High-voltage PMOS drive circuit

A drive circuit, high-voltage technology, applied in the direction of logic circuit, logic circuit interface device, eliminating voltage/current interference, etc., can solve the problems of pulse width not too small, easy to be interfered, and loss, etc. Conduction loss, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

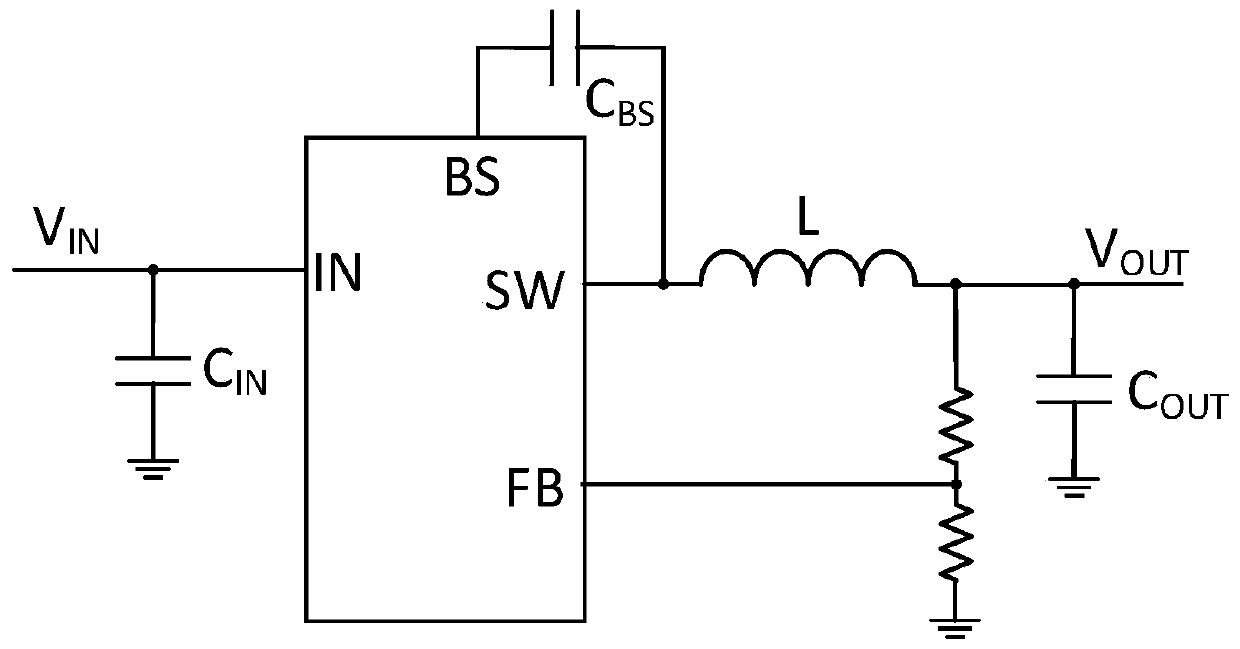

[0044] Such as Figure 6 Shown is a circuit block diagram of the high-voltage PMOS drive circuit of the present invention, including: a pulsed potential shift circuit 101 , a latch 102 , a buffer 103 and a clamper 104 . The pulsed potential shift circuit 101 receives the low-end logic signal Lin to generate a high-end voltage difference signal; the latch 102 converts the high-end voltage difference signal into a high-end logic level, and locks the level voltage through positive feedback; the buffer 103 receives the lock The high-end logic level provided by the register generates a high-end drive voltage with sufficient drive capability for driving high-voltage PMOS transistors. The required drive capability is determined by the size and switching speed of the PMOS transistor. The high-low voltage difference of the high-end drive voltage is determined by the PMOS The working condition of the tube is determined; the clamper 104 provides the negative terminal voltage for the latc...

Embodiment 2

[0064] On the basis of Embodiment 1, the traditional pulse-type potential shifting circuit is improved, the shifting pulse generation circuit can be dispensed with, and the pulse width of the low-end logic signal Lin can be directly used for driving, and it is no longer necessary to generate double pulse widths for shifting control , and there is no common phenomenon of the traditional solution, even the latch in the first embodiment can be removed, and a high signal-to-noise ratio can be ensured.

