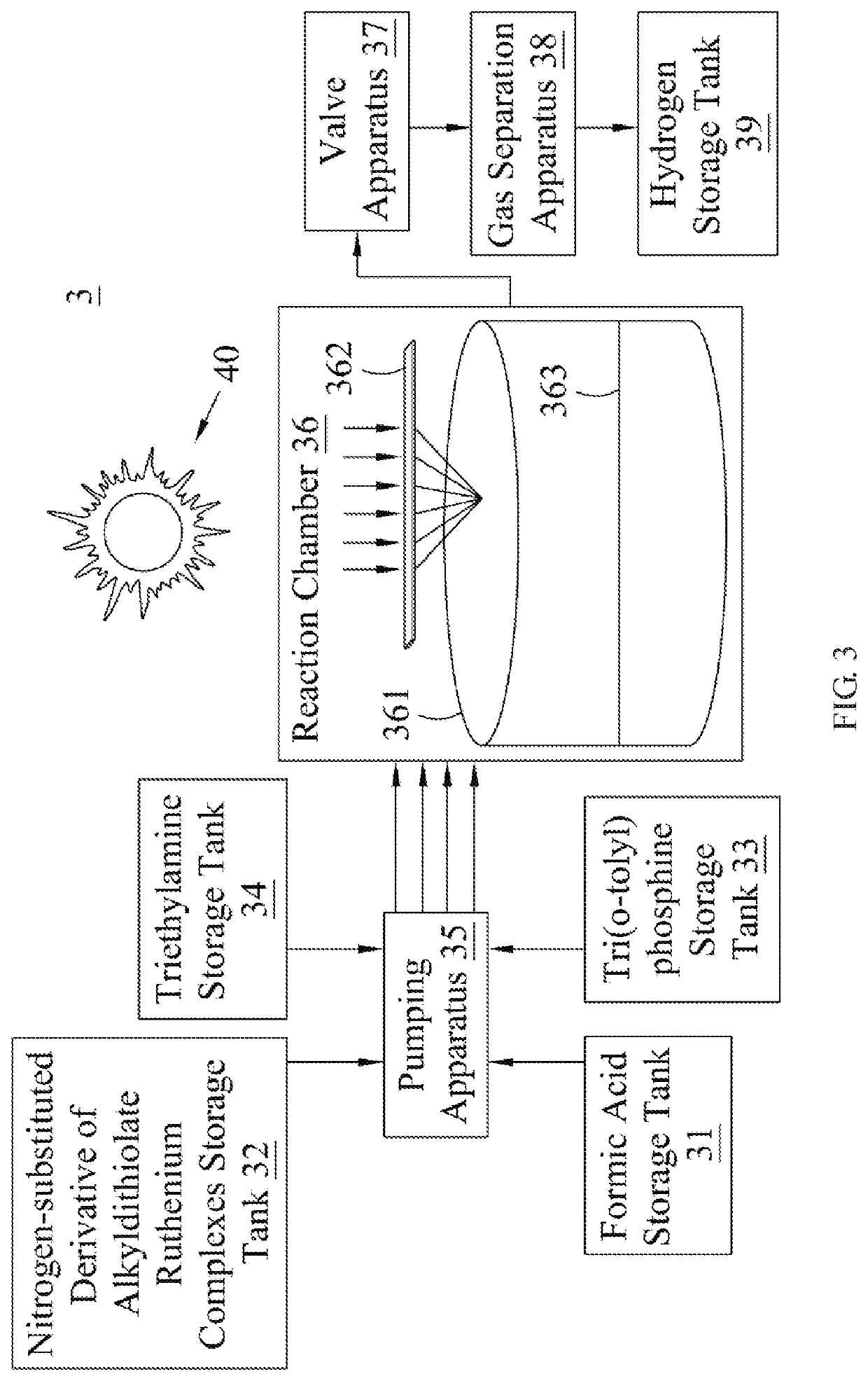

Hydrogen generation method, system, and solution used therein

ActiveUS10710878B2Improve utilization efficiencyLow costHydrogenOrganic-compounds/hydrides/coordination-complexes catalystsPhoto irradiationElectron donor

A hydrogen generation method including steps as follows: adding a nitrogen-substituted derivative of an alkyldithiolate ruthenium complex as a biomimetic hydrogenase photocatalyst into a solution, adding an organic acid into the solution, adding a P-ligand into the solution, adding an electron donor into the solution, and irradiating the solution with light in order to generate hydrogen.

