Bonding apparatus and bonding method

A technology of bonding device and pushing device, which is applied in optics, instruments, nonlinear optics, etc., to achieve the effect of preventing the dislocation of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Next, embodiments of the present invention (hereinafter referred to as embodiments) will be described in detail with reference to the drawings.

[0034] [A. Structure]

[0035] [1. Overall structure]

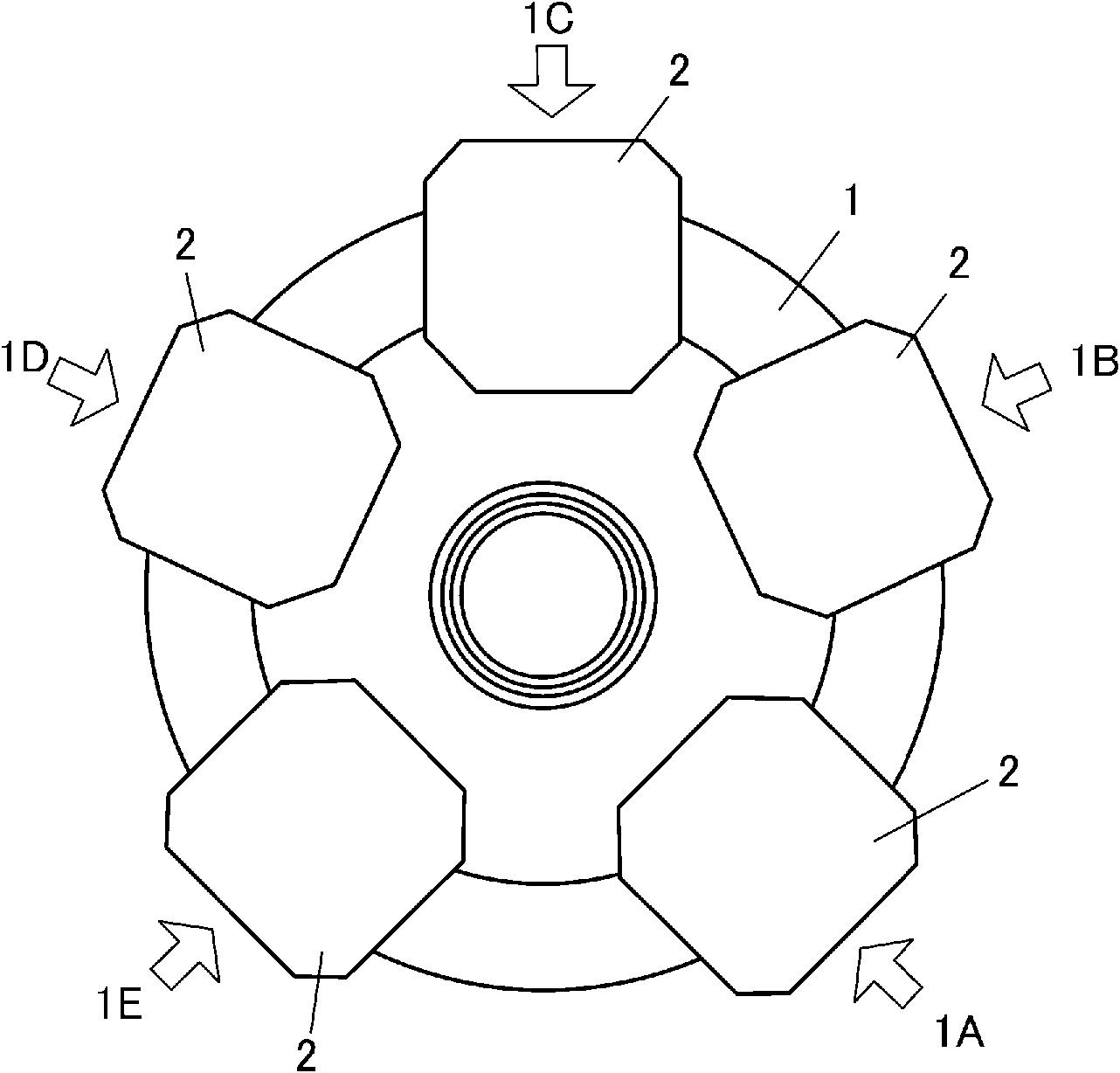

[0036] First, the overall structure of the bonding apparatus of this embodiment (hereinafter referred to as the apparatus) will be described. This device is figure 1 As shown in , five holding devices 2 are mounted on the turntable 1 . The turntable 1 is configured to be intermittently rotated by an index mechanism in accordance with the insertion and removal position 1A, the adhesive material preparation position 1B, the positioning position 1C, the vacuum bonding position 1D, and the curing position 1E.

