Method for performing synchronous desulfurization, denitrification and dust removal in bag type dust collector

A bag filter, desulfurization and denitrification technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as reducing the concentration of soot, and achieve the effects of reducing load, reducing the content of soot, and reducing treatment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

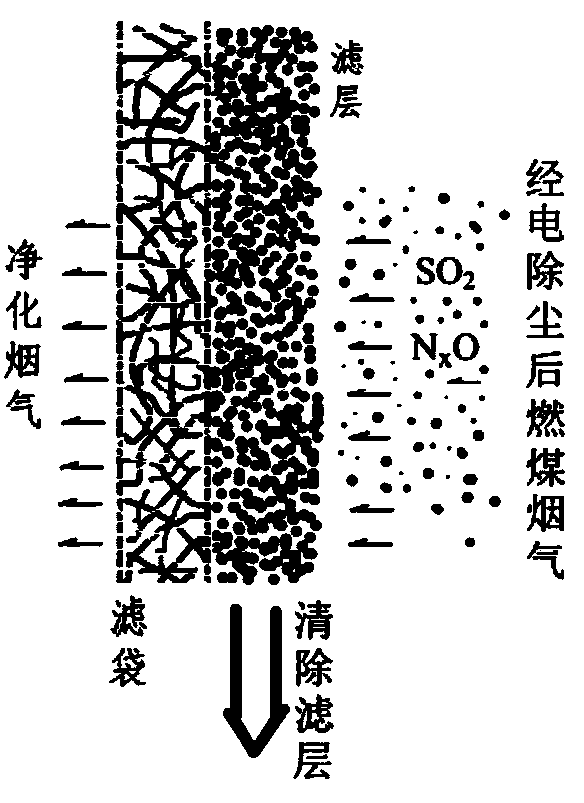

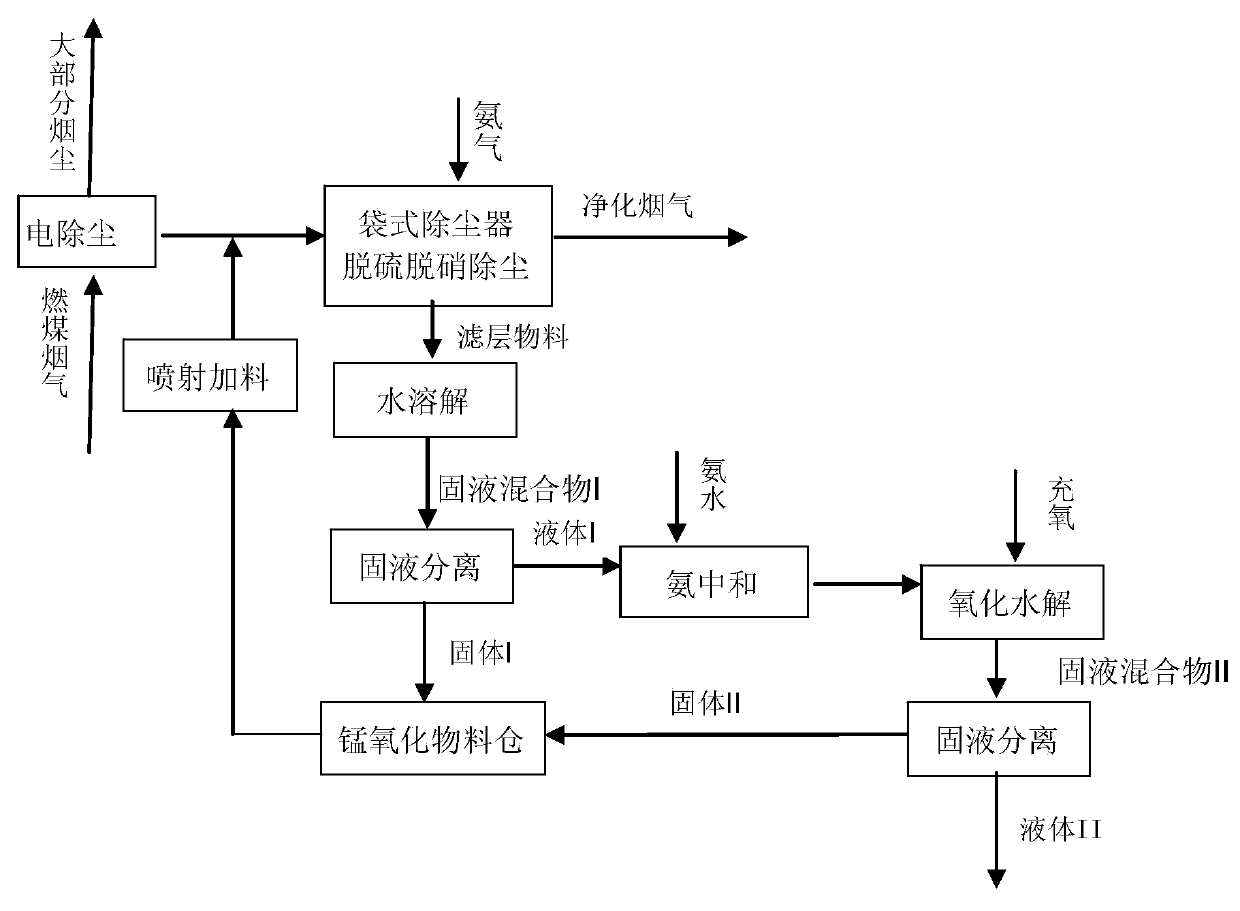

[0051] Such as figure 1 and figure 2 As shown, this embodiment illustrates the method for synchronous desulfurization, denitrification and dust removal in the bag filter of the present invention, and the specific steps are:

[0052] a. The coal-fired flue gas produced by burning coal powder is passed through an electric precipitator to remove most of the dust, and the sulfur content in the flue gas is about 550PPm;

[0053] b. Adjust the temperature of coal-fired flue gas after electrostatic precipitator to keep it stable at 200-210°C; in this way, the temperature of coal-fired flue gas entering the bag filter can be stabilized at 200-210°C. The temperature requirements of ammonia reduction flue gas denitrification also meet the requirements of safety and service life of filter bags.

[0054] c. Inject industrial manganese dioxide powder into the connecting pipe between the electrostatic precipitator and the bag filter, so that the manganese oxide can quickly react with the...

Embodiment 2

[0063] a. Coal-fired flue gas passes through the electrostatic precipitator to remove most of the dust, and the sulfur content in the flue gas is about 550PPm;

[0064] b. Adjust the temperature of coal-fired flue gas after electrostatic precipitator to keep it stable at 150-160°C;

[0065] c. Inject natural high-grade manganese oxide ore powder into the connecting pipe between the electrostatic precipitator and the bag filter, so that the manganese oxide can quickly react with the sulfur dioxide in the coal-fired flue gas, and remove large amounts of coal-fired flue gas. Part of the sulfur dioxide forms manganese sulfate, and reacts with part of the nitrogen oxides in the coal-fired flue gas, and the nitrogen oxides are removed to form manganese nitrate; manganese sulfate, manganese nitrate, unreacted manganese oxides and soot enter with the coal-fired flue gas In the filter bag of the bag filter, it is trapped on the surface of the filter bag to form a filter layer, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com