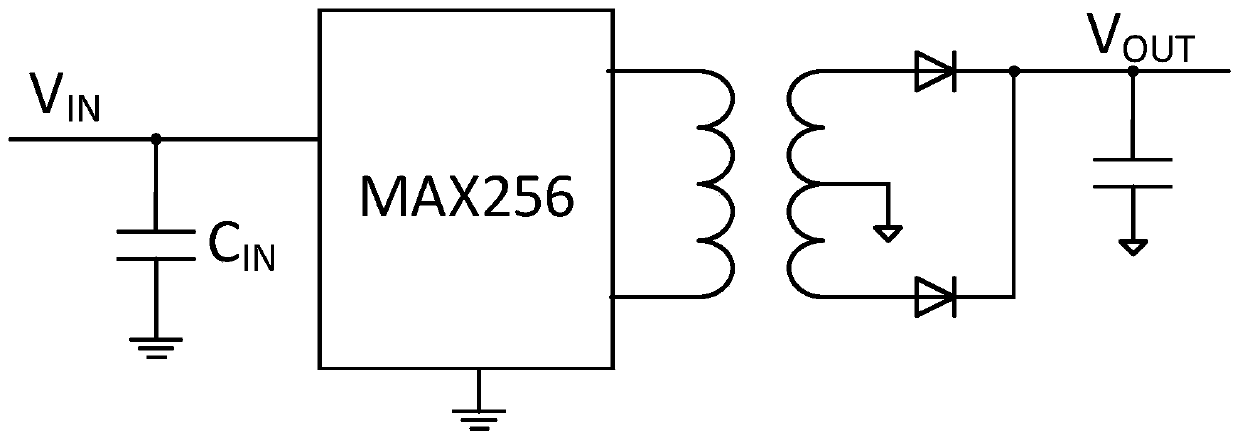

[0065] Such as Figure 8 Shown is the circuit block diagram of this embodiment. The present invention is more preferably a high-voltage PMOS drive circuit with a double-layer potential shift circuit, including: a double-layer potential shift circuit 201 , a buffer 103 , and a clamper 104 . The double-layer potential shifting circuit 201 receives the low-end logic signal Lin and the bias voltage provided by the clamper 104, and outputs a high-side logic level. The bias voltage contr...

Embodiment 3

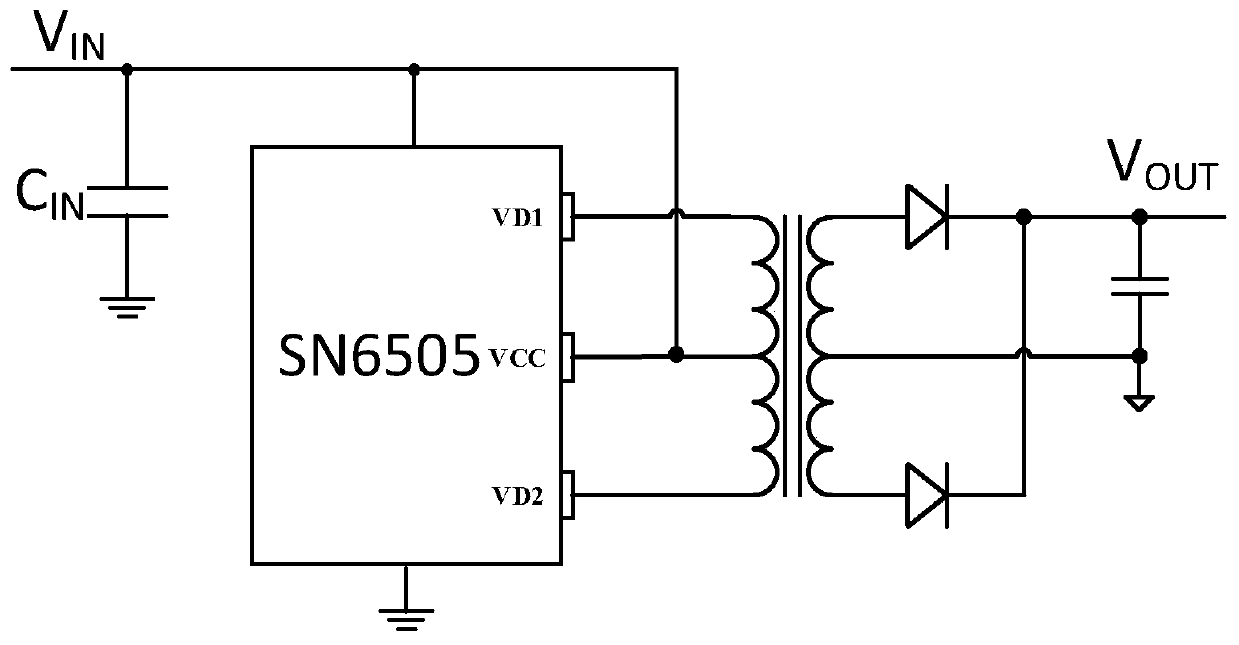

[0072] The basic structures of the NOT gates that make up the buffer 103 in Embodiment 1 and Embodiment 2 are as follows: Figure 11 As shown, the source of NMa is connected to the negative power supply terminal of the buffer, which is at a high voltage, which requires a high-voltage isolation NMOS transistor to realize, but there is no such device in many semiconductor processes. Therefore, in this embodiment, the buffer is implemented by a double-layer inverter, which is a buffer that does not require a high-voltage isolation NMOS transistor, thereby reducing the requirements for semiconductor technology.

[0073] Familiar with the clamping principle of the double-layer potential shifting circuit in the second embodiment, a double-layer inverter can be produced in a similar way, such as Figure 12 As shown in 303, the double-layer inverter of this embodiment includes a PMOS inverting load transistor PM3, an NMOS inverting control transistor NM3, and a PMOS inverting clamp tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com