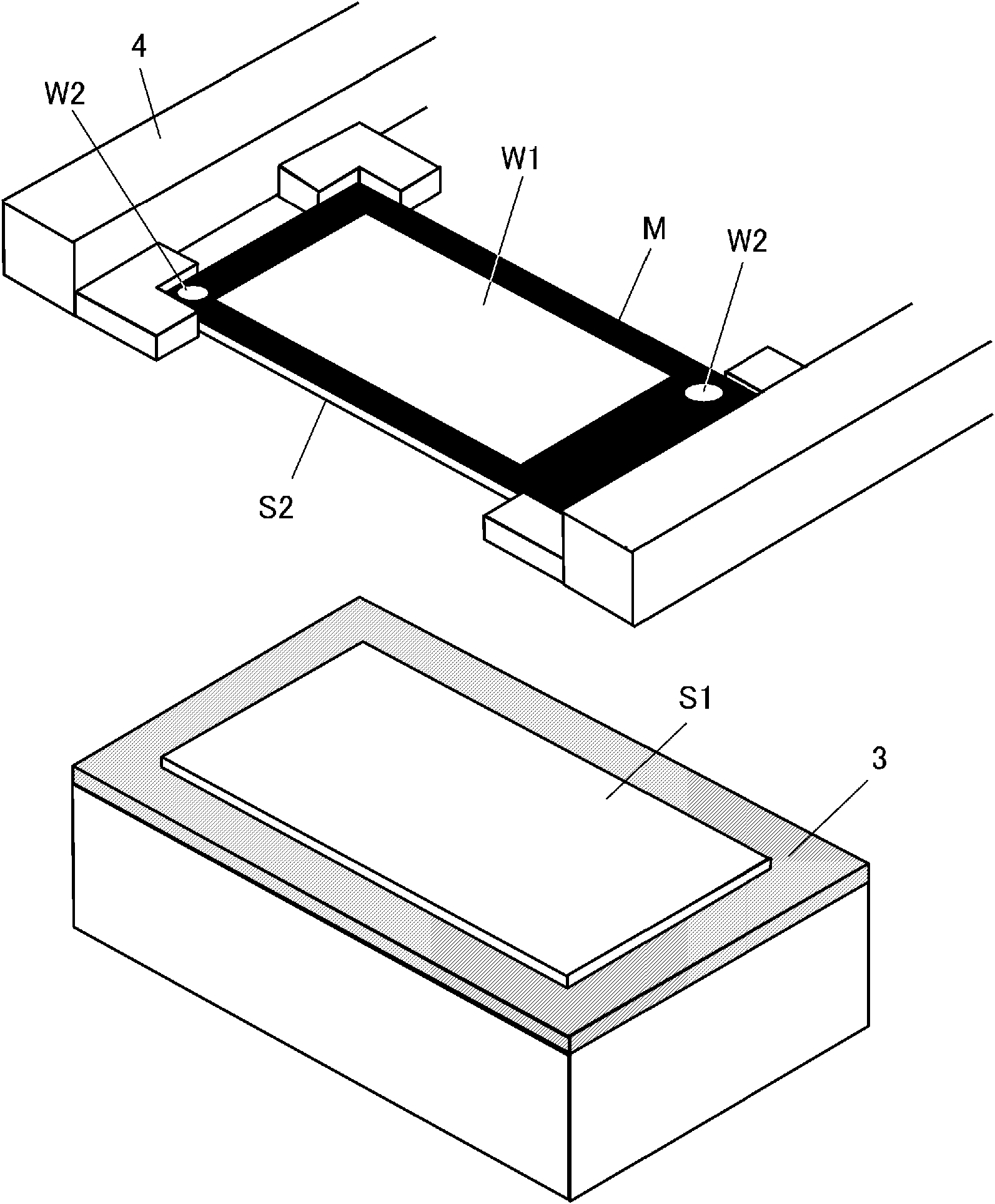

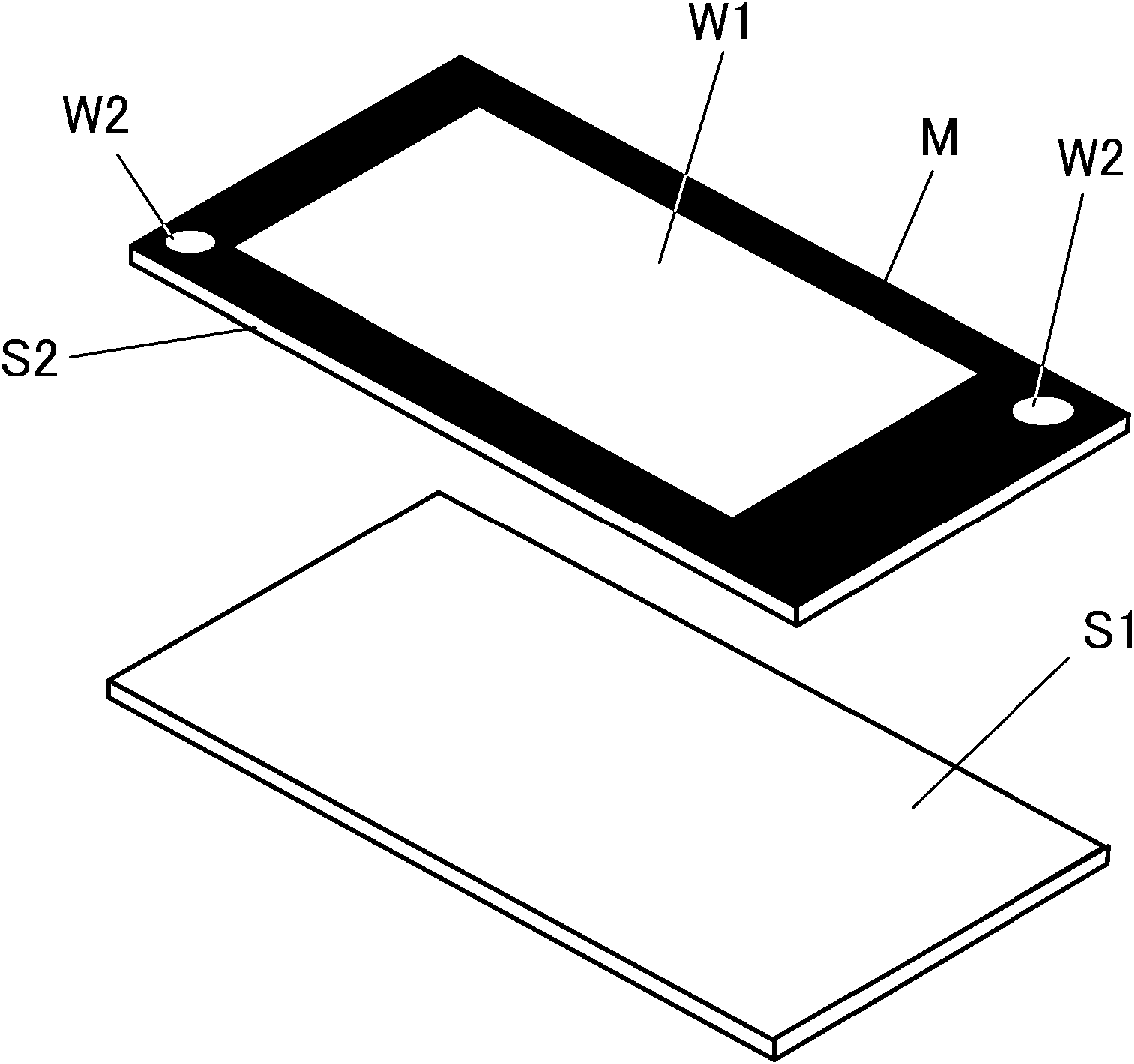

[0037] holding device 2 such as figure 2 As shown, it is a device that holds the workpiece S1 mounted on the placement unit 3 and the workpiece S2 held by the holding unit 4 facing each other up and down. In this embodiment, a liquid crystal template is used as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com