Owner:NAT CHIAO TUNG UNIV

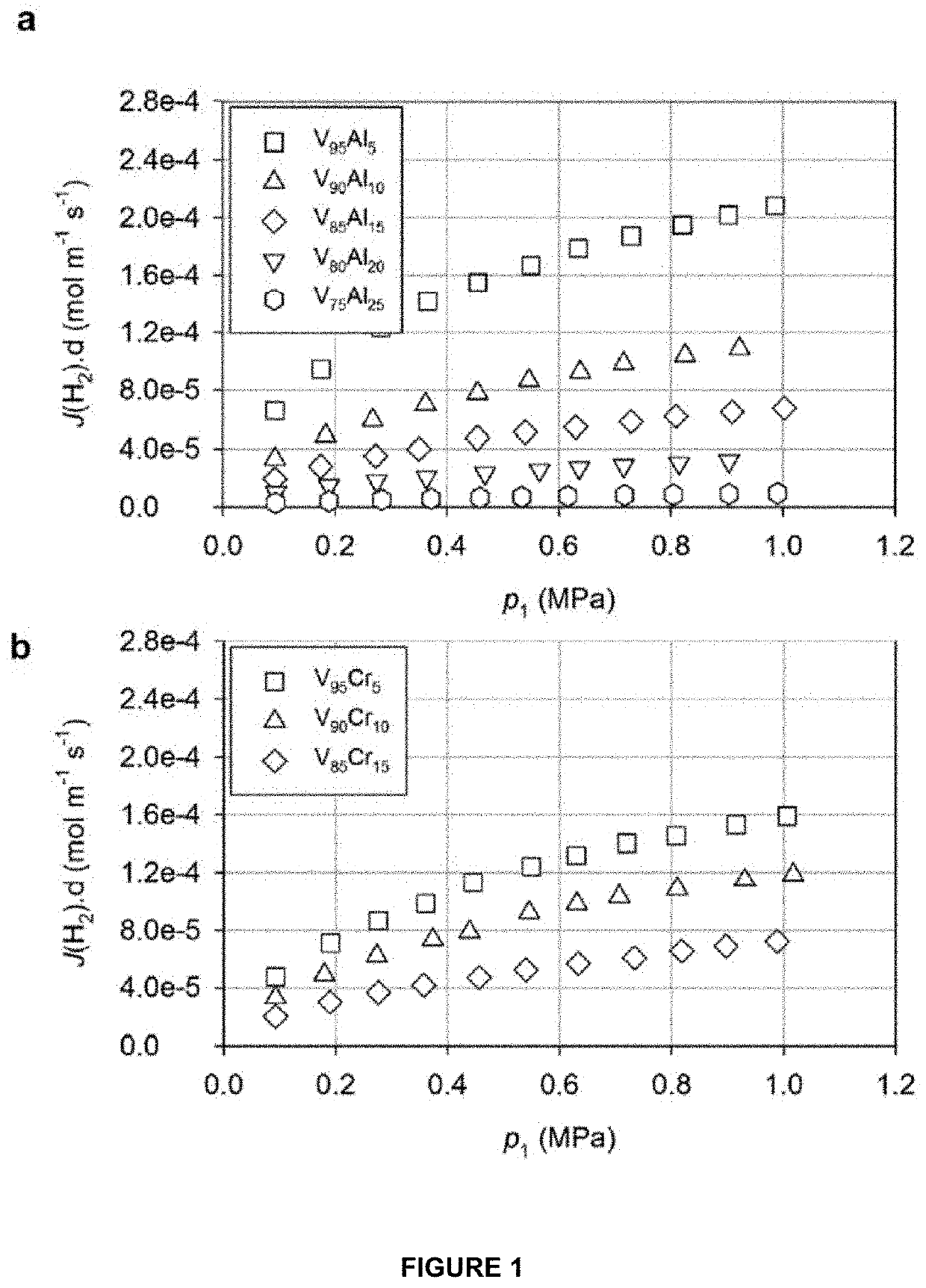

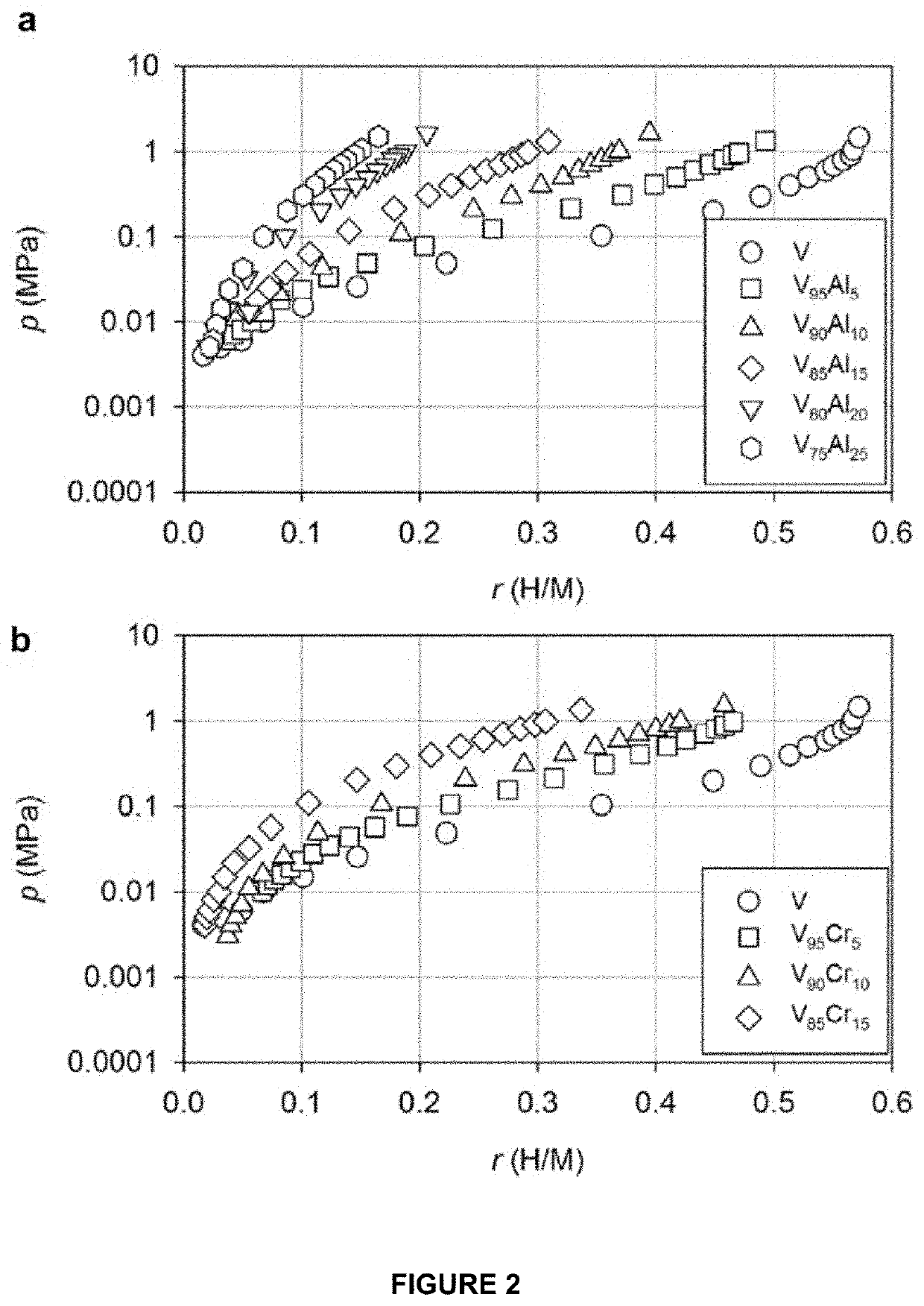

Alloy for catalytic membrane reactors

ActiveUS10590516B2Raise the ratioMinimize impactProductsSemi-permeable membranesAlloyCatalytic membrane

Owner:COMMONWEALTH SCI & IND RES ORG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com