Additive manufacturing device and method

An additive manufacturing and generating device technology, applied in the field of additive manufacturing, can solve the problems of long time-consuming, long waiting time, unfavorable manufacturing efficiency, etc., and achieve the effect of thorough water removal and less material amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

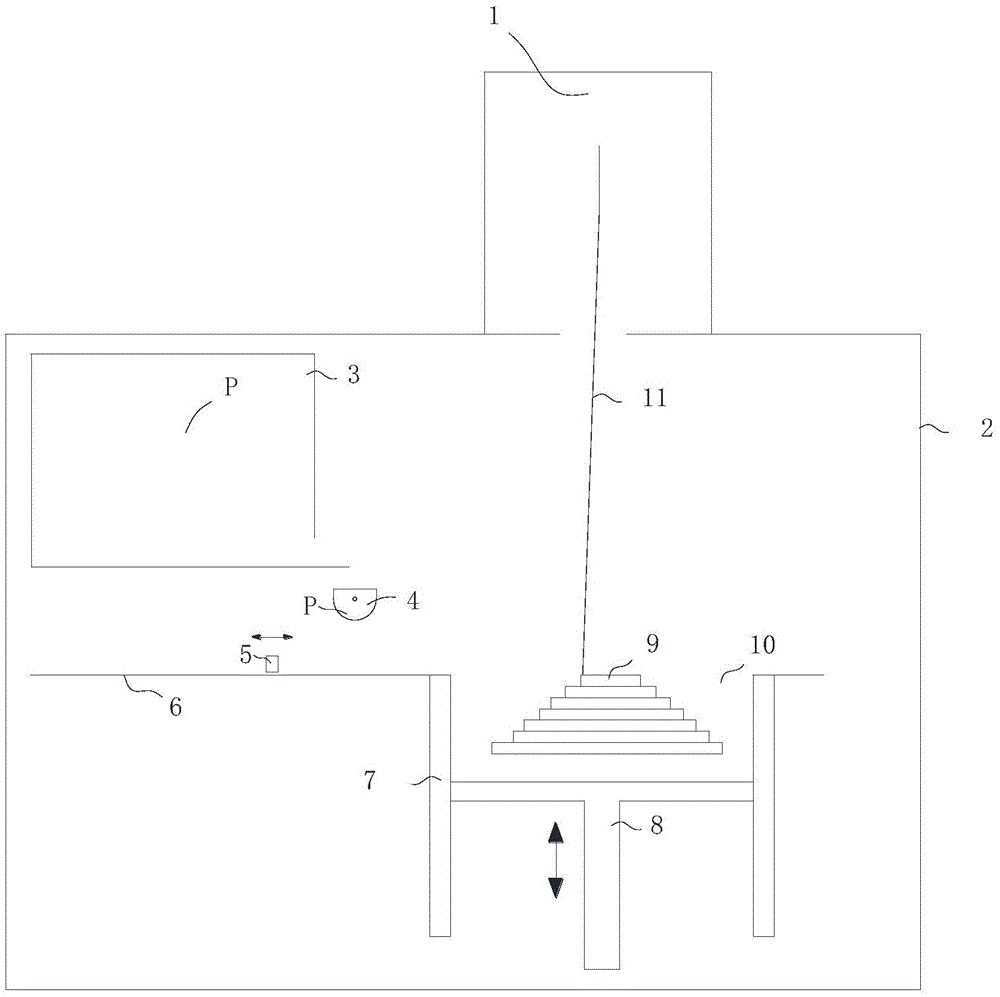

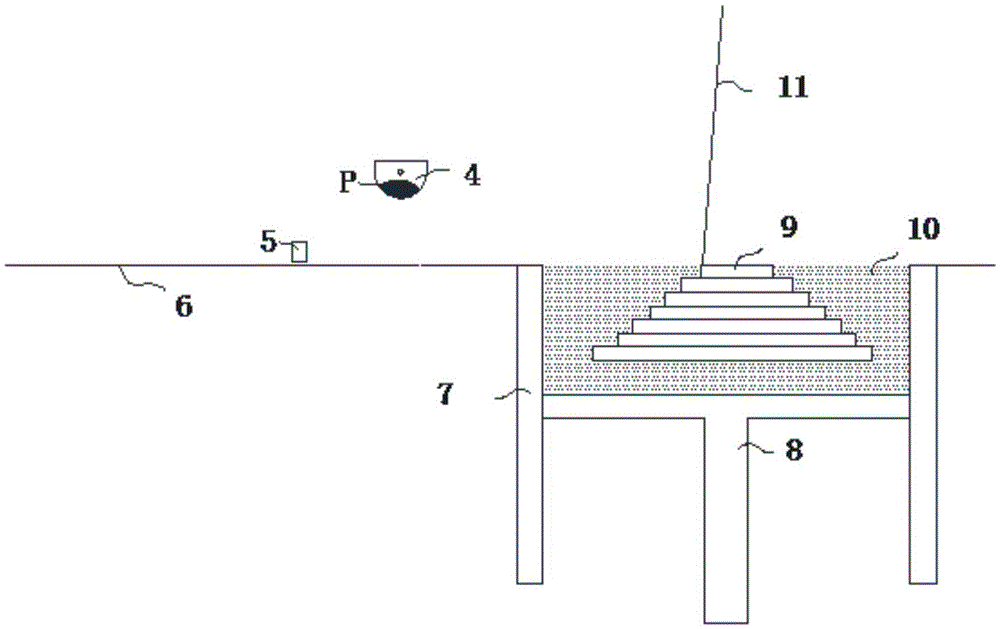

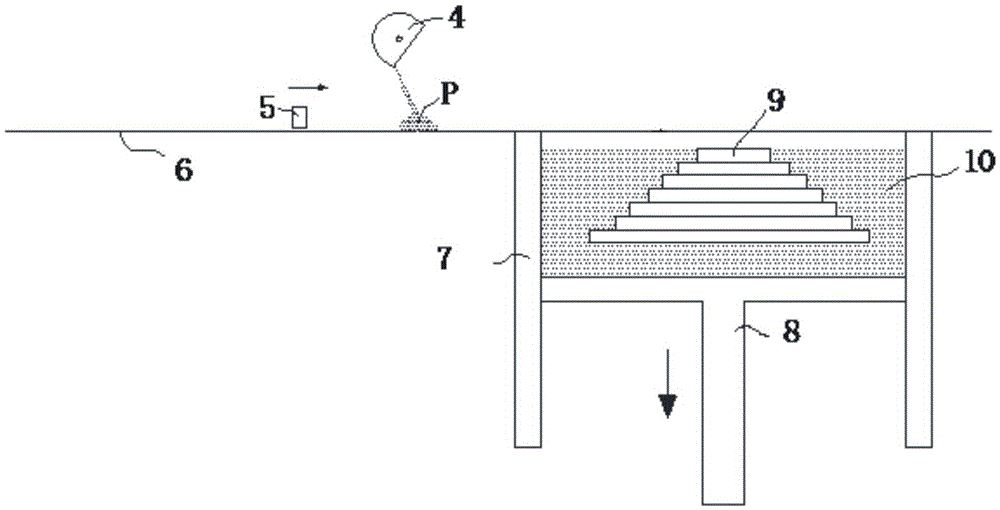

[0054] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0055] In this embodiment, an additive manufacturing device is provided, including an electron beam generating device and a forming chamber, the electron beam generating device is located above the forming chamber, and the ray generating device is used to generate molten powder material Ray, the forming chamber is used to provide the airtight chamber required for manufacturing; the forming chamber also includes a powder receiving box and a powder box, and the powder receiving box is arranged at the outlet below the powder box for The powder material delivered from the powder box is accepted and pretreated, and the pretreatment includes heating the powder material to a predetermined temperature and pouring out the powder ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com