High-temperature tensile test fixture for structural simulation parts with online observation and full strain pick-up

A technique for tensile testing and simulating parts, which is applied in the direction of applying stable tension/pressure to test material strength, measuring devices, instruments, etc., and can solve problems such as inability to pick up full strain information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention will be described in detail below in conjunction with the examples, and the examples are intended to explain rather than limit the technical solution of the present invention.

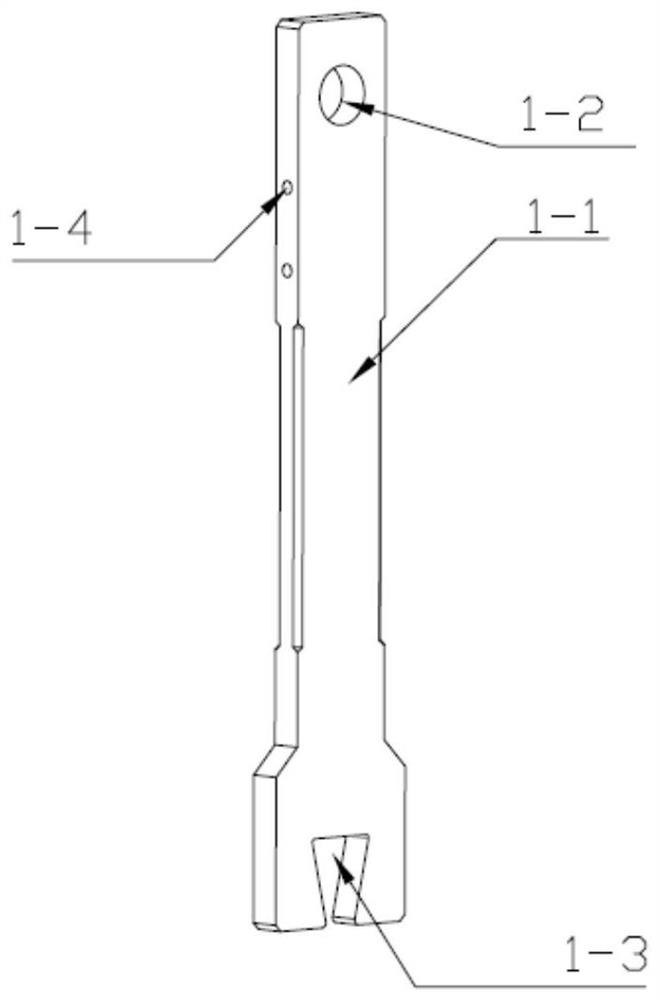

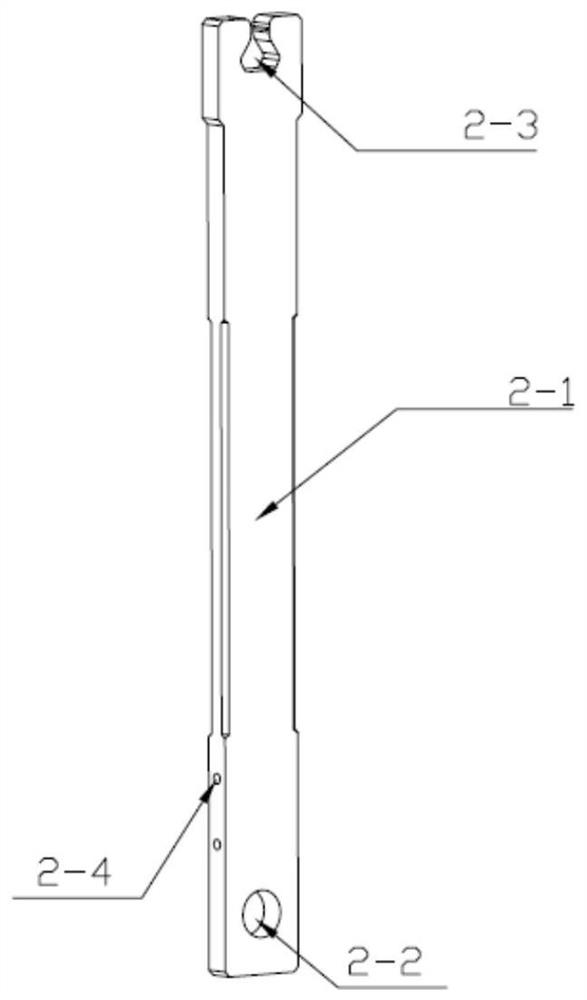

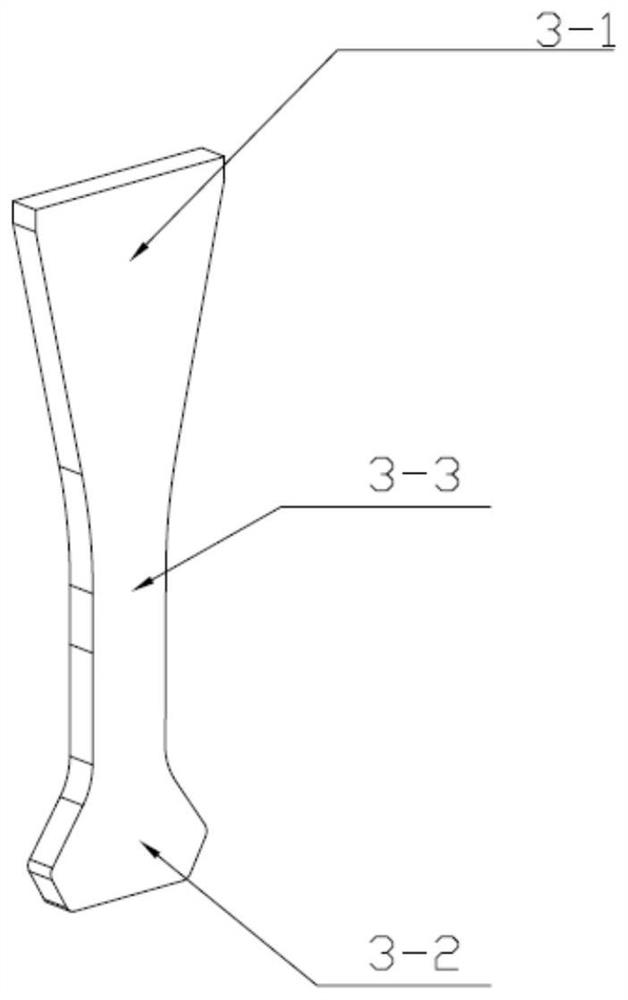

[0024] Such as Figure 4 As shown, the high-temperature tensile test fixture of the structural simulation part that can be observed online and fully strain-picked mainly includes upper and lower fixtures 4-1 and 4-2, and the composite material structural simulation part 4-3 used in the experiment is fixed by two clamping ends between the two clamps. The specific design of the upper fixture 4-1, the lower fixture 4-2 and the structural simulation part 4-3 is as follows: figure 1 , 2 , 3 shown. The upper clamp 4-1 is composed of the upper clamp 1-1, the upper pin hole 1-2, the upper clamping groove 1-3 and the first cooling water hole 1-4, and the lower clamp 4-2 is composed of the lower clamp 2-1 , the lower pin hole 2-2, the lower clamping groove 2-3 and the second cooling wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com