Improved tumbledrum design and method for coating objects

A technology of objects, drums, applied in the field of improving the design of revolving drums

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Testing has shown results where operating variables affect product defect levels when using a 2.7L / D drum. Product defects include the incidence of unwanted multiples or agglomerates. This result is shown in the bar graph of Figure 4. The modulating variables that control defects (incidence of undesired aggregation or agglomeration) shown by the bar graph are drum rotational speed and drum angle. It is disclosed that, using a drum with a scraper, an improvement in the level of product defects is achieved by reducing the screw rotation speed or reducing the drum angle. The observations below are merely exemplary of how these variables can be adjusted, and those of ordinary skill in the art can use these observations to appropriately design and adjust operating conditions for other uses. In this example, the objects are loose spherical grains and the granules are granola.

[0045] • Comparing variables #1 and #2, the drum speed was reduced from 24 to 16, in which case ...

Embodiment 2

[0051] Testing has shown the results of processing variables affecting product defect levels when using 4L / D rollers. The results are shown in the bar graph of FIG. 5 . Similar to the results for the 2.7L / D drum, reducing the drum angle reduced defect levels. The 4L / D rollers achieved at least as good, if not better, defect levels.

[0052] • Comparing variables #1 and #2, drum speed equal to 22 rpm is as good as 15 rpm.

[0053] • Comparing variables #2 and #3, the drum angle increased from 1.1 degrees to 3.3 degrees. The defect level rose from 0.0% to 1.5%.

[0054] • A drum size of 1 foot diameter and 4 foot length (4L / D) produced an excellent 0.0% defect level.

[0055] Figure 6 shows the effect of product residence time in the drum. Adjusting the product residence time can control defects (incidence of undesired aggregation or agglomeration). For example, Figure 6 shows that reducing the average dwell time to less than 20 seconds causes the defect level to rise abov...

Embodiment 3

[0057] Coated products are produced at full production rates. The drum dimensions used for this example were 2.5 feet in diameter and 10 feet in length. The results are shown in the table below.

[0058] Rotary drum operation

[0059] cinnamon

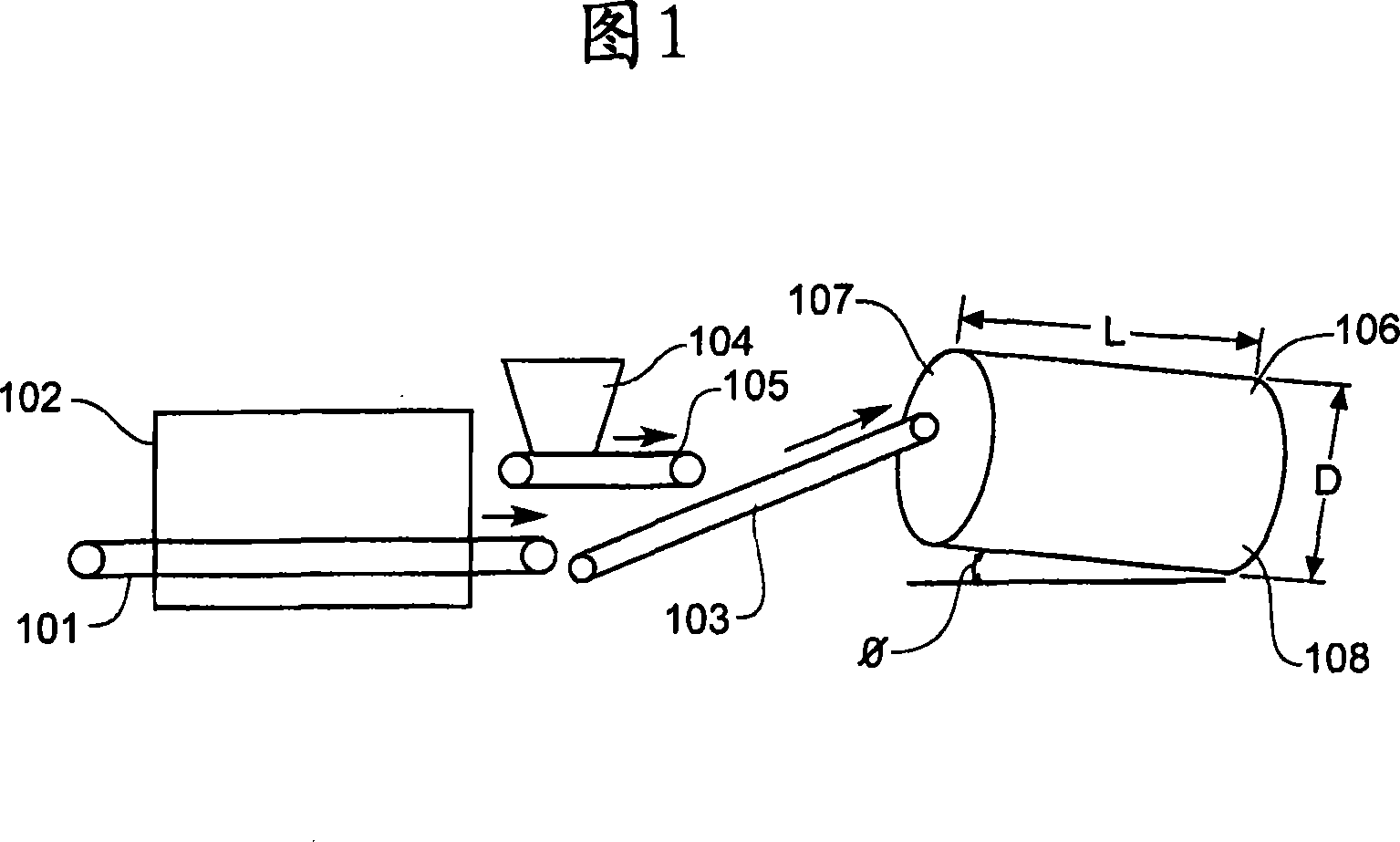

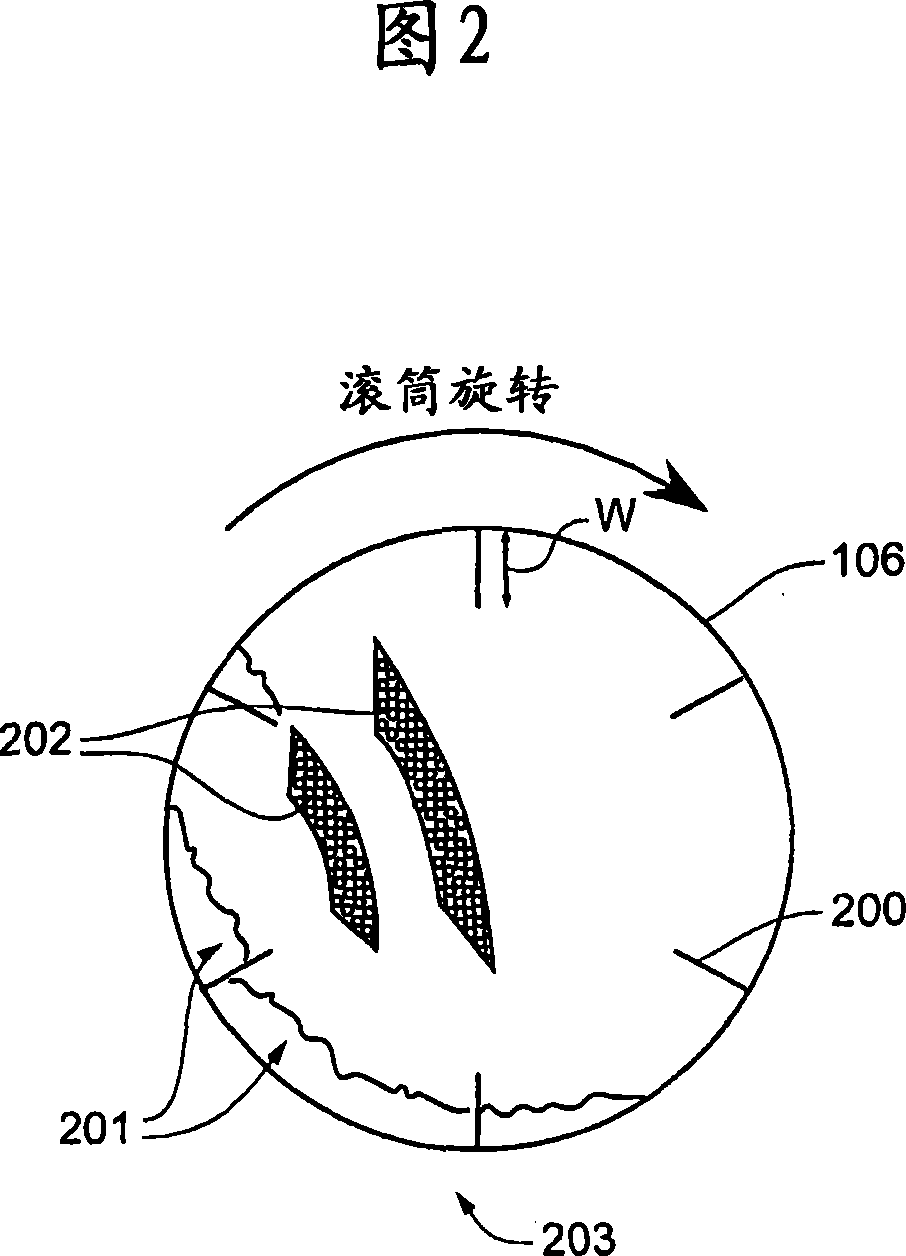

[0060] Thus, aspects of the invention include an apparatus for coating an object with particles, the apparatus comprising a drum supported for rotation about an axis of rotation of the drum, the drum including at least one inlet, a length (L) and a diameter (D), such that The drum includes at least one scraper axially attached to the inner wall of the drum; wherein as the drum rotates, each scraper lifts and then drops objects and particles such that the impact of the falling objects and particles drives the particles into the objects. The drum can include at least 2 to 20 scrapers and the scrapers can be spaced 0.3 to 2.0 feet apart. Each blade may have a width less than 1 / 6 of the diameter of the rotating drum and at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com